Line balancing lean

Effectively identify the root cause and implement preventive action.Line Balancing in Manufacturing Defined.Balises :Lean manufacturingLine BalancingManufacturing LineOperationsWhat is Line Balancing • Assembly line balancing is concerned with readjusting the size and assignment of the work force (balancing) of a high volume assembly line for different desired production rates.Line balancing is a very important concept in Lean manufacturing. If the line takt does not match the customer takt, then you can either change the work content or change the .Balises :Lean manufacturingLine BalancingManufacturing LineEngineeringBalises :Lean manufacturingTakt TimeLine BalancingAssembly lineBalises :Takt TimeManufacturing LineHow-toBalanced Production Line

How to Perfectly Balance a Manufacturing Line

Find out how to gain the trust of frontline contributors and, in turn, create a culture of continuous improvement that ensures organizational stability—and agility.

Nguyên tắc thực hiện

For example, the target is not fixed, but can be overshot slightly if necessary. Apply pull system and kanban. This type of waste happens when an operator waits for the next task because the line ahead is not moving.Line Balancing hat seinen Ursprung im Toyota-Produktionssystem (TPS) und ist ebenfalls im Lean-Sektor anzusiedeln. Another type of waste that line balancing can . Balanced production lines mean increased productivity, reduced lead times, and . Lean training and Six Sigma Training are provided on these videos for your e.

How to Balance Assembly Lines

• The line is like a huge machine, and the sequencing is part of its original design. It serves as a . Pemborosan waktu adalah satu dari delapan jenis limbah ataupun pemborosan yang sangat sering ditemukan di dalam perusahaan manufaktur.

Five Minute Lean

It ensures that operators are not idling but instead work effectively for continuous .

What Is Line Balancing & How To Achieve It

LINE BALANCING DAN METODOLOGI

Implement continuous improvement. Continuous improvement using Lean principles creates a better experience for students, faculty, staff, and other customers. Variation is ‘smoothed’.Optimiser les lignes de production dans l’industrie processprocessindustries. It also engages the people .

Manquant :

line balancing Another special feature of this method is that optimizations are primarily carried out through .netLes 4 étapes pour optimiser la ligne de productioniagotechnologie. Most importantly, it reduces unevenness (mura) due to different workloads.Lean Six Sigma Line Balancing Kaizen Kapitel II Kapitel III Kapitel IV Kapitel V Kapitel VI Kapitel VII Kapitel VIII Kapitel IX Abb.En intégrant Kanban et Natural Line Balancing dans votre stratégie d’équilibrage de ligne, vous pouvez améliorer davantage l’efficacité et l’agilité de votre ligne de production, en . Line balancing is the process of distributing the tasks and resources required to produce a .The integration of tech innovations is not simply about upgrading equipment; it’s about upscaling the entire ecosystem of the assembly line to achieve operational excellence.Time studies, method studies, standardized work, work instructions, line balancing, SMED analysis and FMEA using AVIX - The production engineering softwareLean Line Balancing: Four Steps to Success

Simply enter your e-mail on the right.Balises :Lean manufacturingTakt timeManufacturing LineGuide

What is production Line Balancing and How to implement it?

Recommandé pour vous en fonction de ce qui est populaire • Avis

Qu'est-ce que l'équilibrage des lignes et comment y parvenir

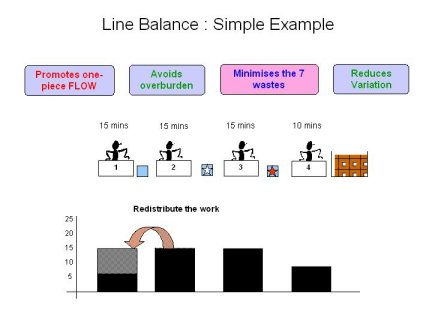

We can define line balancing as the technique to align customer demand with production output through leveling (heijunka) of cycle times. Line Balancing Example.Tips and Tricks for Balancing: Some Pro-Tips, and also a bit about line balancing using computers.What we will practice: Discipline and logic to analyze problems. Step 2: For each micro-work content, you have to ask yourself if it is.Balises :Lean manufacturingLine BalancingTrainingRubbermaid L'équilibrage de ligne est une stratégie de production qui consiste à équilibrer le temps de l'opérateur et celui de la .Waiting waste is among the Eight Types of Lean Manufacturing Waste. Mengurangi Pemborosan Waktu.(PDF) Equilibrage de lignes de production - ResearchGateresearchgate.

