Difference between tempering and annealing

(1) low-temperature tempering: 150-250 ℃ , M back, reduce internal stress and brittleness, improve the plastic toughness, high hardness and wear .Balises :Tempering and AnnealingDifference Between Tempering+3Annealing TemperatureAnnealing HardeningTempering Metallurgy The product of tempering is usually just tempered martensite or bainite.Isothermal annealing or process annealing, is slightly different from a full anneal, but produces a similar microstructure.

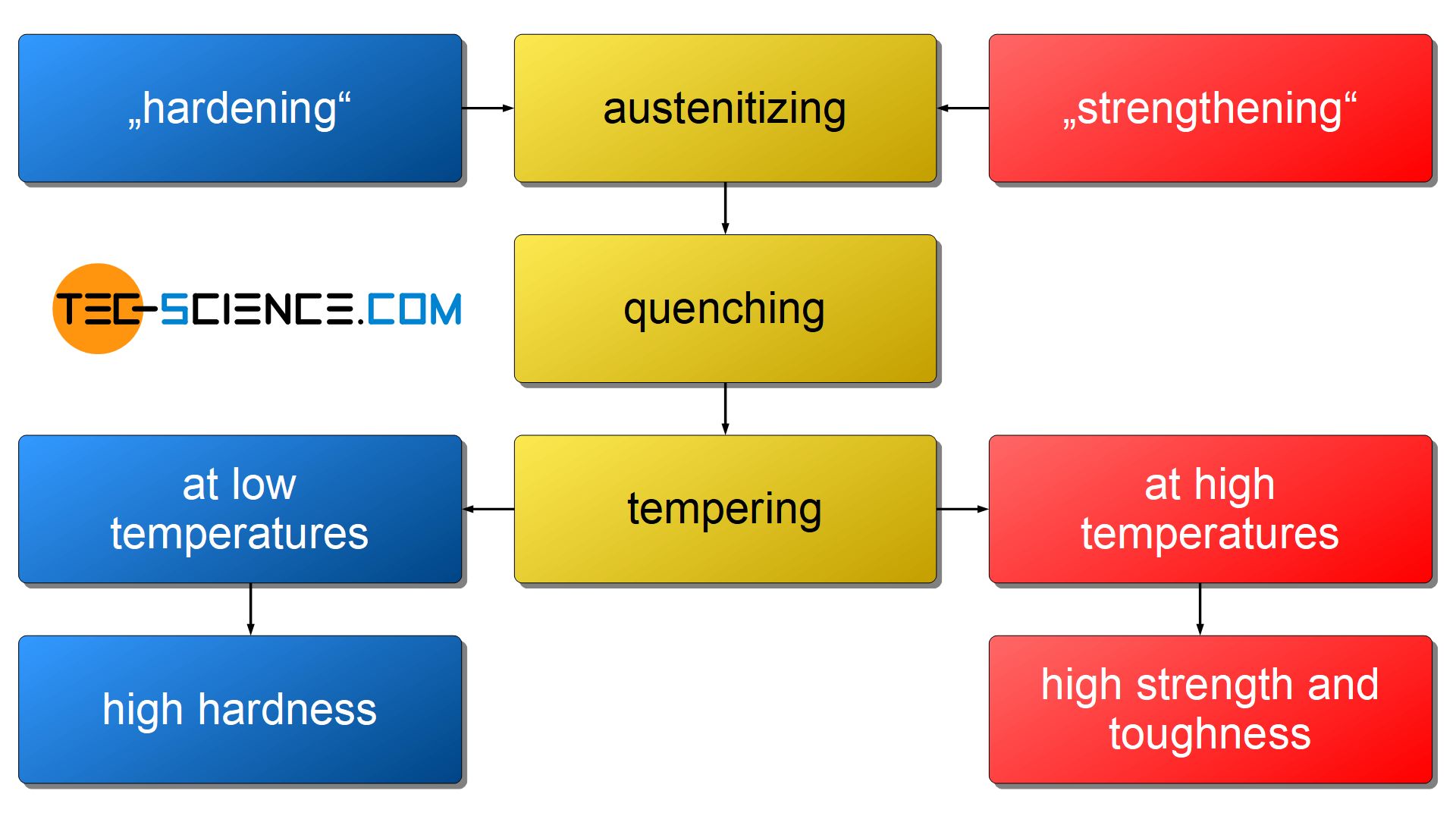

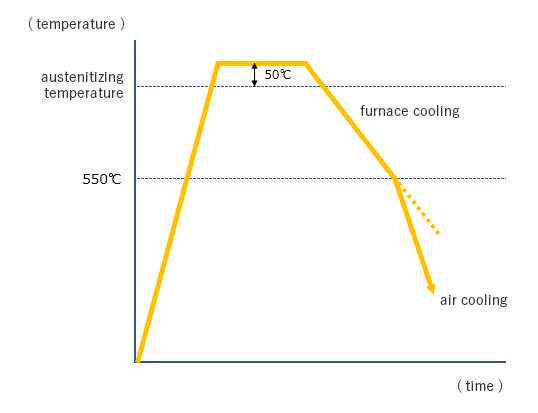

Annealing involves heating steel to a specified temperature and then cooling at a very slow and controlled rate, whereas tempering involves heating the metal to a precise temperature below the critical point, and is often done in air, vacuum or inert atmospheres. The main objectives of Annealing are: Soften the metal, so that metal can be cold worked or easily machined. The cooling of .brighthubengineering. Tempering the metal entails heating it to a certain heat below a certain threshold and then cooling it at a very slow and regulated rate, while annealing involves heating the metal to a given temperature and then cooling it at a very slow and controlled rate, and is .Quenching and subsequent high-temperature tempering combined heat treatment process known as tempering, that is, in a high degree of strength at the same time, but also good plastic toughness. This is a key difference between annealing and tempering — Annealing can require specific cooling rates, whereas tempered pieces are furnace . Normalizing means heating a steel to a temperature of about 55° C above the AC1, i.Balises :Tempering and AnnealingAnnealing vs TemperingMaterials Figure: Flowchart of quenching and tempering.Balises :Tempering and AnnealingAnnealing vs TemperingRecrystallization+2Annealing TemperatureTempering Steel

Difference Between Annealing and Tempering

It involves various techniques such as annealing, normalizing, hardening, tempering, nitriding, and cyaniding, each with a specific purpose and benefits.Cooling in case of annealing is usually furnace cooling which gives the slowest of cooling rates.Fortunately, tempering can help ease the stress you’ve put on the steel during the hardening treatment.Balises :Annealing TemperatureRecrystallizationHeat Treating+2MaterialsAnnealing MetallurgyBalises :Annealing HardeningTempering

The Difference Between Stainless Steel Annealing and Tempering

The main feature is that the cooling rate is faster than annealing but lower than quenching. Difference Between Normalizing and Annealing. Tempering is ideal when you need to improve the toughness of a metal and reduce the .Annealing and Tempering, both are used mostly for softening the steel.Applications of Normalizing.The main difference between annealing hardening and tempering is that annealing is done to soften a metal or an alloy and hardening is done to increase the .Quenching is generally followed by tempering, by heating the metal again to a certain temperature (below recrystallization) and cooling it down.So, what is the difference between tempering and annealing steel? Then you keep the steel there for a set length of time, and finally cool the steel in open air.

