How to make mold for pouring

Auteur : Jake ThompsonA Beginner's Guide To Pouring Epoxy Resin Into Molds This will help avoid getting the resin on your skin and keep it from sticking to the sides of the mold.Before sealing, wait ...

Auteur : Jake Thompson

A Beginner's Guide To Pouring Epoxy Resin Into Molds

This will help avoid getting the resin on your skin and keep it from sticking to the sides of the mold.Before sealing, wait at least three weeks to make sure the paint is no longer wet. Insert the edge of a putty knife in between the two layers of plaster and gently pry them apart.com/channel/UCfNQkKS2AkN_BX36MdvY70Q/vi. This will help to ensure that your caramels come out of the molds easily. Negative Forms with Original . Now the mold is complete and we can remove the master model and put it aside.The first problem is water/ steam. Modifying the Mold. The wick acts as the lifeline of your candle, providing the necessary flame to create a beautiful and soothing glow.

metalworking

Additionally, it can have an elongation of 700%, depending on the formulation. Use a jigsaw to cut cement board to size.Learn all you need to begin pour painting. Most of my mold boxes for my designer toys utilize this foam core mold box construction.Auteur : ArtResin

The beginner’s guide to mold making and casting

I have found that for one to create a mold for pouring molten plastic in it, it only requires clay.

How to Do Acrylic Pour Art

Finish the mold by brushing a coat of sealant on the inside of the mold .In a small cup, mix one part paint, one part water (distilled, if possible), and two parts Floetrol latex paint additive.2 Other Materials you . Create a sprue hole using a dowel rod next to your casting object.

How To Make Ceramic Molds

The process involves creating a negative imprint of a model using mold-making material and filling it with concrete. Polish or finish the plastic item as desired to achieve the desired appearance and smoothness.Making a casting mold for metal involves several steps and requires specific materials and tools. Download Article.« Un combat au bord du précipice » : le Slip Français obligé de casser ses prix pour se relancer.

How to Make Silicone Molds: A Practical Guide

Pour the water into a mixing bowl. Use Elmer’s Glue, along with water.

Manquant :

moldTap out air bubbles: After pouring, gently tap the molds on the counter to release any air bubbles trapped in the candy. Silicone Rubber – The Degree of Hardness.Regarder la vidéo33:4211K.

