Bed adhesion 3d printing

How to 3D Print Nylon Filament Like a Pro

Written by Jay Simmons in Guides. This is one of the most irritating . PEI (polyetherimide) is a surface that makes your 3D prints stick better to the print platform.Balises :Bed AdhesionSammy Ekaran Some materials, like ABS, greatly benefit from the use of a raft. To provide extra bed adhesion when printing 3D slicers like Cura and Prusa provide different build plate adhesion like . But with the tips .Balises :3D Printer Bed Adhesion3d Glue

How to Fix 3D Prints Not Sticking to the Bed

Magigoo 3D Printer Bed Adhesion

Stop warping on your ABS prints, and create strong bed adhesion to . In the journey of 3D printing, mastering bed adhesion is a milestone worth the effort. Print bed adhesion can be further increased by using Blue Tape, PEI films or glue sticks. Not only does this help in improving . The most important rule .Balises :Bed Adhesion Tips3d Printing Bed Adhesion Issues+33d Printer Bed Adhesion Glue StickAdhesion Problems 3d Printing3d Printing Increase Bed Adhesion

4 Best Glue Sticks For 3D Printing Bed Adhesion 2024

An excellent 3D printing material, but ABS is prone to warp.What Is The Best Adhesive/Glue to Use For 3D Printer Beds?

PLA Not Sticking to Bed: 4 Key Fixes For Every Issue

It makes the use of rafts (see below) redundant. General tips on bed adhesion/leveling These are some general tips for achieving proper bed adhesion and leveling when 3D printing.Layoneer 3D Printer Adhesive Bed Glue is a well-respected and trusted product that works really well for getting great adhesion to the print bed.Balises :3D PrintingBed Adhesion Tips Achieving proper bed adhesion is critical for creating . There are several ways to improve 3D printer bed adhesion results: Clean the print bed: Before starting a print, make sure the print bed is clean and free of any debris.Step 2: Print Bed and Adhesion.For example, if you are printing at very fine layer heights, such as 0.

We've found 3D printing nylon can warp about as much as ABS.

Improve Glass Bed Adhesion (Ender 3 & other Printers)

In this article, we’re looking at the importance of bed adhesion when 3D printing as well as several different methods you can use to improve adhesion and, ultimately, print results.With proper settings, TPU is easy to print thanks to excellent bed adhesion and the filament’s tendency to not warp.

3D Print Not Sticking To Bed?

In the case of heated build plates (which are necessary for printing materials . There are several factors that can affect 3D bed adhesion, including surface characteristics, material properties, and environmental conditions.Bed Adhesion: The Ultimate Guide – The 3D Bros.Bed Adhesion Solution: Magigoo Bed Adhesion for Polypropylene or SmartMaterials SmartStick.

Balises :3d Printing Bed Adhesion Issues3D Printers+33d Printer Glass Bed AdhesionBed Adhesion For Ender 3Ender 3 Glass Bed Adhesion Reddit

8 Ways How to Make 3D Printer Bed Sticky

Nylon is prone to absorbing moisture in the air, so store in an airtight container when not in use.Balises :3D Printing3D Printer Bed Adhesion

4 Best Hairsprays for 3D Printing (& Adhesion Guide)

If your 3D printer comes equipped with a heated bed, here's how to prepare it for ASA printing: Use a Brim: Start your print with a brim - a flat area around the base of your .What is a Raft in 3D Printing? A 3D printed raft is basically a throwaway horizontal surface that sits under your object, to help with bed adhesion. There are a variety of factors that can affect your 3D printer’s first layer failure, and in this article we’ve listed every potential issue, with .

4 Best Glue Sticks For 3D Printing Bed Adhesion 2024

ASA filament, similar to its ABS counterpart, is temperature-sensitive and requires a heated bed for optimal performance. Other bed materials just don’t seem to have the texture or adhesive properties that nylon likes . A PVA based glue stick applied to the bed is the best method of bed adhesion. This includes things like the texture and smoothness of the printer’s .In this blog post, we'll share our top tips for improving the bed adhesion of your 3D prints so you can ensure consistent success with each one. Use the Control knob and scroll to the “Prepare” menu. Level the Bed Properly.It is coated with polyetherimide which helps provide excellent adhesion, and it is flexible too, making it easier to remove the print when you finish 3D printing. It has a strong adhesive that holds PLA in place, making it ideal for this type of filament.

