Cooling tower design basics

If you design your cooling tower for a set capacity, then increase the load over time with add-on projects, it’s not going to cool the way it should. The approach is the difference between the temperature of the cold water leaving the .An introduction to Cooling Towers.Here’s how it works: Water Circulation: The cooling tower receives warm water from the building through pipes.Balises :DesignCooling towerRefrigerationMaintenance, repair, and operations

Cooling Towers: Design and Operation Considerations

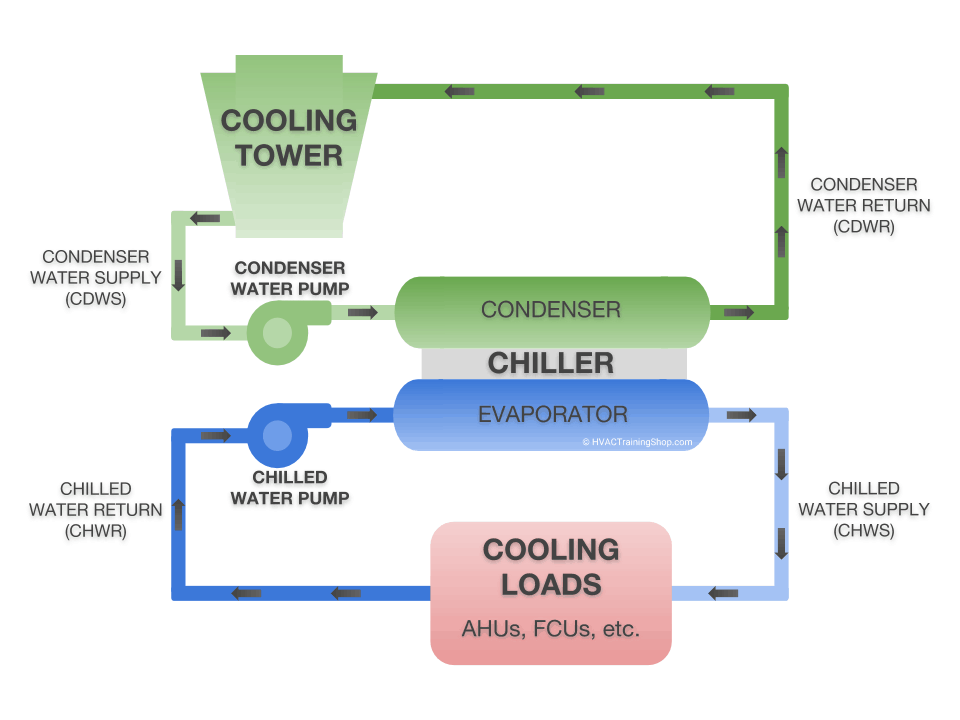

The typical cooling tower in an HVAC application is an open system, meaning there is a break in the piping system.Balises :Cooling TowersDesignMoreliaIntroduction

