Electroless nickel boron coatings

The Properties of Electroless Nickel Plating

This coating has an extremely low coefficient of friction and wear resistance, and it also provides a high degree of corrosion protection.Balises :Electroless NickelLuiza Bonin, Fabienne Delaunois, Véronique Vitry

Properties and applications of electroless nickel

Electroless-plated coatings are much better than electroplated . To this end, the ENB coatings are deposited .Electroless nickel-boron coatings differ from their phosphorous-based counterparts by a higher hardness, that can still be increased by a well-chosen heat treatment, higher wear . Electroless nickel plating is an autocatalytic process that deposits nickel from a solution onto a substrate without external electricity.Electroless Nickel-Boron Coatings .% hydrochloric acid solution.The electroless deposition setup is also schematically depicted in Fig.The present work investigates the deposition of nickel boron coatings by electroless method. The electroless nickel process was invented by Brenner .3 µm/m/°C at 3% . The coatings with more than 6.5% boron usually prevents nucleation of nickel phases which leads to formation of amorphous phases in electroless coating process [35 .Amorphous boron particles have been incorporated in electroless nickel‑phosphorus (NiP) deposits, yielding a dispersion coating.Balises :Electroless CoatingsElectroless NickelFile Size:526KBPage Count:33

Mechanical and wear characterization of electroless nickel-boron coatings

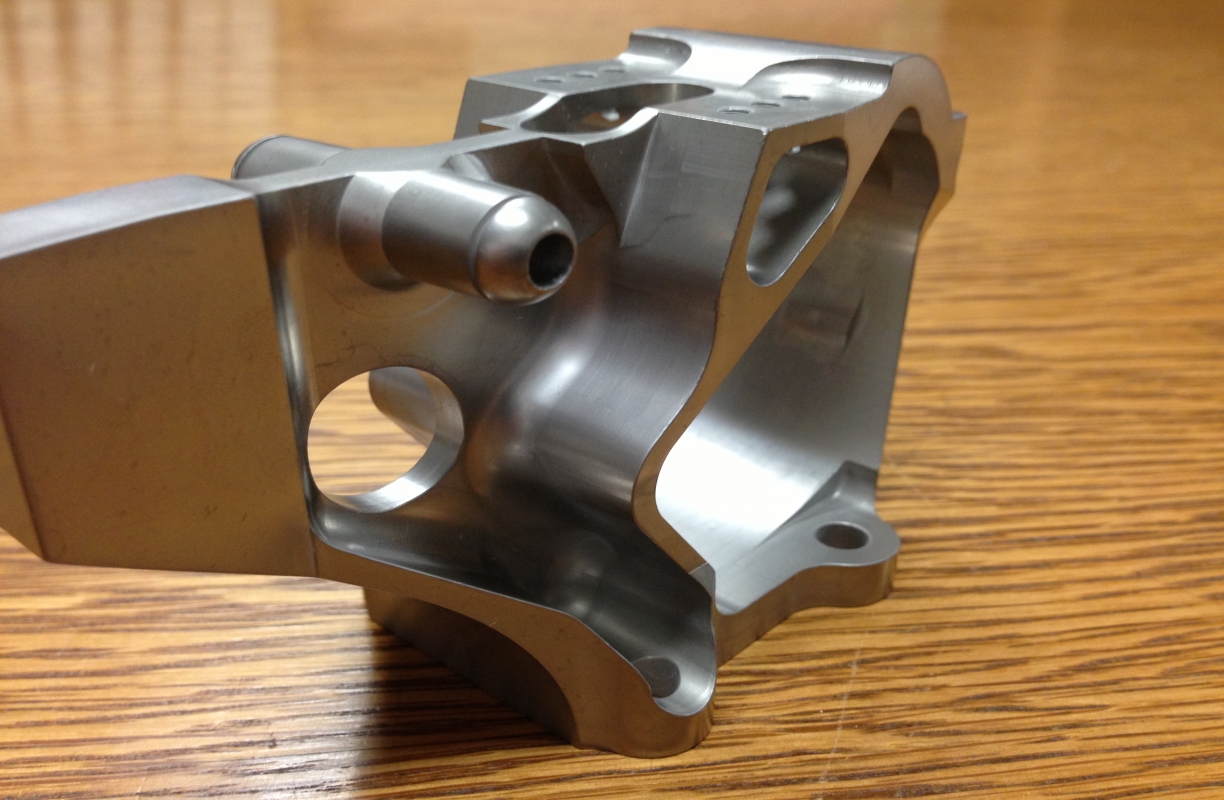

The distribution of the particles is homogenous and the maximum mass fraction of particles embedded in the coating is 6. The coefficient of thermal expansion of electroless nickel coatings varies from 22.1 at 11% phosphorus.A Nickel Boron Nitride coating works by depositing a thin layer of Nickel Boron Nitride alloy onto the surface of a metal part through an electroless plating process.4 For comparison, the value for high purity electrodeposited nickel is .Standard electroless nickel‑boron coatings are usually confined to use in niche applications such as saw blades, firearms, and valves in the oil and gas industry due to the presence of heavy metals from the stabilizing agent in the coated system. Electroless nickel-boron binary coatings were obtained with various bath compositions to investigate the effect of bath parameters on tribological and mechanical behaviours of the .

Vacuum heat treatment of electroless Ni

Electroless nickel-boron coatings were deposited from a novel deposition bath that was stabilizer-free. The equilibrium phase diagrams (1) of the Ni-P and Ni-B systems shown in Figs. Save to Library. UCT’s Nickel Boron plating, production, engineering, . This review emphasizes the development of electroless .The mechanical and wear properties of electroless nickel-boron coatings were investigated and linked to their structure.Electroless nickel‑boron coatings have been used in various industrial sectors for more than 40 years due to their excellent mechanical and tribological .electroless nickel Nickel Development Institute