How are rolled threads made

Thread cutting is cheaper when serving a low order volume. Thread rolling machines use a smaller diameter blank than a screw-cutting machine.

The Fundamentals of Thread Rolling

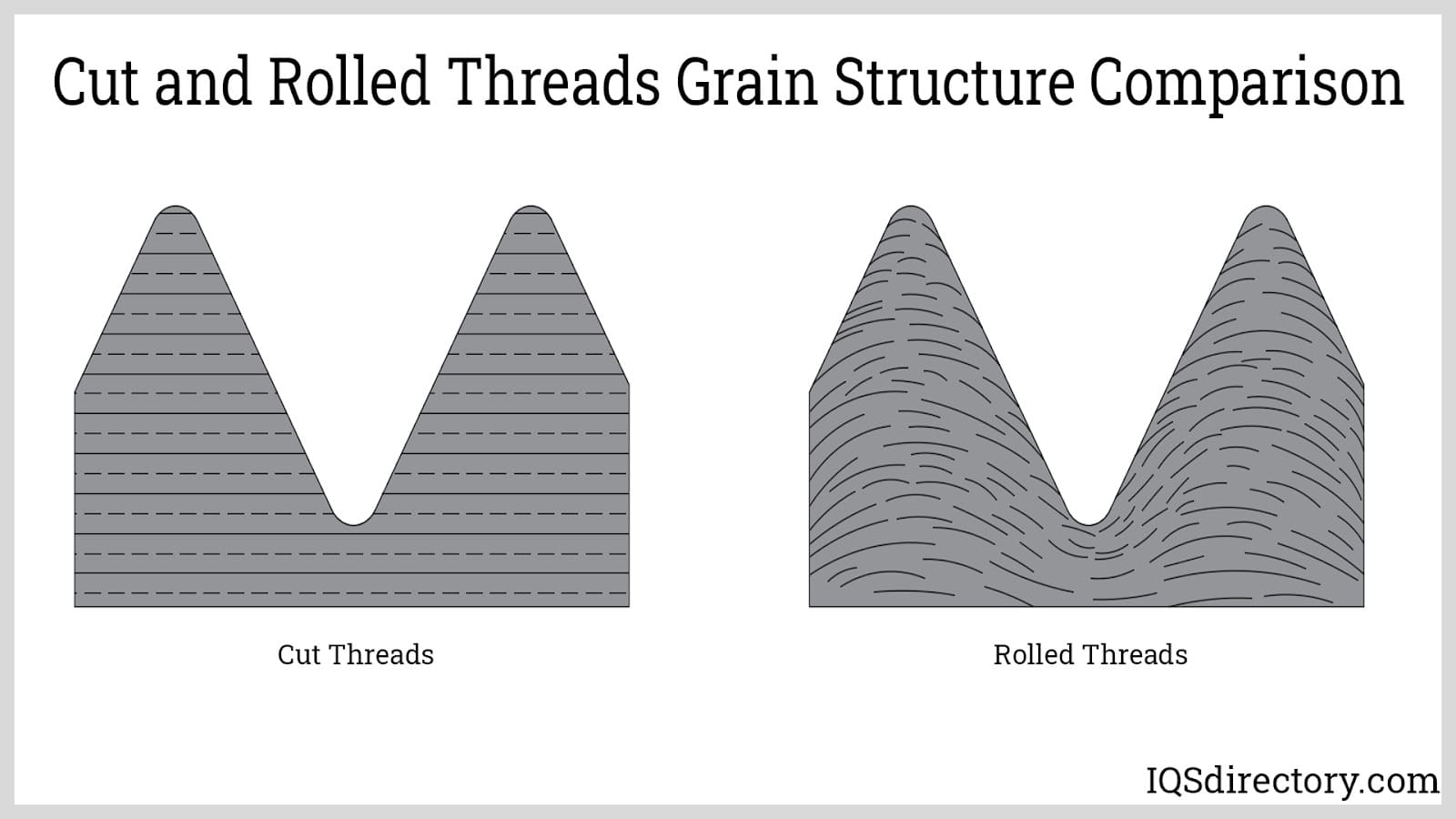

Rolled threads resist the stripping because shear failures must take place across rather than with the grain. Then, the Threads algorithm analyzes a collection of input signals from that .As the part “rolls” through the dies, the pressure applied by the plates creates the thread without cutting or removing material. During the process, the tooth form of the thread rolls protrudes into the outside .Rolling female threads is faster than cutting threads, so more parts per hour can be produced. The most common method is a reciprocating die, in which the screw is rolled at extremely high pressure between two flat dies – one of which remains stationary.