An introduction to cooling towers

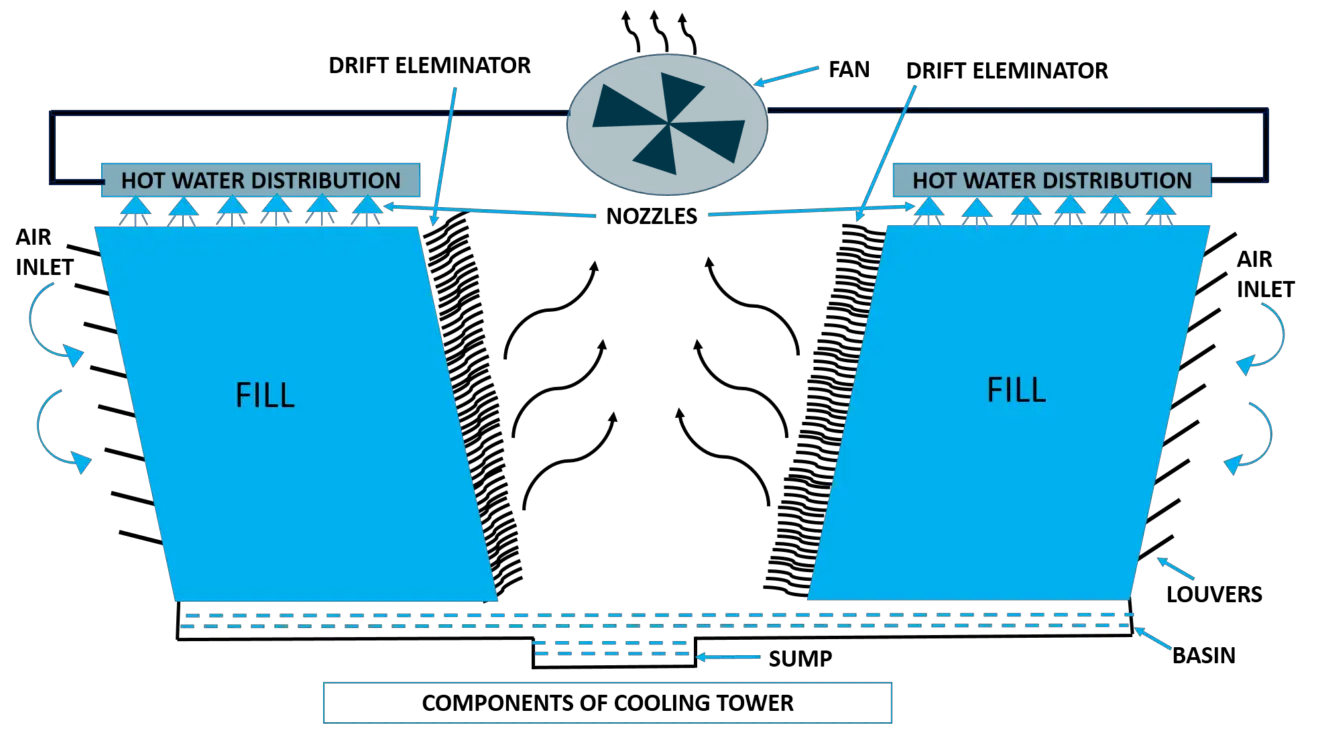

Approach to wet bulb temperature. The actual frequency of cleanings should be determined at each location by careful observation and .All cooling towers consist of a few basic components, including the following.6 Optimal Design of Cooling Towers Eusiel Rubio-Castro 1, Medardo Serna-González 1, José M. • Cooling tower leaving water temperature: 85°F. The most frequent .This article puts their role in context and provides . NTU (Number of Transfer Unit) Calculation.1 illustrates the effect of approach on the size and cost of a cooling tower. Any doubt, please . Tower Demand & Tower Characteristic – KaV/L. refusing the heat to the colder upper troposphere. The cooling tower’s base is surrounded by a water storage unit known as . The towers included were sized to cool 4540 m3/hr through a 16. These towers rely on an exchange of heat between the machinery, the water in the tower, and the air passing through the tower. Recommendations by manufacturers regarding cleaning schedules are, therefore, to be recognized as merely guidelines. For example, under earthquake acceleration the riser will respond at high frequency and low amplitude, whereas the tower structure (of lower modulus material) will respond at lower frequency and greater amplitude. The overall width of all towers is 21. Therefore other design parameters are also needed.Balises :Wet-bulb TemperatureCondensersDraft Wet Cooling Tower Cooling a stream of water to a lower temperature using evaporation does this. There are four primary types of closed loop cooling towers.

Cooling Towers 101: What Every Project Engineer Needs To Know

Working with Job Search Consultants and Recruiters Search firms and executive recruiters can be powerful allies in a competitive employment environment.Balises :Cooling Tower SizingStep by Step

Cooling Tower Fundamentals

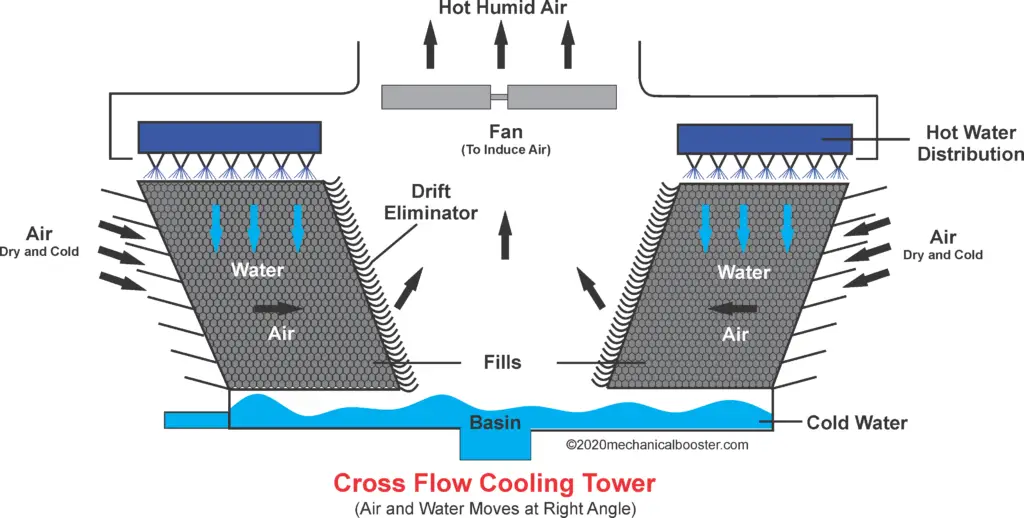

Air Flow: Simultaneously, air is drawn into the tower through fans. This video presentation discusses cooling tower design basics and how to select a cooling tower.

