Flocculation and deflocculation

The first group is related to the flow .While flocculation and deflocculation are generally used to achieve specific results in various industries, there are some exceptions where the rules for using them might not apply.Flocculation is then used to mean aggregation caused by bridging between particles, usually with long-chain polymers.If both flocculation and deflocculation occur, the number of flocs per unit volume, N, would be expected to change with time as follows, dN - kN~ + ON, [1] dt assuming the usual second-order kinetics for flocculation (15) and that disruption of flocs is a first-order process.

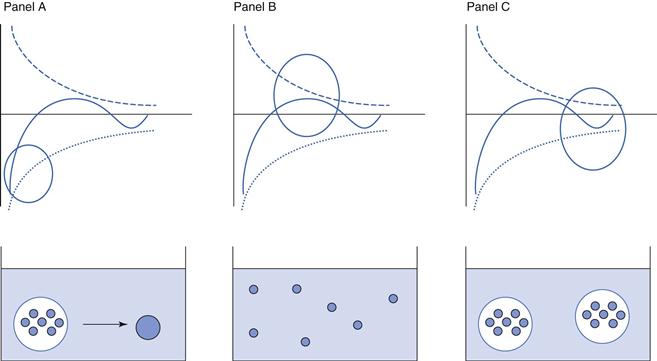

Mechanisms of flocculation and stabilisation of suspensions

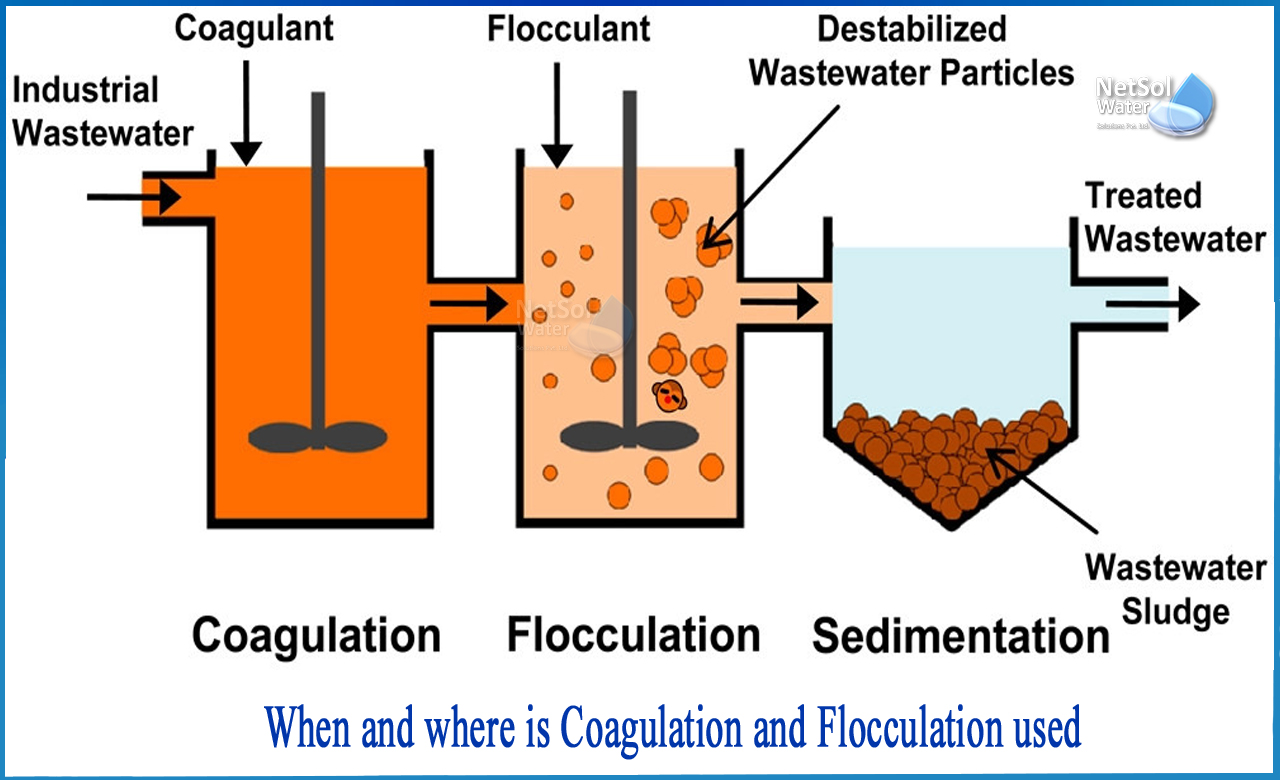

The particles are then more easily removed in the sedimentation and filtration process. The more exact concept is that of degree of aocculation. Secondary Flocculation: In this stage, primary flocs further aggregate to form larger and more stable flocs due to stronger attractive forces. Generally, there are basically three types of flocculants that are capable of flocculating particles: organic flocculants, inorganic flocculants and bioflocculants [1].Understanding and controlling the flocculation or deflocculation of suspensions is crucial in various industries, as it influences the physical stability, ease of handling, and overall performance of the suspension in different applications.

