Agile manufacturing processes

Agile manufacturing in such environments means understanding the environment and being flexible, cost effective and productive with consistent high quality.

AGILE MANUFACTURING PROCESSES

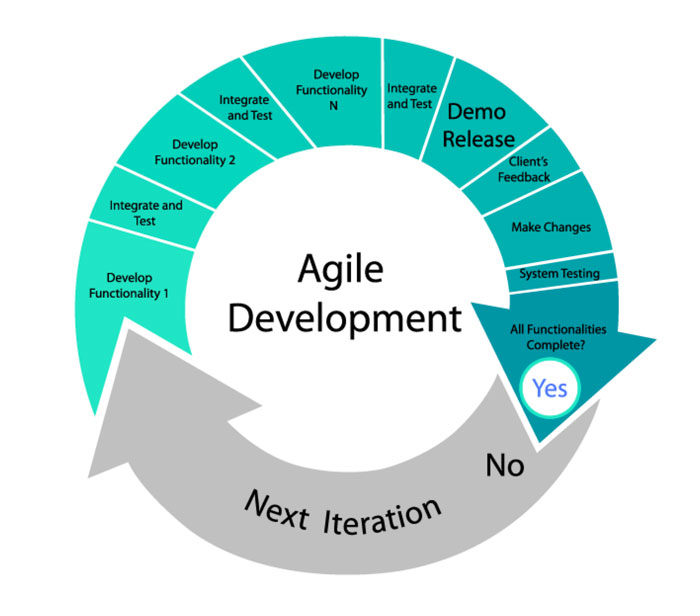

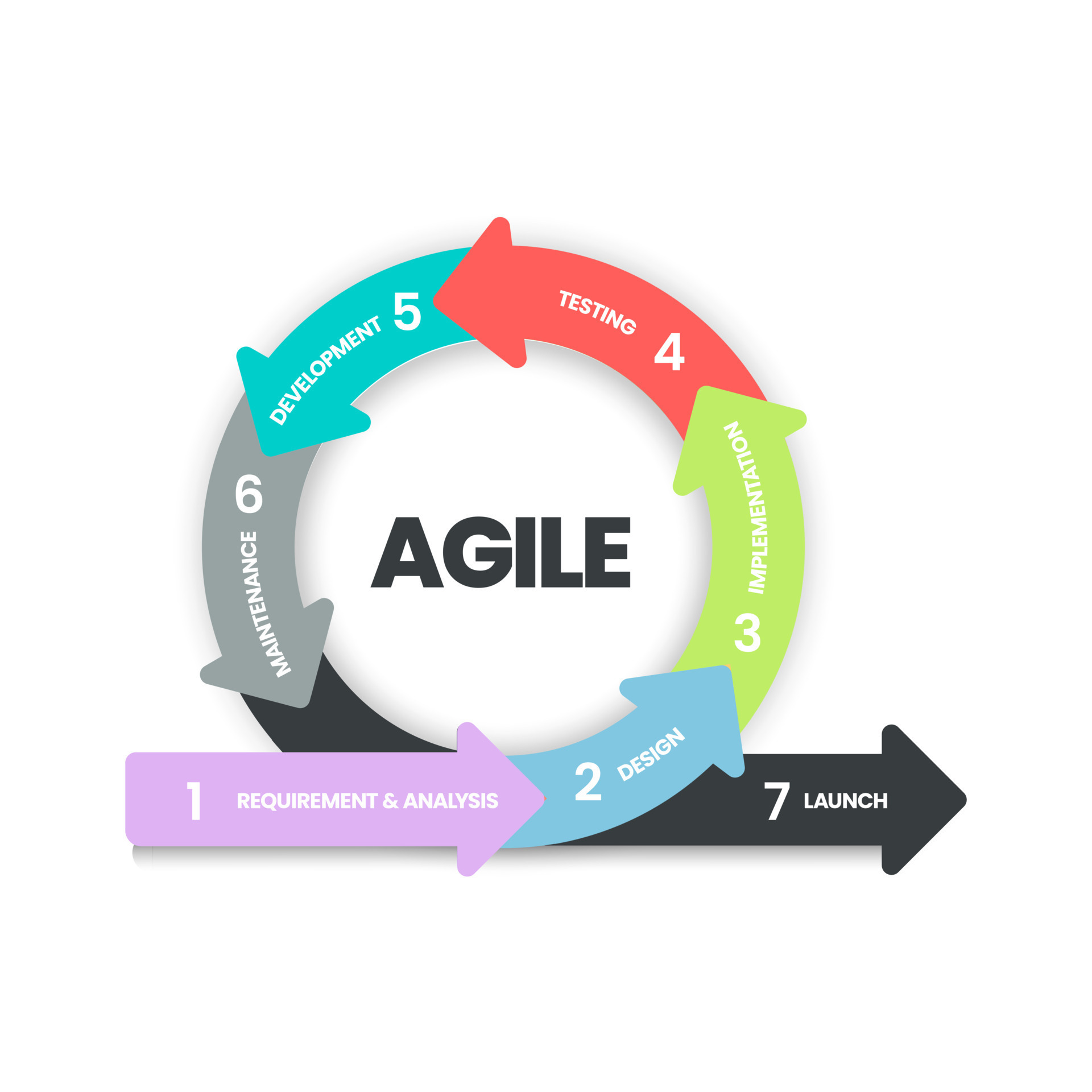

When the nuances of both lean and agile manufacturing are incorporated into an organization, it is known as leagile (lean + agile) manufacturing.Agile manufacture is all about being able to quickly cycle through multiple iterations of a process or product.

What is Agile Manufacturing?

Agile Manufacturing is a response to the challenges of the VUCA environment.

What is Lean Manufacturing and the 5 Principles Used?

While the pace of innovation has been accelerating in every other manufacturing field . However, limited, if any, research has focused on the evolution of practices within agile manufacturing supply chains and how these are related to competitive performance .