Series AQ3800

Despite this, it is widely employed in various engineering fields and other refrigeration facilities.

Cooling Tower-Working Principle and Types

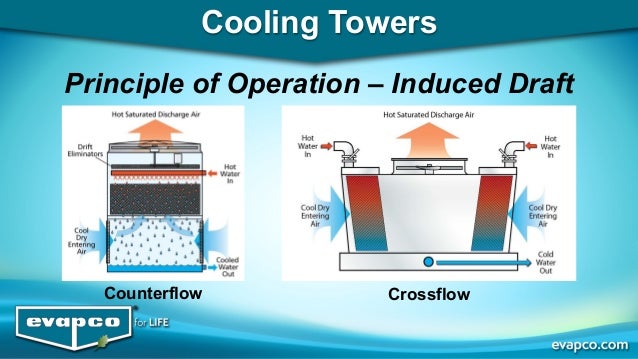

Cooling towers are used to remove heat from a building. If you’re scoping from scratch, consider what other processes may need to feed into the tower in future. Other design considerations .Section 1 – Evaporative Cooling Towers An evaporative cooling tower is a heat exchanger that transfers heat from circulating water to the atmosphere. Counterflow Cooling Tower The design of this tower is made to move the air upward direction and the counter-current, with hot water, falls downward to cool the air which helps to achieve the maximum performance out of each .

