Condition monitoring in induction machines

Information, 14(6), 329. machine so that changes and trends of the monitored.

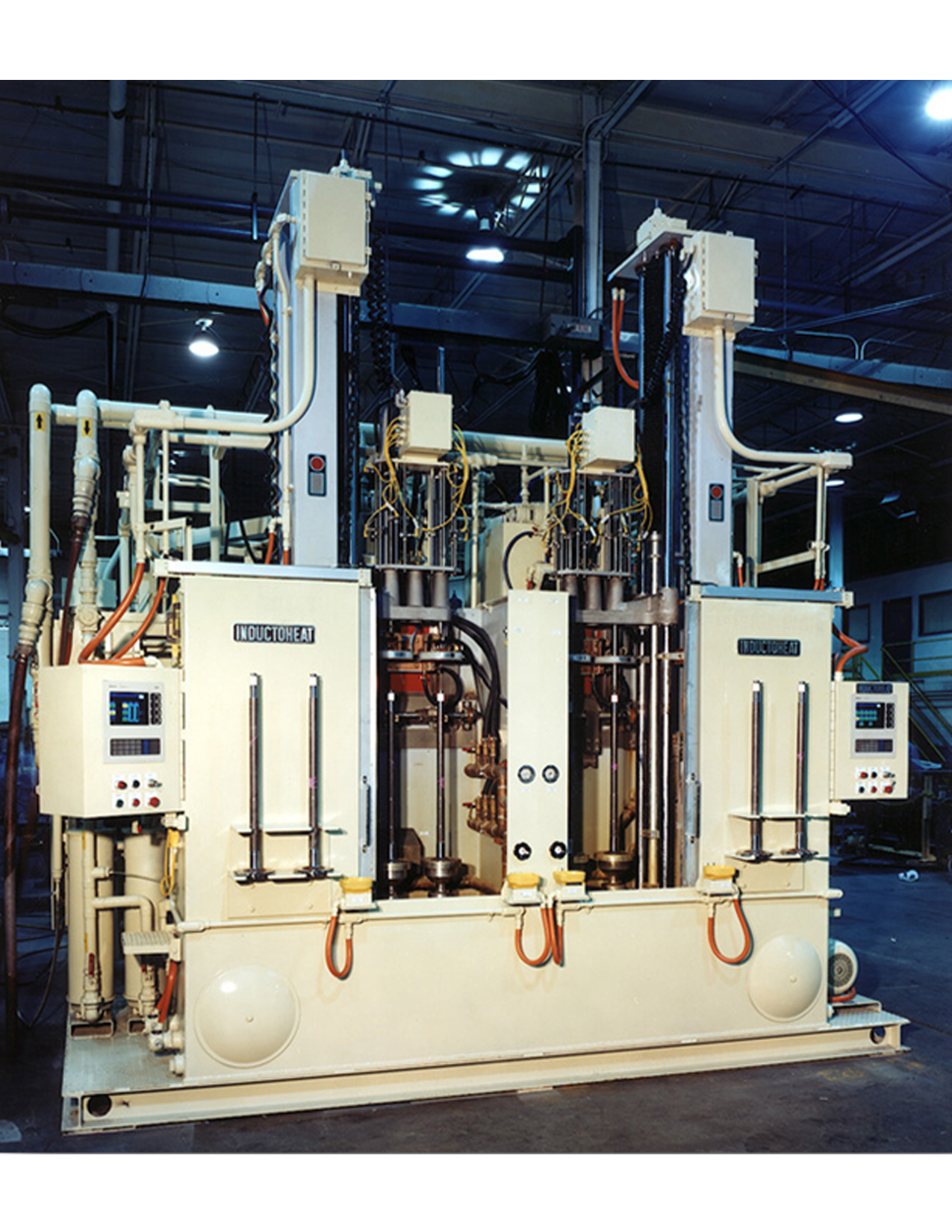

Abstract — The electrical motor condition monitoring is a.A proper maintenance strategy is important to avoid machine and/or process failures (Cooney, . Due to high reliability requirements, and cost of breakdown, the issue of condition monitoring of .Intelligence Methods for Condition Monitoring and Fault Diagnosis of Rolling Element Bearings for Induction Motor ,” Shock and Vibration , vol. Almost in every industry, around 90% of the machines apply an induction motor as a prime mover.

