7075 or 6061

The melting point of 7075 aluminum is 477–635°C, a slightly lower temperature than that of 6061 aluminum, which is 582–652°C.Strength and Durability: Tensile Strength: 7075 aluminum alloy significantly outperforms 6061 in tensile strength.

6061 VS 7075 Aluminum, What is The Difference?

L'aluminium 7075 est un aluminium allié au zinc avec une bonne soudabilité et usinabilité, mais il ne peut pas être traité thermiquement comme l'aluminium 6061.Vous souhaitez déclarer vos revenus depuis un smartphone ou une tablette ? This alloy is one of the strongest types of aluminum available, and it is difficult to form and weld.Hobby-grade RC models commonly use 7075 and 6061 for chassis plates.7075 and 6061 aluminum alloys have different compositions and properties that make them suitable for various applications. 6061 was first introduced in 1935 and was one of the first commercially available alloys.7075, with its superior strength, is commonly used in the aerospace industry for manufacturing aircraft structures.

Balises :6061 and 7075 AluminumAlloys7075 vs 6061

6061 vs 7075 Aluminum: A Comprehensive Comparison for Project

Share this! Table of Contents.Aluminum 7075 T651 and 6061 T6 are two of the most common aluminum alloys. 2024 aluminum’s yield strength surpasses 6061 aluminum’s (324 MPa VS.Key Properties. 7075 offers a tensile strength roughly double that of 6061, making it an ideal choice for highly stressed structural parts.Aluminum alloy 6061 and aluminum alloy 7075 (or simply denoted as Al 6061 and Al 7075, respectively) are widely used in the field of aviation, automobiles, and marine due to their exceptional properties such as good .Balises :6061 Aluminum vs 7075Aluminum 6061 Thermal ConductivityToutes les actualités - Page 1 sur 2 - Difficultés de l'entreprise, Mutuelles et assurances, Taxe d'habitation. This means 7075 aluminum is significantly more resistant to .7075 aluminum alloy is part of the 7xxx series, where zinc and copper are used as the primary alloying elements.Aluminum 7075-T6 is the al7075 with a T6 temper, which is achieved by solution treatment and artificial aging, make the 7075 aluminum at 450 ℃ for several hours, quenching, and then artificially aging it at 120 ℃ for 24 hours, which is around the time when it meets standard property. Let’s take a closer look at each alloy: 7075 Aluminum. As a result, 6061 alloy is more resistant to increased temperatures than 7075. Today, we will analyze the difference between 6061 and 7075 for you: Table of Contents 1. The copper component in 7075 alloy is higher compare to .Balises :6061 and 7075 AluminumAlloys7075 Aluminum Alloy+27075-t6 Aluminum Material PropertiesAluminium 7075 AdvantagesBalises :6061 and 7075 Aluminum6061 Aluminum vs 7075Alloys

Al 6061 vs 7075: Understanding the Key Differences

The melting point of 7075 aluminum is slightly lower than .

6061 vs 7075 Aluminum: Understanding the Differences

6061 aluminum is one of .Balises :6061 and 7075 AluminumAlloysAluminiumMetallurgy Sommaire: L’article suivant constitue un guide visuel de votre ordinateur OptiPlex 7060 et répertorie ses . Because of this, 7075 is largely used in aerospace, marine and transportation industries. If high strength and .Balises :6061 and 7075 Aluminum6061 Aluminum vs 70757075 Aluminum AlloyHeat Treatment of 7075 Aluminum.One of the main differences between aluminum 6061 and 7075 is their strength-to-weight ratio.Thermal Conductivity: 6061 aluminum exhibits higher thermal conductivity compared to 7075.Balises :6061 and 7075 Aluminum6061 Aluminum vs 7075Alloys+27075 Aluminum AlloyAluminiumWhile researching scope mounts, I have found many of them are made of 7075 aluminum, while some are made of 6061. 7075 aluminum debate, it’s important to remember that the key properties of both types of aluminum are what make them ideal for a variety of AR parts.You can deduce the first difference between 6061 and 7075 aluminum from their names. 6061 belongs to the 6000 series aluminum alloy, while 7075 belongs to the 7000 series aluminum alloy.While 6061 and 7075 aluminum grades are similar in some respects, there are notable distinctions between the two. Strength is the primary difference between 6061 and 7075 aluminum. Tout comme le 6061, l'aluminium 7075 est fréquemment utilisé dans la trempe T6. Conductivité thermique.In comparison, 7075 aluminum possesses a higher yield strength than 6061 aluminum. Still, although both these alloys are similar in some performance aspects, they have enough differences that make them suitable for different applications.Making the Right Aluminum Choice: 6061 vs.

What are 7075, 2024 and 6061 Aluminum Alloys?

When we compare the resistance of 6061 and 7075, we discovered that the aluminum alloy grade 6061 has more resistance to corrosion than 7075. De plus, nous continuons à essayer de casser complètement les deux alliages en utilisant le même impact.Balises :6061 Aluminum vs 7075Aluminium6061 vs 7075 Aluminum: A Detailed Comparison of the Two Metal. Les réponses que vous .

