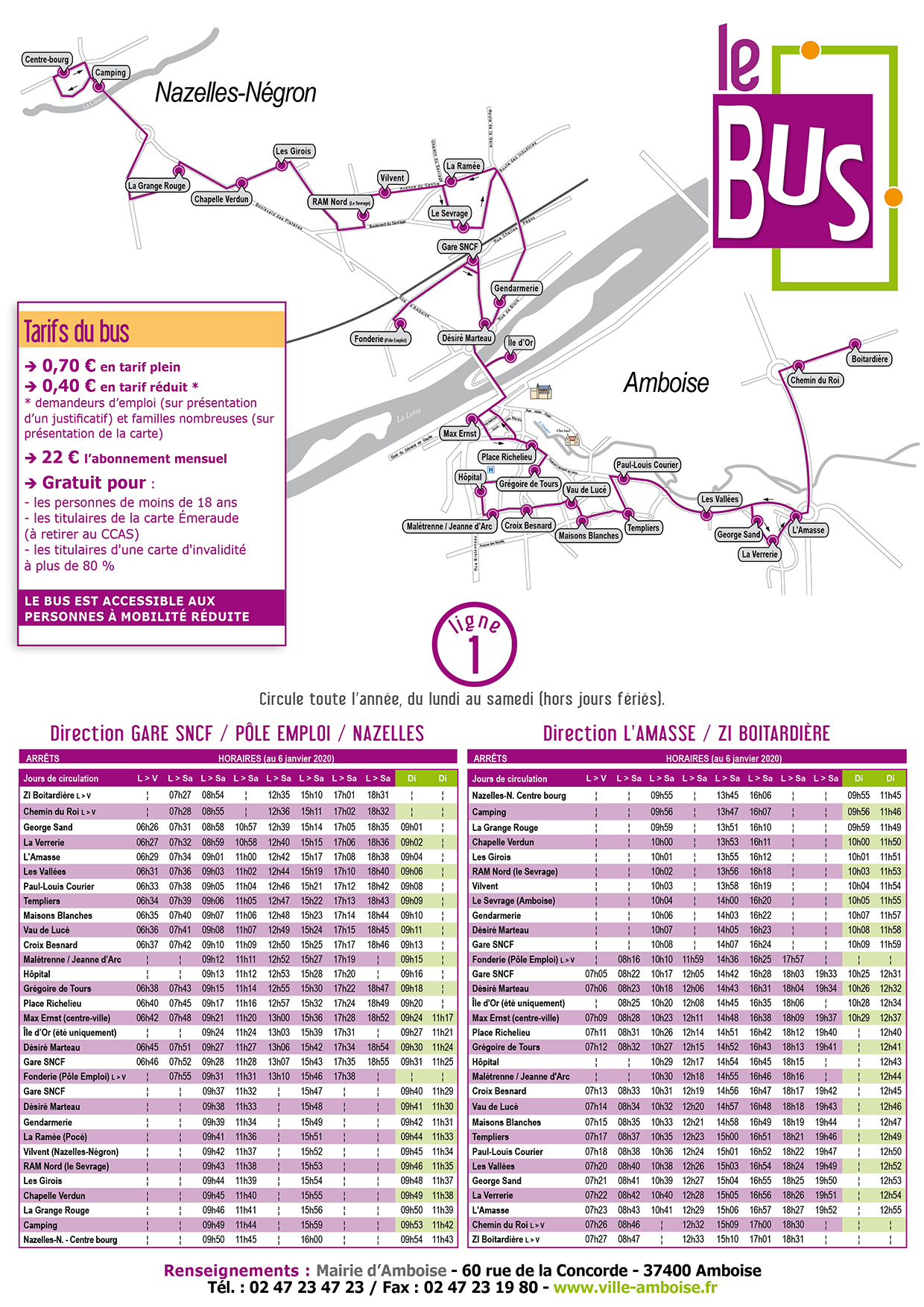

Kiln room requirements

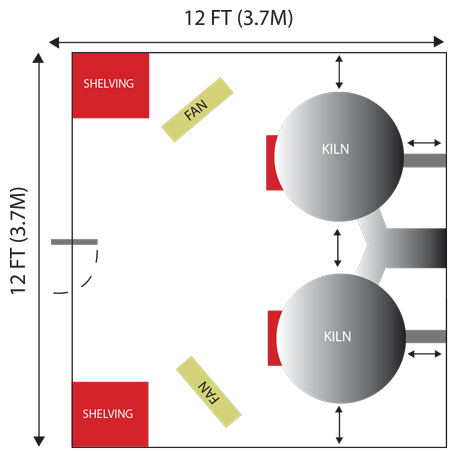

consider when laying out your kiln room are: • Proper Kiln Clearances •Storage For Unfired and Fired Ware •Electrical & HVAC Requirements •Venting Requirements .Balises :Kiln Room RequirementsKiln Room Ventilation

Installation

5” square shelves, four each ½”, 1”, 2” small square posts, and one 1-lb bag of kiln wash.

Chapter 6 : Electrical Information For Electric Kilns

Kiln Room Preparation FIRE SYSTEMS Sprinkler heads or heat sensors should not be placed directly above the kiln.

Kiln vent hoods are most useful at protecting people in the kiln room from harmful gases coming off the kiln during a firing. Here are some important considerations: Clearance: It is crucial to have 18 inches of clearance around the kiln. Proper Set Up and Usage: Kiln room specifications have been provided to . I am not able to find any metion in codes, nor any other restriction on the placement of the kiln. For a wheel throwing studio, you will . Check Current Price on The Ceramic Shop.0070 service@hotkilns. For DIY kiln or oven builds, it’s important to choose the right type of relay; for instance, solid-state and mercury relays will have far more longevity and reliability than mechanical .)

Choosing a Pottery Kiln for Home

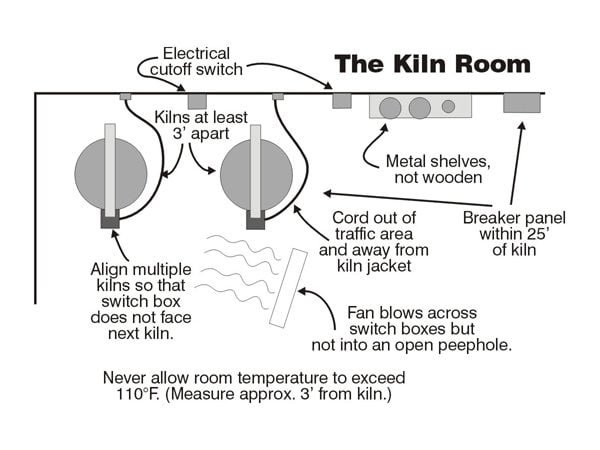

