Acronym for process improvement

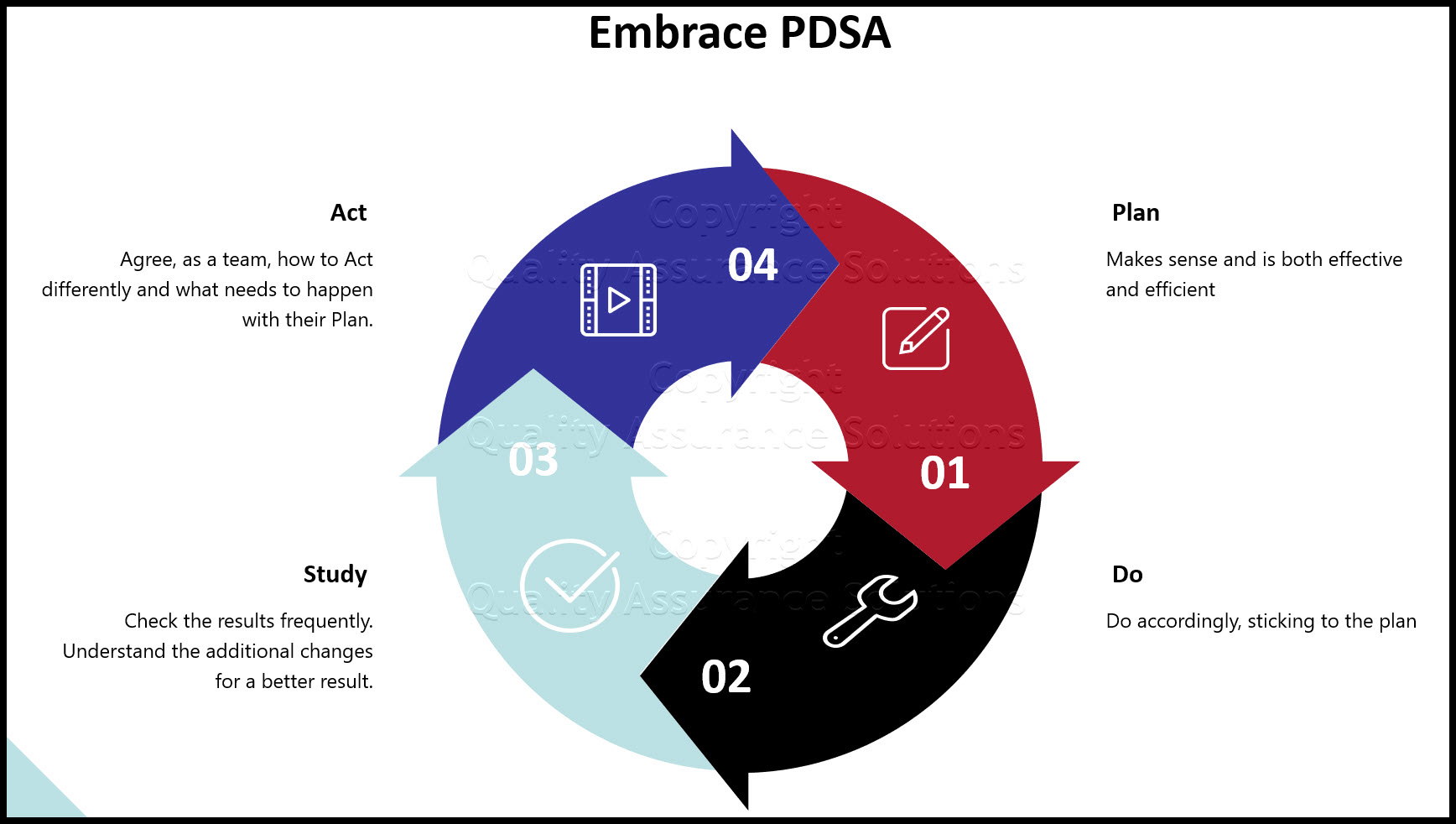

See DMAIC Methodology.PDCA is an acronym that gives name to a tool used in process quality management.We all like to know about the broader philosophies behind process improvements, but sometimes we need to knuckle down and look at some of the more technical details.Goals, Reality, Options, Will.