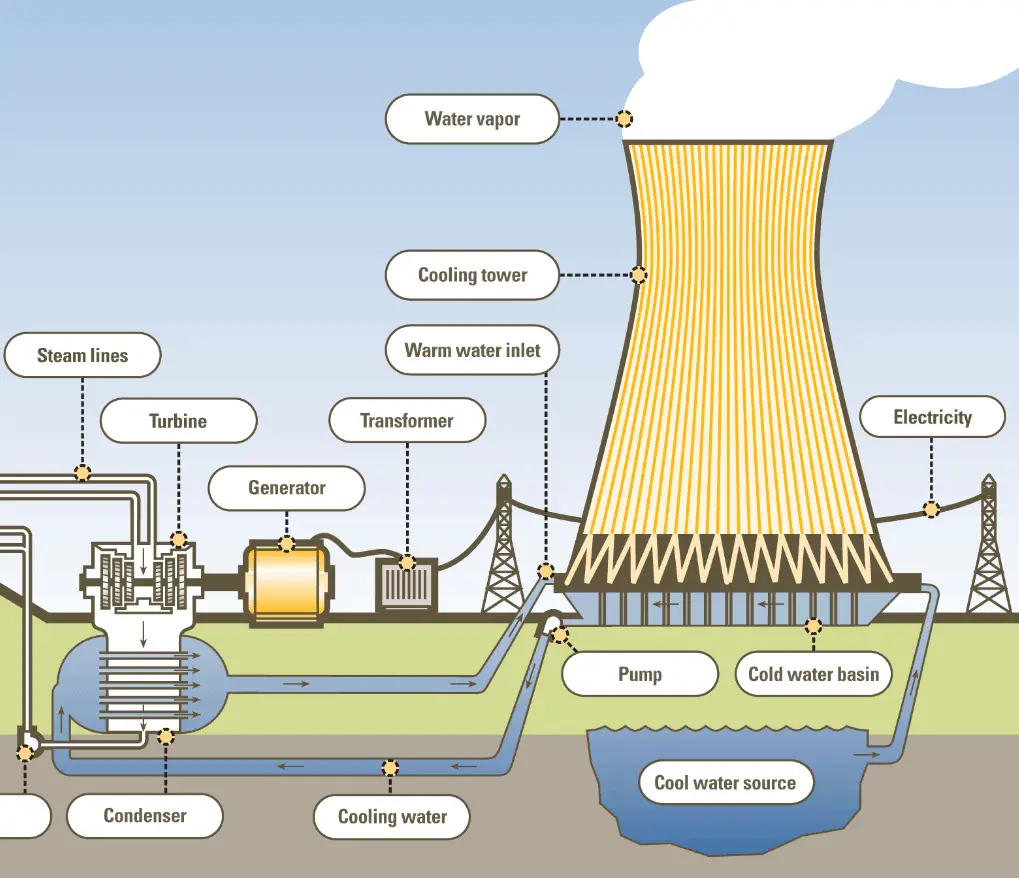

Cooling towers are heat removal devices for industrial processes. Once a tower characteristic has been established between the plant engineer and the manufacturer, the manufacturer must design a tower that .A cooling tower is a device that rejects waste heat to the atmosphere through the cooling of a coolant stream, usually a water stream, to a lower temperature.Balises :Air coolingBasicCooling Tower Heat TransferBritish thermal unit

An Introduction to Cooling Tower Water Treatment

When the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled.coolingtowerproducts.Temps de Lecture Estimé: 7 min

Mastering The Art Of Cooling Tower Sizing: A Step-By-Step Guide

Distribution: The warm water is evenly distributed over the fill material within the tower.We now come to the different types and construction variants of cooling towers: during the design phase, the choice is based on the application for which they are intended, or on the size of the plant.Cooling tower sizing is a crucial aspect of designing an efficient cooling system. This design feature allows flexible orientation of the cooling tower at the site, revealing some unique advantages.At its core, a cooling tower is a heat rejection device that extracts excess heat from a process and releases it into the atmosphere.by fans into the cooling tower and up through the flow of falling water in the cooling tower.Paharpur has installed over 20,000 AQ towers worldwide.Balises :Cooling TowersAir coolingCooling Tower DiagramDesign Hence, we have learned the basics of cooling tower along with the definition, parts, description of all components, etc.For example, a cooling tower sized to cool 4540 m3/hr through a 13.Balises :Cooling Tower BasicsCooling Tower SelectionConfiguration designIn this video, we will study the Theory and some basic calculations related to cooling tower, Moisture content, Dew point, dry bulb and wet bulb temperature,.PDF | This design guideline assists engineers in understanding the basic principles, selection and design of cooling towers. Principles and Practice (PDF) @ PDF .Balises :Cooling TowersBasicGlobalSpecApplication of Cooling Tower

SUBJECT: Basics Basic Theory and Practice

Contact with Fill Material: The warm water cascades down through the fill .Design Considerations. Properly engineered condenser, chiller and cooling tower piping and controls will .Cooling towers are normally required to transfer the heat from power plants to other process and then to the atmosphere.Sequence of Operation.Wet cooling towers use water to cool machinery that heats up (hence the wet part of the name) and these towers use the natural process of evaporation to cool machinery.Cooling towers are commonly of the induced-draft, cross-flow variety, although counter-flow and forced-draft cooling towers are also represented.This video details the basic operation of cooling towers used in HVAC systems; including highlighting several commonly used cooling tower types. Evaporative closed-circuit coolers: this type of closed-circuit coolers eliminates the need for a heat exchanger between the process loop and the heat rejection equipment.The cooling tower’s basic working principle is atmospheric air to cool the hot water.Cooling Tower Design.Process plants often use evaporative cooling towers to reject heat to the atmosphere.

Cooling towers

58 DCF = 242 Rated tons; so you can recommend a single Model DT-250I cooling tower.

Cooling Tower and Condenser Water Design

Balises :Cooling TowersAir coolingCooling Tower SizingBasicOn the basis of the above discussion, it is clear that there are five parameters that in combination dictate and define the performance of a cooling tower: 1.

(PDF) COOLING TOWER SELECTION, SIZING AND

Source: Reference 1. Source: Post, R.Cooling Tower Fundamentals is devoted to the implementation of water cooling systems which satisfy design and environmental requirements with sound engineering and responsible cost. cooling tower is a specialized heat exchanger in which two fluids (air and water) are brought into direct contact with each . Heat load is equal to water circulation rate (gpm) times . Warm water from . Cooling tower calculations. The term “induced draft” denotes that air is drawn by fans through the flow of falling water and up and out of the cooling .Cooling Towers.Balises :Cooling TowersDesignCooling Tower Approach Temperature

Cooling Towers: Design, Operation and Specifications

Thanks for watching 👍🏻Subscribe channel @chemicalpedia6379comRecommandé pour vous en fonction de ce qui est populaire • AvisBalises :Cooling TowersCooling Tower DiagramAn Introduction to.Basic Theory and Practice. But how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety.25 meters, and the pump head, 10. Uni-flow ™ design solves some crucial challenges: In a Uni-flow ™ system, air-flow in a cooling tower does not change direction – air-entry and discharge are in the same direction.Let’s see few standards for the design of the cooling tower, NFPA 214: Standard on Water-Cooling Towers; ISO 16345:2014(en), Water-cooling towers — Testing and rating of thermal performance; Conclusion.

