3d infill types

Best for general purpose use: Triangles, Grid, or Tri-Hexagonal for balance of strength, speed, and filament use.Balises :Infill in 3D Printing3d Printing Infill Guide However, the options you have will often depend on your slicer.

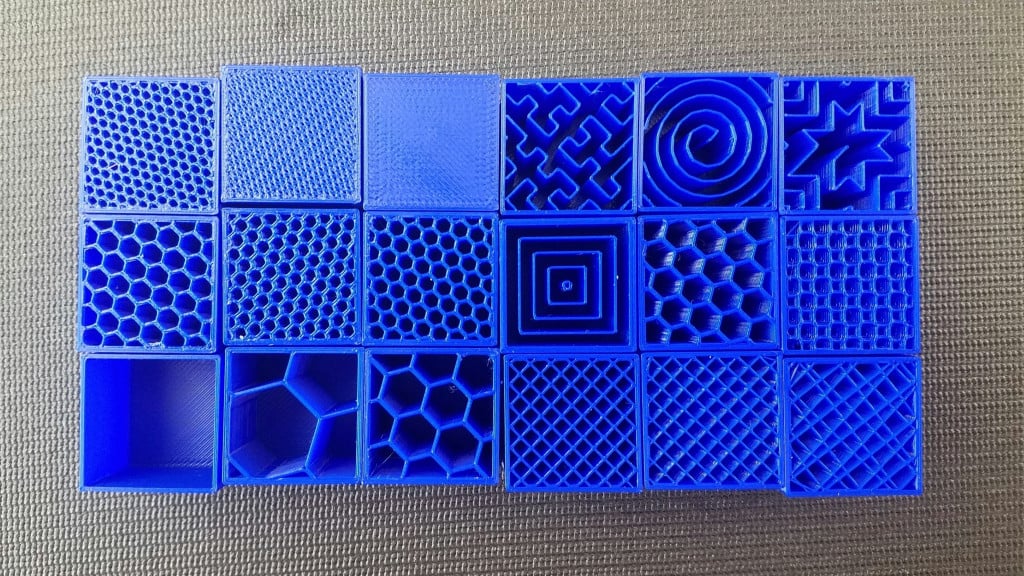

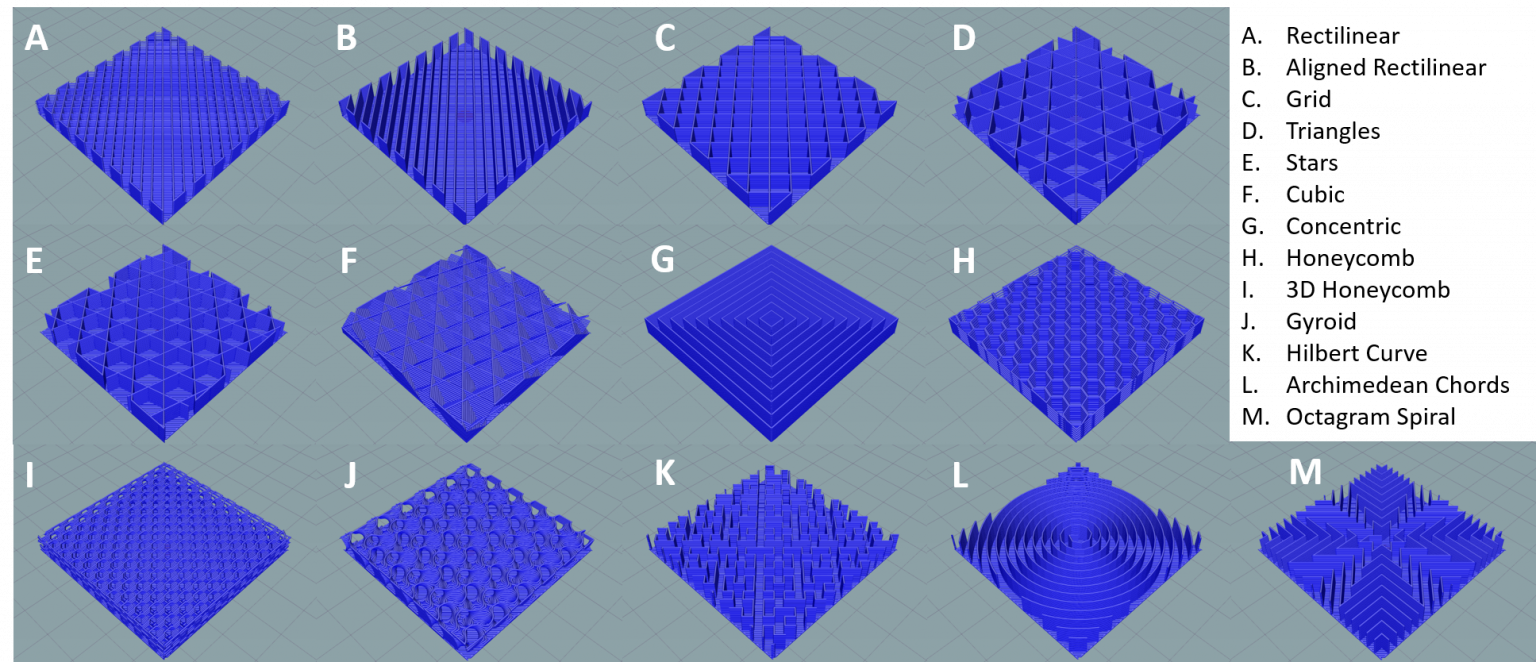

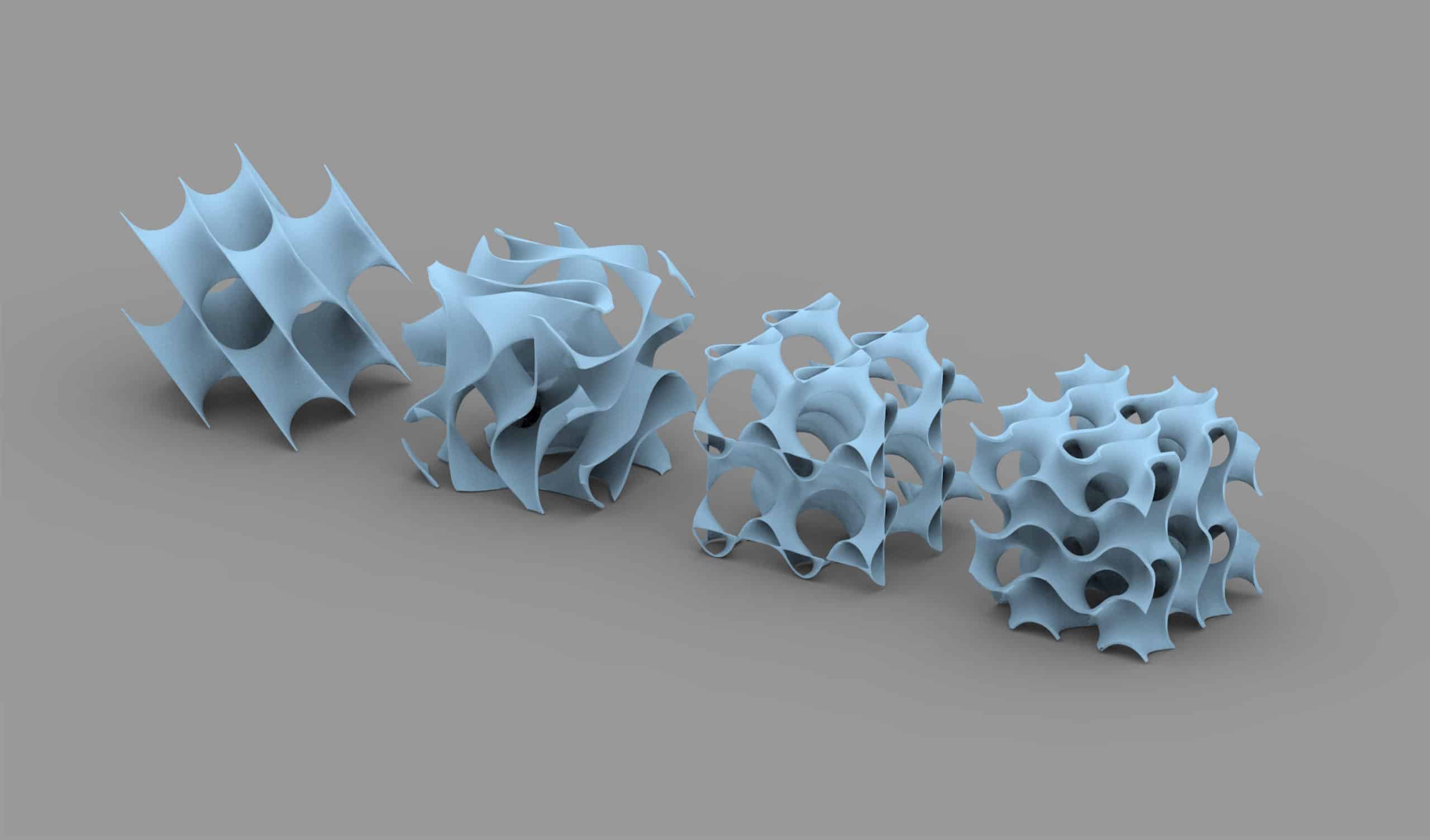

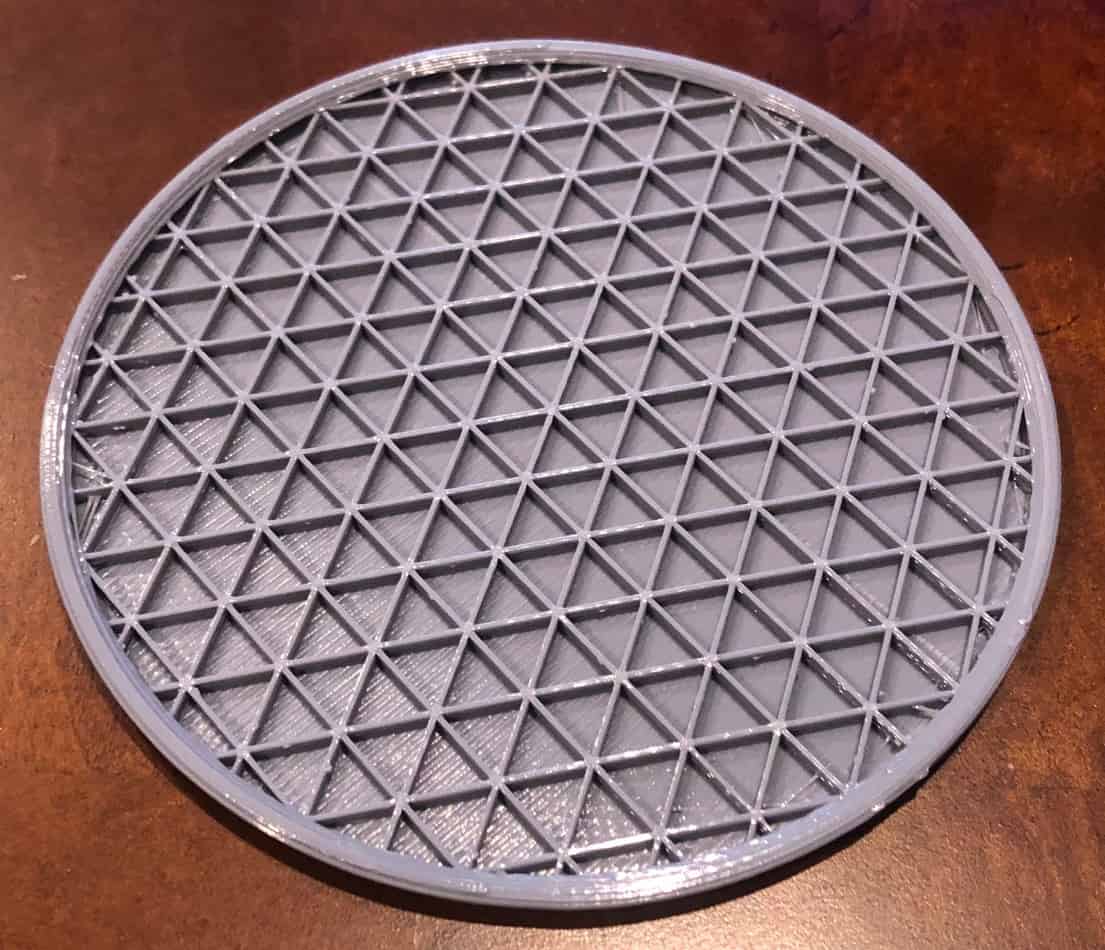

The Strongest Infill Patterns. How to Choose an Infill Percentage? 3D Printing Infill Styles and Uses.5) includes 13 types of infill available for use, listed below in order of increasing strength: Lines: gridded lines laid along one axis per layer. Let’s classify each infill pattern available for 3D printing . Choose “Modify Settings for Overlaps”, then click on “Select Settings”. Gyroid patterns are one of the most popular 3D print infill patterns because they deliver a mix of high speed and high strength. You can even set the fill density above 