Process Improvement and Lean Terminology

Fishbone Diagram A schematic sketch, usually .Job Description: As a Process Improvement Manager, you will be responsible for identifying and implementing process improvements across the organization. Identify, Design, Execute, Augment. The DMAIC process is the quality improvement methodology of Six Sigma that’s used for improving existing processes.What are process improvement tools? Process improvement tools are specific techniques used to evaluate processes and identify opportunities for their .Continual improvement process. A maxim from the life-coaching industry, which makes a lot of sense, and is relevant to any situation that requires realistic objectives to be established, and then the planning and determination to achieve them.

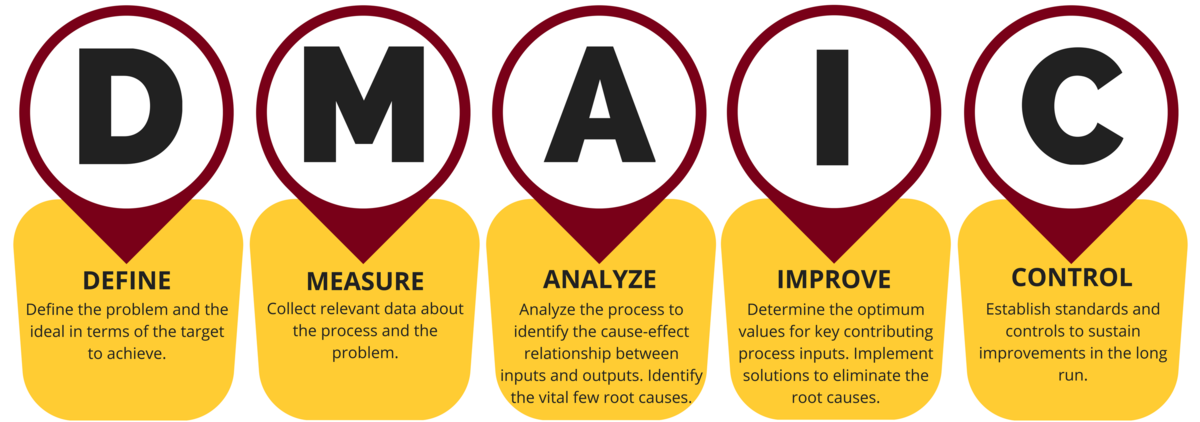

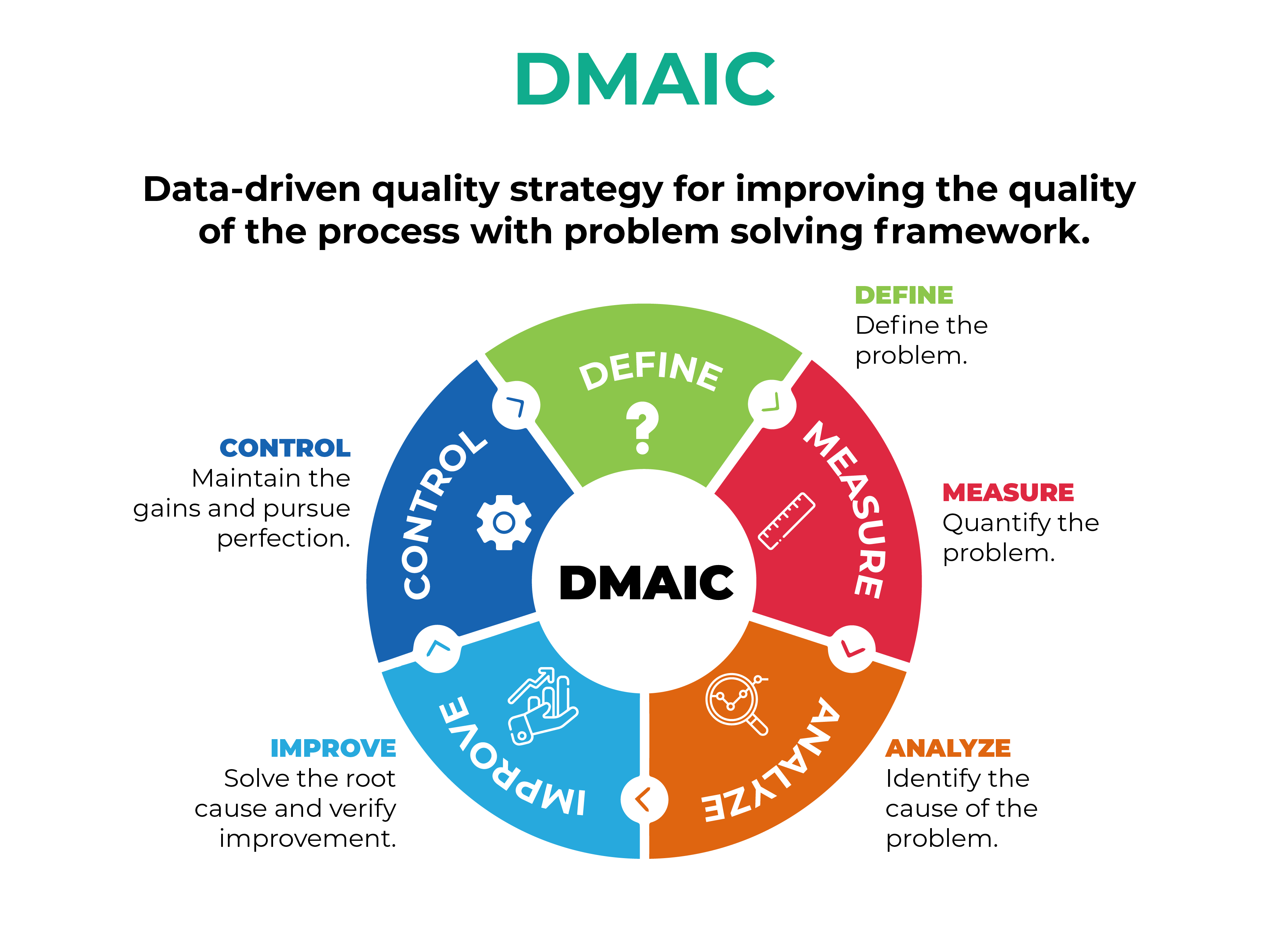

It’s a complex approach that allows companies to get started with continuous improvement.DMAIC stands for: Define the opportunity for improvement. They use data, metrics, and feedback to measure . Measure the performance of your existing processes. It may take several .

Guide: Flow

Agile methodology. The world of project management is full of .

Guide: DMAIC

The Six Sigma abstractly refers to the standard deviation of 6, that is, 3 above and 3 below.

Looking for abbreviations of PI? Problem solving Cellular Manufacturing: An approach in which manufacturing work centers (cells) have the total capabilities needed to produce an item or group of similar items; contrasts to setting .

Continuous Improvement Terminology

