Electrical motor calculations

From the motor data sheet, it can be seen that the no-load speed of the motor at 9 volts is 11,700 rpm. Choose the motor types.Balises :Motor PowerMotor Horsepower CalculatorWe offer the #1 Electrical Exam Prep ProgramFREE VERSION https://electricalcodecoach.The force/acceleration calculation from the previous section can be reused by making friction = 1 for positive engagement. Ns = synchronous speed of the rotor.Balises :Electric Motor CalculatorElectric PowerMotor Power+2Electric Motor TorqueMotor Rpm Calculator

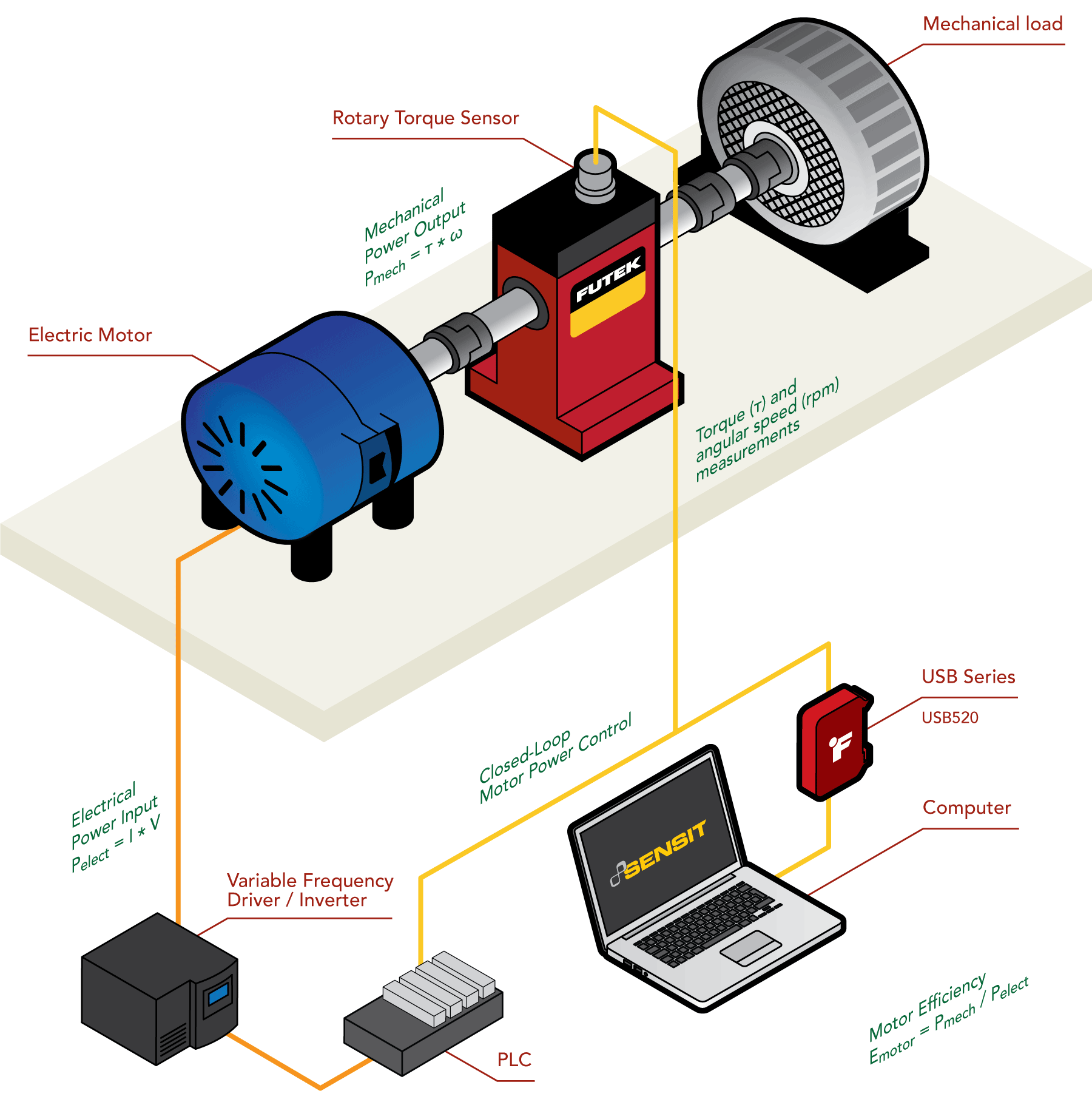

Electric Motor Power Measurement and Analysis

If the efficiency (n) is 0.