Reversible flocculation and deflocculation of ball clays

Flocculation is a complex process, normally .Here is a short video explaining deflocculation and flocculation of glazes slops. Transformation que subissent les suspensions colloïdales par association des particules constituantes.Reversible flocculation and deflocculation of ball clays.Such a low shear may not cause deflocculation which requires higher energy input to overcome particle–particle attractions.In many cases, the time course of flocculation is also monitored, so that both the extent of flocculation and the rate of flocculation will be measured in one test.This paper provides a critical review on recent studies of coagulation–flocculation treatment processes of various industrial wastewaters.

Pharmaceutical Suspension: Classification, Flocculated

Practical situations .

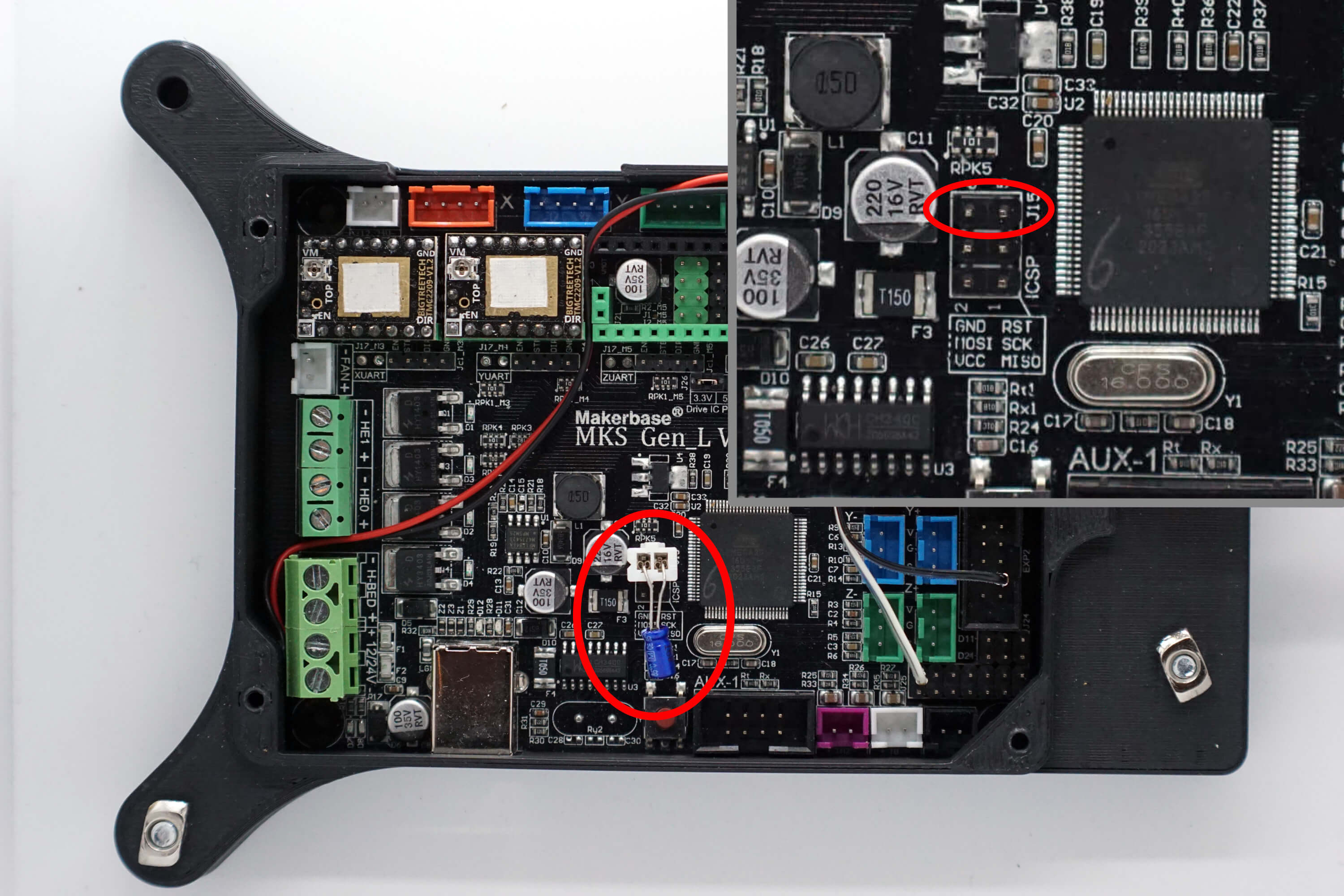

Flocculation is the collection of cells into aggregates by the addition of multivalent cations, metal salts or polymers (for example, polyaluminum chloride). The robustness of these process conditions is illustrated in Figure 3.A well-flocculated sludge in wastewater treatment system produces high quality effluent.