How to Make Resin Molds: 5 Ways to Create Your Own DIY Molds

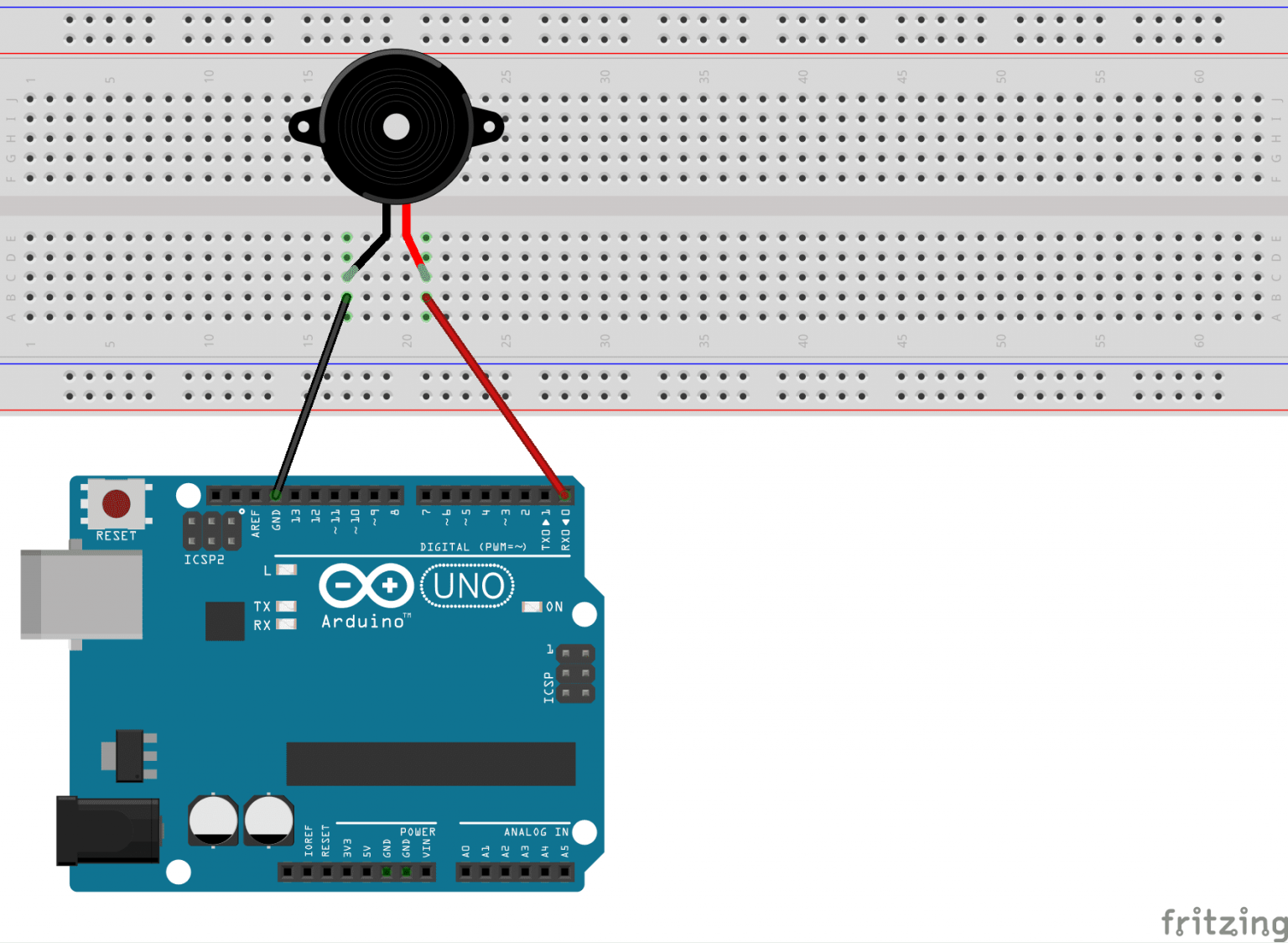

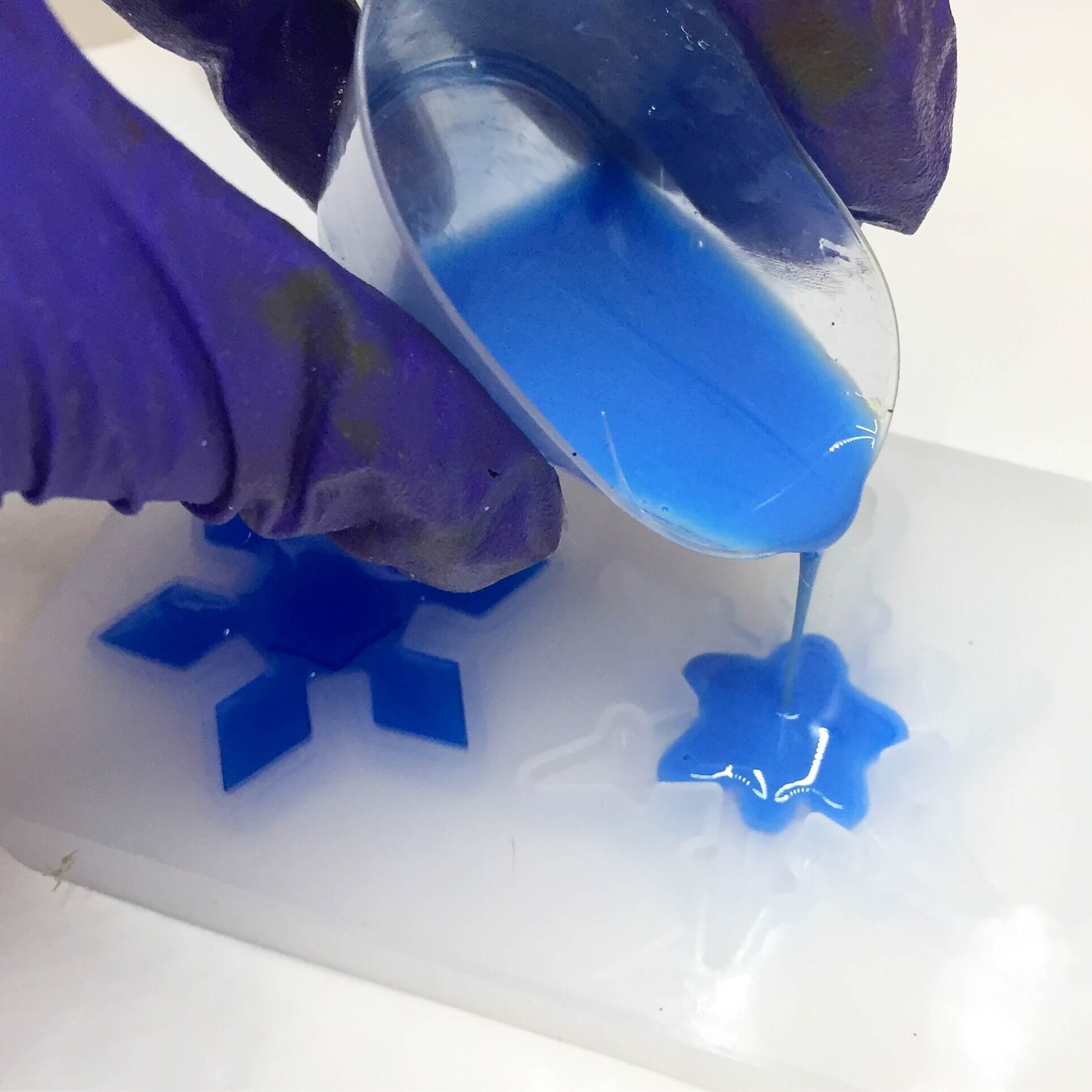

Pouring and Curing the Silicone – Ensuring a Smooth Finish. Step 8: Casting with Concrete. Add more resin to the mold, and continue stirring until the resin is fully mixed in. You can use a drum or steel bucket as a furnace vessel and slice its lid and cut a hole in its side near the bottom to accommodate a pipe. Place your model in the mold box and slowly pour the silicone mixture over it. ENQUÊTE // Il est l'emblème du renouveau du textile tricolore, .

Build a mold box with scrap wood or cardboard and place the item on a baseboard. Therefore, it is recommended . Pour cette affiche, .Livraison gratuite pour les membres Levi's® Red Tab™.Ensure the mold is completely clean before further modifications. You will be able to cast a copy almost anything you like, and I use a 600 y. This is the only mold you need and its cheap and easy to make.This instructional mold making tutorial video shows how easy it is to make a one piece silicone block mold using Smooth-On Mold Star 15. Remove any old chocolate from previous uses of the mold. If you pour 600 F solder or zinc into a plaster or clay mold it will make steam which will spoil the casting.How to make an epoxy resin mold for a resin table. When using Elmer’s Glue-all, your artwork will dry to a .Table of Contents.How to pour resin in a mold. What materials are needed for the mold-making process? . Apply a release agent.Auteur : LullaBelleCreation

The mold is not completely clean. A mold made of metal works for low temperature metals .Montre-le avec la collection Method of Make : des versions limitées et premium d'une sneaker déjà légendaire. Step 7: Cure and De-mold.

Aluminum Casting At Home

By taking these precautions, you can create a safe and efficient work area for making your mold. À la fois moderne et rétro, notre jean Column est inspiré de ceux que portait votre père. Les tissus doux sur la languette et les renforts apportent un . Stop pouring when the top sprues are almost, but not completely, covered.You can buy molds for making candle.Dylan shows you how to use our new Reusable Resin Molds that make DIYing your own pour way quicker and easier! Buy them here: https://blackforestwood.Pouring the Wax into the Mold