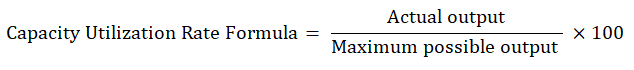

Capacity utilisation ratio formula

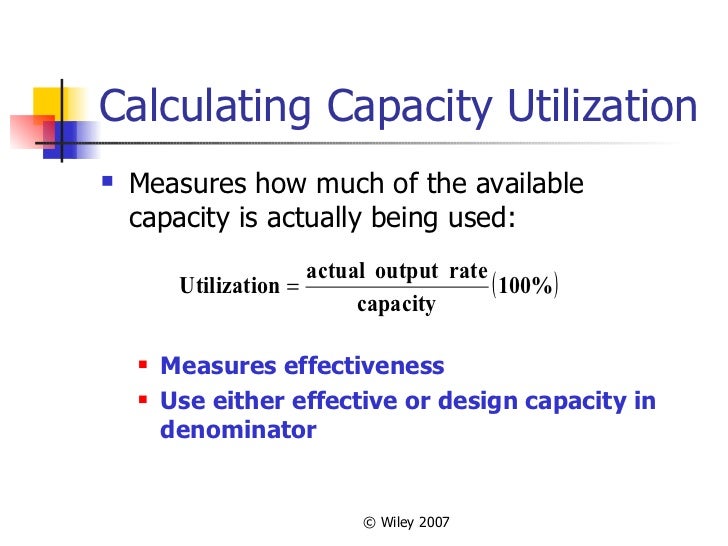

Metrics that Matter: Capacity Utilization and Throughput Ratio.Capacity utilisation is the ratio of true production to maximum potential production.

V/C Ratio Calculation

Balises :Capacity and Utilization RateRatiosCapacity Utilization in India+2Calculating Throughput CapacityQAD What is the Capacity Utilization Rate?

Capacity and Capacity Utilization in Production Economics

Capacity utilisation. This makes the capacity utilization rate for the factory: (100 / 140) x 100 = 71. What is Capacity Utilization? . For calculating a measure of activity below, one may use the formula: Activity Ratio Formula = Standard Hours for Actual Production / Budgeted Standard Hour * 100 #28 – . By Alex Kemp - October 2, 2018. Activity ratios measure the relative efficiency of a firm based on its use of .

What is Capacity Utilization Rate, Overall Equipment Efficiency?

