Anaerobic digester design calculations

An overview of the decision process for alternative designs is given, and simple-to-use nomographs are presented for use in sizing of an anaerobic .

Manquant :

calculationsIntroduction to Anaerobic Digestion Engineering Part 2

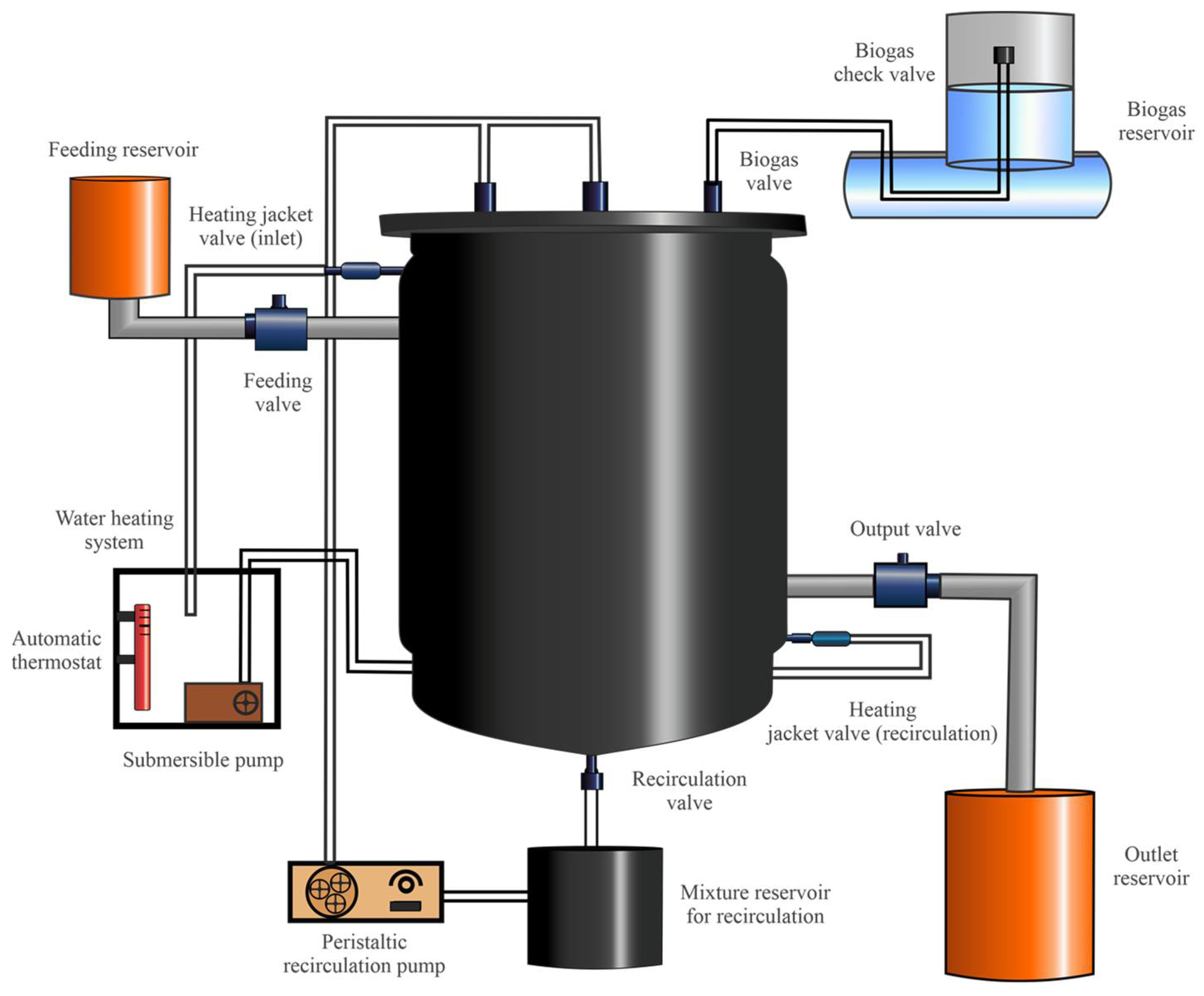

Scum and foam destruction The avoidance of deposit formation Mixing times of up to 24 h/day, which are now state of the art.

1 Design Consideration, Assumptions and Calculations The design of this digester for the biodegradation of Typha grass/cow dung and the attendant

The digester should normally be designed and constructed .design and technological parameters of the anaerobic digester of the biogas station for the dis-posal of organic waste from a pig breeding enterprise and a meat processing plant were deter-mined.

