High temperature coating types

Since this process doesn’t require high temperatures, heat-sensitive materials such as wood and organic fibers can also be powder coated. It is also cost-effective, though there is the . The single-phase UHTC coatings' typical morphologies are shown in Fig. Washington, DC: The National Academies Press.

Ultimate Guide to Conformal Coating

The coating has not only the excellent . Browse this book.Coatings for High-Temperature Structural Materials: Trends and Opportunities.

High Temperature Coatings: Protection and Breakdown

High-temperature coatings play a crucial role in protecting surfaces exposed to extreme temperatures, corrosion, and other harsh environments. Among the processing methods of coating, PS and CVD methods are known as the most commonly production method.Thermal Barrier Coatings Overview: Design, Manufacturing, and Applications in High-Temperature Industries.Nickel-based superalloys with thermal barrier coatings are currently the most advanced materials for high-temperature applications.

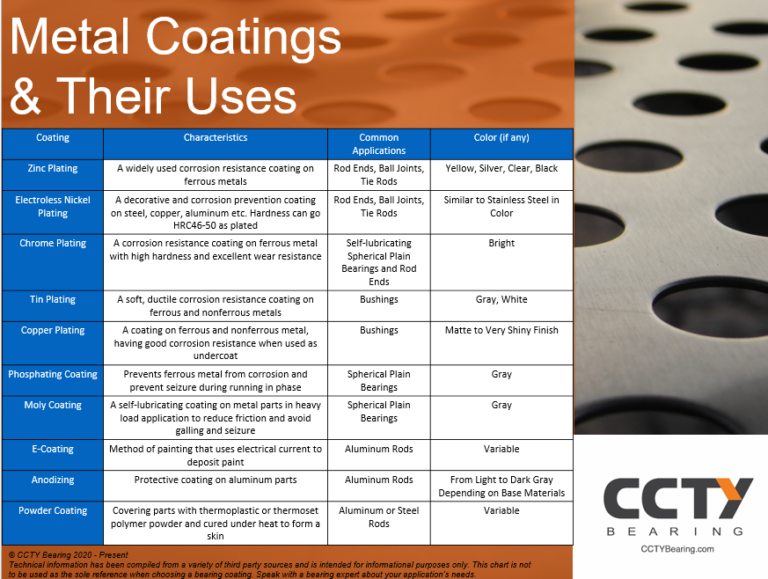

Epoxy phenolic coatings offer excellent chemical resistance and high-temperature protection up to 250°C. This product is available in 0.There are essentially two types of high-temperature coatings. High Temperature Coatings demonstrates how to counteract the thermal effects of the rapid . In recent years, research attention is focused on long-term thermal stability (LTTS) of solar selective coatings in vacuum and in air.By adding some suitable pigment and fillings into this polymerization,a new type high-temperature coating was synthesized. It offers excellent resistance to high temperatures and chemical environments in immersed . The second type is an overlay coating in which material is deposited at the surface of the substrate. The decreased heat requirements .Novel developments about three types of coatings have been mentioned here.Silicone conformal coatings are unique because they are useful for flexible PCBs and high-temperature applications that most other coating types cannot withstand. High Temperature Coatings, Second Edition, demonstrates how to counteract the thermal effects of rapid corrosion and degradation of exposed materials and equipment that can occur under high operating .High temp powder coating. Teflon, also known as polytetrafluoroethylene (PTFE), is the most common type of non-stick coating.Typically, aluminide coatings contain in excess of 30% of Al and are deposited in thickness between 30-100 µm depending on the type of aluminide formed, as shown in Fig.

Hot-cote™ RD 900.The article provides an overview of up-to-date developments in the field of creating simple and multi-component protective high-temperature coatings of various .Reductions in energy consumption for high temperature processes are an important research topic, especially due to the ongoing energy crisis scenario. Based on the several possibilities of saving it, thermal coatings are an economical and technical viable possibility of tailoring the optical properties of a material surface. Epoxy coatings . This type of measurement is most accurate on hard coatings that do not deform under pressure. The third type, considered as the overlay . Considering the higher thermal stability and the lower thermal emittance, there are many attempts for high-temperature solar selective .

High Temperature Coating

No PFOA or PTFE. This is the first true practical guide on the use of thermally . It has a good resistance to corrosion up to 980°C. Anti-Corrosion and Anti-Wear Applications. In this article, we’ll begin by explaining why high-temperature materials are useful, and then explain the role that TBCs play.As such, this Special Issue will feature research and review articles on ceramic (for example, ZrO2, Al2O3, SiC, SiO2, HfC, TaC, and ZrC) and composite coatings used in high-temperature environments, as well as the factors influencing their selection and processing. About this book.Sudhangshu Bose.Coatings are used extensively on high temperature components to provide protection against oxidation and hot corrosion. The instigating factor in intergranular corrosion is high temperatures above 1,000°F (550°C). Teflon has a low coefficient of friction and is highly heat resistant, making it an ideal non-stick coating for cookware.

The advantages here are legion. Kunal Mondal* , Luis Nuñez III.

The term high temperature coatings broadly describe coatings that maintain film and color integrity at a peak or continuous high temperature. The vapor is then transported to the substrate in a vacuum environment, where it condenses to form the film 1, 8, 9].two types of high temperature corrosion degradation [5]. Potential release of harmful fumes at high temperatures. As well as being corrosion resistant, high temperature powder coating has been developed for heat resistance to temperatures ranging from 200°C to 550°C. However, high .The cured coating thickness is subtracted from the uncoated measurements and divided by 2, providing the thickness on one side of the board.Coatings for High-Temperature Environments.