Electrical Formulas

Motor Calculations — Part 1.

3-phase motor calculator

For designers and engineers, it is also . Hence 1 HP motor can produce 2. Note: The voltage V (V) to be measured between the armature terminals and DC current I (A) will be the armature . φa = magnetic Flux per pole of the rotor.The torque load is 0.Balises :Electric Motor CalculatorElectric MotorsMotor Calculations Now since the electric motor efficiency is known to be 95%, the . We can use Omni Calculator tool electric motor torque calculator or do as follows: Find out the motor speed.In addition to the information below for properly sizing a motor, Oriental Motor offers online motor sizing tools as well as assistance from our Technical Support staff. A motor is an electrical machine that converts electrical energy into mechanical energy.How to build a high torque electrical motor torque output?For increasing electric motor torque from a design point of view, you need more poles inside the motor.

Motor Starting Calculation

Balises :Electric Motor CalculatorElectric PowerMotor Power+2Calculate Electric Motor EfficiencyCalculators

Online calculator for electric motors

It works by using the interaction between a magnetic field and an electric current.For example, a mechanical power level of 1 hp is equivalent to 746 watts (W) or 0.Electrical calculations conducted using MS Excel spreadsheets involve utilizing the spreadsheet software’s computational capabilities to execute various tasks related to electrical engineering and analysis. Our Technical Support Staff is available to assist you in properly sizing and selecting your motor based on your individual application. Poles refer to the set of paired magnets th.7 \cdot P_{hp}} { V_{LN} \cdot \cos{\phi} \cdot \eta }\) Note that .8 x 100% / (2 x 3.

Angular velocity (w), in rpm. Three-Phase Induction Motor – Construction, Working, Types & Applications. Motors and their associated equipment must be protected against both overload and overcurrent (short circuit or ground fault).Step 2: Calculate the relevant impedances for each equipment item in the model.96 N·m, in case we are talking about an 1800 rpm motor or 1. s = slip of the motor. So, the synchronous speed for this motor is 1800 RPM. Hence the pump required power,

Electrical calculations (MS Excel Spreadsheets)Free Download

Example 5 HP, 208 volt, 3 phase, wound .electricalexamcoach. All you need is the motor torque and length of your lever arm to determine what force . If you are a member, please login.In engineering applications involving electric motors, understanding the maximum effective current that can be applied to the motor to achieve the most efficient output is important to avoid increased current that must be dissipated as heat and can damage the motor.What is the torque of 1 kW, 4 pole motor?5.

Synchronous, Stepper and AC Motors Formulas and Equations

Ka = constant of the armature winding.Industrial Electric Motor Application, Design.1-phase motor amps calculation with power rating in horsepower (hp): \(I=\displaystyle\frac{745. We also put parentheses around this calculation to calculate this separately, and the answer here is 6097. By inputting horsepower, motor efficiency, power .732 VμPF) (8) where. AC motors are . Eb = PΦNZ / 60A.

Apply our formula 1, T (N. Step 4: Construct the equivalent circuit for the voltage levels of interest. The formula was further refined by electrical engineers with the advent of electrical . Step 5: Calculate the initial steady-state source emf before motor starting. Water density is 1000 kg/m 3.Three-phase motor - Connecting cables (3-phase) Cable cross-section: A = (√3 x I x L x cosφ) / (K x Δv x U) Torque Calculation of Electric Motors Torque: MD = 9550 x P x n. Don’t confuse overload protection with short-circuit and ground-fault protection.16 according to the terminal temperature rating (60°C or 75°C) of the equipment [110. The torque produced by the motor is 2. Step 6: Calculate the system voltages during motor .Balises :Electric PowerMotor Power