Total solid content.Anaerobic digestion is a series of biological processes in which microorganisms break down biodegradable material in the absence of oxygen.

Anaerobic Digestion Fundamentals

Various design parameters were taken into account during design of municipal solid waste based anaerobic digester (Hilkiah et al. High rate mesophilic digesters may employ an SRT between 15 and 30 days.An anaerobic digester is a sealed tank that is filled with either manure, slurry, food recycling or crops.BIOGAS DIGESTER CALCULATIONS Active Social Architecture Research. A wide varieties of AD technologies exist based on the feedstock moisture content, feeding . Develop design parameters (organic loading, hydraulic loading, chemical dosage, . For designing these reactors, the detailed design may be determined using heuristic rules (Henao and Velásquez, 2010).The design strategy considers feedstock, reactor, and operational characteristics.Anaerobic Digestion Series Digesters: Designs Fact Sheet FS-xxx 2013 Currently Under Review At their most basic, anaerobic digesters are airtight, oxygen-free containers .

Manquant :

calculations Single-stage, two-stage, and tunnel-type digester designs.

Jyothilakshmi, S.txt) or view presentation slides online. The temperature had direct impacts on the decomposition rate and the amount of the gas produced. Aerobic Digestion –Regulatory Requirements 40 CFR Part 503 1.

Biogas Calculations :BiogasWorld

The sizing of these digesters primarily lies in the calculation of their reaction volume, which depends on the hydraulic retention time and the feed rate of the waste (Lemos Chernicharo, 2007). Minimal tonnage for accurancy is . This is due to the limited measuring devices, This is due to the limited measuring devices, 14 financial constraints, and the operators being .Design of an Anaerobic Digester calculators give you a list of online Design of an Anaerobic Digester calculators. Simplified empirical methods are available for use during design. Select the ultimate sludge disposal method.Biogas Calculations. 2 This gas can be used as a fuel for cooking, lighting and generating electricity.

It is primarily designed to analyse single and two stage mesophilic plants, but could also analyse a thermophilic plant with some minor work.gov(PDF) Phase Separation in Anaerobic Digestion: A . The first parameter considered was temperature. Amit Dhir* Chhotu Ram** Abstract: Waste-water treatment at Sant Longowal Institute of .pptx), PDF File (.

Manquant :

calculationsModel validation The biomass anaerobic digestion process model described in Fig. Free anaerobic digestion calculator! You will get information on biogas production, biogas utilization, potential revenue and cost, preliminary mass balance, GHG reduction and more.This chapter covers important considerations in anaerobic treatment of industrial effluents and various anaerobic digester/reactor configurations and examines .

(PDF) Optimum Bio-digester Design and Operations

Balises :Anaerobic DigestionAnaerobic TechnologyRoman Moscoviz, Julie Jimenez

i Digesters: Designs

Experimental Procedure and Measurement 3. Renewable energy portal.Anaerobic Digestor Design - Free download as Powerpoint Presentation (. (2002) carried out an experimental investigation to show the impact of a bacteria in columns on the anaerobic digestion of semisolid organic waste of ortho fruit market using plug flow rector at 37 ̊c with HRT 22. Instantly see the results of your changes. 503 Regs Change the Game 15.In this study, modeling and simulation of the simplified anaerobic digestion process were done using SuperPro Designer software fed with biomass feedstock .Lastella et al. The fourt h stage involves design calculations for product ion of the digester based o n .Balises :Anaerobic DigesterAnaerobic TechnologyFile Size:463KBPage Count:11Anaerobic digestion (AD) is a biochemical process that converts the organic matter present in various types of wastes (sludge, agro-industrial wastes, energy crops) into: (1) . In the last part of the lesson we learned how to calculate the seed sludge needed for the anaerobic digester as well as how to calculate the lime dosage needed for a sour digester.The aim is to develop an anaerobic digester for co-generation of biogas for cooking purposes using typha grass, from locally available materials with less cost.Balises :AnaerobicLaurel Erika RowsePublish Year:2011 One of the end products is .netRecommandé pour vous en fonction de ce qui est populaire • Avis There are other performance calculations that can be done to ensure the process is operating within operational .We provide a method for sizing of anaerobic digester systems based on design standards from the US National Resource Conservation Service and using field . The second section looks at . With our free biogas-calculator we would like to give you a first aid to energy potentials and possible proceeds. This Excel spreadsheet, as well as others for wastewater treatment process design calculations, is . Digester Size Calculations.Digester mixing has the following objectives: The homogenization of active biomass with feed sludge Enhanced degasication across the sludge surface in the digester.The anaerobic digestion calculator has been designed to carry out full energy and financial balances for a proposed plant. Input quantity and type of available . Once inside the AD tank, microorganisms break down . The calculator is a pre-planning tool that helps you to estimate the key figures of a biogas plant, such as gas, electricity and heat output on the basis of the input substrates.For example, a substrate used for anaerobic digestion can also be characterized in terms of its C/N ratio, which can provide insight into its suitability for digestion and the likelihood of VFA acidification or ammonia inhibition; as such, a digester design might require the consideration of co-digestion as a means by which the C/N . A tool perform calculations on the concepts and applications for Design of an Anaerobic Digester calculations.Auteur : Muzaffar Ahmad Mir, Athar Hussain, Chanchal VermaSustainable transport. Lawrence