Positioning the Wick.Start by lining your silicone molds with parchment paper. Can you create silicone molds at home? 3. Baby powder is an inexpensive and non-toxic material that ca. Pour a small amount of resin into the mold and stir it around with a popsicle stick or other stirring tool. It can be used with both .; Now that we’ve learned how to heat and pour the candy, let’s move on to the next step: . Cook over medium heat, stirring constantly, until the mixture reaches 245 degrees Fahrenheit on a candy thermometer. In a medium saucepan, combine sugar, corn syrup, and water.Regarder la vidéo7:50My other two silicone making videos are incredibly long and I ramble on and on about every little thing.

Chocolate Molding 101: how to prepare chocolate for molds?

Regarder la vidéo1:11https://www. First, roll out your clay evenly and . Color, cast, and design with these DIY resin molds. Our countertop area has a sink so we flipped the sink over and marked it out. Their intended purpose was to help complete beginner. 2. Highly stable under a broad .Critiques : 1

Levi's® Made In Japan Jean 501® 1933

Tap the sides of the container to force any trapped air bubbles to the top. When pouring resin into a mold, you should use a wooden stick to scrape it in rather than your finger.Molds or Surface for Pouring; Step by Step Guide.This is a how to tutorial that goes over using baby powder as a mold release for silicone molds. Adding a small amount of water to dilute the glue can achieve a pouring consistency similar to Floetrol. Once cured, carefully remove the mold box and extract the model. Wear gloves and protective clothing to avoid skin contact and any unwanted . After curing, check for imperfections or air bubbles and address them accordingly. Take into account the height of your mold (plus a little extra).Auteur : bigstackD Casting Spray mold release and fill the box with liquid polyurethane rubber to create a mold.Once more, pour in the silicone mix and create the rest of the mold.

2 Premium Choice: BECKLY Silicone Mold Making Kit; 8.

How to Make Lead Molds

comWe're back with another episode of Video Friday!Today we are talking about silicon molds .How to Mix Acrylic Paint for Pouring Without Floetrol. It is also very important that there is no dirt, dust, or even fingerprints since that can cause the chocolate to stick.

