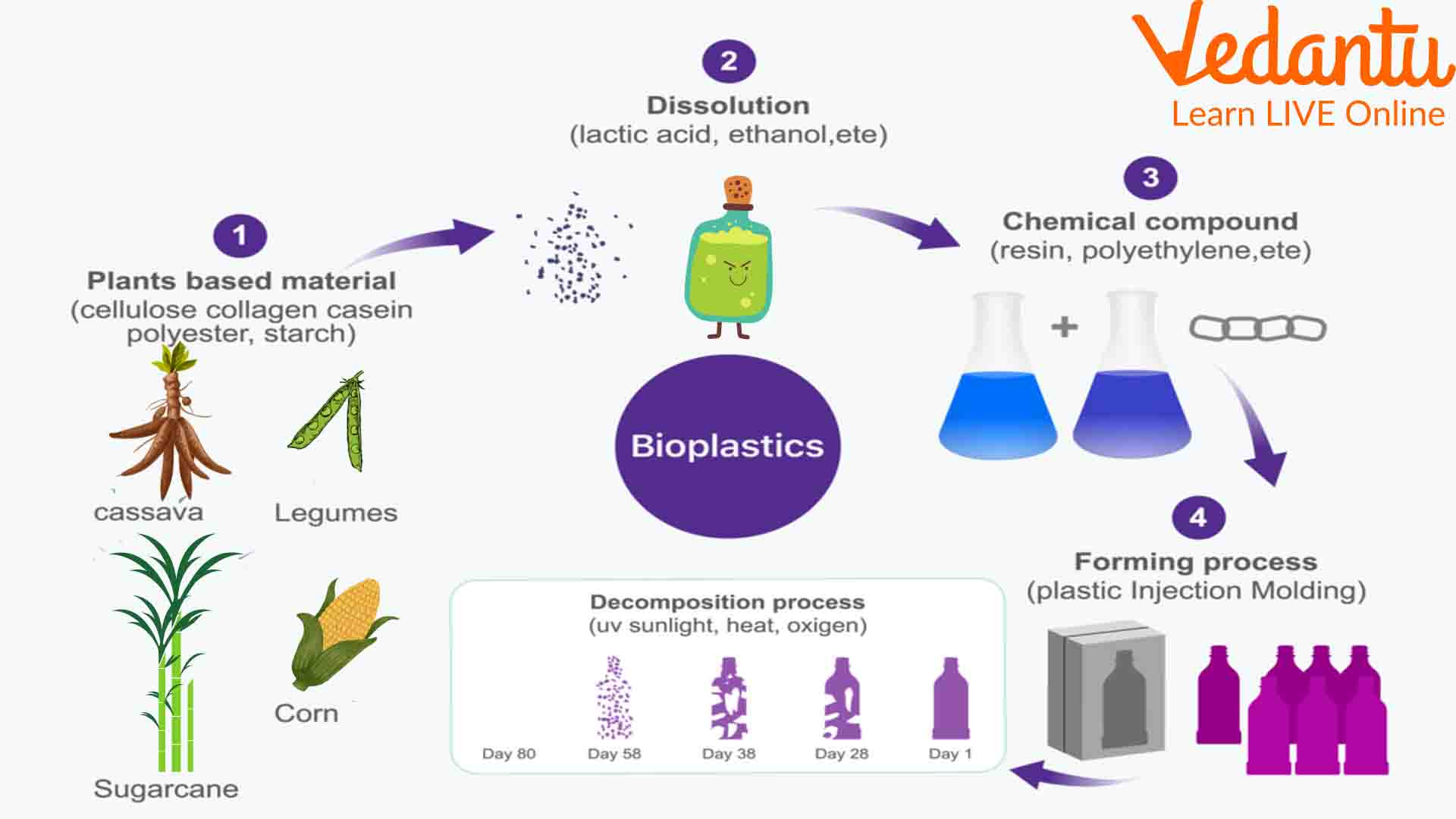

Cellulose based biodegradable plastic

Environmental impacts of the pectocellulosic . Water hyacinth (WH) being abundant in cellulose, can be exploited for this . Research has revealed that cellulose-based films possess high tensile strength .Biodegradable plastic from starch has been around for a long time.Newswise — Strength and biodegradability—these are the benefits of using cellulose to make plastics and other packaging materials. It is used for single-use cling wraps and carrier bags (Kumar .Auteur : Jan-Georg RosenboomHere, we developed a naturally degradable packaging material with high food-keeping performance based on amphiphilic porous bacterial cellulose (BC) film . Ganachari, Manzoore Elahi M.Compared with fossil-based plastics, bio-based plastics can have a lower carbon footprint and exhibit advantageous materials properties; moreover, they can be .However, the types of plastic used in food packaging, such as polyethylene (PE), polypropylene (PP), and polycarbonate (PC), are petroleum-based plastic that is not renewable, not biodegradable . Materials Science. Since this plastic is . It has properties similar to low-density polyethylene (LDPE) and has good biodegradability.Bio-based plastics are made entirely or partially from biogenic raw materials (e.Biodegradable plastics. Published 1 September 1993. Water-resistant.The use of agriculture waste-derived carboxymethyl cellulose (CMC) mainly is to reduce the cost involved in the development of the film, at present commercially available CMS is costly.

Development of Cellulose-based Bioplastic from Corn Stalks

comRecommandé pour vous en fonction de ce qui est populaire • Avis

Bioplastics for a circular economy

Thermoplastic and biodegradable polymers of cellulosesciencedirect.

Subsequently, polyamide epichlorohydrin (PAE), a wet strength agent . Cellulose-based plastics are predominantly produced from wood, and extensive . A review of degradation mechanisms, and the possible approaches to diminish the environmental persistence of these materials, will clarify the current and potential degradation rates of these products after disposal. One of the recent trends of green technology is the development of biomaterials made from food processing waste as an alternative to plastic packaging. Polybutylene adipate terephthalate (PBAT) is the market leader in fossil-based biodegradable materials.Cellulose has been considered as the most emerging biodegradable polymer.

Banapurmath, Sharanabasava V.Cellulose biocomposites from nanocellulose or plant fibers, with polymer matrix, often do not sufficiently contribute to sustainable development, are not biodegradable and the processing approach .

The cellulose-based sheet was tested of its density, tensile strength, and percent elongation, and was analyzed with an fourier-transform infrared spectroscopy (FT-IR) to .Cellulose-based plastics are predominantly produced from wood, and extensive chemical modification is needed to induce thermoplastic behavior. Journal of Macromolecular Science, Part A. Choose Options. Bio-based plastics have benefits, but only when taking a host of factors into consideration, says environmental .can be a promising precursor in production of biodegradable plastic.In conclusion, cellulose-based biodegradable mulches have the potential to revolutionize agriculture by offering a sustainable and effective solution to replace plastic mulches.

