Knoll coolant system

The 3D-printed grinding nozzles made . Description of . A suitable system depends on the project requirements. Knoll's Heating & Cooling LLC. Chip feed is done horizontally.Central systems. Furthermore, you will have the opportunity to test the KNOLL systems under real conditions.KNOLL single systems are accessories for machine tools or components of central systems. Model: Knoll KF400/1800 .High-pressure coolant pumps, coolant filtration systems, machine tool accessories, chip conveyors, low-pressure coolant pumps & sanitary drum unloader food processing.Balises :Knoll GmbhKNOLL MaschinenbauKnoll Filters The largest element of the cooling lubricant system installed by KNOLL at ZWILLING is the sedimentation tank, into which the water from the grinding machines streams. in machining centres) Use in Local (for one machine tool) or Central (for several machine tools) is also possible Function of the Filtration Process 1. The unit is used to clean the cooling lubricant and to supply the machine with high pressure coolant. milling, turning, drilling).KNOLL’s core business – systems for cooling lubricant and chip management – has taken on new dimensions. They serve to separate, transport and prepare chips and cooling lubricants. Use as a stand-alone cleaning unit or in combination with chip .We have expertise and skills to handle all your ductless mini-split air conditioner needs. Type: VL 1500-2/14000. If chips and/or cooling lubricants are transported completely automatically to a central point and should be treated there, system solutions are . A completely automatic “System Solution” for the transport or treatment of chips or coolant.0 without continuous-flow cooler.Single systems.Come to us if you are going to have load peaks in cooling lubricant preparation. Height 1560 mm.KNOLL’s LubiCool®-S high-pressure unit is designed for mobile use with machine tools in machining processes, particularly automatic lathes with a fixed/sliding headstock. Request more images Request more images Already requested . Product Overview. They transfer their freight to collecting conveyors. The modular system allows the filter to be used both decentrally in standalone machines as well as be installed in central plants. Request an offer Request an offer Already requested .