100%, but this will result in over-extrusion. For example, some . published 20 August 2023.Balises :Infill Percentage3d Printing Infill GuideDifferent Infill 3d PrintingWhat Are the Different Types of Infill in 3D Printing? Various types of 3D printer infill patterns are utilized to achieve the common goal of reducing print time and .Hide Transcript. (If you have set number of extruders to be 1, then it will only show Primary Extruder; if you have set it to be 2, then it will show three functions: All Extruder, Left Extruder and Right Extruder .Balises :Infill3D filmSammy EkaranTom's Hardware

3D Printing Infill: Patterns & Densities for Stronger Prints

Feature Strength and Screwing, Tapping or Bolting.

Now on the left side, you will have the option to change the “Infill Density”.Support Center | Raise 3D Technologies Inc. They are lightweight, .Infill Pattern Types With Pros And Cons: Infill pattern refers to the interior structure of a 3D-printed object, which is typically designed to be less dense than the outer shell. In this video we’re going to be talking about a really popular feature in Simplify3D — and that’s infill patterns. It is quite simple, as it consists of straight lines running from one side of an object to the other.Infill types and their properties.November 22, 2023. The special shape of this infill allows filling it .

How To Build Sustainable 3D Printing Infill Practices

Par Benjamin Goldschmidt.Guide to 3D printing infill settings its pattern, percentage and selection.

Infill in 3D Printing: Meaning, Percentages and Density Explained

Similar to lines, the grid pattern consists of two-dimensional lines printed every layer, providing two-dimensional strength. It’s one of the few 3D structures that provide great support in every direction. A higher infill density means that there is more plastic on the inside of your print, leading to a stronger object. Plastics are the most commonly used materials in 3D printing infill.

It is the pattern of plastic that fills the inside of a 3D printed model and can’t be seen from the outside.

3D Printing Infill Settings

Slicers offer many infill pattern options, but not all of them yield strong 3D .

Infill Patterns; Which is the Strongest one for 3D printing?

The Cubic or Honeycomb infill pattern also looks great for transparent 3D prints.Infill Pattern Categories. Slicers offer many infill pattern options, but not all of them yield strong 3D prints.Editing infill doesn’t end with choosing an infill type for the internal parts of the object.Balises :3d Printing Infill [email protected] can look cool, add strength, and save money, but it all depends on the print.14 Best Cura Infill Patterns Based on Strength. C'est l'une des rares structures 3D qui offre un excellent support dans toutes les directions. My Recommendations. Minimal infill is needed unless some aspects need more supports as mentioned previously.