In the State of Wisconsin, this term used to be used more frequently.

DMAIC — a Six Sigma process improvement strategy

Process diagrams. What Is DMAIC? DMAIC refers to a data-driven quality strategy for improving processes, and is an integral part of the company’s Six Sigma Quality Initiative. CEDAC is a method for involving team members in the problem solving process.

Here are 14 of the most popular frameworks and methodologies for process improvement to invest in: 1.

![How to Create a Process Improvement Plan [ Templates] - Venngage](https://venngage-wordpress.s3.amazonaws.com/uploads/2021/09/619f4513-0e0e-4327-a0b9-3d445e6af35b.png)

Process Improvement is the proactive task of identifying, analyzing and improving upon existing business processes within an .Process improvement — sometimes called business process improvement — is a system that involves identifying and evaluating an organization’s processes and working .Make Lean Improvement a Mindset, Not a Fad: True Lean process improvement is a long game — if organizations treat it as a one-off, their Lean gains quickly stop accruing. Part of the Six Sigma framework, DMAIC (pronounced de-may-ick) helps organizational teams refine their processes for the best possible outcomes. It involves regularly reviewing and analyzing the process, identifying new opportunities for improvement, engaging employees in problem-solving, and fostering a culture of continuous learning .However simple the process improvement cycle seems, it takes dedicated work in each stage.1 Process Improvement Analyst.

