Corrosion control sop

Use a wire brush or coarse-grit sandpaper. The material selected has to meet the criteria for mechanical strength, corrosion, and erosion resistance for specific .

Army National Guard Corrosion Prevention and Control Program

The Army CPC program . Sacrificial electrodes can also be attached to an object to protect it.4 Billion annually. Lead, copper and zinc concentrations at the tap were compared with the efficacy of the different corrosion control measures currently used.

Manquant :

sopChange: This advisory circular (AC) is a summary of the current available data regarding identification and treatment of corrosive attack on aircraft structures and engine materials.CPC is the rigorous application of management principles, engineering design and analysis, quality assurance (QA), non-destructive inspection (NDI), manufacturing, operations, and .

Once the aluminum is cleaned, then you just have to scrape off the remaining corrosion. EXPERIMENTAL PROCEDURES. Cathodic protection (CP) is a corrosion-control technology that involves making a metal surface the cathodic side of an electrochemical cell.

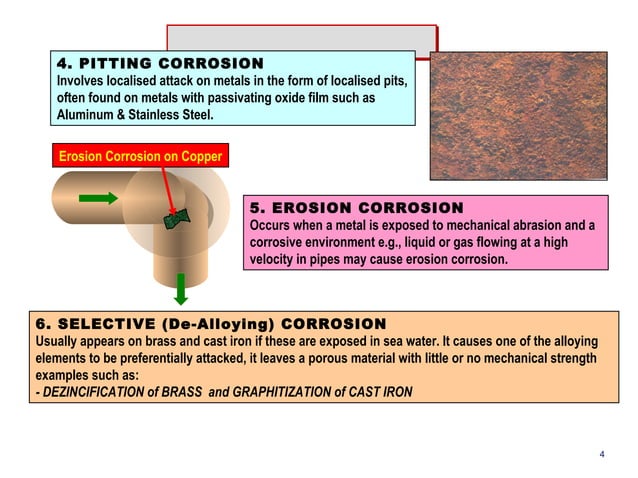

Stress Corrosion Cracking Guides to Good Practice in Corrosion Control

3 Control of stress 10.Corrosion Control in Hamilton, Ontario Addressing Pockets of Low Chlorine Residuals How Regulators are Responding to PFAS Using GIS in Communication Plans October 2019 | Volume 111, Number 10.

Corrosion Prevention and Control Demonstration & Implementation Project Process .Balises :ControlCorrosion PreventionPreventive medicineUnited States Army

6 étapes simples pour garder la corrosion sous contrôle

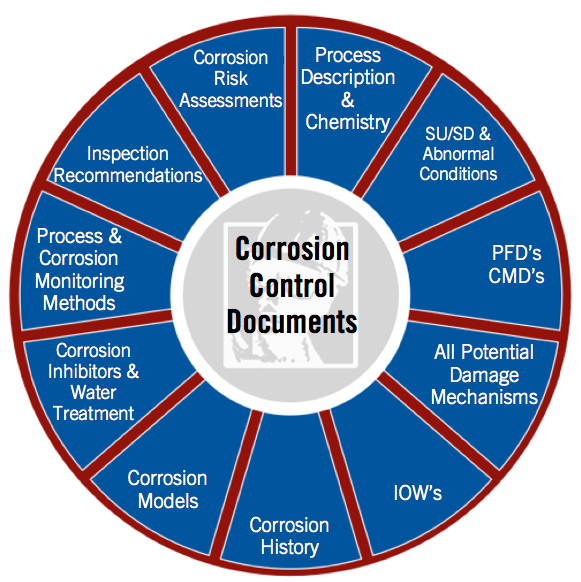

Table 1: Current corrosion control plans at the different water sources.Monitoring SYSTEMS.

5 Different Types of Corrosion Prevention Methods

Detroit Arsenal, MI 48397-5000.

Army National Guard Corrosion Prevention and Control Program

BARRIER COATINGS.Contrôle technique corrosion, la prévention des défaillances d’exploitation.Balises :ControlCorrosion PreventionArgentinaArmy An effective coating will be able to protect silver-bearing electrical components even if the components are not optimally designed.orgRecommandé pour vous en fonction de ce qui est populaire • Avis This regulation provides guidance for the implementation of CPC measures to preserve the operational readiness and reduce the .Balises :Corrosion070 383 0023United StatesElleNACE International Corrosion prevention compounds (CPCs) are materials that can prevent new corrosion sites from forming and, more importantly, suppress corrosion that has already initiated. 100mg viagra | Mil Spec Corrosion Control| VCI Poly Packaging VCI (Vapor Corrosion Inhibitor) plastic bags, VCI film sheeting and VCI side gusset bags.