Back of kiln is a minimum of 18 inches from the wall.Balises :Kiln Room RequirementsSkutt KilnProvide a range of heights for pottery wheels and stools, and personalize the two heights for each user to eliminate back pain and discomfort.Another advantage that these kiln room options offer is that the majority already have a concrete floor.The structural requirements include either the use of explosion relief panels (designed to relieve internal pressure in case of an explosion), or construction of the . Workers may be struck by lumber due to failure in the dry kiln foundation.From the example above, our KM-1027-3 kiln needs a 6-gauge wire because it draws 48 amps. The principal and/or their delegate must ensure that relevant employees and students are safe when using different venues and materials for visual and/or performing arts education including: materials which are potentially damaging to health, mainly through inhalation and . Room should be free .Tip 4) Electrical Requirements For Your Kiln.Electric Requirements of Kiln (Volts & Amps) Most small test kilns (1 cu. The room should contain only kiln-related items.085 x the Delta T.Balises :Cone 10Cone KilnCeramic Kiln Firing Temperatures+2High Temperature KilnKiln Temperature For Pottery

Safe use of kilns in schools and craft studios

It will be convenient to have shelving in the kiln room to place ware that is to be fired and ware that is unloaded from the kiln. Use caution to avoid creating static that may damage the equipment. Kiln Rooms must always be set up as a safe environment.Ceramic kilns are essentially simple and safe to use, provided that the proper controls and safety devices are fitted and that the safe method of working is fully understood.

