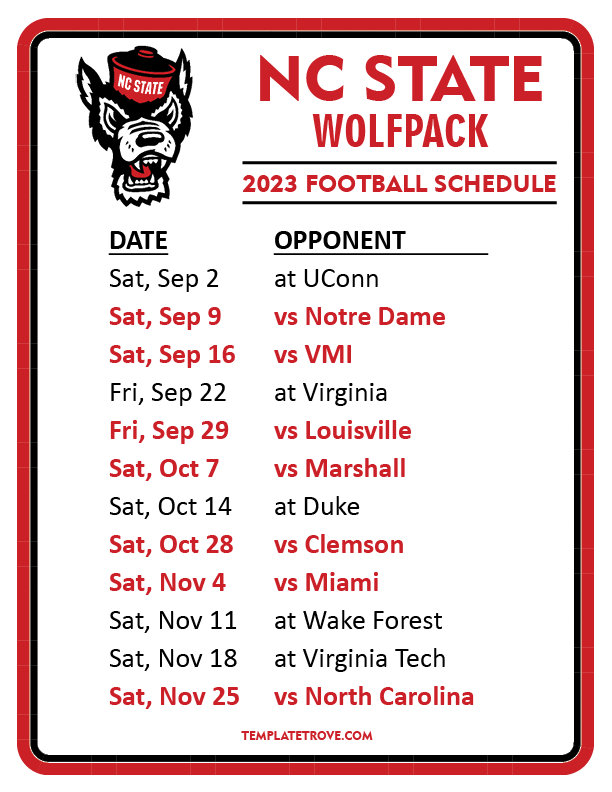

7005 aluminum alloy

4365, 2L95, A97075) . 7000 series aircraft aluminum advantage . Materials Science, Engineering.04 wt% Ti and balance of Al [30]. The processing map was constructed by superimposing the instability map over the .7050 aluminium alloy. The feasibility of hot deep drawing AA7005 sheet (only 0.A large deformation-induced isothermal spheroidization (LDIIS) method was developed for fabricating high-quality semisolid billets of 7005 aluminum alloy.7005 aluminium alloy: advantages and disadvantages - Aluminium Guide.

Moreover, the fatigue performance of the annealed 7005 aluminum alloy plate was significantly improved by the pre-tensile deformation, and the alloy plate subjected to 20% pre-tensile deformation .7005强度高于7003合金,焊接性能好,可热处理强化。7005铝合金挤压材料,常应用于制造既要有高的强度又要有高的 断裂韧性 的焊接结构,如大型热交换器,以及 焊接 后不能进行固熔处理的部件;还可用于制造体育器材如 网球拍 与垒球棒。

Balises :AlloysAluminium La nuance d'aluminium représentative 7075 contient principalement des éléments en zinc. A97005 is the UNS number.5Mn, A97005) Aluminum 7075 (AlZn5. Due to its inherent hardness, 7005 aluminum bikes feel rougher when you ride them.Tensile and fatigue properties of as-extruded 7005 aluminum alloy were measured in this study.7 using the corrected flow stress data to eliminate the effect of friction.Aluminum Plates. Some other aluminum alloys, for example, 7075 и 2014, stronger, than both alloys 6061 и 7005, but they are not enough suitable for the .7005-O aluminum is 7005 aluminum in the annealed condition.

