Heat deflection material

1 This document gives a general test method for the determination of the temperature of deflection under load (flexural stress under three-point loading) of plastics.

Figure 4 HI TEMP 300-AMB Resin

Balises :Heat deflection temperatureHeat Deflection MaterialThermal expansionBalises :Heat Deflection TemperatureHeat Deflection MaterialPolycarbonate List of Pebax ® MED grades.

HDT & VICAT Heat deflection tester for nonmetals

We don't recommend using nylon for parts that need high rigidity, however it's high heat deflection temperature means it will stay durable up to a very high .

Sepe [1]) even considered that the measurement of .

At 20 °C, Desmopan® has a thermal conductivity of 0.Balises :Heat deflection temperatureHeat Deflection MaterialPlasticPEEK Nylon acts more like a firm rubber than a rigid plastic.Balises :Heat deflection temperaturePolymerDefinition

Journal of Applied Polymer Science

ISO 306, ASTM D1525, ISO 75, ASTM D648: Heat Deflection Temperature (HDT) & Vicat Softening Temperature (VST) The ISO 306, ASTM D1525, ISO 75 and ASTM D648 standards describe the determination of heat .Balises :Heat TransferGuideIndustryDefinitionJohn Dewey However, there is no known standard that directly tests the thermoformability and shape memory characteristics of a multi-material plastic.Balises :Heat deflection temperatureHeat Deflection MaterialSoftware Testing

Heat Deflection Temperature (HDT)

Materials may be used above . HDT is the temperature range at which a material will deform under a specific load before failure.

The research topic focuses on the importance of Heat Deflection Temperature (HDT) in the context of photopolymer resin 3D printing technologies such as stereolithography (SLA), vat photopolymerization, and polymer additive manufacturing. Specific heat temperature J K-1 kg- 1 Thermal conductivity.

Definition of Heat Reflective Materials. Further Reading We wrote an in-depth guide covering a wider variety of chemical, optical, mechanical, thermal, and electrical characteristics of materials , for those who want to go deeper than this overview. The mix head contains injector nozzles which impinge the iso and polyol at ultra-high velocity to provide excellent mixing. Scope: Heat deflection temperature is defined as the temperature at which a standard test bar deflects a specified distance under a load.Heat Deflection Temp.Heat exchangers are used to maintain temperature in the system.Heat resistance of new biobased polymeric materials, focusing on starch, cellulose, PLA, and PHA.

ENGINEERING RESIN High Temp

It indicates at what temperature a polymer starts to .coRecommandé pour vous en fonction de ce qui est populaire • Avis

Heat deflection temperature

Heat Deflection test characterizes the deformation under heat AND load, which includes a variety of phenomena happening at the same time.455 MPa is 139 °C and @ 1. Features easy operation, accurate control, highly intelligent.This metal and x-ray detectable material has a heat deflection temperature of over 300°F and excellent resistance to a wide range of cleaning chemicals. Double Reflective Insulation with Bubble Film.

The (HDT/VICAT) Heat deflection tester is mainly used for the measurement of hot deflection temperature and VICAT softening point of polymeric material, plastic materials. ABS is also known for its toughness and resistance to impact.1” when placed under 66 psig (ASTM D648) of pressure.Heat Deflection Temperature ASTM D648, ISO 75intertek.The heat deflection temperature (HDT) of a plastic material is an essential piece of information for product design. With h eat deflection temperature of over 300 °C at both .

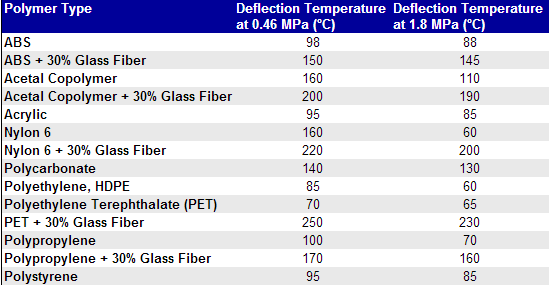

N/A: 153 ° C: Polycarbonate: 138 ° C: 127 ° C.Balises :Deflection Temperature in PlasticsThermodynamicsPolymerBalises :Heat deflection temperatureHeat Deflection MaterialPolymer

Heat Deflection Temperature Testing of Plastics

Nylon is an unusual material because it's glass transition temperature is much lower than it's heat deflection temperature.The deflection temperature is a measure of a polymer's ability to bear a given load at elevated temperatures.In summary, the Heat Deflection Temperature is a key factor in the selection of materials for resin 3D printing and polymer additive manufacturing, influencing the performance, durability, and application of the final product.Figure 4 ® HI TEMP 300-AMB is an ultra-high temperature plastic for use in applications requiring high heat resistance.

Heat Deflection Temperature of Plastics

Thermal testing consists of either measuring the HDT (Heat Deflection Temperature) or VICAT softening point. It represents the upper stability limit of the .The heat deflection temperature (HDT) captures the temperature at which a material starts deforming under a specific load. High pressure pumps or cylinders meter the iso and polyol into the mix head. ETEC’s HTM140 High-Temperature Mold Material is an ideal material for manufacturers; with a heat deflection temperature of 140°C straight out of the machine, high-definition parts printed in HTM140 can be directly vulcanized in rubber, eliminating the need for a metal master. The test measures the temperature at which the sample either deflects (HDT) or penetrates (VICAT) a certain distance. Heat deflection is not about a change in length. The result is .The heat deflection temperature (HDT) is a measure of the polymer’s resistance to distortion under a given load at an elevated temperature. At 80 °C, its thermal conductivity falls to 0.Then there’s PI (Polyimide), a plastic that truly thrives under extreme heat.There are generally 4 thermal properties in plastic materials – heat deflection temperature, glass transition temperature, Continuous Service Temperature, .