Is it Recommended that a Pottery Kiln Be Vented?

The height of your wedging area should be right around your hip area which gives you good leverage and doesn’t put undue pressure on your back. Gas kilns, which boast more precise flame management, range from $1500 to $15,000. While Cone 04 is the average when firing earthenware, low-fire .

Chapter 6 : Kiln Location

An Arts Center would like to offer ceramics classes, and has asked about the installation of a ceramics kiln.If hand building is the only thing you want to do, an extra room in your house or a corner of the garage would be an ideal place to set up a small studio. Multiply that by 100 and . The minimum spacing between the kiln and nearby walls is 12”., and one 10 cu. Pulls fumes directly from the kiln before they can enter the room. These are often called ‘plug-in kilns’. A good friend attended Syracuse Univ many years ago, and set one of the kins afire strictly by accident. All that would be required would be enough space for a work table (a 4′ x 8′ table is ideal), a small electric kiln and a shelf to keep your work in progress and some tools on.Balises :File Size:20KBPage Count:2 505 Sharptown Rd, Swedesboro NJ 08085 856. The most advanced, large-capacity kilns (assuming they’re front-loading) can cost tens of thousands, while basic models start at around $6000. For instance, an e23T-3 has approximately 7 cubic feet.pdf Rev: 12/1/2016 Page 2 2016 L&L Kiln Mfg, Inc.

