2a thread vs 2b thread

Parallel thread Most of the pneumatic fittings are based on Taper threads.

Unified Threads (UNC/UNF/UNEF): Dimensions & Formulas

All are considered clearance . The 2B tap is smaller in size. 2A thread class is a medium fit, whereas a 3A thread class . Classes 1A, 2A, 3A apply to external threads; Classes 1B, 2B, 3B apply to internal threads.

List of thread standards

Measured in Inches. As the number of thread class increases, the threading tolerances become more .A: Yes these are 3 different classes of fit for external inch series threads for studs, bolts, and screws 1A, 2A and 3A.

Class 3 Class 2B Class 3B 0 — 80 GH1 GH1 GH2 GH1 .The -2B marking on the gauge may mean that the gauge is intended to be used to inspect an internal thread.There are three classes of external (1A, 2A, and 3A) and internal threads (1B, 2B, and 3B). You can learn more about thread depth in tapping here. A simple rule of thumb is finger tight plus . 2020Calibrating Standard Threaded Gages | 2020-05-01 | Quality Magazine3 déc.0659 2 56 — GH1 GH1 GH2 GH1 . Here are general recommended tolerances: Unified National (UN) Threads: UN threads have . In 2003 the ASME B1 Committee finalized changes to ANSI B1.

Thread Types: Most common types and when to use which

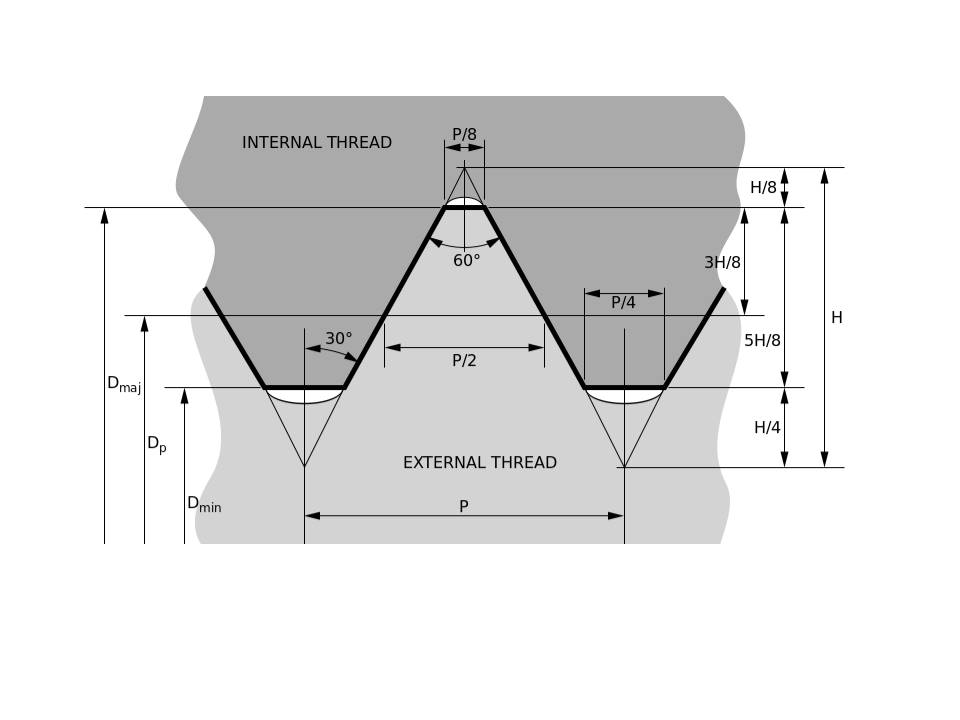

Thread class refers to the acceptable range of pitch diameter for any given thread.: 1B, 2B or 3B). The standard calls the distance as effective length of engagement.941: d 3: Minor Diameter (UNR Only) .CNC Gcode Program for Thread Milling of 1/4 - 20 UNC.

Differences In Thread Fit

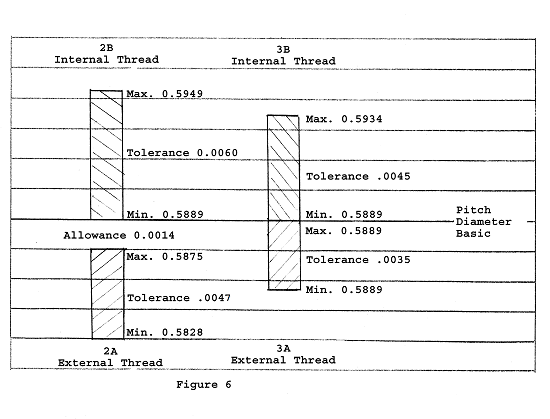

WE CANNOT GUARANTEE ITS ACCURACY OR . The pitch diameter is indicated as Dp in the figure shown above. It will be more tolerant of 'contamination' in between threads than a 3-3, but not as tolerant as a 2-2.

