Centrifugal casting process steps

Once prepared .

Manquant :

stepsCentrifugal casting (industrial)

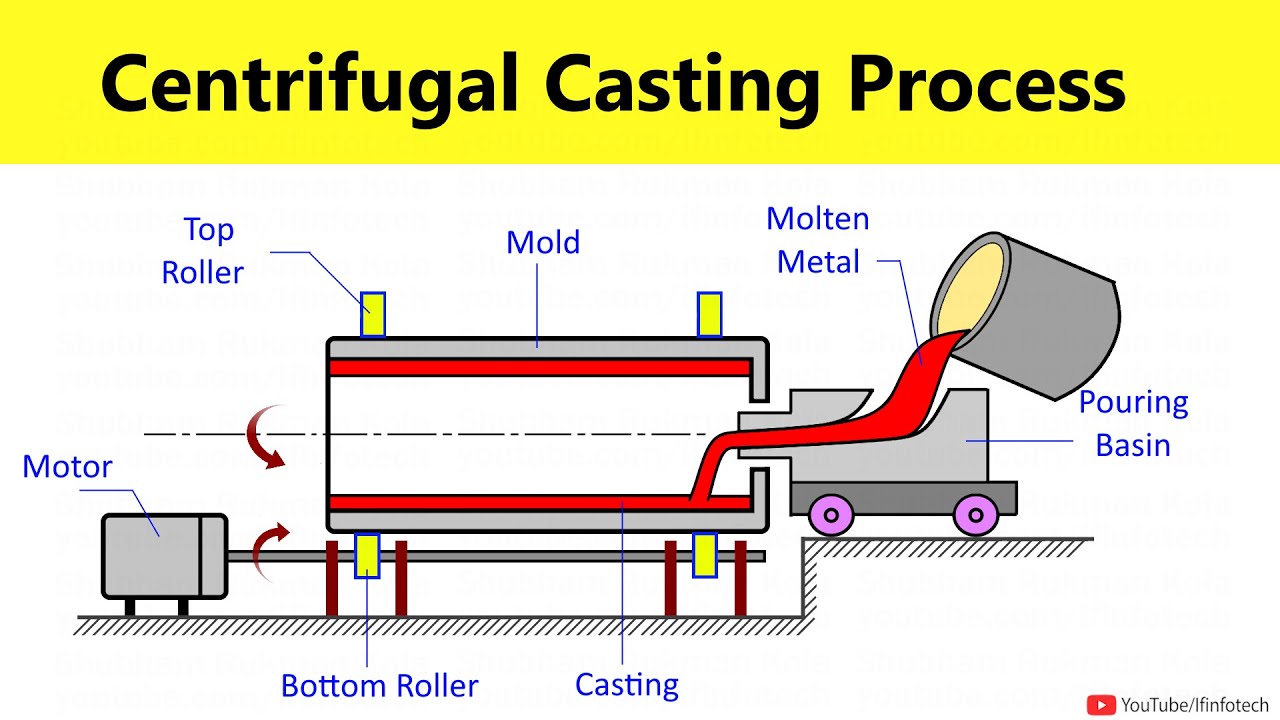

Molten metal is poured directly into a mould, which is rotated at high speed.Hello Everyone Welcome To AIM AMIEIn this Video We have Seen the The Process of Centrifugal Casting.

What Is Centrifugal Casting?

The casting process is the oldest and most popular method of manufacturing means of designing the desired shapes. In a centrifugal casting process, the molten fuel alloy is poured vertically onto a rotating plate (distributor), where the melt flow turns to the horizontal direction. Centrifugal casting process is a solidification method of preparing cast parts.1 Centrifugal casting.Centrifugal Casting Process Explained in 10 Steps.Centrifugal casting is a shaping technique intended for ceramic tubular structure manufacture, where the particle size and density are exploited to produce .

