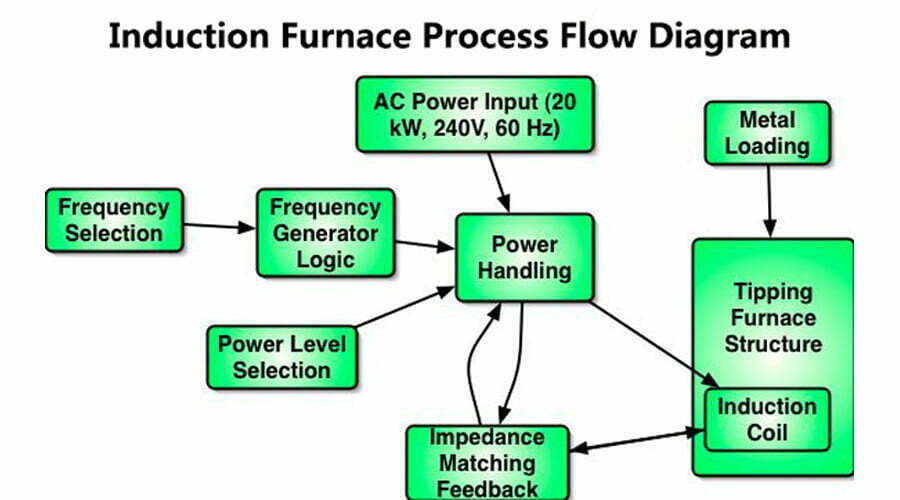

Induction furnace meaning

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, where eddy currents (also called Foucault .

1) GLD is directing the first earth for the system . It can be used in the home for many things, including cooking, cleaning, and more. The main components of the .Induction heating is a process that uses electromagnetic induction to heat electrically conductive materials, such as metals, without direct contact.

Wikipedia

The targeted temperature for .

Crucible Furnace: Types, Advantages, and Disadvantages

Induction furnace definition: a type of electric furnace used for melting a charge of scrap by the heat produced by its own electrical resistance. In fact, it is a special form of electric arc furnace.Induction furnace is to run at maximum power since beginning. The plant engineering product program for the cast iron / steel, light and heavy metal industries covers the entire process chain from melting plants to heat treatment plants. GROUND LEAK DETECTOR.An induction heating system consists of an induction power supply for converting line power to an alternating current and delivering it to a workhead, and a work coil for generating an electromagnetic field within the coil. With proven induction melting technology for every melt shop requirement, we have the experience to help. This signal is an electrical current that starts the motor. Carrying out all processes, from pouring to refining, in the same container reduces production steps, increases energy savings and improves metal . Silica ramming mass is used for melting carbon steels with carbon content higher than 0.The type of furnace used can be tailored to the needs and specifications of the foundry company.

5 Ways to Use Induction Heating in Your Home

Manquant :

meaningInduction Melting Furnace: A Complete Guide

Eddy currents can, however, be generated in any conductor, and magnetic .

Manquant :

meaningWhat is Induction Furnace?

Overview

What Is Induction Heating?

Manquant :

meaningInduction Furnace

Hotter metal leaving the channel circulates upward .Our vacuum induction melting (VIM) or vacuum arc remelting (VAR) furnaces are designed to develop new materials for melting metal alloys, glasses, silica, refractory materials, and oxidizing materials requiring high temperature ranges. See the full definition See the full definition Menu ToggleInduction heating uses electricity to create heat from magnetic energy.The r value measures the ability of a material to support the formation of a magnetic field within itself.

What is induction furnace in Hindi?

INDUCTION FURNACE Definition & Meaning

IH technology has been established using electromagnetic field and thermo-fluid simulation to heat non-magnetic materials such as copper and aluminum with high efficiency, at high speed, and with high accuracy. Using clean scrap .

A Detailed Analysis

Eddy currents are induced in the metal (charge), the . These currents are induced using three electrodes positioned inside the furnace.In an induction furnace, the metal charge material is melted or heated by current generated by an electromagnetic field.the world's leading provider of industrial furnace systems for melting, heat treatment and recycling. In case of voltage exceeding 200V,GLD will turnoff the power unit automatically. The material must withstand temperatures ranging from .An induction furnace works by transferring heat energy via a high-voltage primary coil that induces a high current, a low voltage, or a secondary coil.3 Inductive heating. Induction heating is the process of generating heat by electromagnetic induction. When the metal becomes molten, this field also causes the bath to move. Figure 2 shows as an example the energy balance of three different furnaces in the meltdown phase.Induction furnace melting is a process of melting metal by using electromagnetic induction to produce eddy current heating in metal materials in .The furnace inducer motor gets a signal from the thermostat. This entry has not yet been fully revised.an electric furnace heated by a current which is caused to flow through the charge by electromagnetic induction.In a channel furnace, induction heating takes place in the “channel,” a relatively small and narrow area at the bottom of the bath. Every production cycle, the system generates .

Induction furnace

When the metal becomes molten, this field also .