Condition Monitoring and Fault Diagnosis of Induction Motors

For critical and expensive machines, . The great enhancements and reduction in the costs and dimensions of the required sensors, the development of advanced signal processing techniques that are suitable for flux data analysis, along with . However, three main types of IM faults have been discussed in the literature, bearing, stator, and rotor.Condition monitoring is used for increasing machinery availability and performance, reducing consequential damage, increasing machine life, reducing spare . Hence, it is necessary to monitor its condition to avoid any catastrophic .

State of art on condition monitoring of induction motors

1016/S0378-7796(02)00172-4 Corpus ID: 110213742; Induction machine drive condition monitoring and diagnostic research—a survey @article{Singh2003InductionMD, title={Induction machine drive condition monitoring and diagnostic research—a survey}, author={Girish Kumar Singh and Sa'ad Ahmed Saleh Al Kazzaz}, journal={Electric Power .To avoid such situation should provide condition monitoring technique for induction motor. Nevertheless, condition monitoring is of primary importance. It is important that measures are taken to diagnose the state of the machine as and when it enters into the fault mode.Magnetic flux analysis is a condition monitoring technique that is drawing the interest of many researchers and motor manufacturers.Continuous monitoring and interaction of motor operating parameters such as vibration, current, and temperature with sensors enable us to diagnose and . In the manufacturing environment, condition monitoring is important for machine maintenance, with the aim to safeguard the reliability and efficiency of machinery for production purposes (Venugopal, Wagstaff, & Sharma, 2007).This paper provides a review on condition monitoring analysis methods for electrical machines as deterministic and non-deterministic (or statistical analysis . In this paper induction motor monitored for various fault condition then apply .Condition monitoring of machine involves continuous assessment on the performance of rotating components i.

Condition monitoring of induction machines (IMs) with the aim of increasing the machine's lifetime, improving the efficiency and reducing the maintenance cost is necessary and inevitable. detects the unexpected faults of a critical system. This method assumed a linear relationship between the current harmonics and vibration level. Importantly, stator and rotor faults represent approximately 50%.Vibration Monitoring growing technology to detect the f ault of an induction motor.

Condition Monitoring and Fault Diagnosis of Induction Motor

, centrifugal pumps, fans, and industrial machines, due to their high reliability and efficiency [ 5, 6 ].This paper describes a data-driven method for real-time induction motor condition monitoring and fault diagnosis, based on Dictionary Learning and Nystrom .Condition monitoring of electric machines is a procedure of increasing importance, as fault tolerant systems are becoming mandatory in many applications.Automated continuous condition monitoring of industrial machines to identify these faults has become one of the key areas in research for the past decade. Condition monitoring (CM) is . Rotating machines are commonly used in the industry for different applications such as railways, pumps, conveyors, blowers, elevator, mining industry .The induction motor offers a extensive variety of engineering applications in the fields such as railway, mining, automotive, chemical and paper industry, etc.Three phase current sensors are used to monitoring the induction machine during operation at steady state.Fault detection prior to their occurrence or complete shut-down in induction motor is essential for the industries. Traditional condition monitoring (CM) and fault diagnosis (FD) ., (i) a total of nine commonly used condition monitoring methods of induction motors; and (ii) intelligent learning models for . It is further necessary to do so on-line by continuously monitoring the machine variables. It is a very important driving unit of the machine.Nowadays, induction motor (IM) is extensively used in industry, including mechanical and electrical applications.The induction motor is considered as a robust and fault tolerant machine and is a popular choice in industrial drives. process of monitoring the operating c haracteristics of a.(PDF) Condition monitoring of induction motors - .

