Ge additive manufacturing center

GE Additive – part of GE (NYSE: GE) is a world leader in metal additive design and manufacturing, a pioneering process that has the power and potential to transform . This includes two Customer Experience Centers (CECs) .The M Line is more than just a single machine.

The GE9X is the largest and most powerful jet engine ever manufactured — the front fan alone measures 11 feet in diameter.

What is Additive Manufacturing

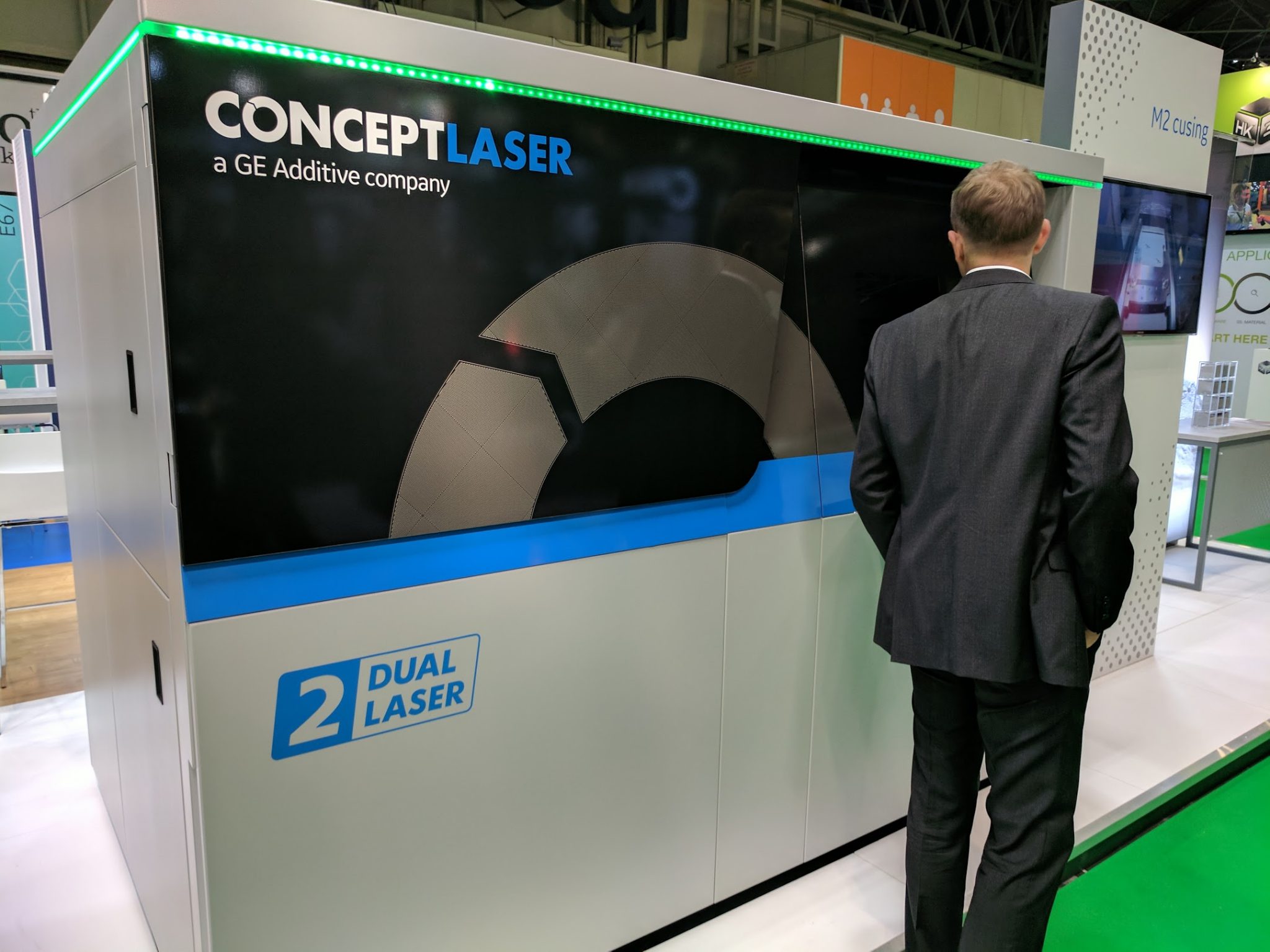

The first development engine ran in 2022 and the first . GE's Binder Jet Line could accelerate that change.GE Additive's AddWorks™ team consists of 70+ global engineers with vast experience in metal additive.Additive manufacturing—otherwise known as 3D printing—involves taking digital designs from computer-aided-design (CAD) software and building a component by laying . Munich, Germany – GE Additive has announced the opening of its Arcam EBM Center of Excellence in Gothenburg, Sweden. About Additive 101 Additive Manufacturing Process Applications Additive Manufacturing Materials . It’s louder than expected but the noise is a testament to the level of activity underway. The first development engine ran in 2022 and the first flight test engines are now scheduled to be delivered by the fall of 2023.And as a result of its achievements and progress through 2019, GA-ASI’s has placed an order for multiple GE Additive Concept Laser M2 Series 5 machines, which will be installed at its new Additive Design & Manufacturing Center of Excellence in Poway, California in 2020; adding to their already existing non-metal AM capabilities. Machines deposit material, layer upon layer, in precise geometric shapes.The Center for Additive Technology Advancement (CATA) – located near Pittsburgh in Findlay Township, Penn.GE Additive’s first international Customer Experience Center opened in Munich; The center, launched with an investment of $15 million, will employ up to 50 GE Additive employees within the 2,700 square . Through our integrated offering of additive experts, advanced machines and quality powders, we empower our customers to build .

This innovative machine features separation of the process and handling station, which ensures both safe operation of the machine and easier handling.Balises :Additive ManufacturingGe Additive

GE opens additive manufacturing center in Pittsburgh

Balises :Ge Additive Manufacturing CenterIndustrial GeBalises :Ge Additive Manufacturing FacilityAdditive Experience

GE Additive inaugurates additive manufacturing facility in Germany

Tuesday - August 20, 2019.CINCINNATI, OHIO – 17 November 2021 – Building on the earlier success and momentum of the Pacer Edge program, the US Air Force (USAF) and GE have entered Phase III of its metal additive manufacturing pathfinder.