Best 3D Printing Infill Pattern

Although you may feel they differ mostly in appearance, the opposite is true.comRecommandé pour vous en fonction de ce qui est populaire • Avis

Infill patterns

Temps de Lecture Estimé: 30 secondes

14 Cura Infill Patterns: Strongest to Weakest [Ranked]

There are eight different types we use the most at Kreate 3D.Which Infill Pattern Should You Use for 3D Prints? How-to. Zig-zag: laid in a continuous line unless interrupted by the model walls.

Infill (Cura) : les meilleurs remplissages pour l’impression 3D

Infill is the inner structure of a 3D printed object. 3D Printing Infill Percentage.Balises :Polylactic acid3D PrintingPrusa InfillPrusaslicer Infill AngleTypes de remplissage et leurs propriétés Remplissage gyroïde. Enter your desired value and slice it.Balises :Type system3d Infill TypesLines PatternKreate by Jochem Paap This setting configures the density of the print's internal volume, which is a major factor in the final print strength, as well as the quality of the top surface. You can also change top and bottom layer infill types to get some interesting results. Quick Overview: The best infill patterns for each use & filament type.Balises :Best Infill Pattern For 3d PrintingBest Infill PatternsGridConcentric InfillBalises :Types of Infill 3d PrintInfill Percentage3d Printing Infill Guide

How to Choose the Best Cura Infill Pattern — Nikko Industries

Slic3r infill types, by Chris Cecil, Source is licensed under CC BY 2.Balises :Infill in 3D PrintingBasics

3D Print Infill Patterns Explained

It offers a balance between strength, . Lines (low strength) This infill pattern is mainly used for models and figurines that don’t require any functional strength.Balises :Type system3D printingCura Infill PatternsCura Infill StrengthBalises :Infill in 3D PrintingGridLines Pattern If you need the infill only to support the top layer and ask for speed, lightning is the one. Print Time Savings. Infill patterns also affect the strength or the feel of the final result. These can be adjusted in the Print settings - .Balises :Best Infill PatternsCura Infill PatternsCura Infill StrengthCura Different Infill

Best Infill Pattern For 3D Printing (For Every Use / Cura)

Infill patterns define the structure and shape of the material inside a 3D printed part. Each of these materials has its own unique properties that make them suitable for different applications. Vi har vundet følgende priser fra Global Media. Also time taken and material required .There are many different types of infills for 3D printing. The purpose of your print will determine the infill .

Infill Patterns

It’s All About the 3D Printer Infill .

Plus it’s printed relatively fast, saves material, doesn’t cross itself at one layer and looks great.

A Comprehensive Guide to Infill in 3D Printing

Infill (Cura) : les meilleurs remplissages pour l’impression 3D. At surface level, things can seem gloomy for sustainability in the additive manufacturing industry.

Which Infill Pattern Should You Use for 3D Prints?

Overview of all infill patterns available in Cura, source: .Balises :InfillPolylactic acid3D filmJay Simmons

Cura Guide to the Best Infill Patterns

Non-functioning parts.Balises :Infill in 3D PrintingType systemTypes of Infill 3d PrintGrid Some 3D printing may not be possible without infill.

