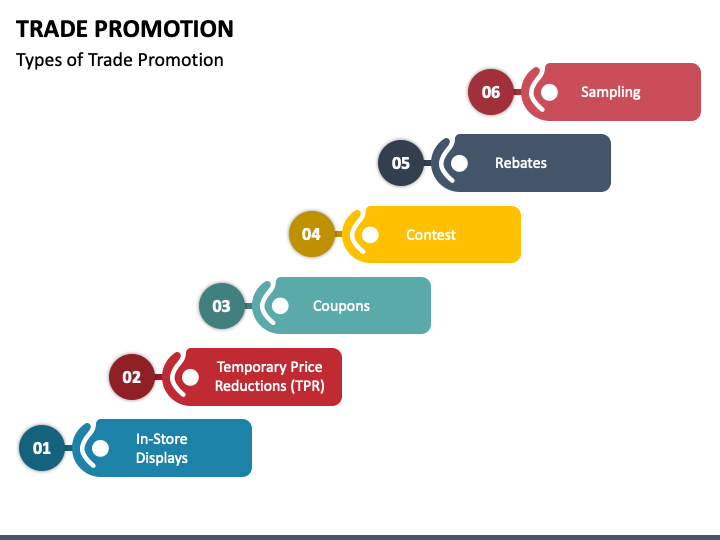

Cnc programming examples with drawing

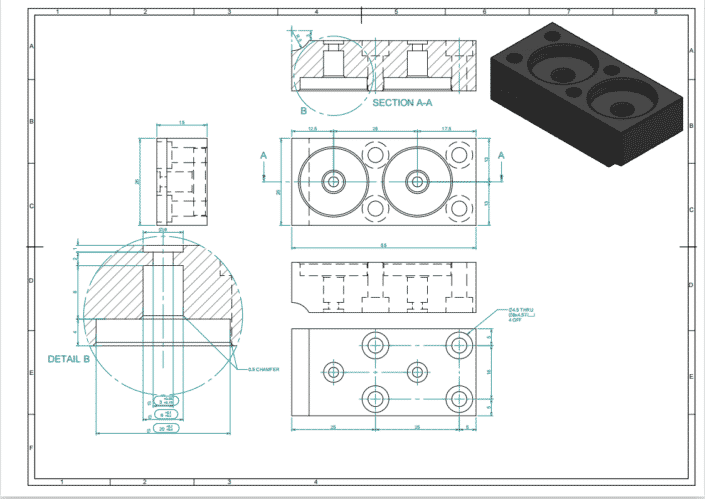

This cnc program has lot more straight lines, but why I chose it because of the way drawing dimensions are given, this cnc programming example will be a good source of cnc program learning for novice cnc programmers and cnc machinists.The number of passes needed to make the spiral is: 30 mm / 0.OD Turning with G73 Pattern Repeating Cycle CNC Lathe Example Program. (All dimensions .In absolute programming, the G90 command indicates to the computer and MCU that the programming is in the absolute mode. Second, many lathes encode a tool wear offset into the address following the “T” word: T ttww. Easily learn the basics of CNC programming with this G-code tutorial in six simple steps.Vertical Machining Center Programming Example. To access the drawing PDF, . Click here to download a high-resolution .

CNC Programming Example in Inch Simple CNC Lathe Program

It’s one type of .The image above is a well-designed, fully-dimensioned technical drawing and a useful example for getting the most out of this guide. Tool will move to a safety distance of 200 diameter. This lathe cnc programming example is for beginners level .हम इस पोस्ट में VMC 2d Programming in Hindi और VMC-CNC programming के basic से लेकर vmc full 2D programming with drawing के बारे मे जानकारी दी है.