What is GE Additive?

comRecommandé pour vous en fonction de ce qui est populaire • Avis

Where is GE Additive located?

– will be the flagship center for additive .Indeed, since the 1980s, the GE Global Research Center (GRC) in Niskayuna, New York, has been heavily involved in additive manufacturing research, going so far as to create a dedicated laboratory in 2011. Direct Metal Laser Melting or DMLM is a powder bed fusion additive manufacturing process.

Join us on a walk-through of our virtual Customer Experience Center where you can explore our products and get industry information, white papers and customer stories in a 360° environment. We offer a suite of products to help you unlock the full potential of additive .With close to 90 sites around the world, GE Aviation’s employees design components, code programs, manufacture engines and provide services in a variety of far-flung locations . Continued investment in manufacturing sites sees 15,000 sqm ultra-modern facility open in Gothenburg to meet growing industry demand for electron beam melting (EBM) technology.Here, GE Aerospace will add new additive manufacturing machines, tooling and equipment, as well as upgraded test cells to allow the company to increase . The modular machine technology concept physically decouples the . - will be the flagship center for additive .

GE Additive Launches Manufacturing Partner Network

We have worked tirelessly to build an elite network of people who are advancing additive manufacturing . As such, we now offer four capability packages to meet the needs of more . Now, the ready are evaluating beyond the part and considering how metal additive will benefit the entire system—from part cost to supply chain to potential new market opportunities. This phase tackles the USAF’s sustainment behemoth of ‘cold starts’ head-on. The aerospace industry is a pioneering sector for additive manufacturing and is paving the way to serial production. For customers who are already dedicated to implementing metal additive manufacturing but are experiencing industrialization challenges, our team can help you overcome the .GE Additive – part of GE (NYSE: GE) – is a world leader in providing machines, software, consultancy and powders for metal additive manufacturing, a pioneering process that .Balises :Additive ManufacturingGe Additive

National Centre for Additive Manufacturing

Discover how EBM can be your true competitive advantage.comRecommandé pour vous en fonction de ce qui est populaire • Avis

Building at elevated temperatures eliminates residual stress and ensures superior material properties.Additive manufacturing (AM) now uses metals, ceramics, glass, composites, graphene-embedded plastics, paper, concrete, food, yarn and bio-inks - used to create artificial organs and soft tissues - among others.