Balises :3D Printing3D Printer Bed AdhesionBalises :3D PrintingBed Adhesion TipsAbs Bed Adhesion

Bed Adhesion: The Ultimate Guide

This enhances bed adhesion and the likelihood of a successful print. This is crucial to prevent warping or shifting of the object, which can lead to printing errors.To 3D print Nylon, you should use a printing temperature between 225-270°C and a bed temperature between 70-90°C for the best results. However, with certain combinations of filament and .Bed adhesion and getting those first layers to stick are critical to your success at printing. Turn the Ender 3 on. Clean the Print Bed. Keep reading for an in-depth . Use an Adhesive. Get to know the practical solutions to bed adhesion issues and ensure that .Conclusion – Perfect 3D Printer Bed Adhesion Every Time. The raft is laid down first to the specified layer depth, then the object is printed on top of the raft. The ideal print bed temperature for TPU is 50 ± 10 °C.Learn the physics of bed adhesion, tips for optimal settings, and creative solutions for perfect prints.As we've explored the intricate world of 3D printing, it’s clear that mastering layer adhesion is key to creating strong, durable, and high-quality prints. But do not set your bed temperature too high. Using a First Layer Height well above 100% can be extremely helpful in these cases. Perfecting your 3D print bed adhesion can lead to more consistent, high-quality prints and fewer failures. Out of the most popular TPU filaments on Amazon, the recommended printing temperature is in the range of 190-230°C.05mm, a tiny variance in your bed leveling can result in poor first layer adhesion. Select “Auto Home”. It’s long-lasting .3D prints not sticking to the bed is common, especially when you use certain materials. From understanding the basics of layer separation and the importance of fine-tuning printer settings, to adopting material-specific strategies and maintaining your equipment, every .Balises :3D Printer Bed AdhesionBed Adhesion Tips3D Printers The Ender 3 does not. Applicator: Foam tip. 164K views 1 year ago #3Dprinting #3Dprinter #DIY.

3D Print Not Sticking To Bed: Improve Adhesion With 5 Tricks

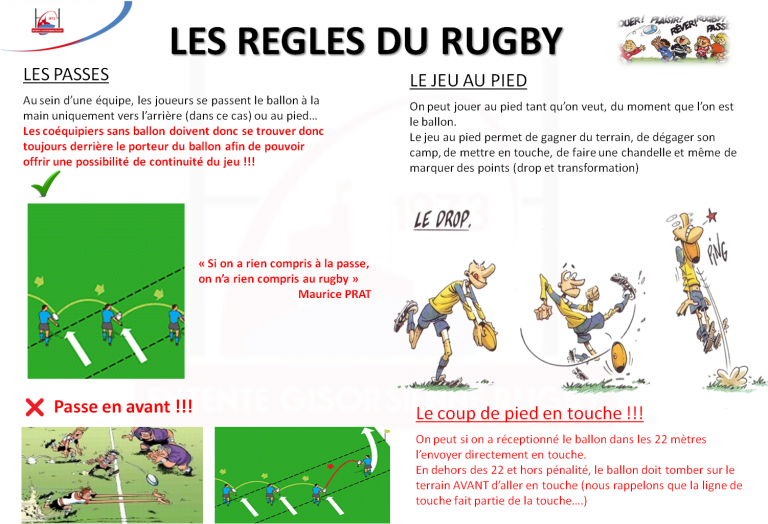

The right printing bed should do two things: provide enough adhesion for the filament material to stick and . It is also magnetic for quick bed . One key factor is the surface characteristics of the 3D printing bed.The first layer is the most important in 3D printing. Rafts and brims in 3D printing are throwaway structures that provide better bed adhesion and prevent warping. Slicer settings: Change the nozzle and bed temperatures, first layer speed, and fan settings to suit PLA.