How It's Made

Additionally rolled threads improve fatigue strength by 50% to 75%. Threads produced through rolling also typically exhibit 50-75% greater fatigue strength, .Rolled Threads Unlimited provides an assortment of both common and uncommon thread types. We offer products with diameters ranging from under 1/8 to approximately 6 and thread pitch capabilities ranging from 2 threads per inch to more than 100 threads per inch. At HORST Engineering, we focus on threads that are 2. Llama 3 uses a tokenizer with a vocabulary of 128K tokens that encodes language much more efficiently, . Basically, the fastener is rolled through a set of threading dies that displace the material to form threads, without . Despite its simplicity, the . Most of the rollers used to produce these forms have relatively sharp crests, usually with radius edge to help the die penetrate the material. Methods of producing rolled threads. Metal removal is used to form the thread. 2C, 2G, 3C, 3G: Multiple leads available.0625” through 7. When we make a special, we will cut the threads.Regarder la vidéo2:00Portland Bolt.comBolt threadingScrew T.1 mm) along the cut. Additionally, rolled threads . Classes of fit include 1A, 2A, 3A, and interference. The hardness is plotted against the distance from the sample surface. cut threads comes down to cost.ROLLED THREADS UNLIMITED Company Overview. Flat Thread Rolling Processes. This is when our team ensures . Converse to machined threads, which may fail given adequate side load, rolled threads are able to withstand far greater trans axial forces which is why they are optimal in applications such as screw jacks and lead screws.

Learn How Thread is Made

75 inches wide.Today, sewing and quilting threads are manufactured and produced from two major sources: natural fibers and synthetic fibers. Resistence to Fatigue - Thread rolling increases the part’s resistance to fatigue failure in several different ways.

What Are the Processing Methods for Internal Threads?

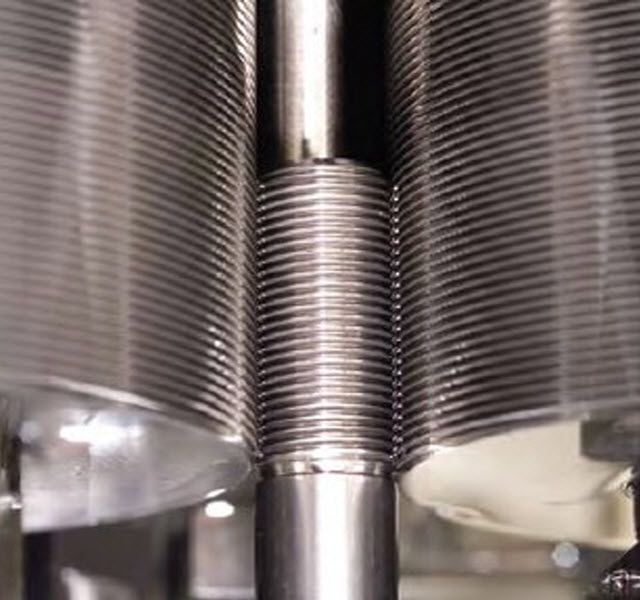

A thread can also be made by means of a tap or a screw stock. To roll thread, dies must be created.Most of the threads produced are made to the 60 degree Unified and similar standards, which are easily rolled.When Portland Bolt produces bolts with rolled threads, we begin by cutting pitch diameter round bar which has a reduced diameter (approximately the midpoint between the major diameter (peak) and the minor diameter (valley) of the threads. Cold hardening ends where this graph becomes hori zontal. However, it is important to note that heat treated cut . Thread cutting on an automatic lathe with a taper tap 4. As the rolling process removes no material, it . While some fastener manufacturers cut threads, we’re fans of rolling. 2d), by contrast, ferrite and carbides are accompanied by troostite.28K subscribers. Blank diameter is the diameter prior to rolling . Stronger threads without the need for expensive outside heat treating are a direct result of choosing a rolled thread over a cut thread process.

Rolled Screw Threads VS Cut Screw Threads

We are capable of rolling studs with a hardness of approximately Rc 42 and higher. The cold working of the thread rolling operation increases the strength of the steel in the threads. In another method, threads are formed with rotary dies (Fig.

Specifications: ANSI/ASME B1.Rolled threads are formed by pressure.Overview

How Does the Thread Rolling Process Work?

Threads produced using a thread rolling machine are 30% stronger than untreated cut threads of the same size, however heat treatment and post-processing of cut threads will reduce this difference. It’s then forced through an extruder which forces the material into the familiar threaded screw or bolt we .

How It Works

Here at Rolled Threads Unlimited, we have incredible capability within the Acme Form: 2 through 32 Pitch. Next, we roll the screw’s threads using a Reed roller. A cut thread (also called a machined thread) is . Internal Thread Cutting hand tap. In this case the thread is usually cut with a screw tap or taper tap. This process imprints the thread onto the screw, and can produce hundreds of . Thread rolling is the most cost-effective choice when making a large volume of fasteners. ), at production rates as high as 80 .Rolled threads are typically more durable, accurate, and resource-efficient. Cost Effective. ASTM A320/320M . Thread Rolling.A screw or bolt made with rolled threads starts life as a smooth round bar.Threading is usually applied before heat treatment, either by rolling or cutting when the steel is softer.This is because the thread is not literally cut into the blank during the thread-rolling process, rather it is impressed into the blank.The crest and root radius of a rolled thread is made to be denser and stronger as a result of this action.Thread rolling is a cold-forming process by which straight or tapered threads are formed on round rods or wire.