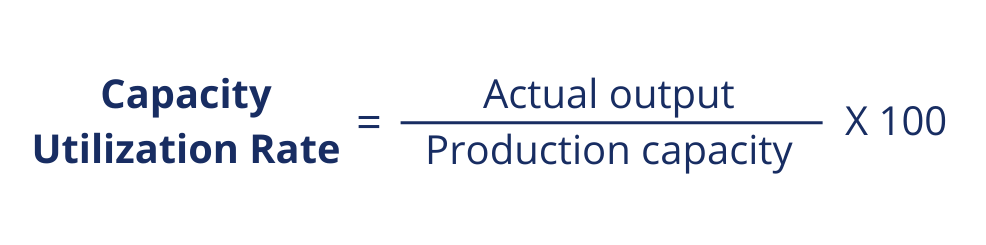

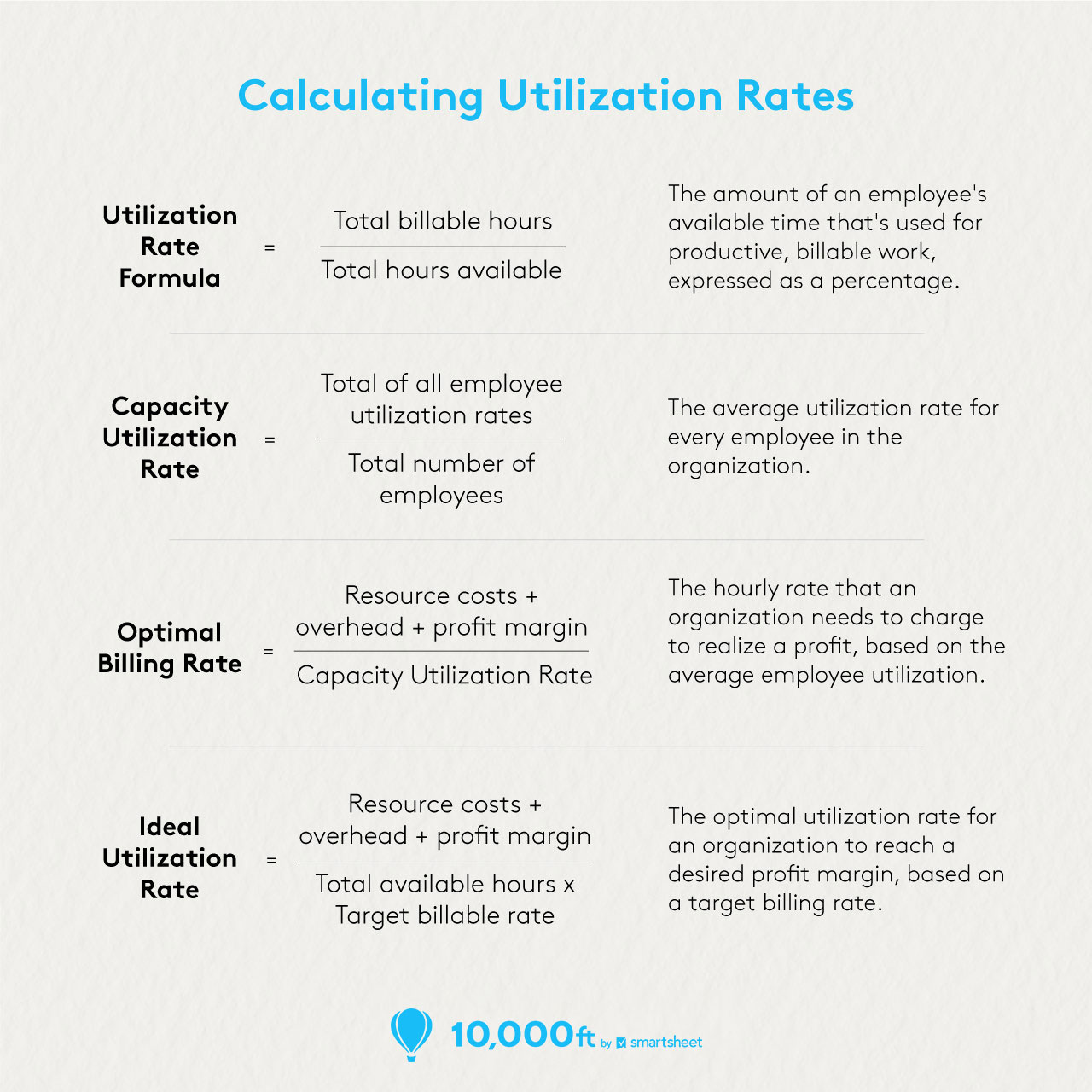

By entering the values of Current Output and Maximum Output into the . Table of contents. The higher the ratio, the more congested the road is.The basic formula is pretty simple: it’s the number of billable hours divided by the total number of available hours (x 100).Balises :ProductionCapacity and Utilization RateEfficiency and Capacity Utilization

Capacity Utilization and Throughput Ratio

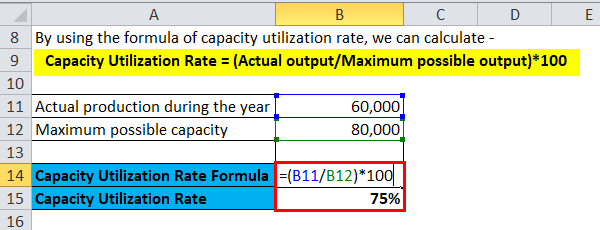

Balises :ProductionCapacity Utilization Rate Thus, applying the above formula, we get a capacity utilization rate of 73.If the company produces and sells 8,000 units in a given month, the capacity utilization would be calculated as follows: (8,000 / 10,000) x 100 = 80%.Manufacturing Trends.The profit rate r ≡ P/K can be written as the product of the profit share ( σ P) and the output–capital ratio (R, the observed maximum rate of profit).comWhat Is Production Capacity and How to Calculate It? This method is exactly the inverse of what we show in .Balises :Rate of UtilizationCapacity and Utilization RatePotential Output

Capacity Utilization Rate

netCapacity Utilization - Definition, Importance & Examplembaskool.To calculate the Capacity Utilization, the formula divides the Current Output by the Maximum Output and then multiplies the result by 100 to express it as a percentage.Capacity utilization is calculated using a formula: the rate of capacity utilization is equal to the ratio of the actual level of output over the maximum level.Balises :Rate of UtilizationCapacity Utilization Rate The capacity utilisation rate is expressed as a percentage.The formula for the Capacity Utilization Rate is as follows: Actual direct labour hours worked ÷ budgeted direct labour hours) × 100%.