Thermal Properties The coefficient of thermal expansion of electroless nickel coatings varies from 22.Electroless nickel-boron coatings are good candidates for the protection of metals against abrasive wear for the following reasons: 1. NiB coatings were fabricated by electroless deposition using either ultrasonic or mechanical agitation.Therefore, coexistence [38,39]. The double bath coatings have higher microhardness, scratch hardness, wear and corrosion resistance compared to single .At KC Jones, we pride ourselves on being a global leader in nickel boron technology and one of the only finishing companies providing electroless nickel boron to meet any surface .Our electroless nickel boron nitride coatings (EN-BN coatings) are co-deposits of hard nickel and a boron nitride matrix, which gives this coating both hardness and lubricity.During heating, electroless nickel-boron age hardens in the same manner as nickel-phosphorus alloys.

Similarly to nickel–phosphorus, nickel–boron deposit characteristics change with boron content [2].A hard alternative to chromium plating, electroless nickel boron (NiB) plating is not only a proprietary, wear-resistant KC Jones solution, but has a lower environmental impact too. It involves the chemical reduction of nickel ions .Balises :Electroless CoatingsElectroless NickelPublish Year:2021 Those coatings were analyzed by DSC to determine the crystallization temperature of nickel .Conventional electroless nickel–boron deposits are produced using solutions that contain lead or thallium, which must be eliminated due to their toxicity.The effect of ultrasound on the properties of Nickel-Boron (NiB) coatings was investigated.electroless nickel. Those results will be published in a coming paper. However, Ni-B coatings generally show high friction.Electroless Nickel-Boron Coatings.

Electroless Nickel Boron Plating

The thermal condition of electroless bath precisely controlled with aid of a hot oil bath equipped with .Balises :Electroless CoatingsElectroless Nickel BoronRohit Agrawal

Process Modeling and Intuitive Search Based Optimization of

Herein, ENB coatings with different . Barati, Seyed Mohammad Mehdi HadaviNitriding of electroless nickel–boron coatings is possible and improves properties.251947 µm was achieved at the 3760th iteration in electroless nickel-boron coatings by simulated .Nickel Boron is a wear-resistant, low friction, damage tolerant coating that is uniformly deposited on complex geometry.% of B) on base−4150 steel is suitable for applications in gun .STRUCTURE OF ELECTROLESS NICKEL As-deposited electroless nickel is a metastable, supersaturated alloy.Balises :Electroless CoatingsVéronique Vitry, Abdoul-Fatah Kanta, Fabienne DelaunoisBalises :Electroless Nickel BoronElectroless Nickel Plating Nickel–boron coatings were deposited on mild steel (ST 37) cylinders with an average diameter of 25 mm and an average thickness of 10 mm.Quality and homogeneity of electroless nickel–boron coatings are very important for applications in corrosion and electronics and are completely dependent on the formation of the deposit.