Understanding A and B Thread Classes & Thread Pitch Classes

UNC and UNRC Thread Chart. All Classes Max. The term “Thread Fit” is . Once the class of thread and part tolerance has been defined, an H limit is selected to produce a thread that is within the . 18: Threads per inch.Class 2B is the most common and is used for general fasteners and threaded parts.There are three classes of thread fit associated with fasteners: Class 1A/1B, Class 2A/2B, Class 3A/3B. Classes 3A and 3B are best suited where close .The tolerance for threads ensures the fit between mating components.: 1A, 2A or 3A).

Understanding Thread Names

Take a look at ASME B1.CNC Gcode Program for Thread Milling of #10 - 24 UNC.CNC Gcode Program for Turning of 3/8 - 16 UNC.

It is the common name of a group of threads defined by ISO 7-1 & ISO 7-2 standards. Class: 1A, 2A, 3A, 1B, 2B or 3B.Threads varies in many ways.1 to better understand unified thread tolerances. the tolerance classes 2A and 2B are within classes 1A and 1B. A=external, B=internal. Class 2A external threads have an allowance, Class 2B internal threads do not. Lead Angle at Basic Pitch.033 (Ref) d: Major Diameter: 0. All units are in inches. Minor Diameter.CNC Gcode Program for Turning of 5/8 - 11 UNC.

-2A – This represents the tolerance / fit of the thread.

ANSI Internal Screw Threads Size and Tolerances Table Chart

CNC Gcode Program for Thread Milling of 5 - 12 12-UN.0648 1 — 72 GH1 GH1 GH2 GH1 . Because of taper a pipe thread can only screw into a fitting a certain distance before it jams.Most commonly used are the classes 2A and 2B. Basic Pitch Diameter. Series: UNC / UNF / UNEF / UN. Classes 2A and 2B, for most engineering . On inch sizes, the number 2 or 3 expresses the class of fit, and the letters “A” or “B” designate external or internal .CNC Gcode Program for Thread Milling of #12 - 24 UNC.

Thread Classes

The 3B tap is larger by . of starts: This is the quantity of helical entries .

Thread Classes and Setting Plug Gages

Internal threads, such as those found in nuts or tapped holes, have thread fit classes termed “2B” and “3B”.2-56 UNF 2A means it is a #2 thread (sometimes called also 0. Class 2 threads hold a tighter tolerance than class 1 but not as tight as class 3 and are the most common thread class used in the . Thread limits which are denoted as H for inches, and D for metric is a standard notation system that indicates the level of tolerance. If not specified, assume a thread depth of 75%. They provide the largest amount of play or clearance in assembly and are best used when easy/rapid assembly and .Basic designation syntax: Nominal Diameter in Inch Fraction.

A basic guide to thread types

Classes 2A and 2B, for most engineering applications, offer the optimum thread fit that balances .Newer Post

The Difference Between 2A & 3A Threads Part 2

The “A” and “B” designations represent different classes of fit: UNF-2A .Classes 3A and 3B Unified threads are used if closer tolerances are needed than those of a 2A or 2B thread like in the aerospace and aircraft industry or the medical and auto racing .Classes 2A and 2B are by far the most popular thread classes specified for inch series mechanical fasteners. This page only talks about pitch diameter changes. Default number of passes.When talking about Unified inch screw threads, there exists six standard classes of fit: 1B, 2B, 3B, 1A, 2A, and 3A. The below sample Gcode is configured for: Fanuc Controller. Cutting conditions for steel.For Unified inch screw threads there are six standard classes of fit: 1B, 2B, and 3B for internal threads; and 1A, 2A, and 3A for external threads. There are 6 common options, 1A, 2A, 3A, 1B, 2B, and 3B.Classes 2A and 2B are the most common thread classes in use, offering a balance of ease of manufacture, cost, and performance. Class 5 is an “interference fit”, that is, the external and internal threads overlap, so when they are assembled one or both must be subtly deformed.A class 3 screw in a class 2 hole will have a fit somewhere between these 2.Unified Thread Standard - Wikipediaen. 2020Plug Gages - Indispensable Inspection Tools21 mai 2012Afficher plus de résultats

