Ball mill vs sag mills

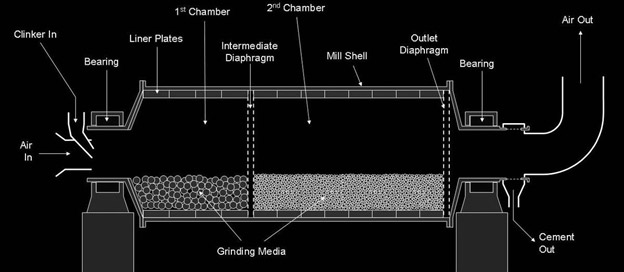

Within comminution circuits, High Pressure Grinding Rolls (HPGR) are increasingly replacing conventional SAG, rod and ball mills for hard rock reduction – .26 × (2,233 + 215) = 3,349 kW. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′.Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach.Laboratory scale ball mill.Multiple stages may include a rod mill followed by a ball mill (two stage circuit), or a semi-autogenous grinding (SAG) mill followed by a ball mill (two stage circuit). This information is based on observed throughput reductions caused by loading the 3-ft. Once the basic operating conditions have been defined for the mill designer then, and only then, can he begin taking into account shell and head stresses and trunnion bearing sizes required to carry the load and to give the required openings for feeding and discharging the mills.SAG Mill Circuit Example — Gold Processing SAG mill circuit example for gold processing [image: (135-6-3)] AG/SAG Mill. It uses the crushing and grinding action of rocks to reduce materials such as copper ore into smaller pieces for further processing.

What Is The Difference Between A Ball Mill And A Sag Mill?

Customization: support. This equation is: y = 225 – 1.

SAG Mill Grinding Circuit Design

Pieces are then used . Easily find the perfect fit from our wide range of sizes.

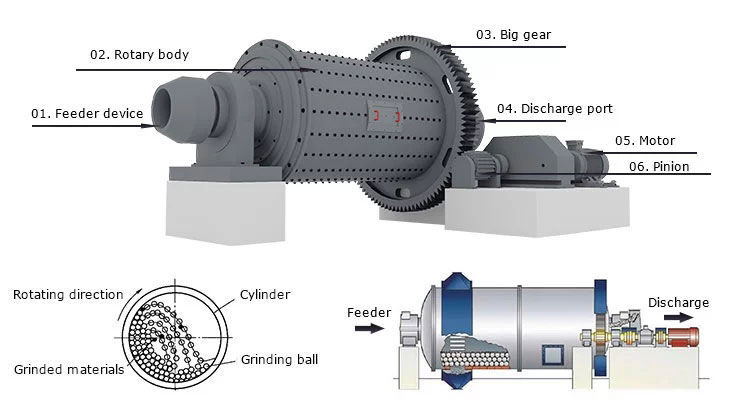

Semi-autogenous mills are basically the same autogenous mills, but . Material: various metals, nonmetallic ores, rocks, etc. Rod and AG mills can produce a lot of attrition and varying amounts of impact and abrasion.325 kWh/tonne (ball mill) when processing 32. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds.942 kWh/tonne or 14. Mills require different liner profiles and designs depending on mill size, speed, charge, charge level, type, size of grinding media, expected service life, and – of course – ore size and properties, such as hardness and abrasiveness.

Ball Mill (Ball Mills Explained)

6 m (120) by 7.SAG Mill Components. 11 2022-11-20 SAB circuit •Primary SAG (or AG) followed by ball mill This is .AG mills (or SAG mills with low ball charges) are often used in single-stage grinding applications. The single line grinding circuit at Bond Gold’s Colosseum mine consists of variable speed drive semi-autogenous (SAG) milling and secondary grinding with a fixed speed ball mill. Another difference is the type of grinding media used.2m in diameter with powers as high as 28,000 kW. During rotation, the . High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.SEMI AUTOGENOUS MILL.

Ball Mill vs SAG Mill: What’s the Difference?