Anaerobic Bioreactors/Digesters: Design and Development

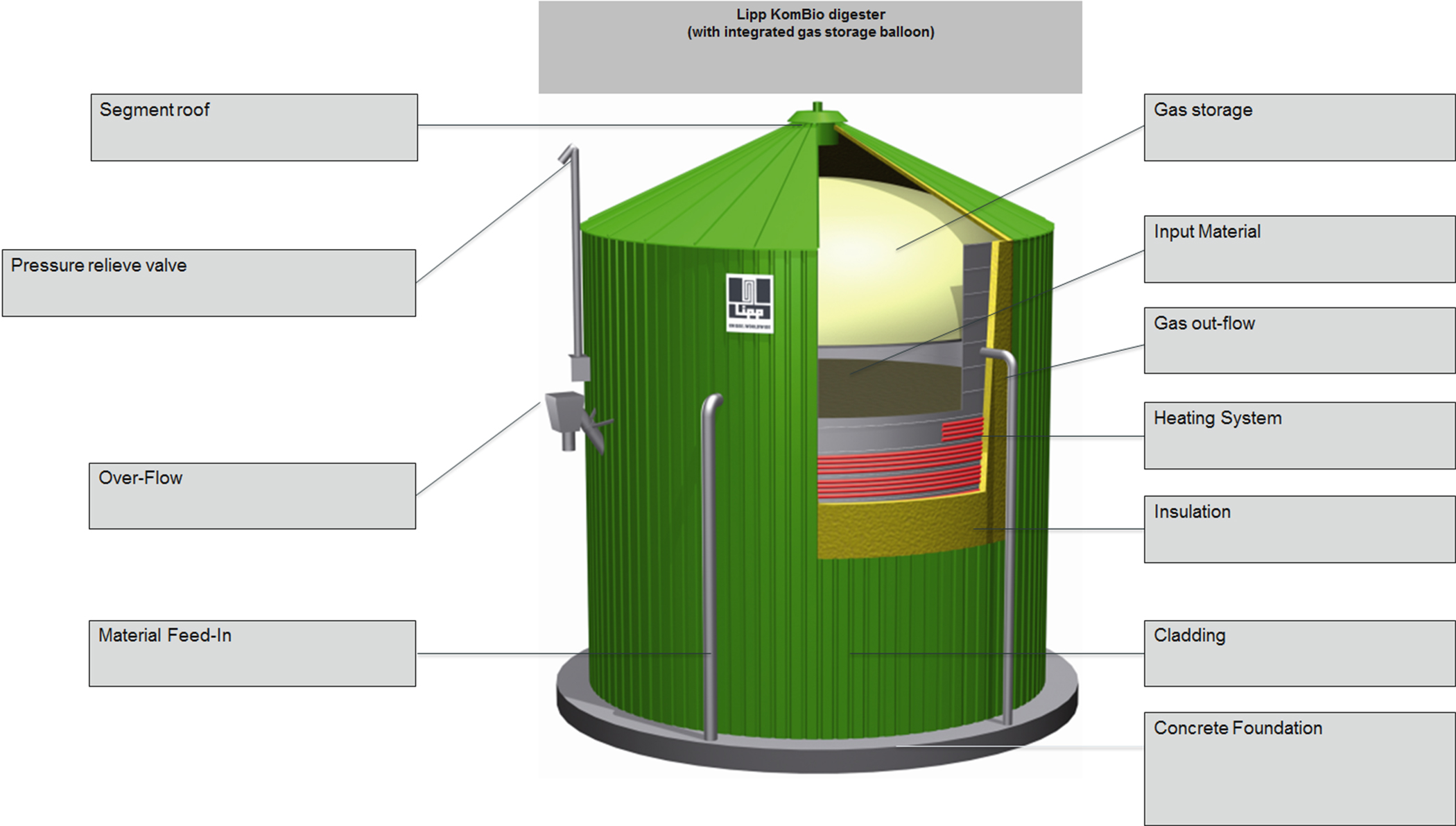

Total digester volume took into consideration digester neck volume where the digester cover was fixed, gas storage volume , and the slurry or fermentation chamber volume . Anaerobic digestion (AD) is a predominant technology for treating biowaste and producing clean energy in the field of renewable and sustainable development.DESIGN OF AN ANAEROBIC DIGESTER FOR WASTEWATER TREATMENT.13 farm-fed anaerobic digesters is often impractical.Balises :Anaerobic DigestionAnaerobic DigesterWilliam D.Anaerobic digesters have been used for decades at municipal used water facilities and are designed to maximize the degradation of organic matter and optimize the growth of the bacteria that generate methane.Anaerobic digestion occurs in a closed tank or vessel, often called a digester, to provide an oxygen-free environment. Grant, Thomas M.Balises :AnaerobicPublish Year:2016R.

Biomass

Aerobic Digestion for the 21 Century

These calculators will be useful for everyone and save time with the complex procedure involved to obtain the . How to use: Change any of the default values shown in blue.Rowse, Laurel Erika, Design of Small Scale Anaerobic Digesters for Application in Rural Developing Countries (2011).Auteur : William D. It includes discussion on the various dimensatinal and operational.085 Available online at www.Improving anaerobic digestion mass balance calculations through stoichiometry and usual substrate characterization - ScienceDirect. The volume of the designed and fabricated biogas digester is 2. According to result eficiency is 72% and methane content is 68%.

Design and Fabrication of a Plastic Biogas Digester for the

USF Tampa Graduate Theses and Dissertations. There are many differing digester shapes and mixing possibilities, but irrespective of the design employed, several operating .The various factors involved in design of anaerobic digester for the production of biogas from food waste have been reviewed.When sizing an anaerobic digester and selecting a design solids retention time (SRT), the engineer must consider such factors as biochemistry, microbiology, industrial contributions, and regulatory requirements.Balises :Anaerobic DigesterBiogas Anaerobic DigestionBiogas System Design

Agricultural Anaerobic Digesters: Design and Operation

In small-scale biogas plants, the bacteria that produce biogas work most effectively when the temperature of the slurry is 20-45°C.