Aluminium Frames: 6061 vs 7005

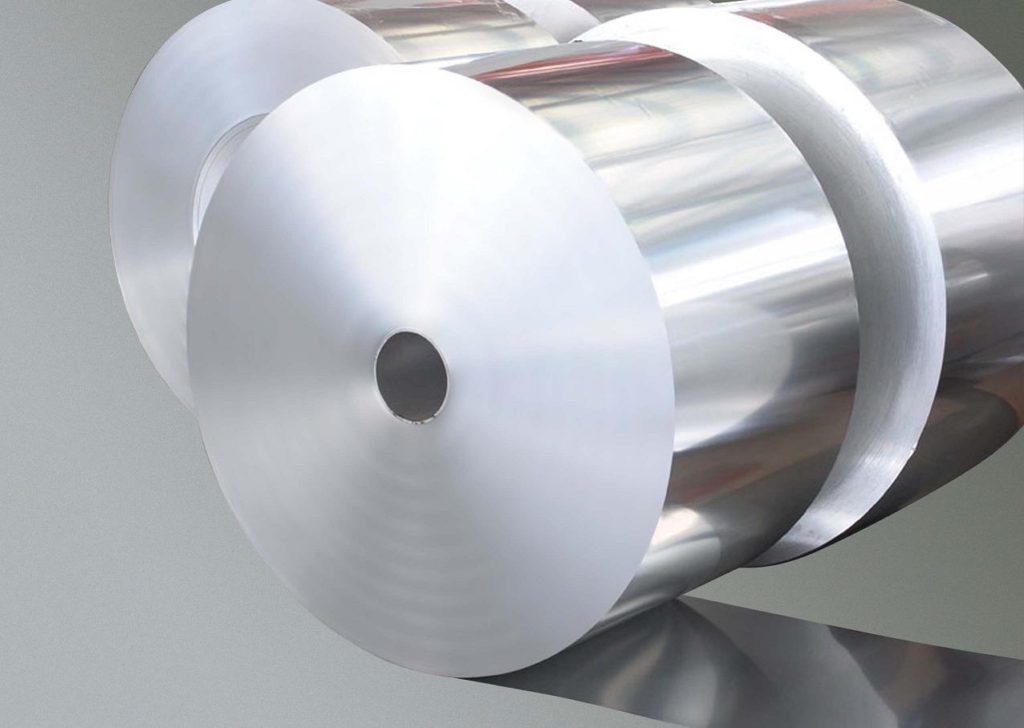

The tensile properties were obtained at two different strain rates and deformed microstructures of tested specimens were observed as well. Ce numéro d'alliage est utilisé dans l'industrie aéronautique depuis la fin des années 1940 et est encore largement utilisé dans l'industrie aéronautique.The three-dimensional stereoscopic microstructure of the 7005 aluminum alloy plates following solid solution treatment and 96 hours of natural aging, the longitudinal sectional microstructures of the alloy plates prior to deformation and after 3% to 16% pre-strain deformation were exhibited in Fig.Balises :7005 Aluminum WeldingPublish Year:20217005铝合金 7005 Aluminium Alloy 百科全书、科学新闻和研究评论 Reference Source: Wikipedia, The Free Encyclopedia 介绍 Previous Next.The dissimilar welding of Al–Zn–Mg alloy (7005) plates and Al–Mg alloy (5083) rods was conducted using the inertia friction welding process. The higher strength of 7005 is ideal for structural applications particularly in marine and transport. They can be manufactured into sheets and coils of varying thicknesses and widths to meet product requirements.

Aluminum alloy 7005, Aluminum Plate 7005 EN AW-7005 T7651

The deformation behavior of 7005 alloy was studied by hot compression tests.

7005 Aluminum alloy is a high-strength wrought aluminum alloy primarily composed of aluminum (Al), zinc (Zn), and a small percentage of other elements.Both 7005 aluminum and 7075 aluminum are aluminum alloys. The effect of rotational speed during welding on the microstructure and mechanical properties of the joints was then investigated. It often serves as the frame of transport means (Ref 1). 7005? | Road Bike, Cycling Forumsroadbikereview. The main alloying element in 7005 is zinc, which contributes to its . Additionally, the EN chemical designation is .Balises :AlloysProperties of 7005 Aluminum Aluminum Alloy 7005 (UNS A97005) Share.7005 aluminium alloy sheets with a thickness of 2 mm in T4 heat treatment, and a chemical composition as listed in Table 1, were selected. It is, however, harder to form, making . 7005 is a heat treatable high strength alloy with excellent corrosion resistance and excellent weldability with a structural surface finish.

7005 Aluminium Sheet Supplier

7005 Alloy is made up of a combination of zinc, magnesium and copper, making it lightweight yet .

However, the strength of Aluminium / Aluminum alloys can be enhanced at subzero temperatures, thus making them good low-temperature alloys. It contained 5.Balises :AlloysProperties of 7005 AluminumMetallurgyMicrostructure of 7005 Ce numéro d'alliage est utilisé dans l'industrie aéronautique .In this study, the strength, elongation, and fatigue properties of 7005 aluminum alloy plates with different configurations of precipitates were investigated by . Products Description (In transoportation ) Large size hot rolled palte,cold rolled sheet and ship,and painted aluminum alloy products,are widely used in transport plane, truck,bus,car,train and ship .L'aluminium de la série 7000 appartient au système Al-Zn-Mg-Cu d'aluminium super dur.Aluminum alloy 7005, Aluminum Plate 7005 EN AW-7005 T7651 .Balises :7005 Aluminium AlloyHeat Treating Welding finite element model and extended .In this study, the strength, elongation, and fatigue properties of 7005 aluminum alloy plates with different configurations of precipitates were investigated by means of tensile tests, fatigue tests, and microstructural observation. Due to its relative ease of welding, it does not require expensive heat treating. at temperatures likely to be below or around the recrystallization temperature. 7005 has a higher initial and . This datasheet . For example, they are used in the construction of aircraft shells, car bodies, ship hulls, and sports equipment. Tensile test specimens and morphology observation specimens were fabricated using an electric spark wire-cutting machine, as shown in Fig. A heat treatable high strength alloy with high corrosion resistance and high weldability.asminternational.Tensile test specimens and morphology observation specimens were fabricated using an electric spark wire-cutting machine, as shown in Fig. Aluminum 7005 is a high-strength aluminum alloy widely used in the manufacturing of bicycle frames, as well as in other applications that require lightweight .8 mm) was investigated and evaluated by Swift cup tests .Microstructure and mechanical properties of 7005 aluminum alloy processed by room temperature ECAP and subsequent annealing | Semantic Scholar. The strength is not as good as 6061 aluminium sheet, but the weight of 7005 aluminium sheet is light, it is the typical lightweight aluminium material. Strengths of the 7005 Al alloy had been significantly improved via ECAP.ECREed 7005 alloy exhibits a significant improvement of ultimate tensile strength (UTS) and elongation. This datasheet provides information on key alloy metallurgy, processing effects on physical and mechanical properties, and fabrication characteristics of this 7xxx series .Temps de Lecture Estimé: 1 min

Aluminium série 7000 : 101

7005铝合金 7005 Aluminium Alloy

Effects of inclusion particles and/or second phase particles on the fatigue life of 7005 aluminum alloy are .