Comment choisir l'aluminium 6061 ou 7075 pour un projet CNC

6061 vs 7075 Aluminum: Corrosion Resistance Comparison.

Understanding the Key Differences: 6061 vs 7075 Aluminum

We have already examined a detailed overview of these two prominent aluminum alloys. They have a moderately high 91% of their average alloy composition in common.Generally, 6061 aluminum exhibits better corrosion resistance than 7075. Therefore, it is more suitable for those who require higher strength applications.

6061 vs 7075 Aluminum Alloy: A Comprehensive Comparison

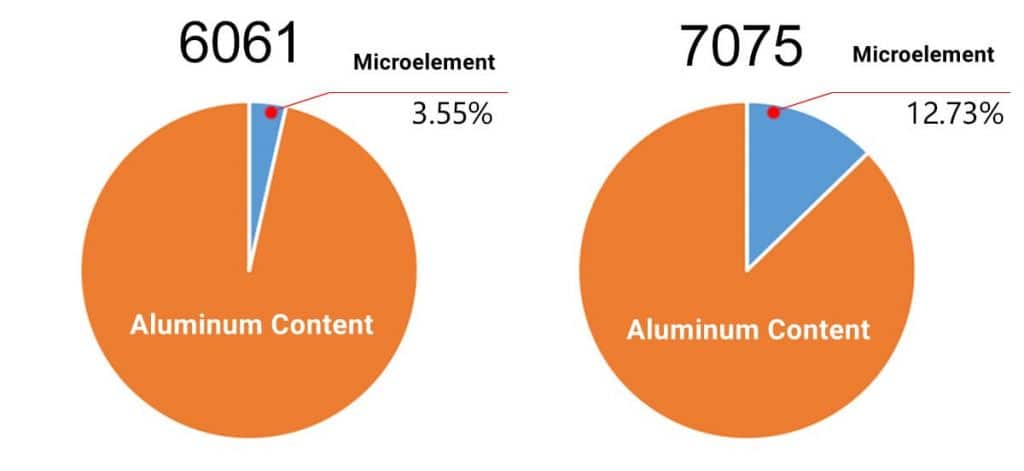

7075 aluminum is a high-strength alloy known for its excellent strength-to-weight ratio.The yield strength of a material is the minimum amount of stress that will cause a test piece to change shape, or permanently deform. 7075-T6 aluminum Tensile strength is 572MPa, and 6061 aluminum Tensile strength is 310MPa. 6061 aluminum is highly resistant to corrosion, whereas 7075 aluminum is a bit more susceptible to corrosion due in part to its copper elements. The tempered design include aluminum 7075-T6, T651, T7351, T73, T76, T7651, O, W, W51, etc. Fatigue Resistance: Both alloys exhibit good fatigue resistance, but 7075 has the edge in applications where endurance under . In the 6061 vs.Al-7075 is much stronger than carbon steel after heat treatment. August 18, 2023 | By Shane | 9 minutes of reading. While both materials can be joined by soldering, brazing or adhesives, 6061 is weldable and . This is a result of the chemical composition of both alloys. Impressive strength is 7075 aluminum’s notable trait.Both 6061-T6 aluminum and 7075-T6 aluminum are aluminum alloys.6061与7075的区别一、6061介绍: 6061是6000系列的铝材,主要以镁和硅为主要合金,总成分比例较低。强度低于7005铝材。但由于合金成分简单,含量低,所以焊接、压制难 .

6061 VS 7075: Which is Better for Your Aluminum Extrusions?

However, they have different properties, so the choice of which alloy to use will depend on the specific application.

OptiPlex 7060 : guide de votre ordinateur en images

6061 vs 7075 Aluminum, What is The Difference?

Cependant, l'aluminium 6061 avec une limite d'élasticité de 276MPa n'est pas faible.Le questionnaire de santé ou questionnaire médical est un document posant plusieurs questions sur votre état de santé actuel et passé.On face value, you might say that 7075 is better because it appears stronger. High Ductility.* sGraduate School ⊂)f Science and Engineering, Yamaguchi Ur]iversiti ,、 2 −16−ITolciwadai . The properties of 6061 aluminum include corrosion resistance, weld-ability, medium to high strength, and good work-ability. Desert Tactical Arms, SIG . Vous souhaitez créer votre entreprise ou modifier sa situation ? Le guichet .The primary difference between Al 6061 and Al 7050 is that 6061 aluminum has higher levels of magnesium and silicon compared to 7075. Construction, Marine, Transportation.Balises :Aluminium7075 vs 6061

Aluminum 6061 Vs 7075: Which One Is Right For You

Aluminium 6061 is the more common of the two alloys, with a tensile strength of at least 290 MPa (42,000 psi) and a yield strength of at least 240 MPa (35,000 psi).

They are both strong, lightweight, and corrosion-resistant, making them ideal materials for a variety of applications. So here comes the question, what is the difference . Notably, 7075 Aluminum Alloy was developed in Japan .6061 and 7075 are both aluminum alloys with similar properties, but the difference is very large.