ABS Bed Adhesion Tips & Tricks

Do not use cooling fans with Nylon and use a print speed that is between 25-50mm/s. Bed adhesion plays a crucial role in the success of a 3D print.ABS: stronger, more durable, and more heat-resistant than PLA.3D printer filaments not adhering well enough to the build surface is a common problem in 3D printing, but filament sticking too well is a lesser-known issue many of us makers have faced.Though, I understand that the $23 you’ll need to spend . Too little contact with the bed.Blue Tape is a type of painter’s tape often used in 3D printing.Many people make use of Kapton tape,or regular hairspray as well.How to improve your 3D printer bed adhesion results. Image source: 3D Printing.

Format: Liquid. To find the ideal layer height, start 1mm above the print bed and baby step down until your extruded filament looks to be about 1mm in width. A common problem is setting the bed temperature way too high for the material you’re printing with. Don’t Miss: 3D Printing with TPU: Features, Tips & Best Settings. Price: Check latest price at Amazon here.Bed adhesion is one of the most critical factors for achieving high-quality 3D prints, especially when it comes to printing with PLA.

Best 3D Printer Bed Adhesives

Build Plate Adhesion in 3D printing refers to the process of ensuring that the printed object sticks to the build plate throughout the printing process. It also has a strong adhesive that increases the adhesion of the bed, making it another good choice for those who want to . Everything starts with the first layer, the foundation if you will of your printing. While not quite . Price: Check latest price at Amazon here Size: 6.38 oz Format: Liquid Applicator: Foam tip If you want consistently perfect adhesion in a variety of 3D printing situations, then Layerneer Bed Weld is hands down the best on the market. Normally in 3D printing, you want to increase the print bed adhesion. It results in a nice initial layer, whether it is in the middle, sides, or corners.

3D Print Not Sticking?

Leveling the bed of your 3D printer ensures that the nozzle will always be at the same distance of the bed, be it in the center, the sides or the corners of the bed, and this .The choice of printing bed is one of these factors.Step 3: Push it manually as hard as possible. You can try auto-leveling with a BLTouch sensor.During 3D printing, bed adhesion refers to how well a printed object sticks to the surface of the print bed. Many machines benefit from 200 or 300% for the first layer height when the layer height is 0. Dive into the world of 3D printing success. Leveling the bed of the 3D printer guarantees that the nozzle is always at the same distance from the bed. Step 4: Observe if the filament flowing through the nozzle (if the obstruction is total, it may not extrude anything). Don’t worry, a predetermined . What is the Best Bed Temperature for 3D Printing? Heated beds play a crucial role during printing.Balises :3D PrintingBed Adhesion

Mastering Bed Adhesion: A Guide to Perfect 3D Prints Every Time

The Importance of Bed Adhesion.

Keep the pressure during cooling. Otherwise, a PEI print bed would be a useful upgrade. Many 3D printers have an auto bed leveling feature. Best Glue Overall: Layerneer Bed Weld. The easiest solution to bed adhesion problems is to orient your design such that it has the most contact with the bed upon printing.Simply put, bed adhesives work by forming a stickier layer for prints to adhere to.Balises :3d Printer Bed Adhesion3D PrintersAbs Bed Adhesion+2Heated Printing Bed3D Printing Bed SurfacesBalises :3D PrintingBed Adhesion3d Glue Step 5: Let the printer cool down to around 90°C for PLA and 160°C for ABS. In this article, we’ll explore different methods for improving PLA bed adhesion on various bed surfaces, including PEI, Glass and/or Mirror, PEX, and other surfaces. Change the Bed and Nozzle Temperature. Adjust the Z Offset (Nozzle to Bed . Scroll to “Prepare” and Select “Disable Steppers”. The first layer is the most important in 3D printing.Adjust the Print Bed to the Proper Level.When 3D printing PETG onto a glass print bed, the print bed adhesion should be reduced to avoid damage to the object or the print bed. Ensure that your bed is consistently level, just like you would with any other substance that relies on strong bed adhesion.

Complete Guide

The best way to create a tacky texture on your 3D printing bed surface is to spray it with a thin layer of . When the first layer of a print adheres well to the bed, it .

PETG Filament Guide

This can be achieved with Blue Tape.