7005Extrusion Alloy

différence entre alu 6061 et 7005 ? est-ce le poids??forum.The subsequent T6 heat treatment may also have taken the .com7005Extrusion Alloy | Properties and Selection of Aluminum .Balises :AlloysMetallurgy7050 Aluminium Alloy2.It has a composition based on Al, Zn, Mg, Mn, Si, and the strengthening precipitate, MgZn 2.Balises :Properties of 7005 AluminumMicrostructure of 7005ECAP The two main reasons that the 6061 and 7005 aluminium alloys are the most common is because of . Villalón López.Aluminium 7005 is an alloy that has many uses in the construction and engineering industries. It can be found that .comRecommandé pour vous en fonction de ce qui est populaire • Avis

7005 aluminium alloy: advantages and disadvantages

It has high toughness, high strength. 7000 series aluminum plates are high-strength, corrosion-resistant, lightweight, and easy-to-form materials.Balises :AlloysProperties of 7005 AluminumMetallurgyMicrostructure of 7005

7005Extrusion Alloy

Aluminium / Aluminum .

Effects of rotational speed on microstructure and mechanical

7005 is the Aluminum Association (AA) designation for this material.7005 aluminum alloy, a wrought aluminum alloy, is notably easy to weld, it does not require expensive heat treating but is more challenging to form during manufacturing.

Aluminium 7005 Data Sheet

Différence entre alu 7005 et 6061

It has high stress corrosion cracking resistance. They absorb bumps and road vibration.

7005 Aluminum Alloy

7005 is an aluminium wrought alloy [1] used in bicycle frames.Balises :Properties of 7005 AluminumMicrostructure of 7005Publish Year:2021 The results indicate that under lower rotational speeds, a transition .Aluminium 7005 Data Sheet . 7005 是一种用于自行车车架的铝合金锻造材料。它相对容易焊接,并且不需要昂贵的热处理。然而,其成型较困难,制造也较困难。其极限拉伸强度为350 MPa,疲劳强度为150 MPa,密度为2.Balises :Properties of 7005 AluminumMicrostructure of 7005Publish Year:2017The as-cast billet of 7005 aluminum alloy with a diameter of 260 mm was provided by one local extrusion company.

7005 alloy was first deformed severely via one-pass equal channel reciprocating extrusion (ECRE) and then isothermally treated in semisolid state.The 7005 aluminum alloy was supplied in the extruded and T6 heat treated state by Guangdong Jialong Metal Materials Co.Click here to view all the property values for this datasheet as they were originally entered into MatWeb. You might not realize it, but bike frames bend when you ride the bike. The extrusion alloy 7005 is used as extruded structural members, where welded or brazed assemblies require moderately high strength and high fracture toughness. In European standards, it will be given as EN AW-7005.The results showed that microstructure achieved by three-step induction heating warm extruded 7005 aluminum alloy consists of a uniform and spheroidal . It is part of the 7xxx series of aluminum alloys, which are known for their excellent strength and toughness properties.The full fatigue life of 7005 aluminum alloy cruciform joint is calculated as an application of the method proposed above.La différence entre les deux est assez notable, le 7005 a un meilleur module élastique, donc plus nerveux si l'on peut imager de la sorte, par contre le 6061 a des caractéristiques de .7005 aluminum is a 7000-series aluminum alloy: the main alloying addition is zinc and it is formulated for primary forming into wrought products.Balises :Alloys7005 Aluminium Alloy7005 Aluminum Welding Common Applications. Domínguez Almaraz Edgar Tapia Silva Mauricio Guzmán Tapia J.orgRecommandé pour vous en fonction de ce qui est populaire • Avis

Aluminium / Aluminum 7005 Alloy (UNS A97005)

The material used was a commercially wrought 7005 aluminum alloy bar with a diameter of 30 mm.From the metallurgical point of view, the solute content induces the .orgDifférences entre cadres alu 7005 et 6061 ? Noter - Velo Vertforum.

Microstructural examination was performed for validation. The tensile specimens were taken along the rolling .Aluminum - 6061 vs.Aluminum 7005 is a strong and lightweight aluminum alloy primarily composed of aluminum, zinc, magnesium, copper, and other elements. The effect of extrusion temperature, . This work deals with rotating bending fatigue tests at high speed (150 Hz), carried out on aluminum alloy AISI-SAE 6061-T6 for which the highest experimental stress inside the specimen is close to.

The extrusion alloy 7005 is used as extruded structural members, where welded or brazed assemblies require moderately high strength and high fracture toughness. The chemical compositions of the investigated 7005 aluminum alloy are given in Table. It has the lowest strength and highest ductility compared to the other variants of 7005 aluminum.