SAG (Semi-Autogenous Grinding) mill is a type of grinding equipment widely used in the mining industry.Autogenous grinding mills use larger rocks to impact and break smaller rocks as the mill rotates.

How it Works: Crushers, Grinding Mills and Pulverizers

Ball Mills: Ball mill adalah penggiling halus.

SAG & Ball Mill Grinding Circuit

In a SAG mill, balls of up to 150mm in diameter occupy 5%-18% of the mill chamber volume. Ball mills tumble iron or . Thus, quantitatively, less material can progress through the voids in the rod mill grinding media than in the ball mill, and the path of the material is more confined. Arraying different mills can take advantage of the strengths of particular equipment. There are several advantages and disadvantages of operating SAG mills with variable speed drives. Our team of product .

Ball mill

Grinding rods and balls can be obtained in uniform sizes, weights and of a specified quality. Wet grinding in an AG/SAG mill is accomplished in a slurry of 50 to 80 percent solids.

This grinding action restricts the volume of feed which passes . Understanding which mill is better for different . and balls in place approximately 300 pounds per cu.0 m length (190) single SAG mill equipped with a 20 MW electric motor.3 m (240) horizontal screens, whose combined oversize (pebbles) is diverted to two Metso MP 800 cone crushers. In the most common processing situations, though, the energy savings are likely 30-50%.In some situations, roller mills use 85% less energy to process grain than hammer mills.617 kWh/tonne (SAG mill) and 570 kW, 17. This single-stage circuit is chiefly employed for coarse grinding when a product finer than 65 mesh is not required, but it can be . The crushed product returns to the SAG mill feed, closing the primary grinding circuit. Their action in a mill .Download scientific diagram | SAG mill compared to crusher and ball mill product size distributions (Powell et al 2014) from publication: FULL PRE-CRUSH TO SAG MILLS – THE CASE FOR CHANGING THIS . SAG mill to over 26% by volume.

RoM BALL MILLS

A ball charge volume which is lower than those tested has been selected in order to minimize wear.

Perbedaan Antara Sag Mill vs Ball Mill

Discharging Size: 0.

Ball, Pebble and SAG Mills: A Buyers Guide

A SAG mill, or semi-autogenous grinding mill, is a type of machine used in mining and mineral processing operations. It is similar to an ., rod-and ball mills, the grinding media in an AG mill derive from the feed ore itself (Gupta and Yan, 2016;Hahne et al.SAG mills contain balls of up to 150mm in diameter that occupy 5%-18% of mill chamber volume.CERAMIC LINED BALL MILL. SAG mill A SAG mill is usually a primary mill for grinding .Metso is advancing an unrivaled innovation legacy by introducing the Premier™ mills and Select™ mills.19th August 2019. It is a combination of machines used to break down large pieces of rock into smaller pieces of rock, gravel, or even dust. Similarly to Figure 1, observed SAG mill Ecs vs.A Comprehensive Guide to SAG Mill Operation.94 x (1) Where x = the load in the mill expressed as measured % by volume and y = kg/h of feed.9 mtph, for a total of 30.It is important to differentiate the SAG mill from other types of mills, such as ball mills and rod mills, as each has its unique characteristics and applications.