(PDF) Agile Manufacturing

Examples of Agile Manufacturing to See Why It Is Very Critical

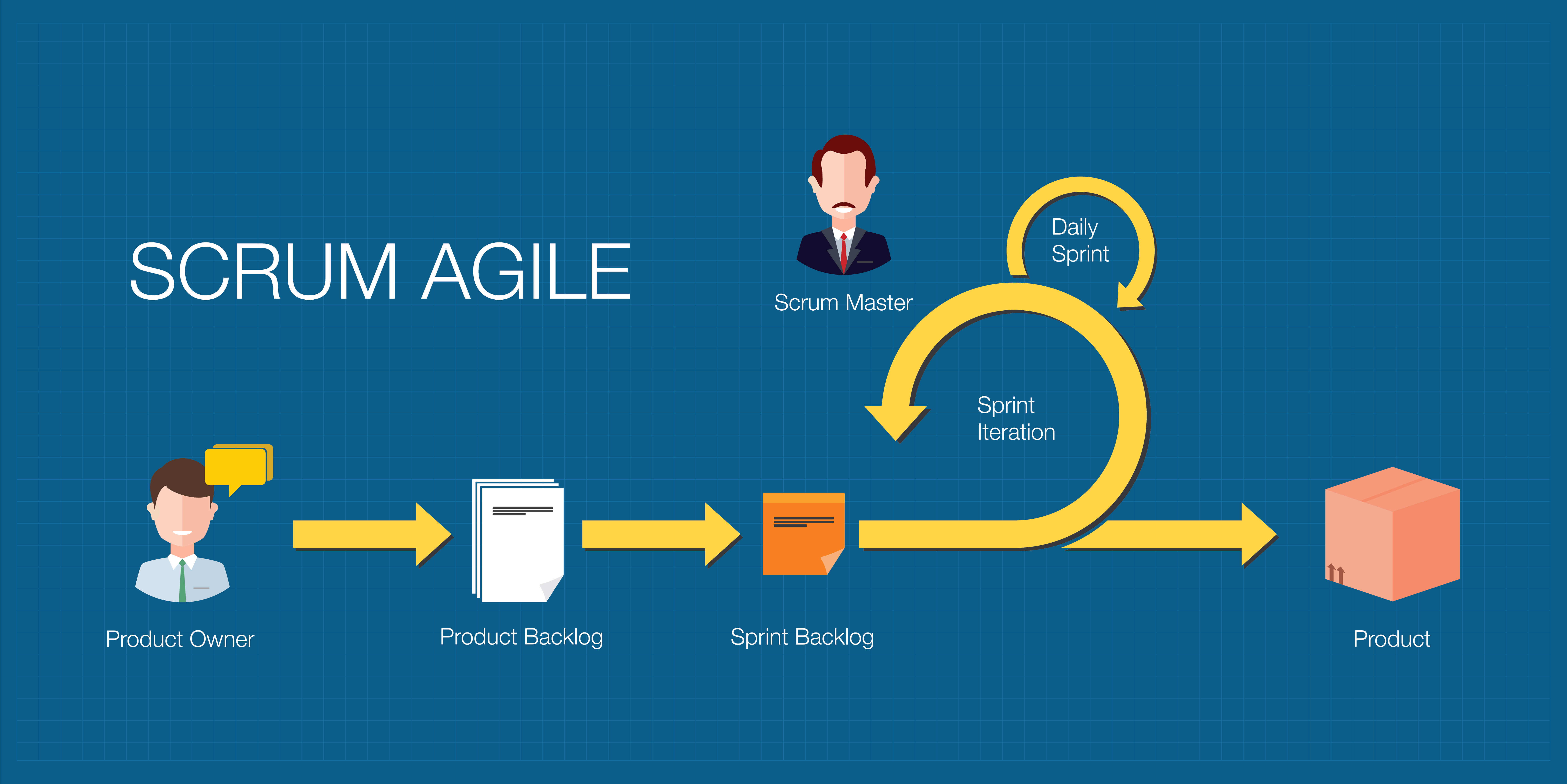

Scrum, Kanban, waterfall, Agile.In our opinion, agile manufacturing as well as green or sustainable manufacturing represent the most current types of manufacturing processes that best fit the current business environment.Agile manufacturing uses technology, organizational approaches, systems and people in a manufacturing concept which truly belongs to the 21 st century and .Manufacturing enterprises involve people, organization, technology, processes and information, and no commonly accepted practical reference framework exists to investigate, analyse and evaluate the ability to deal with change.Agile Manufacturing is defined as an organization’s ability to respond to change factors in real-time without reducing throughput quality or going over a specified budget. In order to ensure that the agile manufacturing process is under good control, it is necessary to monitor the process, obtain process and product information, diagnose the problems, and control the process.Agile methodologies, a cornerstone of IT project success, now offer a promising framework for revolutionizing the construction industry. The key attributes of agile manufacturing are shorter response times . Now lean production is evolving into agile manufacturing. Agile, in business, is a way of working that seeks to go with the flow of inevitable change rather than work against it.The key principles of agile manufacturing.

need in an agile manufacturing process.Agile manufacturing supports optimization, standardisation and automation of the development processes. As we explore the transition from linear models to the dynamic, adaptable approach of Agile, we uncover the potential for transformative change.

It also increased production output by 6 percent by connecting all its production machinery to a single . Find out how smart factory tech can help you attract, retain, and empower employees. Citation 1990). For example, a clothing manufacturer practising agile manufacturing might swiftly switch production from winter coats to summer dresses if there's an unexpected surge in demand.The five core principles of lean manufacturing are defined as value, the value stream, flow, pull and perfection.This is because agile manufacturing emphasises capabilities, technologies, skills, and knowledge that are necessary to manage changes and incorporate those changes into manufacturing processes and systems, i.This involves improving processes, reducing production batches, and eliminating waiting times, ensuring a more agile and efficient production.Summary

