G41 cnc code explained

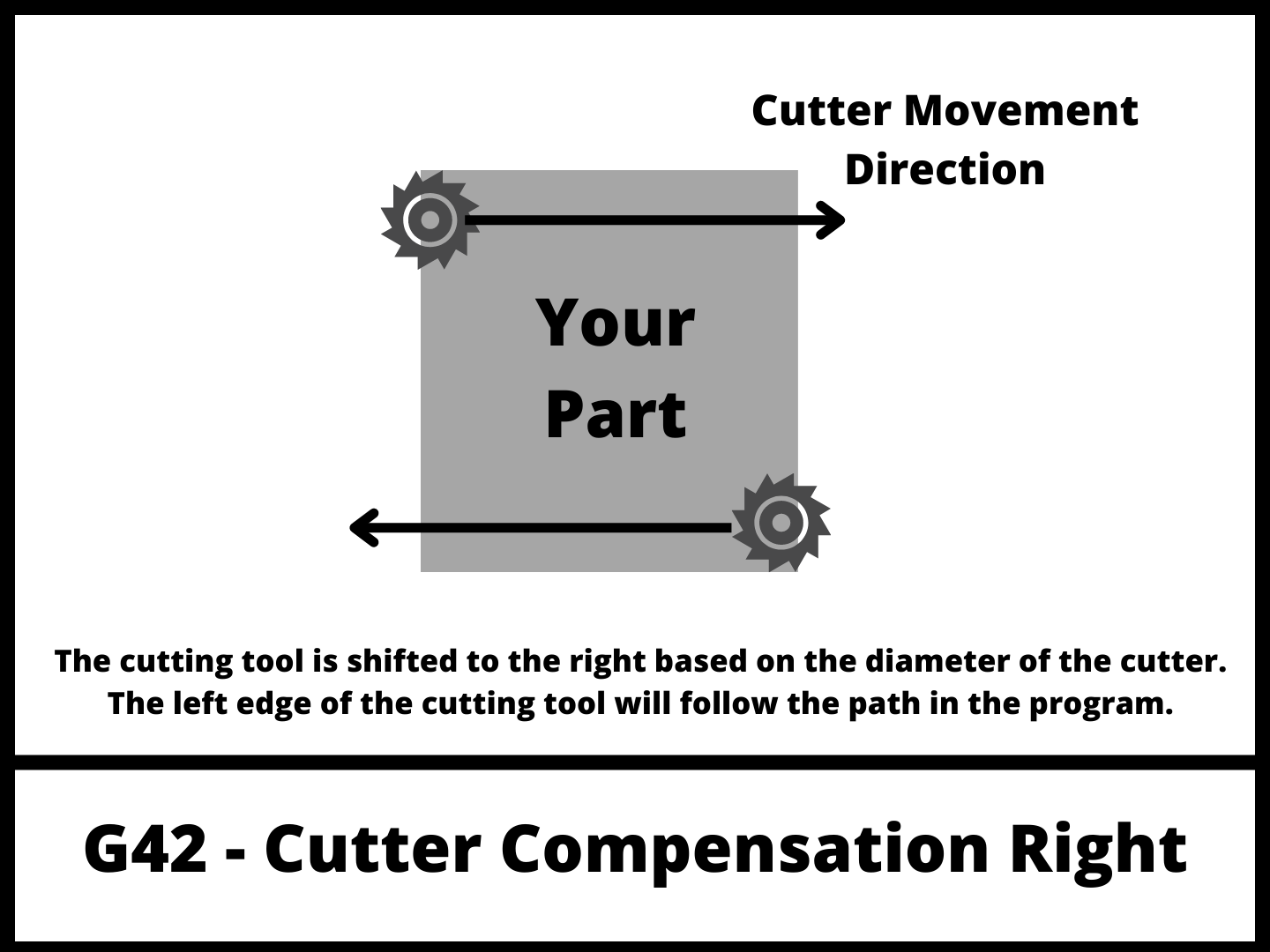

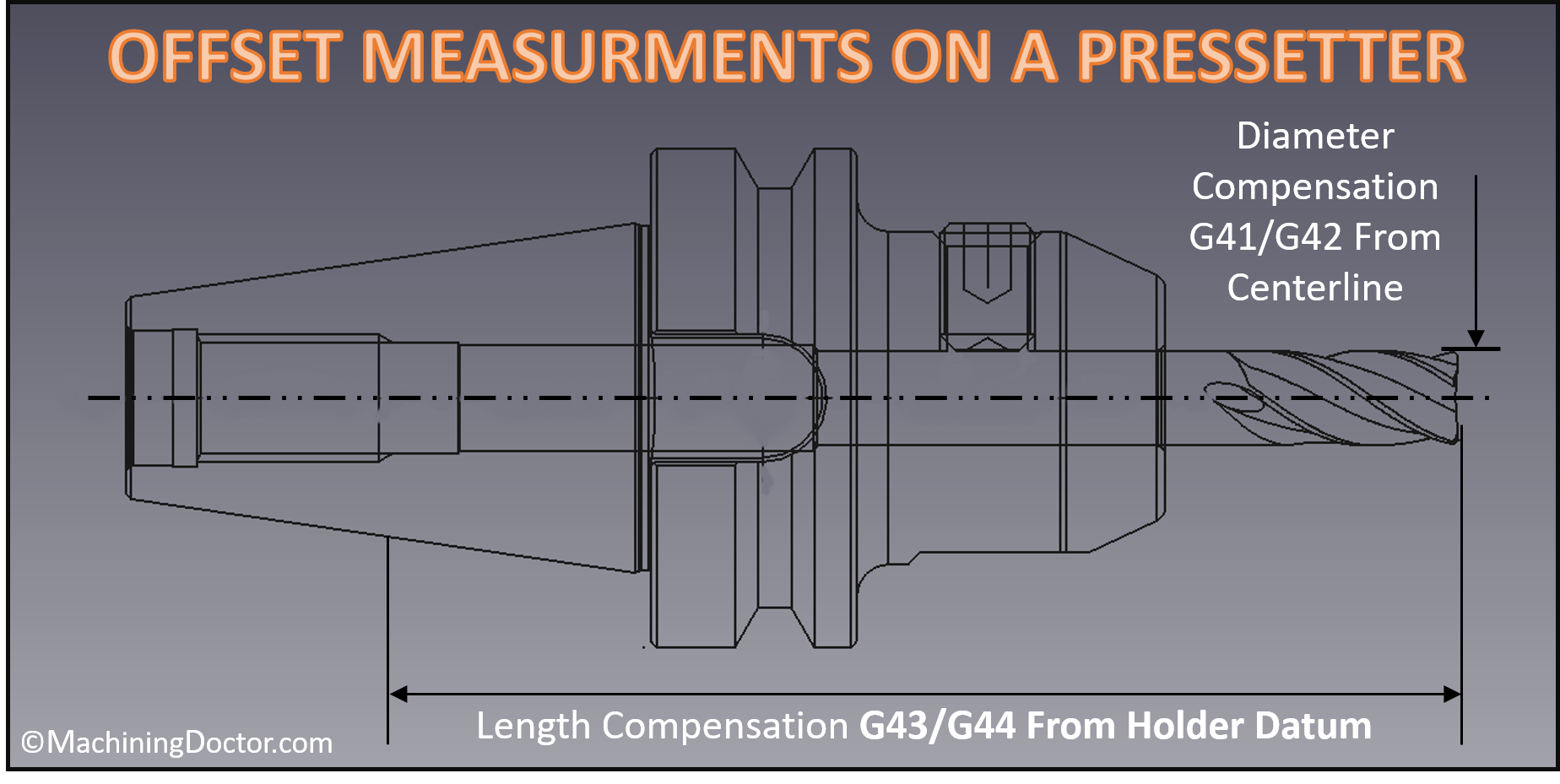

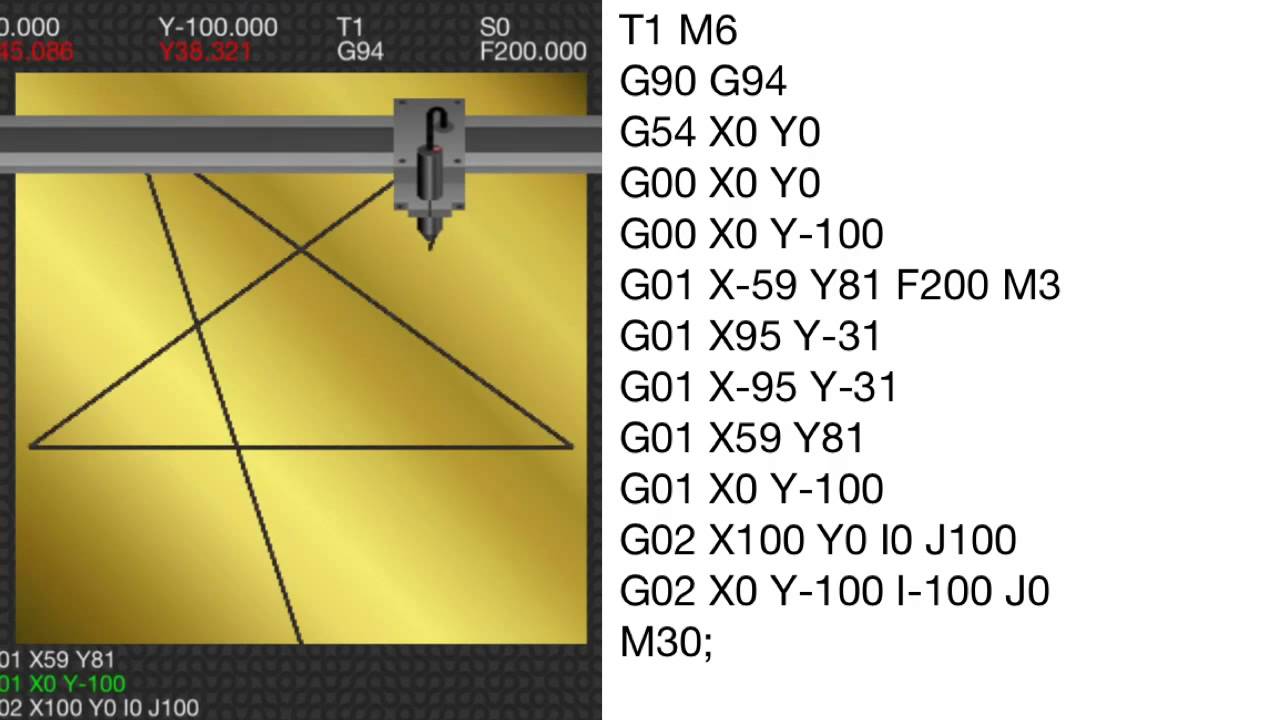

This ensures that the tool cuts the desired shape and size accurately.G41 2D Cutter Compensation Left / G42 2D Cutter Comp.Movement [G00, G01, G02, G03] One of the most frequently used group of codes is movement codes. To turn cutter compensation off, program G40. G90 – Absoluta dimensionamento. Der Zu Korrigierende Weg (Radius Des Schneidwerkzeugs) Kann. This code tells a machine to move as fast as . These are just snippets of code they are not complete programs.If you are interested in CNC programming, one of the main steps in learning G codes is to learn circular interpolation with G02 and G03. However, there are times when the cutter .