Centrifugal Casting: Definition, Importance, How It Works

Process for casting metal. Let's dive deeper into the world of this centuries-old production method. Here’s how it works: Rotational Molding The process begins with a cylindrical mold/die that rotates around its axis at high speeds (can be more than 1000 rpm!). Centrifugal casting is used where we require strength, reliability, and material soundness in the end product.(PDF) Centrifugal casting technique baseline knowledge, . The centrifugal force helps to distribute the molten metal evenly and eliminate any air pockets or voids that might be present, resulting in a uniform and dense casting. In this process, molten metal is poured into the mold cavity inside a vacuum chamber in order to eliminate bubbles and air pockets. These impurities are later machined away, leaving a defect free part. Unique to the centrifugal process is the high force that effectively isolates less dense substances in the casting’s bore area. The melt is injected into the molds by the centrifugal force. The die might be either on a vertical or flat pivot contingent upon the detailed specifications of . Centrifugal castings are the process of casting in which centrifugal force is used for the casting process. Molten metal is fed into a rotating mold where a centrifugal force of up to 100Gs is applied to the metal.Semi Centrifugal Casting Process: The step-by-step process of semi centrifugal casting process, Step:1.Die casting; Centrifugal casting; Basic Steps in Casting Process. Mold Preparation: The process starts with the mold preparation. Slide the crucible to the mold and put your pre-measured metal for that flask into the crucible.The objective of the CCC (Continuous Centrifugal Casting ) process, property of ALU MC3, is to produce, in a continuous manner, tubes directly from the molten metal, thus bypassing all steps described above. Centrifugal casting process was first patented by A. First, prepare a master mold to make that . Casting is made from any type of metal that can be melted and have any shape the designer desires.

Casting Process

While within a few years additional patents were issued in both Germany and America, the development of the art was slow and erratic for over one .The centrifugal casting process starts with liquid metal being filled with a high-temperature die that rotates.Firstly, based on nature of gradation, FGM may be continuous graded structure or step-wise graded structure [7]. It provides a cost-effective solution for complex shapes due to lower machining requirements and manufacturing costs when compared to forgings or fabrications. Centrifugal casting.

Centrifugal Casting Process Explained in 10 Steps

The mold can be held stationary or be rotated during the filling process. 𝑹 Where: F = force, N; m = mass, kg; V = velocity, m/s; and R = inside radius of the mold, m. Balancing Flasks.

What are Centrifugal casting, its types, and applications?

The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed . Centrifugal force projects the metal outwards from the rotational axis and onto the walls of the mould.netCentrifugal Casting - Types, Working, Advantages, .So what are the Investment casting process steps? .The first step of centrifugal casting involves pouring the liquid material — either molten metal or wet concrete — into the cavity of a spinning die. It is also called roto .Auteur : Engineering Study Materials The centrifugal casting of metals is a relatively recent development in the history of the foundry industry.Do Check-out our playlist Related To casting:Types of cas.

The casting process is not by gravity or applied pressure, but by centrifugal forces.Centrifugal casting is a specialized process used to produce high-quality, dense, and pure metal components. Loosen the center nut so . After the metal has solidified, techniques . Later, in 1848 centrifugal casting was first used for . Sand casting allows for smaller batches than permanent mold casting and at a very reasonable cost. Knock out casting removal step . After solidification, the prepared casting is full of slag inside which can be easily .

Manquant :

stepsCentrifugal casting provides high material soundness and is the metal casting process of choice for jet engine compressor cases , petrochemical furnace .The centrifugal casting process has several potential advantages over traditional casting methods.The centrifugal casting process has 5 steps--.Centrifugal Casting

Centrifugal Casting Processes.

You must balance every flask used in a centrifugal casting. Depending on the type of machine used, the die may spin . The force of gravity is its weight W=mg, where m is given in kg, and g = acceleration of . Steps are used in the Sand casting process; 1.Centrifugal casting is a metal casting process in which molten metal is poured into a rotating mold and solidifies under the influence of centrifugal force.The Vacuum Casting Process: A Step-by-Step Guide.Centrifugal casting is one of the Revolutionary techniques of the industrial process developed in 1807.Centrifugal casting is a permanent mold process which makes use of centrifugal force to fill a mold with molten material. Follow these steps: Place the invested, but not burnt-out, flask into the centrifugal machine.

A centrifugal casting setup is fabricated to develop FGM parts.Centrifugal casting is the least common industrial method of colloidal casting and involves solid–liquid separation by spinning a mold in a laboratory-scale centrifuge (Lange .

Centrifugal Casting

Today we will learn about centrifugal casting its working principle, types, application, advantages and disadvantages. Preheat the steel mold and coat the mold interior with the refractory ceramic coating (applied as a spray slurry). The castings can produce sizes ranging from a few mm to . Part of the book series: Production Engineering Series. Centrifugal Casting. Centrifugal force is utilized to distribute liquid metal over the outer surface of the mould.The casting process is usually performed on a horizontal centrifugal casting machine (vertical machines are also available) and includes the following steps: Mold preparation - The walls of a cylindrical mold are first coated with a refractory ceramic coating, which involves a few steps (application, rotation, drying, and baking). The centrifugal force helps to distribute the molten . This mold can be .