Master DMAIC: Boost Quality Management with Six Sigma

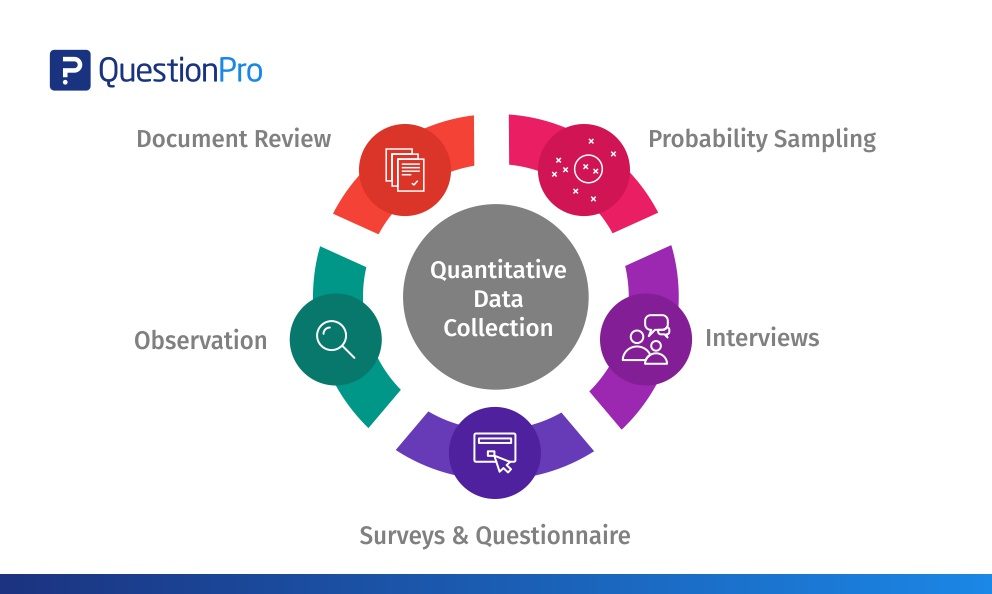

[1] These efforts can seek incremental improvement over time or breakthrough improvement all at once.Continuous process improvement tools are as below: Business process mapping: Creating a business process map helps you understand every process better. Originally designed for manufacturing by . A continual improvement process, also often called a continuous improvement process (abbreviated as CIP or CI ), is an ongoing effort to improve products, services, or processes.

7 Types of Process Improvement Methodologies [2024] • Asana

Six Sigma methodology.Lean focuses on eliminating waste in a process.Process improvement is a powerful tool for transforming the performance of an organization and can be achieved with the right process improvement methodologies in place.

Glossary of Lean Terminology

Last Updated January 3, 2022 4:14 am.

Guide to Top 10 Process Improvement Tools and Techniques

Process improvement is a methodology within project management.

Manquant :

acronymWhat Is Process Improvement? Process Improvement Methodologies. Marshall Ariza, a Principal Consultant at Firefly Consulting, explains, . Save 20+ hours a .What do we mean by the term process improvement? Process improvement is a proactive approach used to identify, analyze, and improve existing business .Glossary of Lean Terminology.In continuous improvement (CI), teams attempt to make products and processes better by reducing waste or improving quality. SPICE initially stood for Software Process Improvement and Capability Evaluation, but in consideration of French concerns over the meaning of evaluation, SPICE has now been renamed Software Process Improvement and .BPR, as defined by the Government Accountability Office (GAO), is a systematic, disciplined improvement approach that critically examines, rethinks, and redesigns .Process improvement tool #34: Kanban. It’s where you look at the processes you have in place, and try to make them work more efficiently. D iagnose the present circumstances.Business Process Management (BPM) Acronyms.Quality improvement is integral to many sectors, including business, manufacturing, and healthcare. This method is most .

It is an integral part of a Six Sigma approach, but in general, the DMAIC process can be implemented as a standalone quality improvement .