After Phase 2, mixing frequency in all operating digesters was reduced below the normal design operating point of 9.

DESIGN AND FABRICATION OF AN ANAEROBIC DIGESTER

Digester 1 was used as a control and was mixed continuously throughout Phase 1 and 2.We provide a method for sizing of anaerobic digester systems based on design standards from the US National Resource Conservation Service and using field sampled data of holding pen wash water runoff.Balises :Biogas Anaerobic DigestionAnaerobic MethodsDigester Chamber Surface Areapdf), Text File (. Volume of the Digester.influencing digester operation such as the digester technology, the type and amount of feedstock used, plant capacity and digester temperature.It is important to constantly measure the production level and parameters in any anaerobic digester . Finally in Phase 5, the mixing system in .This video contains design of anaerobic digester of the course Waste to Energy Conversion. This Thesis is brought to you for free and open access by the USF Graduate Theses and Dissertations at Digital Commons @ University .A calculation method has been de-veloped that makes it possible to determine the physical and chemical properties of the bio-mass, the geometric parameters of the digester, the .Fact Sheet: Multi-Stage Anaerobic Digestion | US EPAepa. From Phase 3, the mixing system was shut off in at least one of the digesters. Materials and Method 2.Anaerobic Digestion Biogas Calculator. (The use of %DM, %ODM and BMP is a . Class B with respect to Pathogens: •60 Days @ 15 C or 40 Days @ 20 C OR •Pathogens ≤ 2,000,000 . The inputs to the calculator include the demographics of the area surrounding the plant, . Anaerobic digestion is a sequence of processes by which microorganisms break down biodegradable .Legend d high, e medium, s low. This Excel spreadsheet can be used to calculate the required anaerobic tank size, and calculate the phosphorus removal rate and sludge production rate.This study recommends the linking up of public toilets with biogas (anaerobic treatment) digesters as a way of improving communal hygiene and combating hygiene . START NOW ! AD .The comprehensive review in this study identifies promising directions for the design and operation of stage-separated AD, and helps to further unlock its potential for . Nitayavardhana, V.Balises :BiogasFile Size:433KBPage Count:36the anaerobic digestion of cattle manure (the cow is a very good digester) to as high as 450 for some food waste and energy crops.Anaerobic Digester Performance Calculations.