Induction furnace Definition & Meaning

LF furnace generally refers to the refining furnace in the iron and steel industry.Author : hani Time : 2020/08/05.

Manquant :

Ladle refining furnace is important metallurgical equipment for refining molten steel from primary refining furnace (electric arc furnace, open-hearth furnace, and converter), and can adjust the temperature of molten steel, process buffer, and meet the requirements of continuous casting and continuous rolling.induction heating (IH) has been developed and deployed for internal manufacturing equipment such as heat treatment and bonding. It uses electricity and magnetism to create heat through a coil. Ladle furnace (ladle furnace) is the main refining equipment in steel production.The most commonly used lining material for induction furnace is acidic lining.induction furnace meaning in Hindi. Power factor to be maintained near to one. Induction? Inductotherm Group companies use electromagnetic induction for melting, heating and welding applications across multiple industries. Induction furnace (IF) steelmaking is one of the two .This article will go over the properties, basic materials and binders, and principles for determining induction furnace refractory lining. It is produced by calcining, crushing and grading of the white crystalline quartz containing 99. When an object is placed in this field, two heating effects occur: Hysteresis losses – these occur only in magnetic materials such as iron . It draws air through the furnace’s combustion chamber, creating a draft that ignites the fuel. Half Bridge induction Heater Using LCLR Work Coil.Induction Power Window Ladle Systems combine the mobility, strength and refining flexibility of a steel ladle with the melting power, stirring action and precise temperature control of an induction furnace.

The channel passes through a laminated steel core and around the coil assembly.

![Induction Furnace - [PPT Powerpoint]](https://reader017.fdocuments.in/reader017/slide/2019112410/545e925aaf79592b708b48e9/document-4.png?t=1631174936)

See meaning & use.

Induction heater

Cross section of Furnace 1-Melt 2-Water-cooled coil 3-Crucible 4-Yokes. This is called inductive stirring. The work piece is positioned in the coil such that this field induces a current in the work piece, which in turn produces . 2) It is the voltage sensing circuit it senses voltage across the DC supply. Only Inductotherm can . See ‘Meaning & use’ for definition, usage, and quotation evidence.In the induction furnace, a coil carrying alternating electric current surrounds the container or chamber of metal. Advantages: Flexible. See examples of . The following are the advantages and disadvantages of crucible furnaces. When an alternating current passes through the coil, it generates a magnetic field that induces eddy currents within the material, causing it to .Induction Melting Furnaces. Further, using the same heating fundamentals as vacuum crucible heating applications, induction heating can be carried under atmosphere for continuous .Induction furnace is a type of furnace for steelmaking which uses electrical energy for its operation.What Is Induction? To heat non-conductive materials such as plastics or glass, induction heat a graphite susceptor which transfers the heat to the non-conducting .If you are melting precious metals, an induction furnace helps you do that and still retain the quality of the metals after the process. iron, cobalt, .An induction furnace melts metal by creating very large currents in the material.The induction furnace is an electric furnace that uses materials to induce electric heating effects to heat or melt materials.INDUCTION FURNACE definition: a type of electric furnace used for melting a charge of scrap by the heat produced by its. There are some misconception of running furnace at low tap initially and then gradually increase to higher tap.Induction furnaces are systems where the heat is generated by induced currents by the electromagnetic field.AOD is mainly used for decarbonization and refining.

But the signal only triggers a relay. LCLR Induction Heater Using Multiple Distributed . How common is the noun induction .

The History, Process, and Application

What is Induction Heating?

Basics of Induction Heating. As a result, the coil generates an alternating magnetic field. It normally consists of high purity silica ramming mass.an occasion when someone is formally introduced into a new job or organization, especially through a special ceremony: induction into Their induction into the .

Vacuum Induction Melting (VIM/VAR) Furnace Systems

Our melting applications cover the needs of laboratories and R&D centers to industries and small . Most materials behave similarly to vacuum: Few materials (e. Induction tempering takes place after the hardening process and involves heating the part to a much lower temperature than is required during hardening. In induction heating, an alternating current (AC) source is used to supply current to an induction heating coil.

This connects the motor to power, making sure it works safely. This constant motion naturally mixes the bath producing a more homogeneous mix and assists with alloying. Easy slag separation. The name OTTO JUNKER stands for first-class capital goods. We offer a variety of smaller induction furnaces to meet the demanding requirements of investment casters, specialty foundries . The refractory lining material is a heat-resistant material used in the construction of industrial equipment that will be subjected to high heat loads.As the world’s leading manufacturer of induction metal melting systems for metal producers today, Inductotherm has built more than 38,500 melting and heating systems for metal and metalcasting producers around the globe. The furnace is automated so that once the material has been melted, the electrodes are removed and the furnace then tips the molten metal into a crucible where it can be easily transferred to . OED is undergoing a continuous programme of revision to modernize and improve definitions.

Manquant :

meaningUnderstanding Induction Furnaces: A Brief Guide

Induction heating

The electric circuit is completed when the channel is filled with molten metal.Induction heating is well suited for specialty metal applications involving titanium, precious metals, and advanced composites.