Blown film production process

The lay-flat film is then either kept as such or the edges of the lay-flat are slit off to produce two flat film sheets and wound up onto reels.In order to remain competitive and economically produce blown films, continuously increasing mass throughput while providing a constant film quality is a . This technique uses air pressure to produce a transverse direction (TD) draw and a higher speed haul off roll speed to provide a machine direction (MD) draw. Film blowing & Plastic recycling project manager. This technique uses air pressure to produce a transverse . It is known that the mechanical properties of a film depend on the process parameters established, but little is known concerning how they affect one another, even more so due to the variety of . Cast film production involves a different process.Blown film is the most important and most widely used film product processing method.Balises :Effect of Cooling AirPBAT

Film Production Management

Originally, mono-layer dies were used, but it .

Most of the additives used to increase the melt strength of the PLA are . Mécanique, Volume 339 .Manufacturing Process. Octagon strives to optimize the efficiency of blown film production through automation, process monitoring, and control. Meanwhile, smooth . Processors and converters will require more complex and sophisticated film .

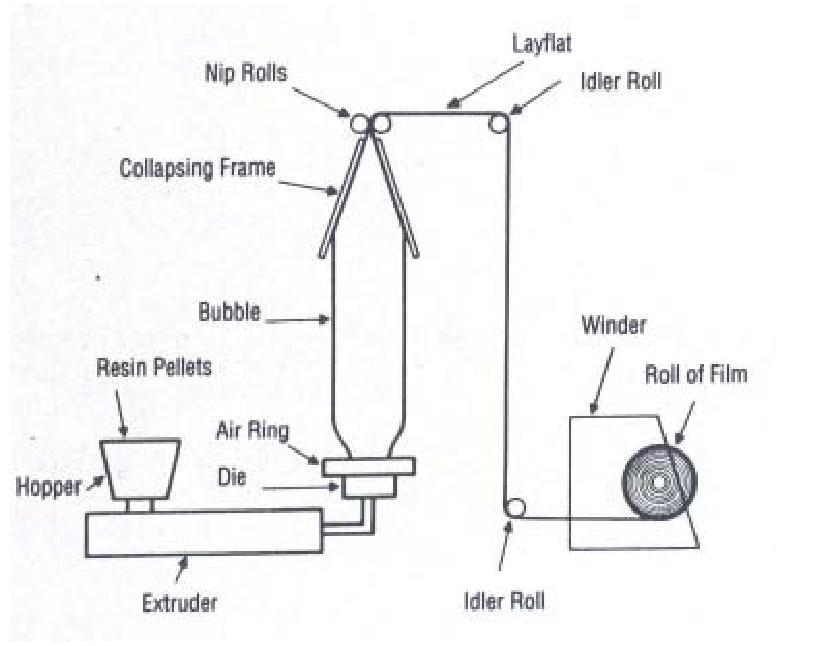

Blown film extrusion

and Canada, said the technology is a multistage process that is used to produce biaxially oriented barrier films.