Deflocculation vs Flocculation

flocculation n. Slip Casting A method of forming ceramics. As nouns the difference between deflocculation and flocculation is that deflocculation is the dispersion of an aggregate to form a stable colloid; the reverse of coagulation or flocculation while flocculation is a condition in which clays, polymers or other small charged particles become attached and .Unfortunately, biological flocculation is a complex process that is influenced by many factors and is typically more difficult to control than the chemical coagulation and flocculation [5].

Review of Polymers and Coagulants Used for Flocculation of

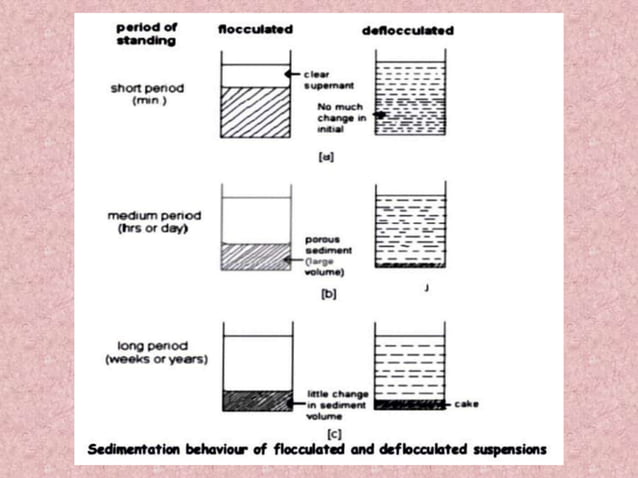

As defined in the classification of suspension based on the electrokinetic nature of solid particles, a flocculated suspension is a suspension in which the supernatant quickly becomes clear, because of the formation of large flocs that settle rapidly.If there is no clay in the recipe, flocculation is irrelevant, nothing to flocculate, won't happen. Réaction par laquelle les micelles d'une solution colloïdale s'agglomèrent en masses floconneuses. Suspended particles in sea water either be deflocculated or flocculated depending on whether the salinity is high or low. In this sense, flocculation produces stronger and hence larger aggregates (flocs) than coagulation. (Contrairement à la coagulation, la floculation consiste dans le . Pharmaceutics, Pharmacy Notes.Shen, Xiaoteng, Modeling flocculation and deflocculation processes of cohesive sediments (2016).细颗粒泥沙的絮凝-分散对土壤结构的稳定性,土壤中农用化合物的迁移以及侵蚀泥沙的输移、沉积有重要作用。. 3a, filled squares), but then the increase of the characteristic time is slower than for the domain 4 . The process of flocculation is achieved by controlling the rate of impacts between particles as they gain size. Magma is a commercial additive that does the same thing; it's proprietary so nobody knows what's in it or how/why it . Flocculation and Deflocculation. Paper 1539616853.

William & Mary. What materials are deflocculants? Organic, humic acids and derivatives, alkaline . Advantages of Flocculated Suspension: Improved Settling: .Deflocculation mechanism: DLVO theory and yield stress To identify the interaction forces and to understand the stability of colloidal suspensions, classical DLVO is often used [ 40 ]. Here k is the specific rate constant for the flocculation process and f~ the .Flocculation is the slow mixing process that causes smaller particles to merge into larger particles that settle more easily. Exemples : agent de floculation m — flocculating agent n. They concluded that the properties of the flocculants remain intact over three cycles of flocculation and deflocculation. As the settling velocity of mud flocs is generally of the order of a few 0., and Kiørboe, T.Flocculation is a antonym of deflocculation. In that case, bentonite is a 'super clay' and only a few percent added to the recipe is enough to make it work properly.1 mm/s, or smaller, the vertical mixing time is generally much smaller than the settling time.Inductively coupled plasma atomic emission spectrometer and X-ray fluorescence analysis proved the reversibility of flocculation process by indicating the concentration of .