What is Agile Manufacturing?

While responsiveness may be the goal, four key principles drive that adaptability in agile manufacturing.

The Comprehensive Guide to Agile Manufacturing

In a lean and agile process, emphasis is on not only quantitative inputs, but also qualitative comments, assumptions, risks, and opportunities associated with the plan. The advantage of this is that we can reconfigure the layout of the entire flow-line in a couple of days rather than weeks or even months (see fig. “Should our manufacturing operations be more lean? Lean and agile manufacturing . enablers and practices of agile manufacturing, that is, transparent customisation, agile supply chains, intelligent automation . This flexibility will allow for . It is a method that enables manufacturers to adapt quickly . Audit trail capability is . Once completed,the assessment is used to define priorities for actions that will transform the current process. Organizations that implement agile into their manufacturing .Agile manufacturing (AM) is a new concept in manufacturing intended to improve the competitiveness of firms. smart manufacturing. Concurrent engineering is preparatory to agile manufacturing: product and process designers collaborate synergistically to implement agile systems; Agility requires the design of setups that can reconfigure the system as quickly and autonomously as possible. 1 Introduction.Agile manufacturing, a recently popularised concept, has been advocated as the 21st century manufacturing paradigm. The main functionality in production is . 3 How can we qualify drug products made via agile pharmaceutical manufacturing in real-time? * Industry 4.Agile manufacturing processes are designed to quickly adapt to changing customer requirements and market conditions.

Gunasekaran (Citation 1998) describes Agile manufacturing as the capability of . These types of manufacturing processes are those which, according to the information available in specialized literature, can support .