G41 and G42 Cutter Compensation

Le G-code est un langage de programmation CNC qui dirige les fonctions d’une machine CNC liées au mouvement de l’outil de coupe. The most common G codes that you’ll encounter time and time again in every CNC program include: G0 – Rapid Move. Now if you want to use G41, that's going to turn on cutter compensation to the left . Bei Der Fräserradiuskorrektur Werden Die Programmierten Werkzeugbahnen Automatisch Um Den Radius Des Verwendeten Schneidwerkzeugs Verschoben. G41 – Ativação do Cortador de Compensação de Raio.G-Codes & M-Codes Explained.Whether you are a.Explanation of CNC G-Code. Considerando que G40 é incluída, para o acabamento de todo o período de compensação. G90 : Absolute dimensioning system. Listed below are the codes that use the G word.Compensación del radio de la herramienta con G41 y G42. G00 Xnnn Ynnn Znnn Innn Jnnn Knnn ; Some CAM systems are able to output the X, Y, and Z with values for I, J, K. Cutter radius compensation is .choose between G41 and G42 in CNC code. This type of movement is called Circular interpolation. G41 is used for left-hand tool compensation, while G42 is used for right-hand tool compensation.Siemens Sinumerik 840D Sl Online-Anleitung: Fräserradiuskorrektur (G40, G41, G42). G71 is our G-Code that lets the controls know that we wish to use a roughing cycle and that the following information applies to that.G41 is a CNC (Computer Numerical Control) programming code used in machining to activate cutter compensation to the left of the programmed tool path.This feature performs three-dimensional cutter compensation. These rules help operators to use a best practice when using cutter compensation .1 - Tool Compensation Dynamic Left. F-É usado para alimentar o movimento do eixo perfeitamente. G54 : Zero Offset no.Applying cutter compensation using the GCodes G41 or G42 enables us to program the part to the same dimensions as the drawing without the need to take into c.

These codes are .

Quick Guide to CNC Compensation Modes

It is OK to turn compensation off when it is already off.

How to Calculate I J K in CNC Programming (G Code)

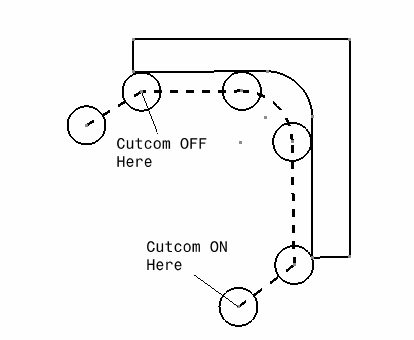

The tool must start away from the cutting edge.

G02 / G03: Ciruclar interpolation (Theory & Examples)

To turn cutter .

The I, J, and K values tell the control the .G40 is a code used in CNC machining that cancels the cutter compensation that was previously applied.G41 is left compensation and G42 is right compensation.G41 is used for left tool nose radius compensation in CNC machining.

The R refers to how far the tool will retract from the part in X when returning in rapid to the start of the cycle. For example, the is a 1″ diameter end mill.

Cutter Compensation is commanded to turn on when it is already on. Cutter radius compensation is a feature that allows the machine to adjust for the radius of the cutting . It’s an error if: A G02/G03 . G64 : Continuous-path mode. The form is: G141 Xnnn Ynnn Znnn Innn Jnnn Knnn Fnnn Dnnn.Here we will explain how to use the G40, G41, and G42 codes in CNC Simulator Pro. G00 : Rapid traverse.

Utilisation des corrections d'outil G41 et G42

What is G02 g code? Codes that begin with G prepare your machine to perform a specific type of motion. Coordinates are programmed to the tool’s cutting edge, and the controller compensates for the position according to the .L'utilisation des corrections d'outils permet d'écrire un programme d'usinage indépendant de la dimension de la fraise utilisée, c'est la CNC qui vas faire le calcul de la trajectoire de . Les machines CNC s'appuient sur ces codes car elles ne peuvent pas comprendre les langages conversationnels, fonctionnant uniquement sur un ensemble dédié de . When I originally started programming by manually writing G-Code, I used cutter comp to offset the tool by the radius.CNC machines run G code to determine the tool path for the piece work. G & M-codes will make up the bulk of your CNC program. Many times, large portions of your CNC program will be exclusively movement codes as the machine performs its cutting operations.G54 – Desvio do Zero.