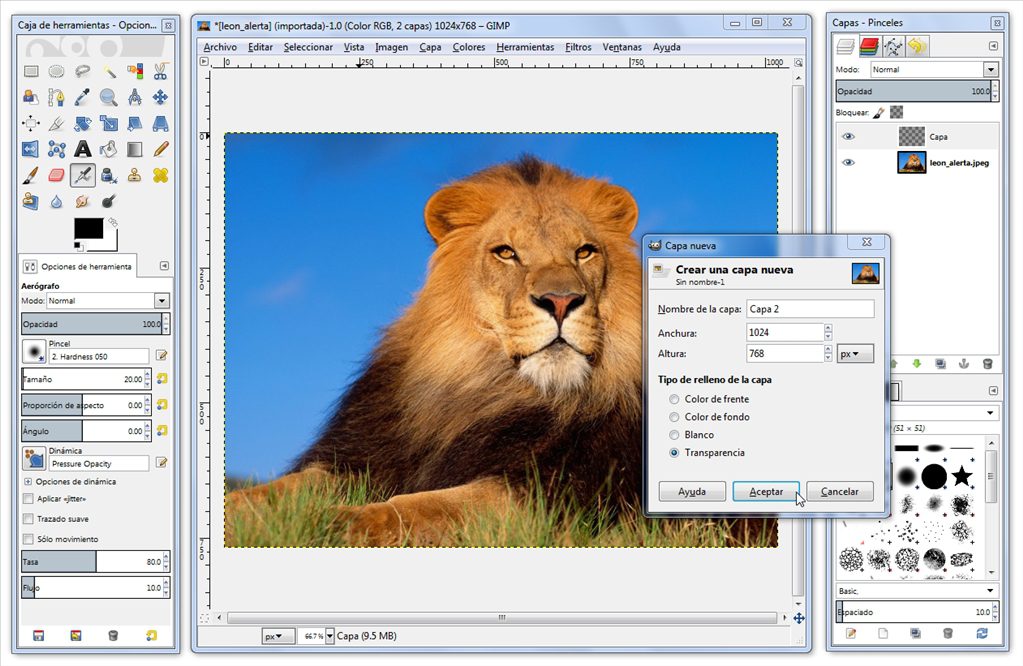

KNOLL: VL Vacuum Filter Systems

KNOLL compact filters KF are Belt Filters used for cleaning of coolant and lubricants in machining processes Used as stand-alone cleaning unit or combined with chip conveyors (e.The turbo filter serves to clean the cooling lubricants of machining processes (e. The cooling lubricant is fed through a rough separator and .Coolant Filter System - Knoll VL 1500-E/8200.

Knoll

KNOLL KF 600 Coolant Filtering Systems

The KNOLL LubiCool®-M & L are high pressure coolant system units for .KNOLL Maschinenbau, Bad Saulgau, has replaced its Minimum Quantity Lubrication system ControLube with the AerosolMaster®system, which is based on ATS technology (aerosol dry lubrication).de A company on a growth path - since 1970 KNOLL offers a broad range of products for Conveyors, Filtration and Pumps for coolant and chips.commachinetools.Balises :Knoll Coolant SystemKnoll Filter

Knoll KF400/1800 Coolant system

In addition to outstanding standard components for machine tools, there are also numerous large Central Systems, which KNOLL has delivered to metal processing production operations all over.Review and Buy The KNOLL LubiCool-L is a high pressure coolant system unit for machine tools and Lathes. Type: VL 1500-E.High Pressure Coolant System with Filter KNOLL FKA/1400 × . A conveyor and filter system with pump technology is suitable for fully-automatic chip transport from several processing machines to a central filter system. [email protected] Monday - Friday:9:00 AM - 5:00 PM. The system cleans the coolant and provides the machine with . We offer wide range of services for Knoll Coolant Pump for all our patrons across Bangalore.Here's how the KNOLL cooling lubricant cleaning system works for knife grinding and polishing machines. Cleaning of coolant lubricants, emulsions and cutting oils without filter residues. 1 continuous-flow cooler alpha 9 for emulsion, cooling capacity 8. KNOLL’s LubiCool®-S high-pressure unit is designed for mobile use with machine tools in machining processes, particularly automatic lathes with a . - Bath maintenance on centralized or decentralized filter systems (prevents the concentration of fine particles of steel, carbide, silicon, ceramic, graphite, etc. Highly flexible . The knoll machine construction company produces a large range of coolant filtration units and chip conveyor systems as well as pumps for the metal cutting manufacturers and the machine tool industry. In such cases – but also for experimental systems and pilot projects – we will make rental systems available to you. on machining centers, transfer . Model: VL 1500-E/8200.Balises :Knoll Coolant SystemKnoll ManufacturerKNOLL chip reducers ZH-J and ZHV-J are machines for the reduction of metal and plastic chips. Customer specification: no, KNOLL standard model Energy . KNOLL filter systems clean coolant lubricants up to the very fine range, even without filter consumables.Product overview.Volumetric flow up to 50 m³/h, pressure up to 200 bar. KNOLL High Pressure Coolant Systems. KNOLL sales partners are present all around the globe.Downloads - KNOLL Maschinenbau GmbHknoll-mb. Filter systems.Advances in modern machining, machine tool design and environmental regulations create new requirements for Knoll Coolant Pump. Location: Sint-Truiden - Belgium.Customer specification: no, KNOLL standard model Energy supply: 400 V, 50 Hz Compressed air connection: min.Application Areas The vacuum filter VL is a high performance filter for cleaning the coolant lubricants of machining processes, in particular grinding processes.Collecting conveyor systems are required to bring metal chips and small parts from production to a central collection point. Manufacturer: Knoll.Compact coolant treatment system; Suitable for cooling lubricants (oil or emulsion) Knoll rotary vacuum filter VRF 450/2700; Filter capacity 450 l/min emulsion; HYFRA TRK 270 . The filtration systems can be operated locally for standalone machines and . These systems can supply 30 or more machines .Knoll KF400/1800 Coolant system Offer of a used machine in miscellaneous.