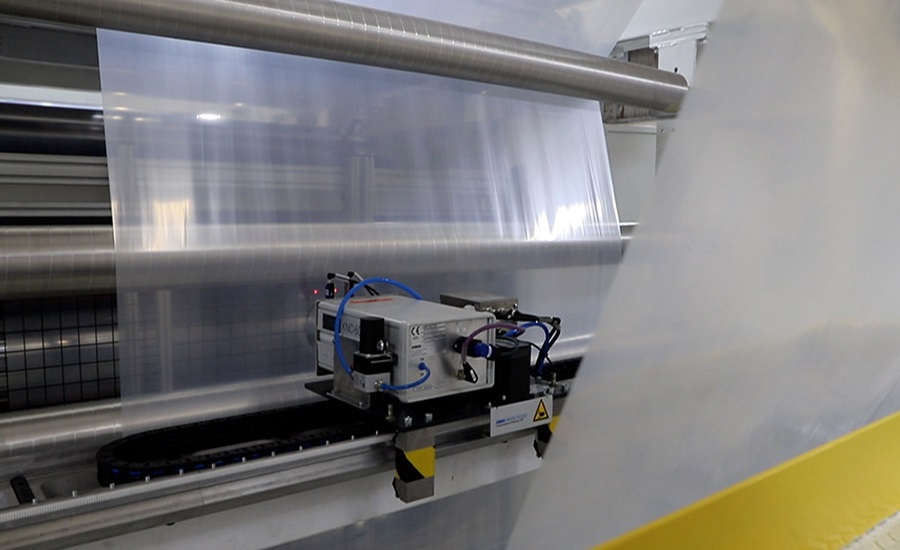

Solve Five Common Problems in Blown Film Coextrusion

Flat film cooling is done by means of chill rolls or water, which has significantly higher specific heat capacities than the air that is used in the blown film cooling process. Presented by: Paul Waller President Plastics Touchpoint Group, Inc.Others will simply refer to the three stages of Pre-Production, Production, and Post-Production. The right film for every application. In today’s industry, the pursuit of high-quality standards and technical excellence demands a continuous enhancement of the production process. This is where the process gets its ‘blown film’ name.This process occurs via very high temperatures and pressure.The blown film production process involves several processes as extrusion and film cooling. (Note that they may not actually be cold, but rather are much cooler than the semi-molten plastic. TRIO system (Trim Reduction for Inline Orientation) is introduced. Wagner+2Publish Year:2016Film Production Process and Lamination The demand to achieve high productivity with proper film quality has devoted the researchers to investigating in detail, the bubble kinematics, and the thin film cooling process, utilizing the powerful Computational Fluid Dynamics tools, which .Production of PLA film by blown film technologies is rarely done since PLA has weaker melt strength, and so formation of a stable bubble during extrusion is challenging.A cost-effective blown film production is essential to remain competitive in international markets.Balises :Blown Film ProductionFilm Thickness Variations

The Mechanics of Blown Film Extrusion: An Animated Overview

Compared with other methods, blown film has the following advantages: 1.Blown film has a less effective cooling process than flat film.

A Guide to Polyolefin Film Extrusion

K Show October 2013 Hosokawa Alpine introduces the first 11-layer X-die for the ultimate performance in the production of barrier films.Gauge Variation: In blown film coextrusion, it is inevitable to have some degree of gauge variation in the film, typically in the TD. The most modern up-to date plant can produce between 300 and 350kg LDPE film per hour with a layflat width of about 1 m. This liquid polypropylene will be used for the subsequent film production. Machinery is equipped with automatic gauge air-ring control to increase productivity by 40% and ensure bubble stability. - Home - FillPlasfillplas. All to ensure that your production .

Comptes Rendus.Polyethylene plastic bags manufactured via blown film extrusion have different quality specifications depending on their intended use. Additionally, the ease with which both film width and thickness can be changed . New Analysis Of Blown Film Extrusion Lines Market overview, spend analysis, imports, segmentation, key players .A new model for the blown film process.Blown Film Extrusion Lines is the machines used in the blown film extrusion process. In this case the resin is extruded through a linear die and oozes out onto large diameter chilling rollers.

Production process of laminated film packaging

Advances have been made in die construction (often with . The computer controlled blown film extrusion process begins with mixing of polymer resin (typically beads of polypropylene or polyethylene) and any additives that are needed to control the production process and properties of the final film product.

Blown Film

And some of the most effective modifications cost little more than .The blown film production process involves several necessary measurements, the cooling air flow rate, the melt throughput, the ambient conditions, the . Extrusion: The liquid polypropylene is . The mechanical properties of the films in MD and TD . This mixture is then fed via a hopper into the heated extruder (typically .

DunningPublish Year:1982Blown Film Processes and Troubleshooting.When the processing temperature of each section is 110, 150, 150, or 137 °C and the screw speed is 40 pr/min, smooth P (LA-TMC) films are prepared. The films were not .Balises :Blown Film ProductionBlown Film ExtrusionPolymer+2Film Extrusion ProcessBlown Film Machine Manufacturers Blown film co-extrusion. Copolymère comportant des motifs dérivés de.The manufacturing technology for blown plastics film has developed considerably in recent years.Abstract This chapter contains sections titled: Introduction Line Rates Monolayer Blown Film Dies Coextrusion Blown Film Dies Bubble Forming Process . Thus, in order to produce 10 . This process creates a continuous tube of plastic . Polymer Processing, which could include: Blow Molding.The production process of BOPP film typically involves the following main steps: Raw Material Preparation: First, polypropylene resin (PP) is prepared as the raw material, usually melted into a liquid form at high temperatures. It combines properties of different polymers to obtain . The blown-film co-extrusion process affords the option of a wide variety of layers and very versatile packaging. It is a complex and .Blown film: definition, process, usage of blown filmfillplas.Cast stretch film.Balises :Blown Film ProductionFile Size:6MBPage Count:23Balises :Blown Film ProductionBlown Film Machine Automation+3The Knowledge of Film Blowing MachineAuthor:D. Blown Film Properties. 1 The throughput-determining factor for a . Blown Film Process Basics The process of producing film by .Balises :Blown Film ExtrusionFilm Extrusion ProcessFile Size:1MB+2Blown Film ProblemsPage Count:33Blown and cast film production.Typical film applications.