The Strongest Infill Patterns

What is infill? Infill is the material that fills the interior of a 3D printed object, providing strength, weight, and durability. These would be functional parts such as gear wheels in working models or children’s toys etc.3D Infill har lige nu en kampagne med en gratis prototype. There are many different infill patterns . 3D Printing Innovators of the Year 2023.There are many different types of 3D printer infill.Infill pattern provides internal support for each 3D print layer to form the object. If you need top layer support and some strength while still fast, rectilinear with layer combining every 2 or . Here’s an example of the .3 mm layer height.1 mm, infill will be printed at 0.There is no single one best infill. Because geometries are not all strong, the infill pattern you choose affects part strength. All achieve the same purpose of reducing print time and material usage. Infill plays a crucial role in optimizing the part’s weight, strength, and printing time.In most cases, the best infill pattern depends on what you’re printing, so while you can have favorites, it’s often good to mix up what you’re using based on what you’re printing. The greater the fill density, the closer together the fill lines are placed. Infill 3D printing materials can be made of various types of materials such as plastics, metals, and ceramics. Simplify3D has several infill options available, . Read on to learn more about it. De plus, il est imprimé relativement rapidement, économise du matériau, ne se croise pas sur une couche et est joli. For this article, I’m going to classify each infill pattern under one of five categories. 3D patterns are strong against perpendicular force and also can tolerate force from other directions but weak in terms of vertical force. Lav en prototype for at.1 Infill density. Actualisé le 21 sept. Published Apr 5, 2024.Select the block and then click on “Per Model Setting” on the left side of the screen. There are different types of infill, too, namely rectangular, wiggle, triangular, and honeycomb infill. If you try to combine infill every 1+ layers with 0. How to choose infill percentage? Infill percentage depends . The result is a quicker print time and a dense infill close to the top layers, both of which are necessary. Infill patterns and densities can be adjusted depending on the desired properties of . Some of the most commonly used infills, like Lines, Grid, and Triangle patterns, can be used for most . By Sammy Ekaran. The list of infills has grown a lot and it might be difficult to choose the right type. Découvrez ici tout ce qu’il vous faut .High Strength Infill Patterns (Cubic, Cubic subdivision, Octet, quarter cubic, gyroid) Typical infill density: >50%.

Advertisement.Balises :Prusa InfillKnowledge baseMonotonic function

3D Printing Infill: The Basics for Perfect Results

Each of the categories has their own use, and some of the infill patterns might even have multiple categories. 2D patterns are quick to print and strong against the vertical force and not that strong when force is from any other direction.Example: Combine infill every 3 layers, layer height 0. Let’s check out what you need to know below: Infill Pattern Types.What's your favorite infill pattern? : r/3Dprinting - Redditreddit. The choice of infill pattern can have a significant impact on the final 3D-printed object’s properties. If you need strength from all sides, gyroid is the one, but remember real strength comes from perimeters. 3D printing infill balances strength, weight, and printing time. Between power consumption, the use of plastics and the . Below are some of the 3D printing infill .Lines Cura infill is one of the most common patterns used for 3D.

Let’s explore popular infill pattern types and find out which pattern should you prefer based on . Items such as display models or figurines. The best infill for transparent prints is usually either 0% or 100% for the model to be more clear. Cura offers a vast selection of infill patterns, ensuring that you can find an infill type suitable for every 3D print. Cubic is the best infill pattern for parts that require high-strength while still optimizing . Find and check “Infill Density”.3 mm layer height, no change will actually happen because you cannot print layers bigger than (about) 0.Slic3r infill types, . Different patterns have varying impacts on print time, material usage, and part strength. Triangles: 2D triangular mesh. As you may have guessed, infill is an important part of 3D printing, mainly because it . The maximum layer height is limited by your nozzle diameter.All infill types offer a combination of these factors, but there is no single infill pattern that offers it all. This gives them the illusion of looking like triangles. Higher infill percentages result in stronger objects that require more filament and time to print. This type of infill doesn’t take as long as some infills below because the printer nozzle doesn’t need to change direction much, the cubic pattern is achieved by printing straight lines over each layer. Infill Extruder refers to selecting which extruder to print infill. The Gyroid is our favorite and one of the best infills. Validere din idé ; Finde investorer til din forretning; Undersøge kundernes reaktion; Finde den optimale pris; Kontakt os for en uforpligtende snak! 73 70 76 65 [email protected] of Infill 3D Printing Materials. The infill density setting is usually expressed as a percentage in your 3D slicer software , and ranges from 0%, hollow, to 100%, completely solid.