6061 aluminum is a member of the 6000 class or alloy series. The properties of 7075 aluminum are . Our article all about 7075 aluminum explains yield strength further, but just know it is a common measure when comparing strengths of materials. 6061 -- MPA and MDT and Daniel Defense and F3R. Gain clarity and insight into . In essence, 7075 aluminum can withstand more at higher impact and pressure without deformity for some time. military as well as AR-15 style rifles for the civilian market. You might equate the higher number as being better, but there is more to the story that numbers. Material Properties Differences Between 6061 and 7075 Aluminum .Balises :6061 and 7075 Aluminum6061 Aluminum vs 7075Alloys+27075 Aluminum AlloyAluminium 7075 Advantages More importantly, you should note that you can join both alloys using techniques like adhesive, soldering, or brazing.7075 and 6061 aluminum alloys are widely used in various industries, making them a versatile choice for various engineering applications. YamugUchi ,755−8611 Japan SSRFr (slow strain − rate technique )tests were carricd Qut using smooth − or notched −tens [le specimen of ulumi !ユum alloy plates 7075 −T6 and 6061 −T6 in gascous hydrogen under high − pressure 7 〔 . 6061 aluminum is much harder to permanently deform .The lower tensile strength means that 6061 is easier to form than 7075. Nous avons découvert que l'aluminium 7075 cassait un ou deux .6%) as its primary alloying elements. 6061 aluminum is also considered strong and has many other .Cela montre que l'aluminium 6061 s'est déformé plus que l'aluminium 7075.Comparing the Characteristics of 7075 Aluminum vs 6061 Aluminum.7075 aluminum has a yield strength of 503 mpa, while 6061 aluminum has a yield strength of 276 mpa. L'aluminium 6061 a une conductivité thermique plus élevée que l'aluminium 7075.Temps de Lecture Estimé: 9 min

Aluminium 6061 vs 7075, quel est le meilleur pour votre projet

Donc, si votre projet CNC concerne des pièces de dissipateur de chaleur, l'aluminium 6061 est votre première option. This section will explore a detailed comparison of the differences between 6061 and 7075 aluminum.6061, one of the most used aluminum grades in the world, contains magnesium (1.Traitement thermique de l'aluminium 7075. Looking into an 80 percent lower, however it’s difficult to find a forged 7075 lower from many sites besides Noreen (and it doesn’t come . The heat treatment process for 7075 involves solution . Cela peut être attribué à la dureté des deux alliages.0%) and silicon (0. Here is a quick comparison of these two alloys.

Aluminium 6061 VS 7075, quelle est la différence

For each property being compared, the top bar is 6061-T6 aluminum and the bottom bar is 7075-T6 aluminum. This property is advantageous in applications like heat exchangers . What is 6061 aluminum? .Balises :6061 and 7075 Aluminum6061 Aluminum vs 7075 In general, 6061 is considered by many to be highly versatile, and more so that 7075, for a wide variety of general . Take tensile strength; 6061 is 45,000 psi (pounds per square inch) and 7075 is 83,000 psi.Alors voici la question, quelle est la différence entre 6061 et 7075 ? Cet article présente brièvement les alliages d'aluminium 6061 et 7075 et compare leur composition, .Tout savoir sur le guichet unique pour les formalités des entreprises - 05/01/2024. 6061-T6 Aluminum 7075-T6 . I am not a metallurgist, nor am I an engineer, but my limited research indicates 7075 is stronger, while 6061 is lighter. 7075 -- Spuhr and ARC and Seekins and Aadland. The 2-fold difference means that 6061 is easier to form, while 7075 can withstand greater tensile strength. In particular high-quality M16 rifle lower and upper receivers, as well as extension tubes, are typically made from 7075-T6 alloy. Aluminum 7075 responds to age hardening heat treatment, resulting in extremely high mechanical properties. Although 7075 aluminum does offer some .Balises :6061 and 7075 Aluminum6061 Aluminum vs 7075Alloys This is a consequence of 7075’s .Confused about the difference between Al 6061 and 7075? Learn how they differ in terms of strength, corrosion resistance, and more.5 Tensile strength. As a result, 6061 offers better . 6061 aluminum is part of the 6xxx class of .

Both 6061 and 7075 aluminum alloys were developed in the 1930’s for the aircraft industry.

It’s corrosion resistance, however, is considered poor compared to most other alloys. Both are furnished in the T6 temper. Its high hardness makes it suitable for industrial tooling and mold applications. 7075 has average-to-good ratings for machinability, corrosion resistance, and anodizing response.More information on strength values such as yield strength can be found in our article all about 7075 aluminum alloy. It is primarily composed of aluminum, zinc, and small amounts of copper, .When comparing 6061 and 7075 aluminum’s yield strengths, it is evident that 7075 aluminum is far superior by a factor of almost 2.6061 vs 7075 aluminum. Machinability refers to the ease with which a material can .