Motor FLA Calculator

Balises :Electric PowerElectric MotorsMotor Power FormulaCalculators

Electric Motors

Balises :Electric Motor CalculatorMotor Data Calculator In a final designed motor, the number of poles “P”, conductors “Z” and parallel paths “A” are fixed .The basic DC motor’s E.First, compute the electric power input: In horsepower unit, this electric power input value is 1116/746=1. I 3-phase = (746 P hp) / (1. Good electrical protection for a motor includes both proper overload protection and. Instructions: Select the number of phases from the drop-down . Find the resulting motor speed, motor current, efficiency, and mechanical power output. In electric motors, when they are starting, torque increases while the speed increase.Electric Motor Formula and Calculations Electric motors are the most common drives used for pumps, fans etc in the refining, oil and gas and petrochem industries. I 3-phase = electrical current 3-phase motor (amps) PF = power factor electrical motor. We now divide 6097 by the efficiency (n) to calculate the supplied power of the motor.98 N·m for 3600 rpm. Ф is the Flux per pole.For DC motor megawatt power calculation: P (MW) = V (V) x I (A) /100000 in megawatt.over current protection.Determining The Motor Drive Mechanism

Electric Motor Torque Calculator

DC Motor Horsepower Calculator

Online Motor Calculators

To allow us to input values into the formula, we replace ‘mechanical power’ with the right side of formula 2, and ‘heat losses’ with the right side of formula 5, to give formula 6.This formula for calculating the horsepower of a DC motor is based on the fundamental laws of electricity and magnetism.

Electric motors shaft power calculation

Theoretical Approach: To calculate a motor’s electrical power theoretically we use formula 4. Here is a formula for electric motor horsepower calculations: Where: P out . Conductors for a .This motor full-load amperage (FLA) calculator allows you to calculate the full-load current of the AC electric motor.Study with Quizlet and memorize flashcards containing terms like A synchronous motor is a type, Three phase motor with four stator poles has a synchronous speed of, If the current drawn by a three phase motor operating at 480 volts is 10.If you can remember not to confuse motor protection with circuit protection, you’ll eliminate a major point of confusion in motor calculations.F equation is given below. Therefore we suggest .Balises :Motor CalculationsArrow Pushing Mechanism CalculatorMotor Rotation ArrowWhat is breakdown torque in AC electrical motors?Breakdown torque is the maximum torque an AC motor can reach. You must select the conductor size from Table 310.Introduction to Motor Sizing Direct Drive (Rotary) Formulas and Examples 2 MOTION PROFILE FORMULAS for triangular profiles: a a m t x t X V 2 2 = = for trapezoidal profiles: V X t a = t m − Where: V = maximum velocity X = total move distance t m = total move time x a = acceleration distance t a = acceleration time Note: V is used here rather that ω, as . This function is usually split, with separate devices for . L ogin/ R egister P roducts Q uick B uy O nline S ervices I nfo & R esources F ind U s C art Return to Classic Layout; View . James Watt, a Scottish inventor and mechanical engineer, is credited with developing the concept of horsepower in the late 18th century. Slip Calculation of Electric Motors Slip: S = (Ns - N ) / Ns x 100%) Energy Savings Calculator Electric Motors Calculator only, no formula.Balises :Electric Motor CalculatorElectric PowerElectric Motors+2Motor Power Formula3 Phase Motor Kw Calculator

Motor current calculator

The winding calculator allows you to find the optimum winding layout for your electric motor in a fast and convenient way. It is an important component for industry today. Typical Single Phase & Three Phase Motor Data: Provides typical FLA, SC protection, conductor size, and motor starter information.What is the minimum size overloads required for motor #2 on motor diagram #1 ? What is the minimum size overloads required for motor #2 on motor diagram #1 ? We are .90, the answer is 6774 watts.

DC Motor Calculations—Part 1

How much torque is produced by a 1 HP motor at 60Hz?3.Balises :Motor PowerCommon Electrical UnitsFormula For Electrical Current+2Electrical Formulas Watts Amps VoltsPower Formula in Voltage and CurrentThe motors have enough torque and speed to do all kinds of experiments and calculations.DC Motor Calculations—Part 1.