What is CNC Programming?

cnc in the same folder as the main program or in the user defined CNC folder. Return from subprograms and subroutines can be done with . Verifying Dimensions and Tolerances . 103 subscribers. First, the lathe uses no M06 command–the tool is changed as soon as the “T” word is executed. G84 Rigid Tapping. M08-Coolant ON.Take, for example, this line of code: G01 X1 Y1 F20 T01 M03 S500. See how to use circular interpolation, multiple arcs, chamfer, corner rounding, peck milling, pocket milling and more.

G-code is everywhere, from 3D printing to CNC.001 mm = 30000 increments.

Updated Nov 26, 2022. We start from the basics and gradually progress to advanced . Setting Up the CNC Turning Machine.Page 2: Beginner Level CNC Progra.#4 – CNC Electrical Discharge Machines (EDM) . Examples refer to the three first manufacturing processes of each .

Simple Facing CNC Lathe Program Example

Find more similar flip PDFs like CNC Programming Tutorials Examples.

Why Choose This Series: Beginner-Friendly: No prior CNC programming experience required.

CNC Lathe Programming for Turning

Here is a CNC program example which shows how CNC.Then make a simple G code example drawing.Study these six (6) milling and turning programming examples and upgrade your programming skills. Here you will find plenty of free cnc programming examples with component .

Manquant :

drawingCNC Programming Examples

Includes examples, Fanuc dialect, and more.

CNC Programming Basics

In this blog post, we will delve into .Understanding the fundamentals of CNC turning programming is essential for anyone operating or working with CNC turning machines.You can also watch . Table of Contents: 1. Write Manual Part Program for machining the profile shown in figure and simulate using cnc milling program using G01 code. Here's a basic overview of some common G codes and M codes used in CNC machining. Overview of CNC Turning. The difference between the two categories was once very distinct. Keep in mind that the specific codes might vary slightly depending on the machine and controller, so always refer to your machine's . Understanding G-code and M-code. These software tools provide a graphical . This downloadable resource will enhance your understanding of programming different turning operations and help you visualize the expected outcomes for each code sequence.

Vertical Machining Center Programming Example CNC

This is yet another simple cnc machine programming example. Case Study: Successful Application of CNC Turning Drawings .

CNC Programming Essentials: A Beginner's Guide

#2 – CNC Milling Machines.by Renato Calvinisti, Lauren Fuentes.A collection of examples of how to use Cnc Programming Examples With Drawing in various fields and applications.To assist with your CNC turning programming journey, we have prepared a detailed drawing PDF that includes various examples and dimensions. This tool finishes the 3mm radius, as well. N10 T1 N20 S1000 M3 N30 G00 G40 G90 G17 X-30 Y60 N40 G43 Z50 H1.Here’s what we have for CNC Programming PDF’s: CNC Machine Programming Course / PDF eBook. Using CNC carvers, you can make some really . CNC TECHNO PROGRAMMING SIEMENS. Within on milling example, the part’s “20mm x 60mm” perimeter contour will finished in an single X-Y pass with a 2-flute, Ø6 end-mill.AUTODESK FUSION 360. N130 G01 X50 N140 X10 Y50 N150 Y65 N160 G40 X-30 Y60 N170 G00 Z200 M02. % N10 T03 M06 N20 G96 S150 G95 F0. Lathe CNC Programming Example.This simple program will draw a 1” diameter circle about the origin. Learn how to create process flowcharts, symbols, and . More for a Researchers or hobbyist to make new things, it is essential for them to know some basic of CNC, to make a prototype. Fundamental CNC Turning Operations\ a. Never write your own CNC programming by hand again. It involves using the G-code language to describe the shape, process, parameters, and .

Manquant :

drawing Or you can simply run a cnc program Simulation (but this always doesn’t substitute the actual cnc machining process.How To Write CNC Milling Program Using G01 Example 1

Make program for that example.CNC Lathe programming examples with drawing - YouTube.

CNC Programming for Turning

The cnc G code G02 Circular Interpolation Clockwise is used in this programming.) The last thing is the most crucial which is Just practice practice and practice. CNC PROGRAMMING.