Manquant :

moldAuteur : Robert ToloneMake Molds for Resin Casting

How to Pour Hard Candy Into Molds

1 Best Value for Money: INCREDIBLE SOLUTIONS Silicone Mold-Making Kit; 8. Once the plastic has fully solidified, carefully demold the plastic item by flexing or gently tapping the mold.Conscients de cette pratique, des revendeurs Levi's® gardaient une grande paire de ciseaux à côté de leur caisse pour découper la martingale de leurs jeans lorsque leurs . The goal here is to take the intimidation out of mold making.Silicone molds are super popular with re. Cut a sheet of acetate to size. Are there easy materials to find so that I can use them to . Pour from a corner and let the silicone envelop the model to reduce air bubbles.

How to make Silicone Molds for Resin

Step 1: Types of Molds.

Step 3: Pour the composition into the molds. in this video I explore 3 kinds of molds: open back molds, one-piece cut molds and rotation.Mold Box Tutorial: How to Make a Mold Box for Silicone Molds.Subscribe for m. I think it's a gorgeous magical crystal effect in .Step 1: Cut Cement Board To Size. To cast higher temperature . Before pouring the wax, make sure the wick is centered in the mold. La braguette zippée originale, créée en 1967 ; Silhouette crop . Apply another layer of release agent to the mold to ensure the clay doesn’t stick during the next molding process.Regarder la vidéo4:10In this video I will show you how to pour a candle into a silicone mold, the optimal wax temperature for pouring a candle. There are a variety of mold types for different applications: Pour mold - Mold made by pour silicone over an original inside of a containing box. 799K views 4 years ago.

Silicone Mold Making

Includes step by step how to pour tutorial, supplies needed, what is acrylic pouring.Use liquid latex to create a resin mold by coating the original item in 20 thin layers.Pouring in one spot minimizes air bubbles, which can affect the mold’s detail and accuracy. In this video I show how to make druzy effects in resin by using selfmade druzy silicone molds. Lastly, clean the mold thoroughly before reusing it.Silicone withstands temperatures from -65° to 400° degrees Celsius. Allow the mold to cure as directed, typically for 16 to 24 hours at room temperature. You now have a rubber mold ready for concrete casting. Triple-check your measurements for the hole in the sink.

Mixing Plaster of Paris for Casting in Molds

If you seal the wood and then pour, you should still wait at least 2 weeks for the final seal so that .Adorés pour leur style classique, ils se portent sur la taille et sont légèrement loose au niveau de la cuisse. After removing the mold box, you may need to make some modifications to the mold to enhance its functionality. Cut your form base from 3/4” . Working with Epoxy Resin. When pouring the tempered chocolate in the mold, make sure that the mold is completely clean. Using a press mold to make pottery is actually similar to making a bisque-fired mold on your own.

Manquant :

moldHow to Use a Press Mold to Make Pottery

How to make an acetate “container” for your silicone – or to use as a mold.

HOW to melt and cast your lead & pewter in silicone molds

Beginners Guide To Silversmithing; Ultimate Guide To Silversmithing .

How to Make a Mold for Epoxy Resin Casting

Pour the plaster into the container, completely covering the ring form. To vent pressure you can cut a hole in the middle of the lid. En réalité, ce jean arbore un fit . Allow the concrete to cure for the recommended time to ensure it sets properly. 5 Easy Options to Create Resin Molds at Home. Create a mother mold to keep the latex’s shape with Plaster of Paris.Without further ado, let’s get into it and discuss exactly how you make silver casting molds.Step 10: Demold and Finish the Plastic Item.Join me as I show you how to make an adjustable and reusable mold for casting. Silicone molds can be made using lots of different strategies. Ce mercredi soir (21 heures, Stade Louis-II), le Lille OSC défiera l'AS Monaco, en match en retard de la 29ème journée de Ligue 1. The finished mold c. Decide the desired finished size of your table. When it comes to pouring the wax into the mold, proper positioning of the wick is essential. Slowly add plaster to the water, stirring constantly, until the mixture . For example, 2 cups of plaster to 1 cup of water. Measure the plaster. Here are the general steps to make a casting mold for metal: Get a 2-piece mold frame made of wood, iron, or a similarly solid material. The casting material is poured into the mold via a pouring . Co-authored by Mason Martinez, . Allow the plaster mold to dry and remove it from the container. Resin casting can be intimida.; Troubleshooting common issues: If the candy mixture starts to harden before you finish pouring, simply reheat it briefly to soften it again. Mixing and Pouring the Mold Making Material.