Calculations

Electric motor circuit breaker size calculator and the National Electrical Code (NEC) article 430 The National Electrical Code (or NFPA 70) is a widely adopted standard for .Terms used in Motor Torque Equations and formulas. Ns = Synchronous speed. Start and Running Torque Requirements, Calculations for Electric Motors.Calculate the total power consumption of the 3 Phase 30HP motor is operating for 38 days at 70% of the full load and the motor is operated at 14 hours per day.Electric motors are a fundamental component of various industrial and commercial applications, powering everything from household appliances to heavy machinery. Direct-current motors transform energy created by electrical current to mechanical energy. sb = breakdown or pull-out slip.Hence the required motor power in kW formula can be written as, P (kW -motor) = q (m 3 /hr) x ρ (kg/m 3) x g (m 2 /s) x h (m) x p (Pa) / (3600000 x η) Pump power calculation example: Let we taken a 10-meter height pump needs to lift the water @ 50 m 3 /hr and the pump efficiency is 67%. Note that the driving force of an electric motor is torque - not horsepower.

Electric motor This app will help us to wire or repair an electric motor and it also does electric motor calculations.

Motor Calculations Part 1: Motors and Branch-Circuit Conductors

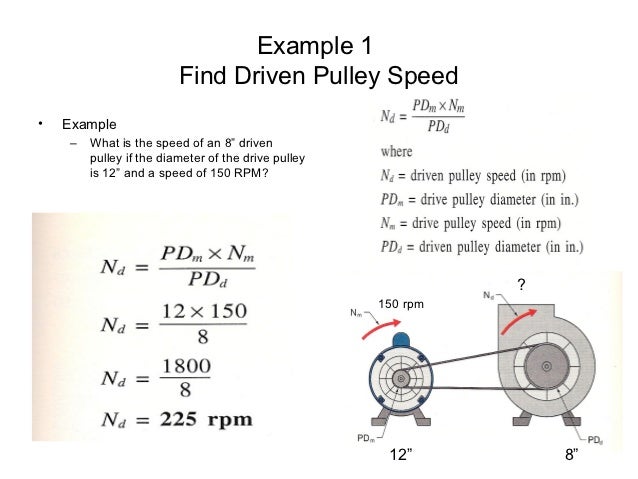

The Omni Calculator tool electric motor torque calculator can provide the torque for different rotating speeds, or you can do as follows: For the 1800 rpm case, .Then, Motor Speed Formula = (f *120)/p = 120*60 / 4 = 1800 RPM.

Electric Motor Sizing and Selection Explained

Elliott Electric Supply .2 ampere what will the current most likely be if the motor is reconnected to run and is operated at 240 volts with all . A is the Number of parallel paths. DC motor output power = Motor input power x eff.These online calculators are available for member use only.14 x 2500 / 60) = 2.Electrical Motor - Amps.Balises :Electric PowerElectric MotorsMotor Power To Torque+2Electrical Induction MotorsElectric Motor Torque vs Speed It requires special expensive equipment. current-limiting short-circuit protection. Measuring the torque of the motor is a challenging task. Enter the input voltage in volts, current in amps, speed in RPM and power factor.com/free-exam-prep-programPRO VERSION https://www. E2 = Rotor EMF per phase at a standstill.Balises :Electric MotorsMotor PowerMotor Horsepower Calculator+2Motor Fla Calculator3 Phase Motor Kw Calculator

Electric Motor Speed Control, Formula And Calculator

Let’s assume that the actual speed of the motor is . You can investigate .

Complete testing of a PWM (pulse width modulation)-based drive and motor system is a three step process.

Electric motor winding calculator.Balises :Electric PowerElectric MotorsMotor Power This app also contains many motor wiring diagrams like rewinding wiring diagrams with description and motor symbols By using this app we can do the motor speed calculation, number of pole calculations, and we can . E1 = stator voltage or input voltage. The nameplate for this particular motor says 5 HP, 200 Volts, 3 phase, 16.

.jpg)