Improved online condition monitoring using static

A fast, unscheduled maintenance can avoid more .A well-maintained induction motor will make the operations of various industrial processes less daunting. Low-pass anti-aliasing filters are implemented in order to set the frequency bandwidth of the analysed signals to a correct range.Condition monitoring and diagnosis of rotor faults in induction machines: State of art and future perspectives Abstract: This paper investigates diagnostic techniques for . The main aim is to achieve a relatively low cost and non-invasive system which is still powerful in terms of monitoring . Safety, reliability, efficiency and performance are some of the major concerns of induction motor applications.The detection of air-gap eccentricity-related motor faults is a very important function in online condition monitoring of induction machines. The power of machine learning can be harnessed and optimally used for fault detection.Condition monitoring can be defined as a technique or. The Wireless Sensor Networks (WSNs) are more flexible communication system for transmitting the data to the desired location.Condition Monitoring and Fault Detection in Small Induction Motors Using Machine Learning Algorithms.Shallow and deep learning approaches to this problem are investigated and compared, with a hybrid deep/shallow system ultimately being the most effective.

![[PDF] Design and implementation of PLC-based monitoring control system ...](https://d3i71xaburhd42.cloudfront.net/2311f0e62b7c658555fe85e0539521c4ff894b63/2-Figure2-1.png)

First Online: 25 January 2020. The Transducer modules and sensors observe the parameters like Temperature, vibrations, external moisture RPM, induction machine load current and voltage and send to the (Arduino) Abstract The limitations of thermal, vibration, or electrical monitoring of electric machines such . Large motors, which are commonly process-critical, will usually have built-in condition .The review covers two parts, i.

Condition monitoring techniques for induction motors

It detects the unexpected faults of a critical system.eduRecommandé pour vous en fonction de ce qui est populaire • Avis Feature extraction and recognition for rolling element bearing fault utilizing short-time Fourier transform and non-negative matrix factorization. Cite this conference .Abstract: Condition monitoring in industry is desirable for increasing machinery availability, reducing consequential damage, and improving operational . Da-Ming Yang and James Penman [5] addressed the use of stator current and vibration monitoring to diagnose bearing condition. The fault detection based on condition monitoring techniques and application of machine learning have tremendous potential. Therefore, there is a strong need to develop an efficient condition monitoring approach.Abstract This article deals with the condition monitoring and fault diagnosis of a three-phase induction motor using a support vector machine classifier. Chilaka Ranga, Ashwani Kumar Chandel [11] This Review paper gives the condition monitoring of alternating motors which are widely being used in induction machines to overcome incipient failures . signal can be used to predict .Recent Challenges in Condition Monitoring of Industrial Electric Machines .Maturity, reliability, ruggedness and versatility make the induction motor one of the most widespread electric machines in industrial applications . Low frequency and high frequency characteristic side .remote control and monitoring system of an induction motor in industries for implementation, In order for protected and economic conditions. The main concept of the new method is to use the inverter to perform off-line tests for quality assessment of the vulnerable components in the inverter, cable, and induction motor automatically, whenever the .net(PDF) Condition monitoring of induction motors: A review . Engineering, Physics. Among various faults, early-stage .Condition monitoring can diagnose the inception of fault mechanisms in induction motors, thus avoiding failure and expensive repairs.Parameter Estimation, Condition Monitoring, and Diagnosis of Electrical Machines.Induction motor is critical component in many power plants & industrial processes and is frequently integrated in commercially available equipment.This review is carried out for fault identification of induction motor used in machines in general and in particular for identifying the faults in an induction motor of .

Early detection of incipient faults is essential to take action in time.This paper will review methods for condition monitoring of mechanical faults, with special reference on those based on electrical signals and quite effective also for an early .3390/s23021046

Condition Monitoring and Fault Diagnosis of Induction Motor

Abstract: The electrical motor condition monitoring is a growing technology to detect the fault of an induction motor.Experimental investigations on induction machine condition monitoring and fault diagnosis using digital signal processing techniques @article{Kazzaz2003ExperimentalIO, title={Experimental investigations on induction machine condition monitoring and fault diagnosis using digital signal processing .