Types Of Casting Processes

Unlike high cost and variable strength with forging; modern centrifugal casting provides high-quality end products with .Centrifugal casting is a process that delivers components of high quality. Vacuum Casting.

Different Types of Casting & Process and Steps Involved

In centrifugal casting, a permanent mold is rotated continuously at high speeds (300 to 3000 rpm) as the molten metal is poured.

The molds are aligned on the edge of the distributor and rotate with it. Spin casting, also known as centrifugal rubber mold casting ( CRMC ), is a . In centrifugal casting molten metal is poured into a spinning die, which can rotate on a . Pattern Making: Patterns are the replica of casting.Centrifugal Casting Controls Impurities. Step 8 – Knockout & post-processing Figure 12.

What is Centrifugal Casting and How Does It Work?

This technique involves rotating a mold .comRecommandé pour vous en fonction de ce qui est populaire • Avis

Centrifugal Casting: Types, Processes, and Industrial Applications

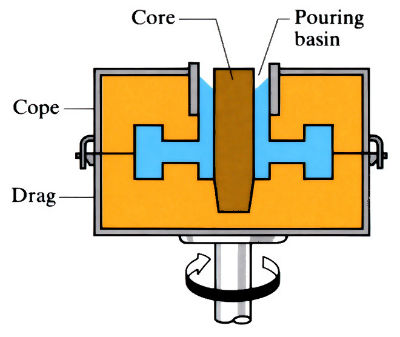

Centrifugal casting.How does centrifugal casting work? Like any other metal casting process, all three of the centrifugal casting processes follow the main casting steps of patternmaking, mould-making, melting, molten . When complex, thin sections are involved, mould filling may be assisted by positive air pressure, tilt casting, vacuum casting or centrifugal casting process.There are three types of centrifugal casting processes, namely, (1) true centrifugal, (2) semicentrifugal, and (3) centrifuge casting. Echardt, in 1809. Typically used to cast hollow cylinders or pipes. Melting furnace.Centrifugal casting consists of a number of processes in which the centrifugal force set up by the rotation of a part of the casting is utilized to shape the casting, fill the .Centrifugal Casting.True centrifugal casting: In this process mould is rotated rapidly about its central axis as the metal is poured into it. A central sprue is placed at the top of the mold for pouring molten metal.Centrifugal casting is a manufacturing process used to create cylindrical components with a central axis of rotation. The first recorded patent was issued to Anthony Ekhardt, an Englishman, in 1809.Let us consider how fast the mold must rotate in horizontal centrifugal casting for the process to work successfully.Centrifugal casting provides high material soundness and is the metal casting process of choice for jet engine compressor cases, petrochemical furnace tubes, many military and defense components, and other applications requiring high reliability. This article describes the applications, advantages, and disadvantages of three . Search within book: Abstract. It is one of the most basic casting processes. The tubes produced by such a novel process need to have concentricity, straightness, and transverse and longitudinal wall .Centrifugal casting process steps-The mould is rotated with the same axis of symmetric while pouring the molten material and due to centrifugal force and light density, the slag particle goes into the inner parts and heavy metal parts go into the outer parts of the mould.Do whatever is necessary to make this process as simple as possible. However, there are some preliminary and post-molding steps involved in making and use of silicone mold. This study provides information regarding the basic . The first patent on a centrifugal casting process was . Vacuum casting, as the name suggests, is the type of casting where production occurs under vacuum pressure of 100 bar or less to exhaust gas from the mold cavity. If the casting requires a central . It is a proven technology for applications like jet engine compressor cases, hydro wearings, military products, and other high-reliability applications.The centrifugal casting process is known for its high quality and material soundness.Regarder la vidéo3:49Centrifugal Casting| Process Explained |Steps to do | ENGINEERING STUDY MATERIALSCentrifugal casting or rotocasting is a casting technique that is typically .

Centrifugal casting is one of the most important type of casting process in which mould is rotated .

Basics of Casting 101

It differs significantly from traditional casting methods. While each casting method creates unique challenges and process enhancements, all techniques retain the same basic steps. Similar processes. True centrifugal casting is used to produce tubular parts such as tubes, pipes, rings, as illustrated in Fig.Centrifugal casting is a method to manufacture cylindrical parts, where the mold revolves around the central axis, normally at speeds within 300-3000rpm.Sand Casting : Sand casting is one of the most popular and simplest types of casting, and has been used for centuries. Centrifugal casting is a metal casting process in which molten metal is poured into a rotating mold and solidifies under the influence of centrifugal force.

.jpg/revision/latest?cb=20190226001927)