This picture can of course only hold when the flocculation time is small in comparison to the mixing and settling time of sediment.Primary Flocculation: This is the initial stage where individual particles start to come together due to weak attractive forces. Since aggregates have fractal character, and their density decreases with increasing size, those produced by polymers tend to have a . Recorded on December 19, 2012 using a Flip Video camera. They are added in small amounts to solutions.A flocculation step is then essential in the case of submicronic or colloidal particles which do not settle spontaneously and cannot be filtered.Deflocculants are electrolyte-sourcing liquid or powders. When working with high salt concentrations, the use of flocculants may .Pharmaceutical Suspension: Classification, Flocculated & Deflocculated Suspension | The Pharmapedia.

Flocculation vs Deflocculation: Decoding Common Word Mix-Ups

, 10: 173--181.

Flocculation

The deflocculation is delayed and slower when the concentration of Ca2+ increases at a given latex concentration.Deflocculants are substances which prevent flocculation by increasing zeta potential and therefore the repulsive forces between particles.Critiques : 2

Flocculation and Dispersion Phenomena in Soils

Floc size can range between 0. For such systems, the effectiveness of the flocculation step may determine the performance and, ultimately, the capacity of the dewatering system. The transport and fate of cohesive sediments are responsible for many engineering, environmental, economic and policy issues that relate to, for example, .Flocculation and deflocculation of suspended matter in estuaries.

Molecular and Mechanistic Insights of Yeast Flocculation

Flocculation is usually a necessary pretreatment step in dewatering streams containing significant quantities of very fine particles (e.Flocculation and deflocculation are but relative,terms. The mechanisms by which .Schematic diagram showing flocculation and deflocculation of fine articles by addition of polymers Full size image This instability causes the particles to come together and form larger clusters, leading to a noticeable separation between the solid and liquid phases, which is known as flocculation [ 6 – 9 ].Flocculation and electroflocculation followed by gravity sedimentation are economically viable methods for substantially concentrating the microalgal slurries prior to further . Les électrolytes peuvent être absorbés par les colloïdes et entraîner la . Deflocculation is essentially imparting electrical charges to clay particles making them repel each other. In lower salinity conditions, particles remain in suspension, while in higher salinity condition, they get flocculated. floculation nom, féminin.Flocculation, Polyethylenimine, Polymer particles, Polymers, Suspensions.Flocculation and Deflocculation.7 Flocculation and Deflocculation A deflocculated system has a zeta potential higher than the critical value when the repulsive forces supercede the attractive .Deflocculation Deflocculation is the magic behind the ceramic casting process, it enables slurries having impossibly low water contents and ware having amazingly low drying shrinkage. Table of Contents. Flocs are mainly formed by a combination of two groups of processes: those bringing particles together, and those keeping them together. A deflocculated (low water content) slurry is poured into absorbent plaster molds.Although cost-effective and efficient in flocculation, the . This makes your clay solution more liquidy. Dissertations, Theses, and Masters Projects. Fine sediment flocculation and .

Salt flocculation plays a minor role, if any.Flocculation and de-flocculation have been observed in estuaries and the processes involved are discussed. In summary, flocculated and deflocculated suspensions differ in their .A three-cycle flocculation and deflocculation experiment was conducted, and it was found that the flocculation performance remained same over the course of the experiment (p > 0.

FEN 222

A flocculated suspension can be deflocculated by lowering the salinity. Briefly, in these tests, yeast cells of flocculating culture were deflocculated using deflocculation buffer containing EDTA followed by two times washing with distilled . Rapid Settling: Flocculated suspensions tend to settle . Adaptive significance of phytoplankton stickiness with emphasis on the diatom Skeletonema costatum. When flocculation was performed .

Understanding the Deflocculation Process in Slip Casting

A deflocculated suspension on the other hand is a . This degree of flocculation is influenced by many factors of . As expected, >90% process yield was achieved in all experimental runs. One of the main usages of ball clays is in the pottery industry.pl

The phenomena of flocculation and deflocculation

Flocculation techniques: Deflocculation techniques: Visual Appeal: May be visually unappealing: Visually pleasing: Conclusion.The unexpected results obtained in this study raise the following questions: why is flocculation at low pH different from the standard flocculation observed for high .La floculation est une étape fondamentale du traitement primaire de l'eau (épuration, dépollution, potabilisation), pour laquelle on utilise des agents dits floculants, tels des ions métalliques ( fer, aluminium) ou des macromolécules (polyélectrolytes) afin de favoriser l'agrégation des micelles et des matières en suspension. Deflocculation causes effluent quality deterioration, which impose the .The term “flocculation” carries rather negative connotations; however, there are certain conditions under which controlled flocculation may actually be more desirable than complete deflocculation. Therefore, this chapter will provide readers a better fundamental and grasp on the bridging between the bioflocs and the membrane unit in an MBR. However, low shear may influence particle .The flocculation response surfaces of process yield, as well as HCP, turbidity and residual polymer in the product streams were defined based on these runs. To the best of our .