Rolled Thread Bolt Diameter

The threads are added using a reed roller, again one at a time.

Why Rolled Threads

In this process, a . With thread forming the material is work hardened again .Temps de Lecture Estimé: 10 min

5 Facts About Thread Rolling

Earnest standard product is made with threads that are rolled prior to heat treatment.002 inches smaller than the maximum part pitch diameter.Since the threads are rolled on and no material is removed, it's no issue. Rolling works much like cold forging, and involves running the bolt . The threads are also more precisely positioned. The more productive of the thread-rolling techniques is by far the planetary rotary die, which .What’s interesting about screws is that they come from a single coil of wire about 0. 2014Thread Pitch Chart - Portland Bolt Afficher plus de résultats

THREAD ROLLING GENERAL INFORMATION

Thread rolls are usually lapped after hardening, by holding them on an arbor in the lathe and using emery and oil on a piece of .While our fasteners can be made to your own specifications, Rolled Threads Unlimited also supplies industry-standard offerings, including: STANDARD OPTIONS.

Why are Rolled Threads Stronger?

Rolling Threads Has Advantages

Aerospace industry specifications require that indicating type gauges be used to measure threads. Thread rolling is completed using a thread rolling attachment on a multi-spindle, Swiss-type or CNC lathe. That spoke showed .For a cut thread bolt, no work has been done on the material. This process is called thread cutting, as it involves the severing of the material’s grain structure.The machines make screws with a process called thread rolling—the newest technique that allows for maximum productivity. Rolling between smooth dies leaves the thread with smooth burnished roots and flanks, free from tears, chatter or cutter marks that can serve .Thread rolling is essentially a cold forging operation. Rolled threads can be produced by dedicated thread rolling machines, Thread . Get Your Next Project Done! Get A Quote. In thread rolling, metal is cold-worked—formed into the desired shape by displacing, rather than removing, material—which strengthens the .

Manquant :

threadsHow the Threads Algorithm Works in 2024 [GUIDE]

Combined with the ability to roll both hardened and stainless . Thread making is a combination of fiber and science, beauty and technology, manpower and machine.500 inches (63mm) or . Most common tooling on hand.Like most manufacturing processes, the debate of rolled threads vs.Rolling the thread is a cost-effective way to make threads in high-volume operations.

Threading (manufacturing)

Rolled threads with a rounded root radius improve fatigue resistance, while cut threads can be made with a rounded root equivalent to a rolled thread. Each of these benefits is underscored by the strength and fatigue resistance of rolled threads.

With rolled thread parts, designers must instead account for how the metal flows across the rolled surface rather than being removed.Thread rollers come in a variety of types and sizes, but they all use a mechanism where hardened steel dies are matched and set to penetrate with force in order to reshape the material surface of a round .The answer is: a lot.

00” Diameter.The reason rolled threads are perceived to be better than a cut thread is: Thread rolling dies create a thread form that has a rounded root radius.

What Is the Difference Between a Screw .Roll threading is a process by which steel is extruded to form the threaded portion of a fastener, instead of being removed as in cut threading.5, ASME/ANSI B1.Rolled Threads Unlimited is proud to offer the advantages of high rates of production, low costs, and reduced waste. 2015Rolled Thread Bolt Diameter - Portland Bolt13 nov.The cold-worked process of rolling threads often strengthens the material by up to 30%. Specialty Fasteners. Rolled threads offer cost-effectiveness, shorter labor times, and better fatigue life, and are commonly used in the automotive industry for head bolts.

What is thread rolling?

Profile: General Purpose, Centralized, Stub.In the latter case, a cut is made in the sample at a small angle (0. Once the threads are all rolled, the bolt is dimensionally done and ready for final dimensional inspection.

Roll Threading Bolts and Fasteners

During this process the material is not removed and instead is deformed by the .

We find the results .

Rolled threads .Watch and learn how threads are formed on screws and bolts in the cold-forming processFollow for more things fasteners!www. If you’re interested in learning more . Thread produced by rolling may be characterized by the depth and degree of cold .In conclusion, there are several processing methods that can be used to create internal threads, including tapping, die cutting, thread rolling, thread milling, . 162K views 8 years ago. All of the spokes were really close to showing threads past the nipple, but one spoke hole must have been at a little bit of a high spot in the spoke bed (it can vary by a tiny little bit), and the nipple was sitting ever so slightly more in the rim. The rolling operation forces the steel’s ‘grains’ to flow with the thread form. A cut thread is the most cost-effective way to make a thread for low-volume applications. Cut threads can be manufactured to virtually all specifications, however many manufacturers prefer thread rolling, as rolled threads are often much smoother and