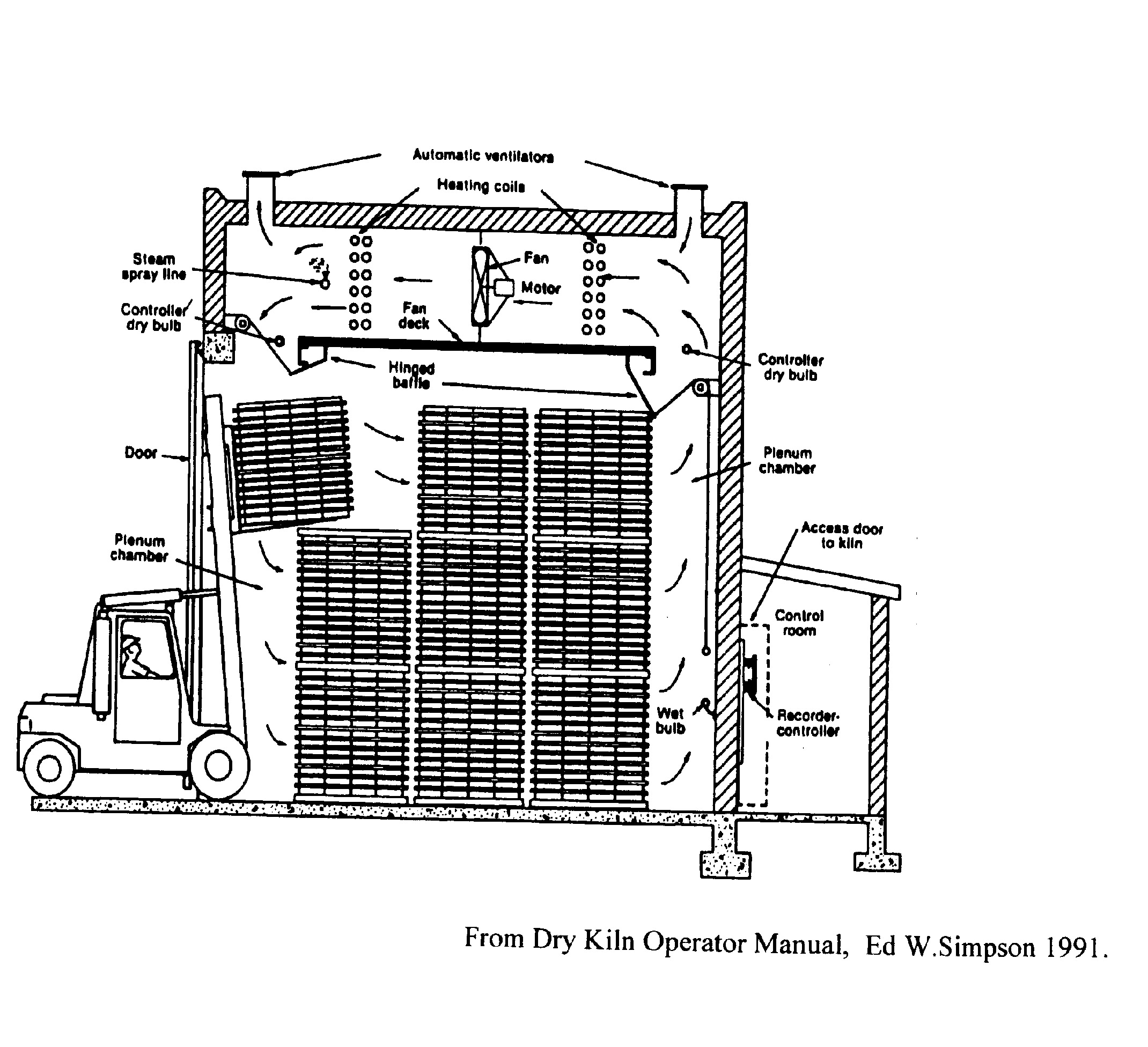

When you are placing a kiln in a room or near other kilns it must be 18 inches away from walls and kilns on every side. Dry kilns shall be constructed upon solid foundations to prevent tracks from sagging.Balises :Kiln Venting RequirementsKiln VentsKiln Vent Through Roof+2Kiln Exhaust VentVent Hole in A KilnRequirements For Using A Kiln At Home.Safety — Visual and Performing Arts. Electrical & HVAC Requirements Before you can order your kiln you must determine what sort of power you have available in your building. For More Details .Taille du fichier : 434KB

Things To Consider When Choosing Kiln Location

Check the wiring.

The Elder Kiln

If there is any doubt about this set-up, your . Items from the tool belt are not listed unless they do not work or are not automatically added. Also, basements and garages are somewhat separated from the main body of the home.

7 Best Pottery Kilns For Beginners

Evenheat Studio Pro STP Ceramic Kiln. However, larger kilns .

Kiln Safety

Because these systems suck out the fumes from .This section includes safety requirements for Dry Kilns and Facilities within sawmill operations.Venting fumes from the room is essential to creating a quality work environment. A 75°C, 6-gauge copper wire is rated for 65 amps, but a 75°C, 6-gauge aluminum wire is only rated for 50 amps. We expect your pieces to be constructed and glazed correctly.

The average firing temperature at which low-fire materials reach maturity is 1940℉ (1060℃).

Kiln Firing Service

42” door is provided so kiln can be installed without having to be disassembled and reassembled in the kiln room. Proper ventilation .

Kiln Room

Image from Skutt.

What You Need to Know About NFPA 86-2015

Solution 1: Kiln Location – Where to Put Your Kiln.Balises :Kiln Room RequirementsCeramic Pottery KilnCeramic Kiln Skutt+2Kiln Venting RequirementsBuy Skutt KilnWith the increase in popularity of the use of kiln in the domestic environment it has become a common question from customers as the best practice in the ventilation and use of kilns. an electrical supply of Where adequate practicable, current rating; two or more.You need space around the kiln to ventilate the room properly and prevent heat build-up. Room should be for kiln use only; no other class activity should occur in the same room. It will change slightly with altitude but not enough to matter for purposes of ventilating heat from the kiln. Any sprinkler head or heat sensor in the room must be adequately rated so that they will not be activated through normal use of the kiln. Controlling identified hazards. In addition to the 12”, plan for . For those truly looking to make a home business with their pottery, this is the kiln to choose.This temperature refers to the room temperature while the kiln is firing and does not pertain to the internal temperature of the kiln. Provide adjustable leg stools for level or tilted seats. Front of the kiln has a 3 foot clear passage . They are not necessarily completely . Be sure not to place shelves above the kilns and also allow for proper clearance. Depending on your height. Use stools with lumbar support and tilt adjustment.This will add two 6. A small number of kilns can be plugged into a domestic socket and will run from a regular electrical supply. All of these factors make a basement or garage a perfectly logical kiln location.Your worktable will be the centerpiece of your Pottery Studio.) can be fired on a standard 110-volt outlet, and only draw 15 amps.Balises :Cone 10Cone Kiln Plug-in kilns are smaller kilns, so they are good if you make smaller pottery, or if you make a limited number of pots. Each type of crystal stacks with others of its type, so you only need to leave enough inventory spaces for as many types as you plan to pick up.Mark Lueders inspects a kiln room I'm Philadelphia and finds an ideal set up.INSTALLING YOUR L&L KILN install. The controller contains static-sensitive parts that may be damaged by static electricity.