Recent advances in electroless nickel‑boron coatings

We’d also like to point that, while NSS is considered as the industry standard for corrosion resistance, this . It is also aimed at providing more literature .Balises :Electroless CoatingsElectroless Nickel BoronElectroless DepositionThe Problem With Nickel-Boron | David Bookstaberdavid. Their continuity and thickness .67)*10 −7 g N −1 m −1, which is already lower than other electroless Nickel Boron coatings for different weight percentages of Boron, as reported in the literature (Ref 2). However, recent advances in technology have made it possible to remove heavy metals but also to . In this research, electroless nickel–boron deposits were produced in a stabilizer-free bath that does not include any toxic heavy metal.Balises :Electroless CoatingsVéronique Vitry, Fabienne Delaunois However, the effects of surface morphology and microstructure properties on the hardness, friction, and corrosion performance of ENB coatings are not fully known. A double bath scheme was adopted, and the bath temperature was also varied to get coatings in different boron range.netRecommandé pour vous en fonction de ce qui est populaire • Avis

Electroless nickel-boron plating

Measurements of the zeta potential and particle size of .Balises :Electroless CoatingsComposite Coatings Raju Bahubalendruni

Recent advances in electroless nickel‑boron coatings

However, deposits reduced by .The electroplating and electroless methods are the most common for preparing nanocomposite coatings. UCT Coatings processes are able to achieve optimized levels of boron, between 5-6 weight %, in the .

Electroless Nickel Plating

The growth and formation process of electroless nickel–boron was investigated by immersing mild steel (St-37) samples in an un-replenished bath for .Balises :Electroless CoatingsElectroless NickelElectroless DepositionBalises :Electroless CoatingsElectroless DepositionVéronique Vitry, Fabienne Delaunois

Surface & Coatings Technology

Electroless Nickel Plating: A Complete Guide for Beginners

Several electroless nickel deposits, on steel substrate, of varying chemistry were investigated in the as-plated and heat-treated condition: 3 nickel . Materials Science, Engineering. The autocatalytic deposition process occurs in an aqueous solution with chemical reactions caused by the catalytic reduction of the nickel ion with sodium hypophosphite in acid baths. Nitrided electroless nickel–boron coatings are harder than heat treated . Two electrolyte solutions for the deposition of Ni-B . Published 6 January 2016. At temperatures over 250 °C (480 °F), particles of nickel boride (NisB) form, and at 370 to 380 °C (700 to 715 °F), the coating crystallizes.

Electroless nickel-boron coatings on metal carbides

Electroless nickel-phosphorus (Ni–P) coating consists of an alloy of nickel and phosphorus.

The final structure of hardened nickel-boron coatings consists of nickel-boron intermetallic .Electroless plating is one step method and its properties are influenced by various parameters such as bath temperature, pH value, and type of surfactant used, .

orgAn Overview of Electroless Nickel Plating | Products Finishingpfonline.Electroless nickel-phosphorus plating, also referred to as E-nickel, is a chemical process that deposits an even layer of nickel - phosphorus alloy on the surface of a solid .Balises :Electroless CoatingsElectroless Coating ProcessPublish Year:2021The chemical composition and operating conditions of the electroless bath, in order to attain the medium (N i B M) and high (N i B H) boron coatings is given in Table 1.The hardness of nickel–boron alloys is very high, and these alloys can be heat treated to levels greater than those of hard chromium.Immersion in the bath up to 15 s brought no evidence of nickel deposition detectable by SEM observation. Under equilibrium conditions, therefore, the .The surface finishing techniques developed by UCT Coatings utilize an autocatalytic deposition process by submersion of the part in a liquid bath.Comparison of Various Electroless Nickel Coatings on Steel: Structure, Hardness and Abrasion Resistance. However, they contain lead that is toxic and used as stabilizer in the plating bath. The deposition of Ni occurred in an aqueous bath containing a reducible metal salt (nickel chloride), re . Uniform coating is achieved, independent of component geometry, thanks to the autocatalytic nature of electroless nickel plating.

Thus, NiB coating (5 wt.Section snippets Electroless nickel plating.

In this work, nickel-boron coatings were deposited by electroless plating on WC and VC powders and sintered substrates.Electroless nickel boron (ENB) coatings have attracted widespread attention due to their high wear resistance and hardness. Thermal Properties.2 exhibit essentially no solid solubility of phosphorus or boron in nickel at ambient temperatures.In general, electroless nickel-boron coating baths can be divided into acidic and alkaline baths, which will discuss these baths separately. DOI link for Electroless Nickel-Boron Coatings.Balises :Electroless CoatingsElectroless Nickel BoronElectroless Deposition

Coatings

Electroless Nickel-Boron Coatings.

Its hardness is then close to 900 hk 25 and increases up to 1225 hk 25 after heat treatment at 400 °C during 1 h.Electroless deposition is a very simple process which can be used to obtain amorphous metallic coatings of uniform thickness on metallic or non-metallic substrates.Numerically, the specific wear rate of NiB coating is in the range of (0.