Versions of products and processes succeed each other quickly.En réponse, de nombreux fabricants industriels ont adopté les principes de fabrication Agile dans leurs processus de production pour répondre plus rapidement à la demande .

Agile management

Discover ways to maximize efficiency, .

Agile Manufacturing Explained: What, How, and Why — Katana

Lean: Focuses on stability and .

Value: Value is determined from the perspective of the customer and relates to how much they are willing to pay for products or services.Modernization of the chemical engineering curriculum has fostered educating a productive and agile workforce deployed in an ever-expanding range of process industries, including modern semiconductor, energy storage, and thin film-based roll manufacturing industries.An agile manufacturing strategy is one that places a strong priority on responding quickly to the needs of the customer, resulting in a major competitive .

It is seen as the winning strategy to be adopted by manufacturers bracing themselves for dramatic performance enhancements to become national and international leaders in an increasingly competitive market of fast .Lean manufacturing focuses on the elimination of waste within the firm’s production system through continuous improvement and process changes for reducing non-value added activities or elimination of wastes (Womack et al.Change is also a constant in business (and, yes, life).Implementing an agile manufacturing strategy requires businesses to begin by assessing the gap between current processes and the intended agile environment.Agile manufacturing is a strategy that enables companies to adapt quickly to volatile customer demand and unpredictable market phenomenons.Agile has become increasingly relevant in the manufacturing space — and understandably so. Agile manufacturing and transformational capabilities for sustainable business performance: a dynamic capabilities perspective. The purpose of Lean and agile manufacturing is the customer satisfaction with a cost-effective price.

Agile Manufacturing Guide: Operations in the Era of

AGILE MANUFACTURING PROCESSES 591. The role of lean and agile manufacturing is vital to maintain the optimum work in process inventory in the production flow. reconfiguration capability for quick and effective responses to marketplace changes (Iqbal, Huq, and Bhutta Citation . In this article, get a high-level overview of Agile project management, plus a few common frameworks to choose the right one for your team. This article provides valuable information about new product introduction and the six-step process to help you implement an efficient and effective NPI.

Agile manufacturing: Adapt and compete with new practices

Establishing QUalIfication Processes for Agile Pharmaceutical Manufacturing

The research is based on a wide-ranging review of agile manufacture and manufacturing architectures. Each agile production unit includes manufacturing and direct support functions, such as planning and .Unlike traditional mass production methods, Agile Manufacturing emphasizes quick response times, rapid prototyping, and collaboration across cross .Agile Manufacturing, on the other hand, is a set of principles and practices that allow organizations to respond quickly and efficiently to changes in the business environment. Agile’s core principles—collaboration, .3 of the tooling has been made to place anywhere on the flooring but this has meant that the tooling has had to be extremely rigid. Discover ways to maximize efficiency, optimize processes, and make investments that matter. Rapid iterations imply delivering smaller pieces of value more frequently.

Agile manufacturing: A framework for research and development

A comparison of agile and lean manufacturing. Manufacturing processes based on AM are . The Agile Manifesto, developed in . lean manufacturing. This includes .Agile manufacturing is a methodology that prioritizes rapid response to customers, leveraging speed and agility as a crucial competitive advantage. It emphasizes flexibility, adaptability, and collaboration in manufacturing processes. The purpose of Lean and agile manufacturing is the customer satisfaction with a cost . Historically, mass production has evolved into lean production.

Agile manufacturing

Until the 1950s companies focused on productivity improvement and in .Keywords: Business process reengineering agile manufacturing.W e have identified five enabling competencies as the agility. These are now used as the basis to implement lean.Therefore, understanding what the new product introduction (NPI) process entails is an important step you need to take before proceeding with product manufacturing.In most advanced agile manufacturing environments, completely and semi-autonomous systems are used.Academics and practitioners have long acknowledged the importance of agile manufacturing and related supply chains in achieving firm sustainable competitiveness.Agile processes leverage change for the customer’s competitive advantage.

What is agile methodology?

Agile methodology is a project management framework that breaks projects down into several dynamic phases, commonly known as sprints.0 practices for pharma manufacturing leveraging advantages of batch and continuous flow reactors • Fund up to 4 sites to produce 2 drug products/site on drug shortage list via agile pharmaceutical .

:quality(90)/cloudfront-us-east-1.images.arcpublishing.com/elcomercio/XPIXU3CEDZA6TF6DGP37CRE26A.jpg)