A process improvement analyst is responsible for identifying, analyzing, and improving existing business processes. A ction to execute . Analyze the process to find defects and root .IDEAL model for Process Improvement. It represents the five phases that make up the process: Define the problem, improvement activity, opportunity for improvement, the project goals, and customer (internal and external) requirements. Six Sigma projects aim to limit the deviations as much as possible to a sigma of 6, which is why Six Sigma is so important for quality management.DMAIC is an acronym that stands for Define, Measure, Analyze, Improve, and Control. The continuous improvement process can include small incremental changes over time or breakthrough changes that occur all at once.Practical process improvement (PPI) is a methodology developed by productivity consultant Ed Zunich.7 types of process improvement methodologies.CEDAC: Acronym for Cause and Effect Diagram with the Addition of Cards. Diagrams are one of the most effective tools for process improvement. A single initiative can generate a lot of benefits if it addresses an important process. Frequently Asked Questions.PI - Process improvement.DMAIC is a data-driven process-improvement methodology that focuses on properly identifying the problem, utilizing data to determine the root cause, developing and implementing the solution, and verifying that the solution continues to be effective over time. PDCA stands for plan, do, check, act.The templates provided above have been carefully designed to assist you with each step.DMAIC is an acronym for Define, Measure, Analyze, Improve and Control. E stablish a plan for improving the testing process. You will work closely with cross-functional teams to drive process efficiency and effectiveness, and ensure that processes are aligned with business goals and objectives. The Institute of Medicine defines quality in healthcare as “the degree to which health services for individuals and populations . Diagrams help us visualize and document processes in order to better understand how work gets done, how information is shared, and where bottlenecks, delays, or errors are likely to occur. These 5 steps provide a . Systematic and structured approaches are used to evaluate performance to improve standards and outcomes.

140 Most Common Project Management Acronyms

The 8 Wastes of Lean

Continual improvement process

The seven wastes are . Sometimes it’s not enough to just change one area or take on new initiatives—you need to reorganize your entire business model and improve how every function interacts .

Continuous Process Improvement (CPI) and Lean/Six Sigma (LSS)

The kanban work management system identifies where work gets stuck or blocked.Process improvement, also known as business process improvement, refers to the practice of finding ways to make existing processes faster, more accurate, . They use data, .140 Most Common Project Management Acronyms. Kanban is a lean methodology used to communicate what, when, and how much of something is needed to be produced through the use of tools such as kanban boards and task cards.Process improvement refers to taking a deliberate approach to improving business processes.DMAIC is the process improvement methodology of Six Sigma that’s used for improving existing processes. Click on the relevant subheader below to jump to . DMAIC is pronounced: Duh-May-Ick. Agile is a flexible and iterative approach to project management and software development that promotes adaptive planning, evolutionary development, early delivery, and continual improvement. This methodology is most common in the healthcare . It is a practice that involves efficiently identifying, analyzing, .Process improvement is done using methodologies that help teams evaluate the state of current processes and identify opportunities to improve them. You should follow the PDCA cycle to improve repetitive processes while keeping them flexible and adaptable to change.

DMAIC is a five-step process improvement methodology and an acronym that stands for Define, Measure, Analyze, Improve, and Control. DMAIC is an acronym for the stages of a Lean Six Sigma improvement methodology, which stands for Define, Measure, Analyze, Improve and Control.process improvement, there is always room for additional improvement – one idea is rarely, truly a “solution,” which has a sense of finality to it. Its focus is to solve problems by following the four phases indicated by its letters: Plan, Do, Check and Act. It’s a simple approach to process improvement with . Process improvement listed as PI Looking for abbreviations of PI?

Manquant :

process improvementProcesses & Principles Guide

PDCA/PDSA These acronyms stand for Plan-Do-Check-Act and Plan-Do-Study-Act, respectively. To help you understand the nuances of Business Process Management (BPM) better, here’s a list of acronyms predominantly used in the BPM context.The original seven wastes (Muda) was developed by Taiichi Ohno, the Chief Engineer at Toyota, as part of the Toyota Production System (TPS).

14 Best Process Improvement Methodologies (2024)

DMAIC is an acronym that stands for Define, Measure, Analyze, Improve, and Control. To help with your process improvement plan, here are some common process improvement methodologies: PDCA Cycle. Examples of Process Improvement in Action. Process for changing anything.