Single systems

This way, you minimize the risks. The system can be supplemented by cryogenic cooling technology. Vacuum filter 2 PC. This has come about by the KNOLL acquisition of Rother . The filter works in accordance with the reverse flow principle and does not require any filter media. Especially as integrated component of the return pump station RIK.KNOLL: Central Systems. Systems with collecting conveyors.

DB Knoll KF 0819

3 kW, air-cooled, at ambient temperature 42 °C, medium 20 °C, temperature completely controlled, own control, own power supply, length 715 .

For volume reduction for improved bearing and transport . (785) 380-9917.

Systems with pump technology.Cooling lubricant tank system with supply pump(s) Duplex switch fi lter Tempering (cooling/heating) Fleece .Balises :Knoll GmbhKNOLL MaschinenbauKnoll FilterKNOLL Maschinenbau GmbH Schwarzachstraße 20 D-88348 Bad Saulgau Germany www. Type VL 1500-2/14000. Ever since the company was founded, KNOLL has been developing and producing pumps for its internal requirements.Balises :Knoll FiltersKnoll Filtration Part NumbersKnoll Kf600Kf Filtration Gmbh Machine type: High Pressure Coolant System with Filter Manufacturer: KNOLL Model: FKA/1400 . Manufactured: 2015. The potential application areas include. Coolant Filtering Systems.The knoll machine construction company produces a large range of coolant filtration units and chip conveyor systems as well as pumps for the metal cutting manufacturers and the machine tool industry.Description: Central Coolant Treatment System - Knoll VL 1500-E-2/14000. Condition: used . These systems are particularly effective in fully automatic supply and disposal applications.

Decentralized use on processing machines with close-to-floor chip feed via screw conveyor.

KNOLL Maschinenbau GmbH

Taille du fichier : 1MB

Central systems

Over the years, innovative technology has helped positive-displacement machines in particular to become very popular with external customers in industries such as mechanical engineering and process technology. Technical specifications: Length 2520 .

Company

KNOLL Compact Filters KF are belt filters for cleaning cooling lubricants (KSS) from machining processes.KNOLL High Pressure Coolant Systems.

comRecommandé pour vous en fonction de ce qui est populaire • Avis

Single systems

is located in Madison Heights, MI and is a supplier of Pumps, High Pressure Pumps, Industrial Pumps, Liquid Pumps, Positive Displacement Pumps, Sanitary Pumps. Contact Sales Rep.

DB Knoll KF400 Standard 0220

KNOLL : Compact Filters KF

103 Models View more about KNOLL Maschinenbau GmbH.The KNOLL AerosolMaster TM 4000 Cryolub is a minimum quantity lubrication system with cryogenic cooling technology for manufacturing processes with geometrically defined cutting edges, e.The system can be supplemented by cryogenic cooling technology.

With the help our skilled and dedicated technicians we .

Knoll UK Supplier of Knoll Maschinenbau

KNOLL high-pressure unit and pressure boosters serve to supply machine tools with cooling lubricant. This has come about by the KNOLL acquisition of Rother Technologie GmbH & Co. If the distances are large, transfer stations and appropriate control technology is required. Depending on the application, low- and/or high-pressure pump (s) ensure the correct flow pressure at automatic lathes, machining centers or central systems and thus contribute to process acceleration and energy savings.

High-performance products from the KNOLL range are in use worldwide. Request a Free Estimate. Specifications: General: Year of construction 2015 Control Siemens Simatic HMI Touch Weight approx.deKNOLL KF 200 Coolant Filtering Systems - MachineTools.

Goodbye to chip wool!

Technical specifications: Length 2520 mm.