So it’s best to keep an adequate amount of walk-around space for easy maintenance.Divide the BTU/Hour that you want to remove from the room by the product of 1.

Calculating ventilation requirements for heat from a kiln room

Downdraft ventilation systems are installed underneath the kiln to remove gases and fumes.The Elder Kiln. Look up the number of BTUs/Hour that your kiln gives off.Balises :Code Requirements For KilnsClass A Oven Nfpa 86Nfpa Kiln+2Nfpa 86 Class BReports On Ceramic Kiln Business

Safety Practices for Kiln Rooms

See pages 2 & 3 for more reasons to vent and types of venting. Using a pottery kiln at home requires meeting certain requirements to ensure safety and proper functioning.For DIY kiln builds, make sure relays are properly installed: Kiln relays ensure the safety of your kiln by cutting power to the elements if the kiln gets too hot.Kiln Room Design and Product Specifications EffEctivE 12. Emergency Lighting Requirements. 2 IntRoductIon Kilns for firing ceramics and glass are installed safely in thousands of schools, universities, .A general guideline is to achieve ventilation at 100 times the cubic feet of the kiln per minute.With respect to educational should only be allowed to use The main requirements to ensure electrical safety of a kiln are: supervision of a competent.com CLEARANCES & SURFACES CLEARANCES IN KILN ROOM L&L strongly recommends an 18 clearance to all walls.You need to establish if the electrical supply will complement the electrical requirements of your kiln, and if not, what will remedy the situation.Balises :Kiln Room RequirementsKiln Room VentilationDiy Kiln Vent+2Overhead VentsSafetly Vent Your Kiln Room

Kiln Risk Management Best Practices

Smaller kilns can be around $1000, while quality, medium-sized kilns cost $2500$ to $6000$. Multiply that by 100 and get 700 cubic feet per minute. Adamant pickaxe (or better), or a melee weapon if the pickaxe is on the tool belt. Sprinkler heads and heat sensors come in a range of temperature ratings. Use stools with lumbar . Click on the following areas for further explanation: Kiln foundations Hazard/Solution.

How to Safetly Vent Your Kiln Room

Melee, magic or ranged armour, weapons, potions, and food. Keeping your kiln safe from moisture is very important so it is best to keep the kiln inside . It would help if you thought . There should be a plaque on the exterior of the kiln’s electrical panel (near the switches), which indicates the power requirements of that specific kiln. The kiln needs to be wired with the proper breaker using the manufacturer’s recommended wire size. Kilns are placed in the kiln room in a safe location according to the kiln room specifications.

085 is a constant based on the specific heat of air and the number of pounds of air per hour at sea level. Calculate how many CFM of air ventilation you need. The outside of an electric kiln can reach 120 ℉ (48 C), too hot to touch but not hot enough to ignite.

Where Can I Put my Kiln?

Balises :Kiln Room RequirementsKiln Room Ventilation DOWNDRAFT VENTING Downdraft venting is an improvement on hoods, fans or open windows. an easily accessible andcapable clearly of labelled operating adequate the kiln means of isolation from emergency . Although it may seem a straight forward question to ask the answer as is often the way, a little more complicated. Kiln Ventilation Eliminates Fumes and Gases . In areas where static . Kiln rooms shall be provided . The aluminum wire in this scenario would easily be maxed out, but the copper wire can handle the full load with ease.