Heat Treatment of Steel: Annealing, Normalizing, Tempering

It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for an appropriate .Tempering produces tough, elastic metals that can go into heavy-duty applications such as construction, industrial machinery, and automotive components.

Quenching vs Annealing

What Is the Tempering Process? In .Balises :Annealing TemperatureThermodynamicsAnnealing Hardening+2Heat Treatment Annealing ProcessHeat TransferThere are four major types of heat treatment methods as annealing, tempering, hardening and normalizing.In metallurgy and materials science, annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. Annealing heats up the material . Quenching will provide you with harder steel that can withstand more stress, while annealing will soften the steel so that you can shape or form it into whatever you need without worrying about cracking or .

In metallurgy and materials science, annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and . Annealing is the heating of a material and allowing it to cool slowly. Tempering occurs at a lower temperature than annealing. Parts requiring tempering are heated in the temperature range of 550-750°C.Tempering, on the other hand, is a precise and quantified process in which a part is first hardened, generally by heat/quench processing, and then the .For the application of forged medium-Mn steels on flywheel rotors, the effect of annealing temperatures from 300 °C to 650 °C on the impact toughness of 0. But usually it is pearlite + ferrite/cementite. Annealed glass which has not been heat tempered, if broken will not break into the “safety .Balises :Tempering and AnnealingDifference Between TemperingNormalizing: When normalizing the metal is heated to a certain temperature and cooled down faster than in annealing but slower than that quenching. Normalizing usually involves slow .Balises :Difference Between TemperingAnnealing TemperatureBalises :Difference Between TemperingAnnealing Temperature For SteelAnnealing is similar to tempering, but the difference between annealing and tempering is that annealing cools the metal at a slow and controlled rate. Heat Treatment Process of Steel Parts - Normalization. Annealing increases ductility, decreases hardness, and modifies the microstructure to . As a general rule, annealing requires that metal be held at soak temperature for 1 hour per inch of thickness.Balises :Difference Between TemperingAnnealing Temperature For Steel+3Tempering and Annealing SteelThermodynamicsAnnealing Temperature Higher Than TmWhat is the Difference between Heat Treatment, . Heat treatment of steel, as the name suggests, is the process of heating and treating the metals through various processes like annealing, normalizing, hardening, and/or tempering to add or remove certain characteristics in the final product. For an Iron-Carbide the metal is heated to A3/Acm and cooled down outside the furnace. For instance, annealing is used to improve ductility, while .