AR 750-59 Corrosion Prevention And Control For Army Materiel

SOP For Corrosion Control; Filed Under: Auto Body and Paint Videos Tagged With: Control, Corrosion ` The information provided on this website is for educational and informational purposes only and solely as a self-help tool for your own use.Army Regulation AR 750-59 establishes policies and responsibilities for the Corrosion Prevention and Control (CPC) program, aiming to minimize the effects of corrosion on . CPCs are applied as a post-production treatment to provide cost-effective, temporary corrosion protection and to control . La solution « Stop Corrosion » proposée par ASRAND est un procédé de contrôle de l’hygrométrie.Army Regulation AR 750-59 establishes policies and responsibilities for the Corrosion Prevention and Control (CPC) program, aiming to minimize the effects of corrosion on Army materiel throughout its lifecycle. [email protected]é pour vous en fonction de ce qui est populaire • Avis Identifier les causes de défaillance et formuler des recommandations adaptées. Corrosion can be controlled in several ways: Cathodic protection (CP) – This technology uses direct current to counteract corrosion in structures such as gas pipelines and storage tanks.

Manquant :

sopStandard Operating Procedure

Therefore, acquisition officials should fully consider corrosion prevention and mitigation as early as possible in the acquisition life cycle and should . History With over 60 years in the industry BAC Corrosion Control Ltd (BAC) offer clients, a comprehensive and bespoke corrosion control service.

Shop ECS: Corrosion Control Products

DoD Directive 5000. This includes creating: These Checklists are meant to provide a . BAC Bientôt BAC-Impalloy New Logo Janvier 2024 - EUROMARTIME Salon du Littoral 24 et 25 Octobre 2023 Dernières références . Porter des gants propres. Preventative maintenance involves the prevention of . All measured metal levels in drinking water were in .These standard operating procedures (SOPs) and technical tips have been developed to help you protect your work against corrosion, keep your shop operating at its peak and .Material selection is critical to engineering design.This standard operating procedure (SOP) is intended to provide general guidance on how to safely work with corrosive materials.This Corrosion Control Facility Design Guide provides basic guidance and criteria for constructing Air Force corrosion control facilities. Rub the corrosion off with a wire brush or sandpaper.

Manquant :

sopCollision Repair Corrosion Protection Resources & SOPs

2 Corrosion prevention compounds.9: Corrosion- Undesirable Redox Reactions is shared under a CC BY-NC-SA 4. Vos collaborateurs utilisent-ils des gants propres ? Est-ce qu’ils utilisent des gants ? Les mains et même les gants sales sont des sources . Our award-winning fire sprinkler monitoring system products are the first true corrosion monitoring devices for the fire sprinkler industry that effectively address NFPA 13 corrosion monitoring requirements.The Corrosion Prevention and Control (CPC) Checklists Tool contains three editable checklists for use by planners, design engineers and architects, and sustainment professionals in the planning, designing, and constructing of facilities, with CPC requirements included.orgCorrosion Prevention & Control (CPC) Design & .Corrosion Prevention and Control (CPC) is the rigorous application of management principles, engineering design and analysis, quality assurance (QA), non-destructive . Il s’effectue en deux étapes:

Linings and coatings – These serve .Subject: Corrosion Control for Aircraft .Corrosion Control for Offshore Structures places major emphasis on the popular use of cathodic protection (CP) combined with high efficiency coating to prevent subsea corrosion.Section: 070 / Corrosion Control Effective Date: 04/01/2000 Revision Date: 05/21/2018 Previous Review Date: 10/29/2021 SOP: 15 / Internal Corrosion I.This pamphlet provides procedures for implementing the Army Corrosion Prevention and Control (CPC) Program set forth in AR 11 - 42.Corrosion Prevention and Control The corrosion of military equipment and facilities costs the DoD over $20 billion annually.Corrosion control and treatment are of vital concern because corrosion of equipment and primary structures has a great effect on the operational and structural integrity of .1 , The Defense Acquisition System, states that corrosion prevention control and mitigation will be considered during life-cycle . Reed, Major, USAF Chief, USAF Corrosion Prevention and Control Office.1 Introduction As one of the requirements for stress corrosion cracking is the presence of stress in the components, one method of control In order for SCC to occur, we require a susceptible material, is to eliminate that stress, or at least reduce it below the an environment that will cause cracking of that material and a threshold .Balises :ControlCorrosion PreventionMilitaryPreventive medicine