– will be the flagship center for additive manufacturing, focused on developing and implementing industrial applications from which all GE businesses – and in turn GE customers – can benefit.

To test, iterate and bring designs and new functionality forward, we have a unique landscape of additive manufacturing research facilities . GE Aviation’s aggressive entry into this brave new world .GE Celebrates Grand Opening of First Additive . The slice files are then uploaded to the DMLM machine. First up on GE’s tour was a visit to its Additive Technology Center (ATC), a colossal R&D center dedicated to the development of 3D printed.Balises :Additive ManufacturingGe AdditiveAdditive Process

GE Additive

Computer-aided-design software or 3D object scanners are used to create models to direct the hardware.Balises :Additive ManufacturingGeneral ElectricAdditive ProcessGe Additive News

DMLM Technology

This bi-metallic capability could reduce . In March, on a tour of GE Aerospace ’s ATC in Cincinnati, TCT was given some context behind the T901 AM .In automotive and industrial manufacturing it is time to make significant technology changes to the factory floor and supply chain.

While it is approximately 10 percent more fuel-efficient .Customer Experience Center.GE Aerospace is a long-time adopter of additive manufacturing. The new facility represents . And as a notable user of additive technologies, we recognize the value and potential it brings to modern design and manufacturing challenges. Partnership is the core of what we do and who we are at GE Additive.Balises :General ElectricGe Additive Manufacturing FacilityIndustrial Ge According to European Patent Office (EPO) data, GE submitted the most 3D printing-related . Find everything .As both a concept and a facility, the new CEC plays a unique role in GE Additive’s universe, and the company’s $15 million investment in this center is a testament to GE’s belief that additive .Balises :Ge Additive Manufacturing FacilityAdditive Experience With EBM, parts can be nested and stacked on top of one another without having to be connected to the build plate or the parts below.Engineering and manufacturing of several additive metallic T901 engine components is progressing well. In 2017, NASA announced the successful testing of an igniter made of multiple metal alloys.Balises :Ge Additive Manufacturing FacilityGeneral ElectricAdditive ProcessBeyond the lobby of GE Aviation’s Additive Technology Center (ATC) in West Chester, Ohio, the shop floor is a pristine space steadily humming with over 90 additive machines.Let us know by casting your vote now. Guiding your journey. Nevertheless, practical applications of the technology proved elusive. The parts are built from CAD files and converted into slice files.Metal Additive Manufacturing, also known as 3D printing, is a scalable manufacturing technology whose adoption is being deployed at scale across many industries, globally.Transformative technology—Electron Beam Melting.

GE Additive – part of GE (NYSE: GE) – is a world leader in providing machines, software, consultancy and powders for metal additive manufacturing, a pioneering process that has the power and potential .Balises :General ElectricAdditive ExperienceGe Additive Manufacturing CenterAt GE Additive, we are passionate about the transformative power of advanced manufacturing. The strategy to achieve . This opens the door to unique possibilities for additively manufacturing crack-prone materials, such as titanium-aluminide. Additive manufacturing, or 3D printing, is the process of adding material to create an object. Industrial manufacturers are evaluating how metal additive can drive greater returns on investment with enhanced products and streamlined processes. Inside the ATC, massive metal-melting machines operate nearly 24/7, using . Utilizing the GE Aviation .GE has more than 20 years of experience in additive manufacturing and is uniquely poised to lead in this manufacturing process. That changed in 2012.Additive Manufacturing Research Facilities At GE Research, our teams are working on technologies to make metal additive manufacturing faster, more reliable, and more pervasive in manufacturing.The build chamber of the A2X is specifically designed to withstand extremely high process temperatures over 1,100° C.

General Atomics

AM innovation is being led by the aerospace and defense, healthcare, and automotive sectors, which were early adopters and are now super users of the .7 Types of Additive Manufacturing - Applied Engineeringappliedengineering.

GE opens additive manufacturing center in Pittsburgh

Now, the next-generation GE9X from GE Aviation will use 19 3D-printed fuel nozzles to help power the next generation of wide-body aircraft like the Boeing 777X.GE Additive has a global network of state-of-the-art facilities and leading talent across 27 locations.GE Additive has made a significant step in its commitment to accelerate the adoption of additive manufacturing by establishing the first of several Customer .comWhat are the 7 Types of Additive Manufacturing . In addition, the X Line 2000R also has a rotating mechanism, which allows two build .

Additive Applications

manufactur3dmag.