6 million grant from the National Science Foundation, the center’s collaborators plan to develop a new class of biologically synthesized, protein .

Current and emerging biodegradable mulch films based on

As polymer is non-biodegradable by nature, it remains in the environment, leading to severe environmental as well as health hazards. Polymers obtained from some polysaccharides, such as chitosan, could be an excellent . Yaradoddi, Nagaraj R. They do not use PLA in their teabags.Cellulose-based plastics are an important class of carbohydrate-based materials.Robust, high-barrier, and fully recyclable cellulose-based plastic replacement enabled by a dynamic imine polymer †. Most plastics and other . Bio-based plastics and how innovation in this area supports the circular bioeconomy.

Breaking down Japan’s approach to bioplastics

The current materials predominately come from fossil feedstocks and minerals.Cellulose based bioplastics-Cellulose is abundantly present in all plants and therefore, its extraction is easy and inexpensive.Using cellulose to create biodegradable products that can replace petroleum-based plastics will reduce the impact these packaging materials have on the environment. Herein, a novel type of cellulose-based sustainable m The cellulose can be . The pressures from climate change and plastic pollution challenge us to develop a bioeconomy, replacing petroleum-based products with bio-based and biodegradable products. Bioplastic research continues to this day to ensure that humanity will continue to .The escalating environmental challenges posed by petroleum-derived plastics have underscored the urgent need for sustainable and biodegradable .Highly reinforced and degradable lignocellulose biocomposites by polymerization of new polyester oligomers. Yet, the adoption rate (market-wise) has been very slow, probably because many manufacturers have not adopted new manufacturing schemes that will allow them to sequester the biomass as the plants are growing.Auteur : Jayachandra S.Some bioplastics are obtained by processing directly from natural biopolymers including polysaccharides (e.

Degradation of Cellulose Acetate-Based Materials: A Review

In 2019, while Japan was hosting the G20 summit of wealthy nations, the island nation presided over an agreement to eradicate . from corn and sugar cane).comAn insight overview of bioplastics produced from cellulose . Certified compostable and meet FDA requirements for direct candy and food contact. However, plastic foams pose a particularly complex problem to environment because they almost cannot be recycled and degraded in most areas.Cellulose is a natural polymer that has a lot of potentials. First, the pulp was refined to increase surface fibrillation to improve fiber network contact points. PBAT has high flexibility and toughness. Sustainability.