G-Code circular interpolation explained

It’s okay to turn compensation off when it is already off. G17 : X-Y plan selection. Both of the examples below represent the drawing above.In this second part of the series, I will demonstrate how to use G41 and G42. For this, you need to learn some easy math that allows you to specify any arc with two different methods: with I J K, or . Compensation allows the machine to adjust how it reads the CNC G code so that the same program can be used in multiple ways. First rule: G41 (left side compensation) and G42 (right side compensation) .There are three rules to remember about Cutter Compensation commands–G41/G42.G41, G42, and G40: Cutter compensation. Write a g-code program that feeds the cutter around a 1 inch by 1 inch rectangle whose center is at 1, 1. When this code is .

CUTTER COMPENSATION (G40, G41, G42)

Now cutter compensation is activated using either the . Se debe programar una direccin D para seleccionar el radio correcto de la herramienta o el corrector del dimetro.1 (Cutter Radius Compensation) 5min.G41 and G42 are cutter compensation commands used in CNC turning. Welcome to our comprehensive guide to using the G41 CNC code. When activated, G41 shifts the toolpath to the left (or, more accurately, in the direction of the tool’s nose .

G41 G-Code Command

Il signifie « Code . Circular interpolation is a fancy way of referring to programming a circular arc with G code. answered Jul 12, 2013 at 9:44. To turn cutter diameter compensation on left (i. Las utilizamos cuando queremos indicar la compensación del radio de la herramienta en función del sentido del mecanizado.

Mastering GCode G41, G42, and G40: Tool Compensation Power

G41 and G42 are the two codes that we need to include in the program in order for the machine to calculate the cutter compensation. Left tool radius compensation.CUTTER COMPENSATION (G40, G41, G42) To turn Cutter Compensation off, program: G40. If the value in the selected offset is negative, cutter . If tool #1 is currently in the CNC spindle, calling tool #2 with the T02 command will ready it in the tool changer.G41 is a G-code used to activate the left-hand cutter radius compensation.G41 seleccionar la compensacin de la herramienta de corte de la izquierda, es decir, la herramienta se mover hacia la izquierda de la trayectoria programada para compensar el tamao de la herramienta. G42 – Ativação do Cortador de Compensação de Raio.

CNC machines need to move to cut, drill, and grind parts along with many other functions. It can use for move cnc control tool right of the countering direction.

Fräserradiuskorrektur (G40, G41, G42)

100″ to the radius for the tool’s position. Use absolute coordinates (gcode G90). S : Spindle speed.

G41 CNC Code Explained: An Easy Intro for Beginners [Cutter Comp Left] August 2, 2023 by Brandon Fowler. Redundant means repeat., the cutter stays to the left of the programmed path when the tool radius is positive . Using compensation modes allows the CNC to run the same . When using the R value with circular interpolation programming you can tell the machine to do an arc of greater than 180 deg by using a minus value before it. In this guide, we’ll .The T code is used at the start of a program to make sure the correct tool is loaded before any machining is performed. These commands are essential for machining with precision, especially when dealing with complex geometries, contours, and profiles.Cutter compensation (cutter comp), also sometimes called Cutter Diameter Compensation (CDC), provides a way to adjust the toolpath at the machine to compensate for tool size, tool wear, and tool deflection. A D address must be programmed to select the correct tool radius or diameter offset. After this initial setup, the T code is used every time the machine switches to a new tool. The new coordinate can be absolute or relative, depending on the effective mode . After completing this unit, you should be able to: identify the reasons for using cutter compensation. how to program dynamic cutter compensation when using g-code. First rule: G41 (left side compensation) and G42 (right side compensation) should be used on the first G01 . G41 : Cutter radius compensation activation (left hand side movement) G40 : Cutter radius compensation de-active. On a CNC machine, it is usually recommended to use climb milling, this needs to be taken into consideration when writing our programs and deciding which . “ - [Instructor] In this movie, we're going to be talking about cutter compensation.

Maîtriser G41 et G42 en CNC Programmation de tournage

This is called a redundant command. G41 is typically used when the cutter is on . Cutter compensation is a feature in CNC machining that adjusts the tool path based on the size of the cutting tool being used.

Try and memorize these codes while you wait for the next video.

G40 G-Code Command

The U on the first line of code is the depth of cut of each roughing pass.Cutter compensation is a common practice in machining.The tool must be positioned “off the part”.