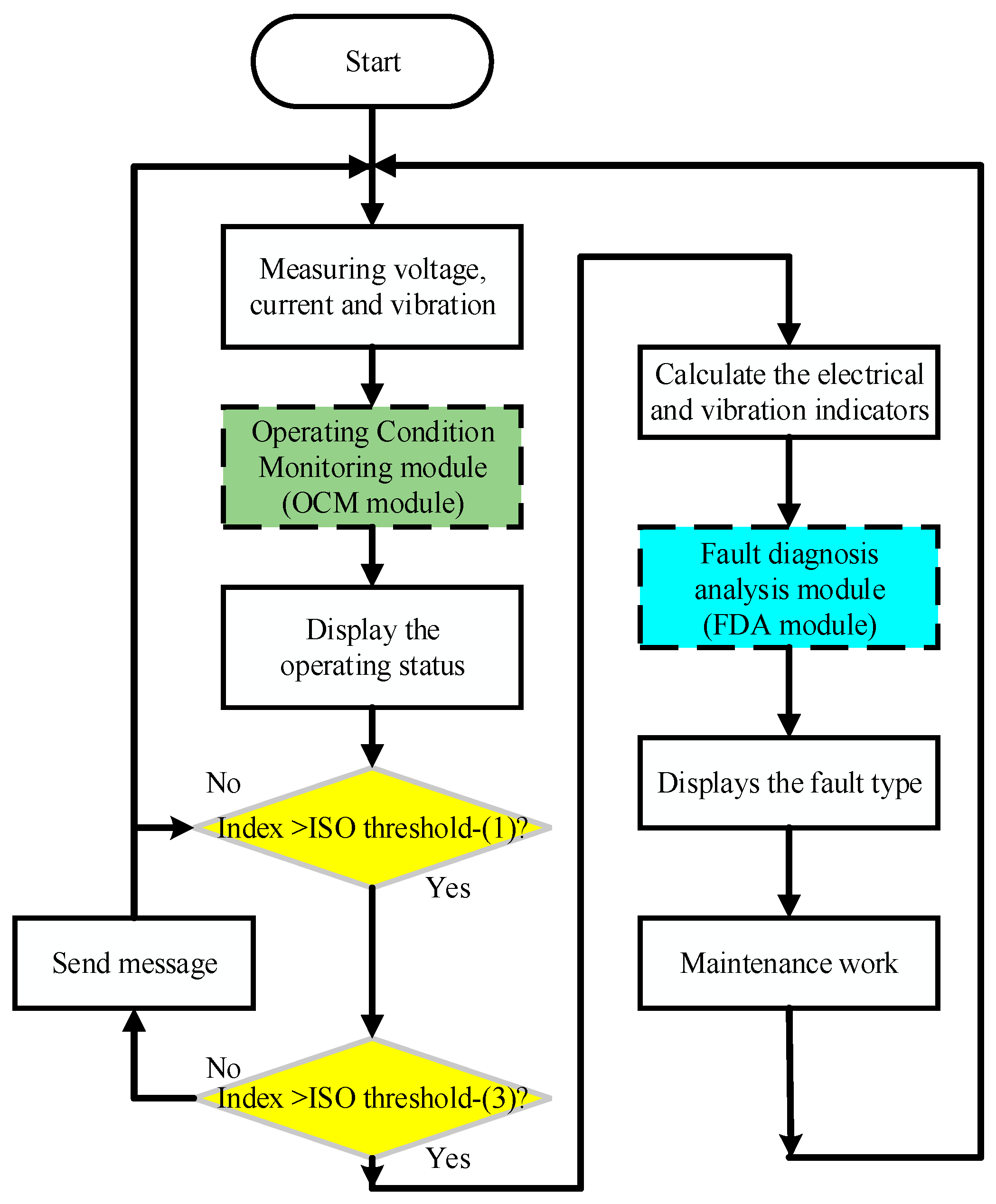

A new strategy for monitoring the condition of adjustable speed induction machine drive systems is presented in this paper. Introduction Summary of space phasor theory On-line signal processing of space-phasor quantities The effects of time harmonics on various space-phasor loci, harmonic amplitude estimation Monitoring .