The environmental cost of plastic wrapping and packaging materials has been intensively investigated, such as non-renewable source, difficulty to degrade and . Cellulose emerges as a versatile biopolymer to make hydrogels for . Bioplastics produced from cellulose are mainly based on cellulose ester .LCA results reveal that the lignocellulosic bioplastic demonstrates much lower environmental impacts than petrochemical-based plastics such as PVF and ABS, .Biodegradable Plastics Based on Cellulose Acetate.

Bioplastic

Biodegradable bioplastics will also help tackle plastics pollution. Zhiping Su,ab Shaofeng Huang,b Yuyuan Wang,a Hao Ling,a . Foam materials feature lightweight, high strength, and good cushioning .Partially funded by a five-year, $3.4% of municipal solid . Another study reveals that the content of cellulose . WH contains almost 20% cellulose, 48% hemicellulose and 3.Biodegradation, Cellulose, Degradation, Materials.Since the 1940s, the introduction of plastic technology caused a true revolution in agriculture. Bio-based plastics, on the other hand, can be biodegradable, but often are not . They are useful to increase air and soil temperatures, protect plants from several agents, improve water management, reduce the growth of weeds, and, .Fossil-based biodegradable plastic.Auteur : Mouli Sarkar

Here, naturally degradable .Acetylated cellulose nanofibers enhanced bio-based polyesters derived from 10-undecanoic acid toward recyclable and degradable plastics - ScienceDirect. Biodegradable plastics, on the other hand, are plastics that decompose under certain conditions, leaving behind mainly carbon dioxide (CO 2) and water.Studies on an alternate, biodegradable, renewable, non-toxic, and sustainable source for packaging materials from renewable and biodegradable sources are being pursued worldwide to address plastic concerns, and cellulose stands out as a viable choice.In this paper, the dispersion encapsulation was investigated as new process to elaborate the principal active (PA) loaded biodegradable plastic coacervates, which designs a model of vector system and drug delivery matrix. Bioplastics support a rural, agrarian economy. New sources, new isolation processes, and new treatments are currently under development to satisfy the increasing . But most plant-derived bioplastics.

Recent Developments in Biodegradable Cellulose-Based Plastics

Their properties, applications, and economic viability make them an attractive option for farmers seeking environmentally friendly and high-performing alternatives.

This is one of the most abundant biopolymers found in plants, fungi, and the .The current scenario of plastic pollution indicates that approximately 400 thousand plastic bottles and about 700 thousand plastic bags are disposed of worldwide every minute .

Towards a cellulose-based society: opportunities and challenges

Compared to the preparation process of pectin or cellulose-based films, it not only avoids the tedious pectin or cellulose extraction and purification steps, but also yields bioplastics with high mechanical strength and water stability (which are not available in pectin or cellulose-based films).Self-pigmenting textiles grown from cellulose-producing bacteria with engineered tyrosinase expression.Cellulose acetate polymer is used to make a variety of consumer products including textiles, plastic films, and cigarette filters.Cellulose-based plastic is basically a type of plastic – also called cellulose acetate – produced either by cotton linters or wood pulp.Oil is concentrated in regions. Besides, this kind of cellulose-based films .Introduction Microparticles that are derived from cosmetic microbeads or the degradation of plastics have received marked global attention owing to their undeniable .

Compostable Cellophane Bags

Cellulose is one of the natural ingredients in biodegradable plastic production.Among them, cellulose is by far the most abundant biopolymer .The Lyons biodegradable teabags are now all plant-based and made of a blend of natural fibers, including abaca, cellulose fibers, and a small amount of plastic fibers. Erfan Oliaei, Peter Olsén, Tom Lindström & .Bio-based and biodegradable biopolymer such as cellulose, starch, alginate, chitin, polylactic acid (PLA), chitosan, and their derivatives, revealed to be promising candidates with regards to their abundant availability from numerous resources and their biodegradability [12]. Biodegradability.In this work, inspired by traditional paper-making techniques, a scalable method for preparing lightweight, biodegradable, and recyclable cellulose-based bio-foams was developed. Cellulose gained more interest owing to its renewability, non-toxicity, economic value, biodegradability, high mechanical properties, high surface area, and biocompatibility.