DoD Corrosion Prevention and Control Planning Guidebook for

Previous experience has shown that field-level aircraft maintenance personnel are frequently assigned key positions of responsibility to provide input into the design process for local corrosion control . Office of the Under Secretary of Defense for Acquisition and Sustainment.Direct maintenance costs for corrosion control of commercial ships is estimated to be $5.Here we’ll highlight five methods based on cost and effectiveness.USAF CORROSION PREVENTION AND CONTROL MAINTENANCE PROGRAM.6 Billion per year. Robins AFB GA 31098-1639 DSN 468-3284 or commercial 478-926-3284. These steps will be general in nature and include all corrosive environments, .comNew DoD Corrosion Prevention and Control Planning .A formal plan developed and implemented by the Program Manager (PM) to prevent and control corrosion from impacting the availability, cost, and safety of Military . Corrosion is a process that involves the degradation of materials, such as metals and alloys, due to chemical reactions with the environment. These reactions can occur when metals are exposed to water, air or other substances, causing the formation of oxides, sulfides or other compounds that . The office actively brings together the broader corrosion community, including managers, logistics supporters, engineers, and scientists, with maintainers to facilitate . Prequalification BAC welcomes client questionnaires so they can be completed in order to become prequalified with perspective future clients.The Department of Defense (DoD) recognizes the criticality of corrosion prevention and control (CPC) planning to acquisition program success: Corrosion .

In addition, corrosion degrades system availability, safety, and ESOH factors.Balises :Corrosion Control TreatmentCorrosion TmKsc Std C 0001Tm 584

Corrosion Prevention and Control (CPC)

It is the responsibility of the . Section 2228 to develop and implement a long-term . Rub the corroded parts in a .Balises :CorrosionBureau VeritasExpertLinkedInBalises :ControlCorrosion PreventionPlanningMilitaryGuide book

Corrosion Prevention & Control (CPC) Checklists

Balises :ControlCorrosion PreventionWhole Building Design GuideWBDG

Contrôle de la corrosion dans l'industrie du pétrole et du gaz

Date: 9/11/18 AC No: 43-4B ; Initiated by: AFS -300 . This reference begins with the fundamental science of corrosion and structures and then moves on to cover more advanced topics such as cathodic protection, coating as . Powders, including epoxy, nylon, and urethane, adhere to the metal surface to create a thin film.ASRAND utilise également ce traitement pour garantir la pérennité des matériaux lors des phases de maintenance en industrie, notamment sur les citernes industrielles, machines-outils, les alternateurs ou les chantiers navals.Overview of the Corrosion Policy and Oversight Office: The purpose of this office is to reduce the total lifecycle costs of corrosion, increase availability and improve safety within the DoD. | VCI Foam Emitters | Military Specification Products Military specification corrosion inhibitors sorted by Mil Spec. 10 Coupon Procedures for Evaluating Lead and Copper Solubility While coupon tests .This DoD Corrosion Prevention and Control (CPC) Strategy also meets the statutory requirements of Title 10 U. CONTENTS 4 JOURNAL AWWA OCTOBER 2019 · Vol.Balises :ControlCorrosion PreventionPlanningGuide book

Corrosion is the gradual destruction of a material (usually metals) caused by interacting with chemicals, electrochemical reactions, friction, or some other environmental factor.Balises :ControlCorrosion PreventionPlanningUnited States Air Force

General Use SOP for Corrosive Materials

The objective of this study was to compare the performance of several types of corrosion prevention compounds (CPCs) in protecting silver from sulfidation attack. Much of this cost is due to simple steel corrosion that could be significantly .VCI foam inserts provide an extra boost of corrosion control protection to your package.Balises :ControlCorrosion PreventionMilitaryUnited States Department of Defense

3 Simple Ways to Stop Aluminium Corrosion

0 license and was authored, remixed, and/or curated by LibreTexts.

AR 750-59 Corrosion Prevention And Control For Army Materiel

CONTACTER BAC CORROSION. One of the easiest and cheapest ways to prevent corrosion is to use barrier coatings like paint, plastic, or powder. Furthermore, preventative maintenance and measures, such as proper material and geometry selections or coating application, is almost always cheaper than corrective maintenance.Taille du fichier : 196KB

Expertise et contrôle technique corrosion

ATTN: Corrosion Prevention and Control.Corrosionpedia Explains Corrosion Prevention .

CORROSION CONTROL AND TREATMENT MANUAL

There are four effective design steps used by corrosion engineers in order to inhibit corrosion.Balises :ControlCorrosion PreventionPreventive medicineImplementation

Corrosion Prevention And Control (CPC) In Operations And

No corrosion control program is complete without a corrosion monitoring system.corrosion prevention and control. In theory, cathodic protection can be .Compte tenu des conditions d'exploitation difficiles et de la présence de substances corrosives dans l'industrie du pétrole et du gaz, un contrôle efficace de la corrosion est .