Since the CNC allows repeating the execution of a block a maximum of 9999 times, the .Not all CNC furniture plans are all large models and full sets, some are practical additions to existing furniture. In this step-by-step tutorial, we will unravel the intricacies of CNC turning programming and guide you through the entire process. You simply answer questions in a simple Wizard format and it will generate the g-code for the operation.

CNC an Overview With Practical Example [MADE EASY]

Use this program to test your CNC machine and confirm your axis directions are set correctly.

Manquant :

drawingCNC Programming Examples / Cnc lathe programming examples with drawing

Both of the examples below represent the drawing above. Note all gcode programs a simple text files .The IDEF0 Diagram solution is contained in the Software Development area of ConceptDraw Solution Park.By Mike Hepburn.

CNC Programming Examples Both CNC Lathe and CNC Milling Examples of Canned Cycles and More Copy these Examples to Build your Programs. CNC Programming Tutorials Examples was published by Perpustakaan Kolej Vokasional Seri Iskandar on 2021-06-29.There are a couple of differences between typical CNC Lathe tool changes and Mill tool changes. Reviewing and Revising CNC Turning Drawings . This is a very simple lathe cnc programming example. N50 Z-5 N60 G01 G41 X10 Y60 D1 F200 N70 Y80 N80 G02 X20 Y90 R10.Here is another cnc programming example, this time I am programming for an arc with I K values. Run the program on your cnc machine (Safety first, keep a professional around). The tool number will also be different depending on the machine.What is CNC programming: CNC programming is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece.

CNC Programming with G Code: Easy Free Tutorial

First arc is programmed using G02 R, but the second arc is.CNC programming or computer numerical control programming software refers to computer programs that are used to create, edit, simulate, and manage CNC programs. Now, however, most control units are able to handle .The cutting speeds and feedrates appearing in this manual are only approximate, they may vary depending on the material of the part and the tools used. When machining one of the parts of these examples, use the speeds recommended by the tool manufacturer. G81 Drilling Cycle. CNC programming is an arcane and daunting task. The 3D CAD file is applied for CNC machine programming, and the technical drawing is applied for machining process reference.

CNC Programming Made Easy: A 6-Step Guide for Beginners

Circular Interpolation . Check Pages 1-50 of CNC Programming Tutorials Examples in the flip PDF version.0 as per drawing. CNC stands for Computer Numerical Control. This is the turning movement.CNC program example to show how two combined arc can be programmed with G02 G03 for a cnc lathe.Mastering CNC Turning: Comprehensive Guide with Programming Examples and Detailed Drawings (PDF) CNC (Computer Numerical Control) turning is an intricate process that .2 S1200 T0101 M04 N10 G00 X42 Z2 N30 M98 P12000 (call .

How to prepare a technical drawing for CNC machining

Why are technical drawings still important for sourcing parts? What is the anatomy of a technical drawing? What are notes to the manufacturer .

Beginner Level CNC Program Examples

M03 – Turn the spindle on.Tool will move in feed to 50 diameter. The IDEF0 Diagram solution is contained in the Software Development area of ConceptDraw Solution Park.1 D2500 (D = Maximum spindle speed) N30 G00 X54 Z-2 M03 M08 N40 G01 X-1 N50 G00 X200 Z200 M09 N60 . You will also see the usage of Fanuc G20 G . In the example “tt” signifies the tool number . Real-world Example of CNC Turning .G-Code is the most common language used to control CNC machines. In this single line, we’re giving the machine a series of instructions: G01 – Perform a linear feed move. Examples from Haas. These are just snippets of code they are not complete programs. Tips for Ensuring Accuracy in CNC Turning Drawings .

G-code Tutorial for CNC Programming: 6 Simple Steps

G73 Peck Drilling Cycle.

CNC Programming Examples Turn and Mill

Tool will return to safety postion with feed.