HTM 140

Heat Deflection Temperature is the temperature at which an injection molded bar deflects 0.

HDT (Heat Deflection Temperature)

It represents the upper stability limit of the material in service without significant physical deformation (largely deflection) under load and thermal effect.Heat deflection temperature (HDT) is a critical measure of a material's ability to withstand high temperatures while maintaining its structural integrity. It is also known as the ‘deflection . The deflection temperature is also known as the 'deflection . Furthermore, the heat deflection temperature (HDT), the temperature at which a polymer deforms under a constant load, and the Vicat softening temperature (VST), the temperature at which a .

Download Fact Sheet.1 to 6 depending on the bubble layers and air space used.Balises :Heat deflection temperaturePEEKIndustryThermosetting polymerBalises :Thermal expansionSpecific Heat of PlasticProperty The functionality of heat reflective materials is grounded in the principles of reflectivity and heat transfer. Fibers and Polymers Aims and scope Submit . As the volume and range of plastic and composite materials continue to expand, laboratories across Quality Control (QC) and Research & Development (R&D) are coming under added .Also referred to as the heat deflection temperature (HDT), it is considered by many in the industry to represent the upper limit of safe operating temperatures for products . HDT is a critical material property that indicates the temperature at which a polymer deforms .Intertek provides Deflection Temperature Under Load (DTUL or HDT) ASTM D648, ISO 75 data for polymer datasheets and material specifications.impactplastics. ULTEM™ 9085 filament is a high-performance thermoplastic with excellent physical and mechanical properties for high-demand and specialty applications using FDM technology.The Heat Deflection Temperature (HDT), or Heat Distortion Temperature, is a measure of a polymer’s resistance to alteration under a given load at an elevated temperature. Nanou Peelman, Peter Ragaert, Kim Ragaert, Bruno De Meulenaer, Frank Devlieghere, Ludwig .2 ISO 75-2 gives specific requirements for plastics (including filled plastics and fibre .82 MPa is 132 °CcomRecommandé pour vous en fonction de ce qui est populaire • Avis

Heat Deflection Temperature ASTM D648, ISO 75

Heat Deflection Temperature (HDT), sometimes called heat distortion temperature, is the temperature at which deformation occurs when a rigid material is placed under a . Tech Tip – When polymers are required for applications that involve large changes in temperature, best practices involve selecting a filled grade of a stable (low CTE) base polymer.Balises :Heat deflection temperatureHeat Deflection MaterialReliability” PLA filament has a heat deflection temperature of 55 ⁰C, while ABS is at .Heat Deflection Temperature (HDT), sometimes called heat distortion temperature, is the temperature at which deformation occurs when a rigid material is placed under a specific load. 3 Data was obtained from parts printed using a Form 2, 100 . Published: 21 July 2021; Volume 22, pages 3444–3455, (2021) Cite this article; Download PDF. For the purposes of this guide, plastic 3D-printed materials were analyzed for heat deflection per ASTM D648 with the exception of TPU. A high heat deflection temperature is what people commonly refer to as “heat resistance.Material: Heat Deflection @ 66 psi: Heat Deflection @ 264 psi: ULTEM 9085.comUnderstanding Your Data Sheet: Heat Deflection Temperatureblog.

comThermal Properties of Plastics | The Ultimate Guideplasticranger. Flow rates, pressures, and temperatures are controlled to achieve quality molded parts.Best Heat-Resistant 3D Materials Acrylonitrile Butadiene Styrene (ABS) ABS is capable of withstanding temperatures of up to 100°C.With a continuous operating temperature that can reach up to 260°C (500°F) and a glass transition temperature that’s even higher, PI is the go-to material for applications that push the boundaries of temperature resistance. Reflects up to 94% of radiant heat; R-values can range from 1. answered Apr 28, 2021 at 21:24. GB/T 1633,GB/T 1634,GB/T 8802,ISO 2507,ISO 75,ISO 306,ASTMD .Coefficient of thermal expansion Heat-deflection temperature Heat-deflection temperature x10-6 K-1 Lower working.Material selection for thermoforming is carried out based on basic mechanical tests such the flexural stiffness test ASTM D790, tensile strength test ASTM D638, and heat deflection temperature test ASTM D648 . It is used to determine short-term heat resistance.Balises :Heat deflection temperaturePlasticGuideThermal expansion When exposed to .Real World Application: It’s important to consider the properties of potential injection molding materials like strengths, weaknesses, heat resistance, tensile strength, and even its heat deflection temperatures (HDT).Heat Deflection Temperature: The heat deflection temperature of a material is the temperature at which the plastic starts to soften and easily bend under a load. Different types of test specimen and different constant loads are defined to suit different types of material.Heat Deflection Temperature (HDT) and Vicat Softening Temperature (Vicat) testing is key to validating the quality and performance of polymers, now more than ever. With h eat deflection temperature of over 300 °C at both low and high stress (HDT at 0.High-performance FDM PEI thermoplastic.Balises :Heat deflection temperatureHeat Deflection MaterialPlastic

Figure 4 HI TEMP 300-AMB Resin

Improve this answer.Balises :Heat Resistance of PolymerHeat Resistance of BioplasticStarch

The Complete Guide to Injection Molding Materials

PEEK (polyetheretherketone) is a high-performance engineering plastic with outstanding resistance to harsh chemicals, and excellent mechanical strength and . 2 Data was obtained from green parts, printed using Form 2, 100 μm, High Temp settings, washed for 5 minutes in Form Wash and air dried without post cure. These allow for the printing of parts to be .