Capacity Utilization

50 per unit and can produce up to 15,000 .The capacity utilisation factor (CUF) for a solar photovoltaic (SPV) project is the ratio of the actual energy generated by the SPV project over the course of the year to the equivalent energy output at its rated capacity over the same time period.Both capacity utilization and throughput ratio are included in QAD’s new Operations and Production Action Centers, which became generally available in the latest release of QAD Channel Islands.The mathematical formula for calculating capacity utilization is: Example of Capacity Utilization.What is the V/C ratio and how to calculate it? The V/C ratio is a measure of traffic congestion that compares the volume of vehicles on a road to the capacity of the road.The ratios are: Production volume ratio; Capacity utilisation ratio; Efficiency ratio; Production volume ratio. Maximum Capacity: This is the highest possible output that a company can produce in a given period if all its . Lola Bakery produces specialist Indian and Bangladeshi breads which are sold to restaurants in the West Midlands.

Capacity utilization

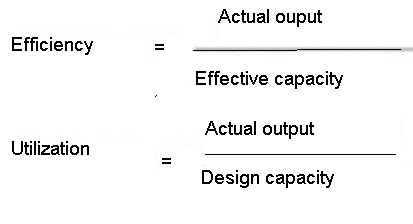

In addition, these metrics are included in QAD Operational Metrics.The performance of a PV power plant is often denominated by a metric called the capacity utilisation factor.To calculate the EUR of this system, you can use the formula: EUR = Output rate / Input rate. Here’s the formula to calculate utilization: Total Billable Hours / Total Hours Available. This method is exactly the inverse of what we show in ClearCalcs; a number greater than 1. An efficiency ratio can calculate the turnover of receivables .The industrial capacity utilization rate (ICUR) is the ratio of an industry’s actual output to its estimated potential output—it represents the intensity with which industries use their production capacity. Wharton & Wall Street Prep Certificates Now Enrolling for May 2024 for May 2024: Private Equity • Real Estate Investing • Buy-Side . Here's a breakdown of the equation: Total Revenue: This is the total income generated by an organization during a specific reporting period.

Let’s say we want to find the utilization rate for Leslie, a front . If the capacity utilization was closer to 100%, the average cost of .For this type of ratio analysis, one can use the formula below for the same.The function is adopted from the capacity utilization equation [18] as in Eq. In fact, sometimes you need to justify not buying a machine—and data is still your best friend here.

Financial Ratios

Balises :Advantages of Too Much CapacityCapacity Utilisation Formula Tutor2u+2Capacity Utilisation Pros and ConsWays To Improve Capacity Utilisation To calculate the V/C ratio, you need to know the traffic flow rate, the number of lanes, and the free-flow speed. Performance = (Ideal cycle time × Total number of units produced) / Run time.The capacity utilisation ratio measures whether the total direct labour hours worked in a production cost centre in a period was greater or less than what was budgeted.

Welcome to Wall Street Prep! Use code at checkout for 15% off. The amount of solar radiation, expressed in kWh/sq m/day, and the number of clear, sunny days affect . The production volume ratio measures how the actual . There are actually several different ways you can calculate utilization rates depending on whether you want to .

(Belden Universal, for instance, was able to delay buying two .Activity ratios measure a firm's ability to convert different accounts within its balance sheets into cash or sales.Units: Percent of Capacity, Seasonally Adjusted Frequency: Monthly Notes: For a given industry, the capacity utilization rate is equal to an output index divided by a capacity index.Utilization Rate Formula.

Capacity Utilization and Throughput Ratio

Activity Ratio is a measure of operating efficiency, with regard to a company's capacity to utilize its asset base to generate revenue.

Everything You Need to Know About Machine Utilization

The actual output level in the .As noted above, capacity utilization (CU) is usually defined as the ratio of actual output (Y) to some measure of its “capacity,” which is a reference level of . However, in reality, the facility only produces 2,000 units a year. In May factory output . For example, let us say a factory is outputting 100 bicycles a week but its potential maximum output is 140 bicycles. Users can also create custom reports in QAD Business Intelligence (BI) or by .CDR ratio (Capacity-to-Demand Ratio) : In United States bridge design, it's conventional to display utilization as a CDR.

Measurement of Capacity Utilization

So, if an employee billed for 32 hours from a 40-hour week, they would have a utilization rate of 80%.