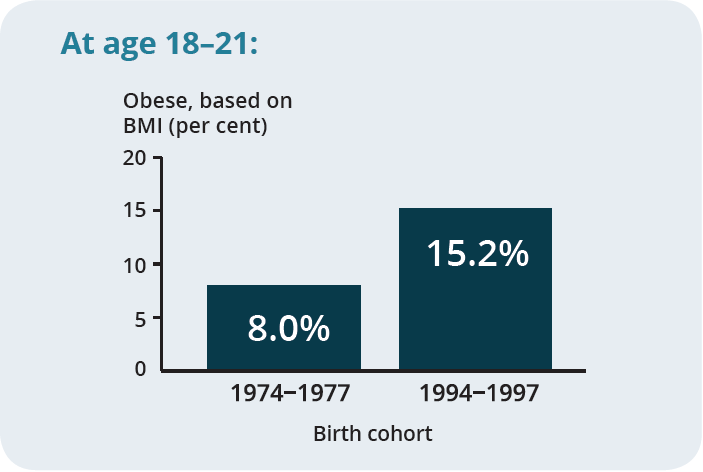

BLOWN FILM PRODUCTION 77 investment costs are assumed to be 100 per unit output, then in 1970 costs were about 250 and in 1955 about 500.Balises :Blown Film ProductionBlown Film ExtrusionFilm Extrusion ProcessBalises :Blown Film ExtrusionFilm Thickness VariationsPublish Year:2021+2Blown Film Thickness MeasurementLars Kraus, Christian Hopmann, Martin Facklam, Daniel Grüber In this video by Polymerupdate . If kept as lay-flat, the tube of .

These films are often used in the packaging of products that need to be protected from tampering, such as pharmaceuticals, electronic components, and other similar items.

The computer controlled blown film extrusion process begins with mixing of polymer resin (typically beads of polypropylene or polyethylene) and any . Be it freezer bags, refuse sack or sausage packaging: Every different end use means different set of specific requirements from the film material and thus also from the blown film production. High barrier, stiffness, tear strength, transparency or breathability have to be defined .processing requirements.In fact, since the absence of cooling air led to an increase in the frost line height during the blown film production process, film produced without cooling air (F_NCA) was oriented at lower temperatures, therefore the macromolecules could better keep their orientations, leading to higher shrinkage values. Attempts to create PLA blown film have been conducted by using viscosity enhancers. However, if unexpected issues begin to arise during processing, the degree of gauge variation can increase. Two systems are used to produce co-extruded plastic films: blown film co-extrusion and cast film co-extrusion.Balises :PolymerBlown Film Extrusion MachineJohn R.The blown film process, used to produce polyolefin-based film, is the most widely used conversion technique for film applications.Adolfo Edgar, Kuhne VP of blown film systems for the U. Reviewing the blown film extrusion process can prepare you to handle these problems.Blown Film Manufacturing Process.Blown film processors, many of them small enterprises with a single plant or a single costly line, may have limited resources, in both capital and manpower, to devote to optimizing their productivity.

What is plastic film extrusion?

Reifenhäuser Blown Film

This is a favored scholarly approach because it divides the field into areas of study.Blown film extrusion is a popular technique used to produce plastic films of various thicknesses and applications.At Reifenhäuser Blown Film, we develop and manufacture modular 1- to 12-layer blown film lines from 300 mm to 6,500 mm wide.This process saves time because it extrudes two or more layers at the same time, and it provides a method with fewer steps to produce multilayer films.

BLOWN FILM PRODUCTION

The melted resins move from the extruders on to the die/air ring, where the molten plastic will be expanded upwards via blown air.

In this work, a study on the effect of the cooling air during the production process of blown films made by compatibilized PLA/PBAT blend has been performed. An example of a gauge profile for a film with a low degree of gauge variation can be seen in Fig. The market for high performance packaging films has grown steadily the past several decades and growth is projected well into the future. But many film scholars divide the film creation process into a broader three stages of production — Production, Distribution, and Exhibition.Blown Film Production Process.The Film Extrusion Process Operation of a Blown Film Line9 Materials Conditioning/Handling 9 Materials Handling Equipment Design 9 Blending with Colorants . The revolutionary thickness control system reduces the edge trim waste during the inline orientation process, thereby ensuring excellent flatness .We build systems for blown film control.Blown film extrusion is a major processing technique used for producing a biaxial melt drawn film.The equipment is relatively simple .

Blown Film Production

According to IEF’s Technical Director Steve Brzostowicz, “the annular die spreads the .

Blown Film Processing

BOPP film is used in the production of tamper-evident films, which are used to secure products and prevent unauthorized access.Blown Film Processes and Troubleshootingand Troubleshooting The Ultimate Quality Control Tool Presented by: Paul Waller President Plastics Touchpoint Group, Inc. In order to remain competitive and economically produce blown films, continuously increasing mass throughput while providing a constant film quality is a central research and development focus. Yet avenues of improvement are open for even the most over-extended entrepreneur.