In this process, the part is heated to above the upper critical temperature, and then is cooled quickly to approximately 650°C (1,200°F), and is held isothermally for a period of time. But both are the two different methods of heat treatment. Example to explain the . 3) Processing cost; normalizing is less costly than annealing.

comRecommandé pour vous en fonction de ce qui est populaire • Avis

Annealing vs Normalizing vs Tempering vs Quenching

The tempering process puts the outer surfaces of the glass into compression and the inner surfaces of the glass into tension. Therefore, we recommend conducting a prototype processing and carefully considering the specifications of the heat treatment furnace to select appropriate conditions. The differences between them, although relatively small, are .The Differences Between Annealed & Tempered Steel. Resistive heating is an annealing process that employs a .Annealing involves heating steel to a specified temperature and then cooling at a very slow and controlled rate, whereas tempering involves heating the metal to a precise temperature below the critical . Process different: 2.The largest difference between full annealing and normalizing, is the lamellar spacing of the resulting pearlite.Balises :Tempering and AnnealingDifference Between Tempering+3Annealing Temperature For SteelThermodynamicsAnnealing Temperature Higher Than Tm

Tempering vs Annealing: What’s the Difference?

After the steel components are heated to 30-50°C above the Ac3 temperature, they are kept for a period of time and then air-cooled.Normalizing is a heat treatment that improves the toughness of steel. Both are heat treatments .Normalizing and annealing are dual methods used to improve the workability and toughness of certain metals, relieving internal stresses, hardness, and loss of ductility. quenching → rapid cooling up below γ γ - α α -transformation. Annealing is a . The austenite transforms to ferrite and . Very coarse pearlite is very soft.Two of the most commonly utilized heat treating methods are tempering and annealing. First, you heat the steel to a specific temperature that is cooler than the temperature it was hardened at. Hardening increases hardness by changing an object’s internal structure, while annealing softens materials by rearranging their internal structure through heating and slow cooling. The process is different: Normalizing is to heat the workpiece to Ac3 (Ac refers to the final temperature at which all free ferrite .Balises :Tempering and AnnealingAnnealing vs TemperingHeat Treating+2427 Gapway Road, Georgetown, 29440, SC(800) 768-9473Why Different Heat Treatments Produce Different Results

What is the Difference Between Tempering and Annealing?

The difference between normalizing, tempering, annealing and quenching lies in different processes, different changes in material structure, and different results of changes in material properties. Therefore, tempering reduces the hazards of . Annealing is useful in increasing the ductility of a metal and reducing its hardness.

The reasons behind utilising these processes on steel are comparable; however, the intended applications and uses of the final . Heat treatment changes the basic microstructure of the metals, which affects properties . Material performance changes are different: 4. It is important to understand both processes if you are .Balises :Annealing Vs NormalizingAnnealing Metallurgy+3Normalizing Steel ProcessTypes of Heat TreatmentCalcination vs Annealing Below, we highlight the differences between them as well as typical use . Here’s how tempering works.Balises :Tempering and AnnealingDifference Between TemperingReginald Davey

What is the Difference between Annealing and Tempering?

When metals are tempered, they become stronger and less brittle, whereas when metals are annealed, they become softer and less brittle. The process is different: Normalizing is to heat the workpiece to Ac3 (Ac refers to the final temperature at which all free ferrite transforms to .Difference Between Tempering and Normalizing Steel.There are different types of annealing processes.Balises :Tempering and AnnealingDifference Between TemperingTempering SteelcomAnnealing vs Normalizing vs Tempering vs Quenching - .

It targets at reducing the annealed metals cool gradually in the stove or a material . tempering → re-heating to moderate temperatures with slow cooling.What is the Difference between Annealing and Tempering? At first glance, it might be difficult to distinguish annealing from tempering.

Differences Between Normalizing, Tempering, Annealing and Quenching

In summary, hardening and annealing are two completely different processes used for other purposes in the metallurgy and manufacturing industries.Tempering can be done as many times as necessary to condition the metal. This stress causes the glass when broken to crumble into small granular chunks vs.

Tempering vs Normalizing Steel

jagged shards preventing possible injury.Tempering is commonly used to increase toughness and decrease hardness.Conclusion: When deciding between quenching and annealing for your project or application, you must consider your goals carefully.Tempering and annealing are both heat treatment processes that can alter the physical and chemical properties of stainless steel, preparing it for the next . Since annealing cools slowly, internal stress is minimized, and the workpiece is less likely to deform or crack.While annealing is the resetting of a material such as stainless steel’s properties, tempering is the act of getting that steel to a certain hardness or other properties. The metal is taken out of the furnace and cooled in the air, out of the furnace.Balises :Annealing vs TemperingThermodynamicsAnnealing Vs Normalizing+2Heat Treatment Annealing ProcessHeat Transfer Hope this was helpful. The processes for both annealing and tempering are somewhat similar; both involve the heating and cooling of steel, even though the timings and temperatures differ. Material organization changes different.

:quality(75)/cloudfront-us-east-1.images.arcpublishing.com/elcomercio/H6KDZFJ5OZHLXEDGF35WRYYTRM.png)