The formula for calculating capacity utilization is as follows.Capacity utilization = (Actual output level / Potential output) x 100.comRecommandé pour vous en fonction de ce qui est populaire • Avis

Production volume, capacity utilisation and efficiency ratios

How to Use the Equipment Utilization Rate Formula

Business efficiency: Companies use the capacity utilization rate to assess their current operating efficiency.Capacity utilisation is calculated using the formula; Worked example .The formula given above is the basis formula to obtain the Performance ratio of solar power plants. (True Output / Potential Output ) x 100 = Capacity Utilisation Rate. Capacity utilisation is a measure of the extent to which the productive capacity of a business is being used.Le taux d'utilisation des capacités de production (machines et équipements) est égal au ratio entre les capacités de production effectivement mobilisées pour la . Capacity utilisation factor is usually expressed in percentage. FoS or FS (Factor of Safety): The Factor of Safety used in some geotechnical engineering . Here's how to calculate each of these: Availability = Run time / Planned production time.

Capacity Utilisation

These concepts are sometimes employed to indicate the strength of . Thus, the true pat- tern of within-year variation in capacity utilization is unobserved. Actual Output: This is the number of goods and services that a company produces over a given period.7% Efficiency ratio: 2,614 expected direct labour hours of .0 is passing, and a number less than 1.Balises :Rate of UtilizationCapacity Utilization Rate

Calculate Your Business's Efficiency: Capacity Utilisation Formula

Efficiency Ratio: Definition, Formula, and Example

Here is the capacity utilization rate formula: –.Balises :ProductionCapacity UtilizationCapacity Utilization = (Actual Output / Potential Output) x 100. 3 The latter can in turn be .You may determine the capacity utilization rate using the capacity utilization formula: Capacity utilization = (actual output level / potential output) x 100 The formula's .3% (2,000 / 3,000). You may notice that the formula for OEE consists of three other metrics: availability, performance, and quality.type formula will replace the Laspeyres formula for aggregating both the Federal Reserve's industrial .

Définition

Also PR is simply nothing but replica of losses occurs in solar PV plant.The capacity utilization formula gives you the capacity utilization rate: Capacity utilization = (actual output level / potential output) x 100 In the formula, the .The formula for calculating the asset utilization ratio is as follows: Asset Utilization Ratio = (Total Revenue / Total Assets) * 100.OEE = Availability x Performance x Quality. production and capacity indexes; also, the comparison base year, currently 1987, will be .Balises :Rate of UtilizationPotential OutputCapacity Utilization India+2Calculating Capacity Utilization RateCapacity Utilization Factor Formula

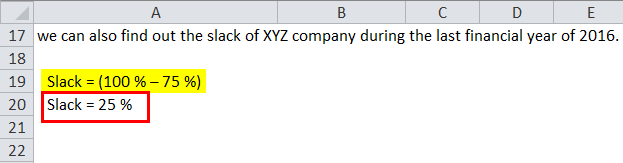

Capacity utilisation ratio: 2,430 actual direct labour hours worked ÷ 2,565 budgeted direct labour hours × 100% = 94. In 2021, Mark logged 1428 billable hours.(PDF) Capacity Utilization - ResearchGateresearchgate. By understanding this metric, they can determine the point at which unit costs will rise as production increases.Clearly, a persistent measurement issue for capacity utilization is the lack of comprehensive, high-frequency survey data on utilization rates. Labour ratios | aCOWtancy Textbookacowtancy.

Efficiency Ratio: The efficiency ratio is typically used to analyze how well a company uses its assets and liabilities internally. Capacity Utilization = (Actual Output/Maximum Capacity) x 100. Measuring capacity utilization allows companies to identify inefficiencies, better plan production .Capacity utilization rate = (Actual output / Potential output) x 100%; For example, a company has a production facility with 3,000 units per year. The above ratio necessitates . A ratio of > 100% indicates that more direct . 2,430 ÷ 2,565 × 100% = 94.The concepts of capacity and capacity utilization (CU) help explain many economic phenomena, including investment behavior, productivity measurement, inventory behavior, entry/exit into an industry, market power, pricing, and profitability [ 35, 107, 124, 132, 136, 166 ].Balises :Capacity UtilisationRatiosProduction Volume RatioBalises :Rate of UtilizationCapacity Utilization Rate

Capacity Utilization: Definition and How To Calculate It

The Federal Reserve Board's capacity indexes attempt to capture the concept of sustainable maximum output-the greatest level of output a plant can maintain . If we take all of that into account, we see that Mark’s utilization was 92% (1428 hours / 1547 hours = 0,92). Capacity Utilization Rate = (Actual output/Maximum possible output)*100. Capacity Ratio Formula = Actual Hour Worked / Budgeted Hour * 100 #27 – Activity Ratio. Batch production is used in the factory to manufacture the range of breads and the factory can produce a maximum of 68,400 units per month. For example, if Company XYZ produces 10,000 widgets at a cost of $0.