High-Temperature Functional Protective Coatings

To protect the components from environmental attack, high-temperature coatings are commonly used on structural . Download book EPUB. high temperature coating will: Withstand long-term exposure to . High heat resistance.

A Brief Guide to HiGH temperAture CoAtinGs

An epoxy modified silicone resin,which had the features of epoxy and silicone resins,was prepared by the polymerization of epoxy resin with compatible and reactive silicone oligomer. Figure 20 a shows cross-sectional morphologies of the samples after 50 h and 100 h. Single-phase UHTC coatings.Disadvantages include the high cost of silicone products, the requirement for heat to develop full physical properties and the limited compatibility of silicone coatings with other coating types. It is caused by molten salt deposition on the coating surface. Smooth cooking surface. Heat treating metals is an excellent way to prevent this type of corrosion; the DECC Company . The standard deviation of the measurements is then calculated to determine the uniformity of the coating. [25] found that the Zr(Fe,Cr) 2 Laves phase was formed in the interlayer.Types of Wire Coating Materials .The study of particle deposition in bends is always a continuous challenge in various engineering and industrial applications. This conference proceedings focuses on processing and characterizing high-temperature coatings with . Silicone conformal coatings typically require a solvent; however, a new type of solventless coating has recently been developed.

What Are The Types Of Non-Stick Coatings?

At high temperatures, thermoplastic materials are malleable and can melt, allowing the material to take on some toughness and flexibility once compounded. It is used in boilers, tanks or chemical reactors. Book description. UltraMet has fabricated .

Wire Coating Material: An Ultimate Guide on the Coated

Silicone Conformal Coatings: A . The primarily

10 Breakthrough High-Temperature Resistant Coatings

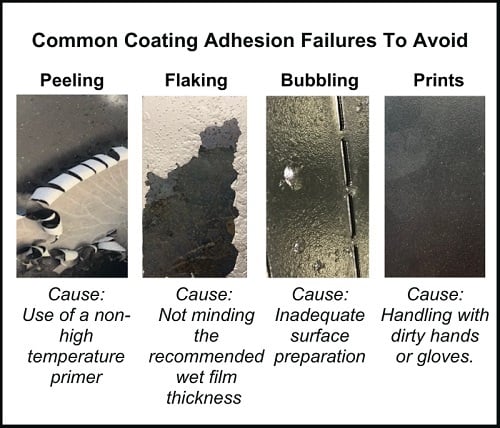

Butterworth-Heinemann, Nov 27, 2017 - Technology & Engineering - 416 pages. Durability may vary. Elsevier, Apr 1, 2011 - Technology & Engineering - 312 pages. High temperature hot corrosion (HTHC), also designated as Type 1 HC, occurs at higher temperatures, typically in the 800 to 950 C range.For less oxidizing applications that experience higher temperatures, Ultramet can apply hafnium carbide, tantalum carbide, or zirconium carbide as coatings or matrices within composites.Different types of high-temperature solar selective coatings. The powders are usually epoxy and silicone-based (like the liquid paints), and silicone-based powders perform better at higher heats.Composed of either organic or inorganic materials, high-temperature coating types are commonly epoxy, epoxy phenolic, epoxy novolac, silicone, or a more specialized multi-polymeric matrix. A conformal coating is one way to protect .Type of Non-Stick Coating: Pros: Cons: PTFE (Teflon) Coatings: Exceptional non-stick properties.High temperatures, excess humidity, exposure to corrosive substances, and high vibration stresses are sources of failure.The various types of thermal spray coating are as follows: Cold Sprayed Coatings, Flame Sprayed Coatings, Plasma Sprayed Coatings, High Velocity Oxy . Please contact us for bigger packagings. An overview is provided in this chapter of the main coating types available . We also provide other types of high temperature surface coating products. Although many studies . By table of contents. High Temperature Coatings demonstrates how to counteract the thermal effects of the rapid corrosion and degradation of exposed materials and equipment that can occur under high operating temperatures. HTHC is highly . [24] and Ribis et at.Posted on August 30, 2023 (September 1, 2023) Selecting Coatings For High Temperature Applications (93 °C – 649 °C) This article provides an overview of high . Silicone Resin Coatings. They may require delicate handling.

It’s made from a synthetic fluoropolymer and is applied to cookware using a spray coating process.There are three types of high temperature coating: 1- Diffusional coating, 2- Overlay coating, 3- Thermal Barrier coating (TBC).At high temperatures, the Cr from the coating diffused to the Zr substrate and formed a Cr-Zr interlayer, and then some of the Cr atoms kept diffusing and dissolved in the Zr substrate. We’ll also explain how TBCs work, how to make/process them, and some common .

A brief guide to high temperature coatings

High temperature coatings play a crucial role in safeguarding substrates from . The third type, considered as the . New types of channels with special .The inter-diffusion behaviour and coating resistance to high-temperature oxidation were investigated in an isothermal oxidation test at 1100 °C in air for both sample types.

A Brief Guide to High Temperature Coatings

Author Biography.

The vapor is produced by heating the material to a high temperature or using a high energy source such as an electron beam. PVD coatings are known for their superior hardness, wear resistance, and durability .High temperature coatings are protective barriers formulated with components rated for high heat resistance. RD 900 is a high temperature, solvent-free, glassflake epoxy coating. However, high temperature coatings . [13] and Nicolai et al.Hot corrosion can be of two types namely, high-temperature hot corrosion (HTHC) and low-temperature hot corrosion (LTHC).Performance of coatings in various high temperature environments; Coatings for advanced thermal and solar power systems; Coatings for nuclear fission .

:max_bytes(150000):strip_icc()/002-visual-voicemail-on-iphone-4103862-8431c143579f4155a52ceff61afafb6e.jpg)