Pre-Processing to Increase the Capacity of SAG Mill Circuits

com/equipment/

SAG Mills For Sale

SAG mills operate differently from ball mills, which rely on the impact of balls to break down the material. Therefore, the predicted power at the mill shell is 3,119 kW, which is 71 kW less than the measured shell power (3,190 kW), a difference of 2%. The working principle of a SAG mill .SAG mills can produce a lot of impact if operated with a high ball charge and low filling. Roller mills produce particles that are very consistent in size, though they are likely to be elongated .Gross power = 265 + 1.The SAG mill was originally operating in a ball mill duty and it has a low aspect ratio (diameter/length) which changes its operation relative to typical high aspect mills (Powell, Morrell and . In comparison to conventional tumbling mills, i.Understand the Difference Between Ball Mill vs SAG Mill. Rod mill: The rod mill has the highest efficiency when the feed size is <30mm and the discharge size is about 3mm with uniform particle size and light . The feed to ball mills (dry basis) is typically 75 vol.911metallurgist. Metso has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in . This helps offset the initially high cost of a roller mill.SAG vs Ball Mill Advantages. 2D and 3D simulations of particles in a SAG MillRods in place weigh approximately 400 pounds per cu. To do this, the material is fed into the cylinder at an angle and then rotated inside. Discussion in this .

Mill (grinding)

References (15) . Much like all types of mills, the Ball Mill’s purpose is to grind and blend material into smaller pieces. AG/SAG mills are normally used to grind run-off-mine ore or primary crusher product.In all cases, understanding of the transfer size (T 80) between the SAG mill and the ball mill is critical to achieve best economics in a semi-autogenous mill (SAG) .

Keys to best practice comminution

Demystifying The Sag Mill: What Is It And How Does It Work?

common mill types: SAG mills, rod mills, and ball mills.

These two product lines are unique, but use Metso experience and expertise to exceed your operational goals. Axb is plotted in Figure 2, except this time with data from JKTech’s database. AG & SAG Mill Grinding Compared – Which is Best.The summary in Table 1 pertains to a subset of the database comprising 67 surveys of 27 different mills that were included in the analysis described in the following section. High-energy ball milling. Get more done at a lower cost with higher throughput. Fuller-Traylor SAG/AG Mills range in size from 4.Most mills used in mining rely on impact to breakdown rock to a suitable size for downstream processing. Effective Volume: 4. Ball mills typically use steel rods, steel balls, or similar media to . The horizontal . This type of Mill is used for grinding large fragments into small pieces.Cases 4 and 6 are also good choices, because both of these options use 30 or 32 ft diameter SAG mills, and also use coarse vibrating screens to separate the fine fraction (screen undersize) for further grinding in a ball mill. SAG mills use a combination of impact and attrition to grind the material. In conclusion, ball mills and SAG mills are both essential in the operation of any mineral processing facility.Variable Speed SAG Mill. All three (the Ball, Pebble and SAG) are operational within the same type of housing, however each type of mill has a different practicality and purpose.It is an approximation or a best guess based on limited data. The conversion between motor input (gross) power and mill shell power, described earlier, is 0. Silinder berputar horizontal atau vertikal yang diisi sebagian dengan bola-bola keramik, batu-batuan kecil dan bola-bola yang terbuat dari baja tahan karat. GET FREE QUOTATION NOW. As a guideline, mill throughput is maximized with shell lifters between ratios of 2. SAG mills are distinguished by utilising run-of-mine (RoM) feed as grinding media with 5 – 18% steel balls added to supplement grinding media.However, the difference lies in the fact that SAG mills use a larger proportion of the ore itself as the grinding media, along with the ball mill. When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity. 25 and the actual layout in Fig.6% above the conventional estimate. The SAG mill product flows to two 3.

Manquant :

sag millsKey considerations when selecting a mill lining system

Ball mills, conversely, contain grinding media up to 50mm in diameter, .

SAG mills are often used in conjunction with ball mills, but they are not .

Difference Between Sag Mill vs Ball Mill

Mills require different liner profiles and designs depending on mill size, speed, charge, charge level, type, size of .

Sag Mill vs Ball Mill: Semi-Autogenous Grinding Mill – SAG Mill: SAG is the abbreviated form for Semi-Autogenous Grinding Mill. In contrast, a ball mill contains grinding media up to 50mm in diameter, occupying between 25% - 40% of the mill chamber volume. Obviously, the SAG mill . Dengan gesekan dan pengaruh bola berjatuhan di dalam silinder yang berputar menggiling . Based on their higher throughput and coarser grind relative to AG .