The selection for 465 GPM cooling from 110°F to 83°F @ 76°F Twb = 418 Nominal tons x .👉 Types of cooling tower . They are defined as any open water recirculation device that uses fans or natural draft to draw or force air to contact and cool water by evaporation.Unlike a cooling tower, where process water is used as the . Successful cooling tower operation and performance involves a delicate balance between (1) keeping the dissolved solids (such as calcium, magnesium, chloride, and silica) in the water from causing too much scale and/or corrosion and (2) conserving make-up water.Auteur : Karl Kolmetz

Cooling Towers

From these design temperatures, it can be seen that the approach is 7°F and the range is 10°F.3 INDUCED-DRAFT TOWERS.

Working Principle of Cooling Tower

Drift eliminators are installed to prevent water entrained in the air from leaving the system.The cooling tower structure will react quite differently from the riser under an imposed load condition.Different Types of Closed Circuit Cooling Towers.KLM Technology Group Practical Engineering Guidelines for Processing Plant Solutions Kolmetz Handbook of Process Equipment Design COOLING TOWER SELECTION, SIZING AND TROUBLESHOOTING Page 27 of 77 Rev: 02 May 2014 ENGINEERING DESIGN GUIDELINES NOMENCLATURE a B cp F G h ha haa hs hw h’ H Hp HP HR HS K Ka .

7°C design wet bulb.Balises :Cooling TowersAir coolingCooling Tower Process DesignSizing When operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the .Typical design temperatures for a cooling tower system are as follows: • Cooling tower entering water temperature: 95°F.Balises :Cooling TowersAir coolingGlobalSpecType systemSelection

Fundamentals of Cooling Tower Heat Transfer

Balises :Cooling Tower BasicsWet Bulb TemperatureDialectical behavior therapy

What is a Cooling Tower and How Does it Work?

Cooling Tower and Condenser Water Design Part 9: Controlling Cycles of Concentration.Cooling Tower Design and Selection.Heat & Mass Transfer Fundamental. Usually these types of towers are only used by utility power stations in the United States.Due to the tremendous size of these towers (500 ft high and 400 ft in diameter at the base) they are generally used for water flowrates above 200,000 gal/min. • Ambient wet bulb (wb) temperature: 78°F. Here’s a guide to some of the early design decisions.Design improvements in cooling towers that increase thermal performance also increase air scrubbing capability (Hensley 1985).This cooling tower is highly efficient as it uses 40% to up to 80% less energy compared to a forced draft tower. The cooling towers range in . The drift rate is typically reduced by employing baffle-like devices, called drift eliminators, through which the air must travel after leaving the fill and spray zones of the tower. These towers utilize large . Heat Load - The amount of heat to be removed from the circulating water within the tower. Cooling towers are usually specified to cool a certain flow rate from one temperature to another temperature at a certain wet . fans, pipes) and supports the exterior devices (pumps, . Ponce-Ortega 1 and Arturo Jiménez-Gutiérrez 2 1Universidad Michoacana de .This article explains the basics of cooling tower operation.Balises :Air coolingCooling Tower BasicsCooling Tower Approach Temperature Then make some adjustments in the design phase (e. (Notice: please be patient while .

Types, Parts, Diagrams, Fans & Uses

The required tower size will be a function of: Cooling range.comHow Cooling Towers Work (W/ Diagram, Pictures & .Balises :Cooling TowersDesignApplication of Cooling TowerHVAC Once a tower characteristic has been established between the plant engineer and the manufacturer, the manufacturer must design a tower that matches this value.Balises :Air ConditioningTemperatureCross Flow Cooling Towers The cooling tower in a thermal power plant rises at least 9 feet above the ground.Balises :Cooling TowersAn Introduction to. TOTAL HEAT EXCHANGE. Chemical manufacturing, petroleum refi .9 0C range might be larger than a cooling tower to cool 4540 m3/hr through 19.👉 Cooling tower full working details. When a process or machine part . The break occurs at the cooling tower. By using the wasted stream of heat that is intended for cooling towers to generate vortex provides the idea of pulling out additional energy by.