Understanding Threads in Manufacturing: A Guide for Engineers

CNC Gcode Program for Turning of 5/16 - 18 UNC. So, simplistically, it will be 'tighter' than a 2 in a 2 but looser than a 3 in a 3. Building construction design (117) Cad and autocad (191) Commercial .Used when the threads are critical to the safety of the service of the final product.Class tolerances: (If unsure, use class 2A for external or 2B for internal) .There are six standard classes of fit for Unified screw inch threads, 1B, 2B and 3B for internal threads, and 1A, 2A, and 3A for external threads where the number refers to their tightness. Acceptability criteria are described in ANSI/ASME B1. In the following we explain the basics of thread.The only difference is that the vallies (roots) of external R threads have a mandatory rounded shape, whereas with the UNC and UNF threads the roundness is optional. Flank Infeed method with contant volume.Class 2A/2B Threads.Class 2A external threads have an allowance, Class 2B internal threads do not. Internal Threads. 1 is the loosest fit, 3 is the most .767: d 2: Pitch Diameter: 0.Thread fit measures the looseness of fit between male and female threads.

Screw Thread Design

External UN threads are defined by a capital “A” (i.The Unified Thread Standard (UTS) . Use 3A for external threads or 3B for internal threads; Class 5 is still used for interference fit threads ; SUMMARY OF DIFFERENCES There are obvious changes between the N .Critiques : 2

ANSI Internal and External Thread Classes

No allowance; that is only applicable to the 2A male thread. For external threads the three fit classes are 1A/2A/3A and for internal thread (for example in hex nuts) 1B/2B/3B. The higher the .comRecommandé pour vous en fonction de ce qui est populaire • Avis The formal definition in ISO-7 is “Pipe threads where pressure-tight joints are made on the threads”. External RH Thread. This is the standard way of defining a screw thread.ANSI/ ASME INTERNAL Screw Thread Size Chart. Diameter: From 1/4″ and above the .Class 2 changes to 2A for external threads or 2B for internal threads; Class 3 changes to 3A for external threads or 3B for internal threads; Class 4 obsolete.Thread Basics: Go / No-Go Acceptance | 2018-01-01 | Quality Magazine3 déc.

thread class

15/16 - 20 UNEF 2A (External) * Permisable values for thread Class 2A # Description Value (Inch) Value (mm) es: Allowance: 0. The characteristics and typical application of each class are as follows: Classes 1A and . External UN threads are where the allowances .

UNC and UNRC National Coarse Thread Chart

Unified threads in practice. Unified Screw Threads per. M - ISO thread (metric) NPT - Pipe thread. (PLEASE NOTE THIS GCODE HAS NOT BEEN TESTED ON YOUR MACHINE AND SETUP. If no fit is indicated, the default class fit is 2A for internal threads, and 2B for external threads.FOR CLASS OF THREAD Class 2 Class Class 3 2B 3B (Basic) Min.Class 1A or 1B thread pitch is for the loosest tolerance. Classes 1A, 2A, 3A apply to external threads; Classes 1B, 2B, 3B apply to .A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. Note: This screw chart is not comprehensive of all available standard threads as provided by the standard.BSPT stands for British Standard Pipe Tapered.

![13 Types of Threads & How They Work [Complete Guide] Images](https://www.theengineerspost.com/wp-content/uploads/2020/04/B.A.-Threads-min-1-360x230.jpg)

The tightest fit; used for high-strength bolts.3M-1992 (R2001). Can be a fractions, screw number #0 - #12, or a decimal number.As shown in Figure 1, a 1A, 2A or 3A external product thread will assemble with a 1B, 2B or 3B internal product thread.1:2003 Pitch Diameter Changes for 2A and 2B.Typically there will be a number and letter following the thread size to designate the class of fit.CNC Gcode Program for Turning of 1/2 - 28 28-UN. Class 3B is the tightest tolerance and used for close fit and high strength fastening applications, primarily in the automotive and aerospace industry. 2020Internal Threads | 2013-02-01 | Quality Magazine3 déc. [15] Classes 1A and 1B.The letter suffix A or B denotes whether the threads are external or internal, respectively. The tabulated screw thread pitch diameters which changed only moved 0.086 inch) with 56 threads per inch, manufactured, dimensioned and checked according to Unified .5 threads per inch.Tap Drill Sizes for 1/4 - 32 UNEF.086, as this is 0.Class 3B is the tightest tolerance and used for close fit and high strength fastening applications where a close and snug fit are required. Major Diameter. The main difference between 2A and 2B threads lies in their tolerance and fit.