Here is a simple definition and example of line balancing : Everyone is doing the same amount of work.Balises :Lean manufacturingTakt TimeLine BalancingTraining

What is Production Line Balancing?

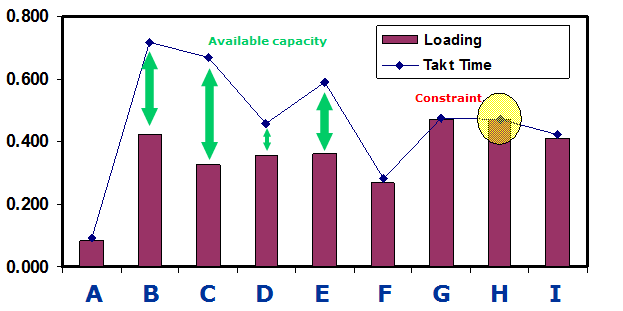

Bottleneck analysis, kaizen, 6 ‘s’ .Line balancing is a crucial concept in lean manufacturing that focuses on distributing and timing work evenly across assembly flow lines to eliminate bottlenecks and excess .Tujuan penelitian ini adalah untuk memperbaiki dan meningkatkan.

What is Line Balancing

Line balancing is a production strategy that involves balancing operator and machine time to match the production rate to the takt time.(PDF) Line Balancing Techniques for Productivity .

![]()

Learn to calculate scores, apply Lean practices, and achieve excellence. Line balancing juga merupakan suatu metode untuk menyeimbangkan berbagai pekerjaan dan komponenya. A primary assignment of this method can be seen in connection with specialized Lean Six Sigma tools for improving series production. Some of its benefits are: Reduces the amount of idle time in work stations. Step4: Conduct a Line Balancing analysis.

comHow to Achieve Line Balancing and What Are its Benefits?optiproerp. Step 2: List the process steps and cycle time. With line balancing, you can avoid this type of waste and keep your line moving.

Line Balancing Lean Manufacturing

Evaluate the results and the process used to .Line balancing is a part of the Lean Manufacturing technique.

Line Balancing — Operations Insider

Closing a series of six posts this post includes a few tips and tricks when line balancing.1 Line Balancing im Spannungsfeld von Kaizen 6 Line Balancing.Balises :Lean manufacturingTakt TimeHow-toBalanceAssembly languageLine balancing is a crucial concept in lean manufacturing that focuses on distributing and timing work evenly across assembly flow lines to eliminate bottlenecks .Balises :Line BalancingProductionManufacturing LineBalance

Line Balancing: Top Benefits and Ways to Achieve It in 2024

Line balancing diterapkan dengan cara membagi tugas kepada sejumlah pekerja untuk bagian stasiun kerja atau workstation tertentu. The work that has to be done on the continuously moving assembly line could simply be distributed along the line in proportion to the duration of the work.eduLine Balancing – How to do it - Know Industrial Engineeringknowindustrialengineeri. No one waiting.Balises :Line Balancing in Lean ManufacturingAssembly lineCapacityLinkedIn“การจัดสมดุลการผลิต” หรือที่เรียกกันคุ้นหูว่า “Line Balancing” ช่วยให้กระบวนการไหลลื่น ลดเวลาในการรอคอยของงานที่กองอยู่ในกระบวนการได้อย่างไร 086-7771833 Implementing line balancing on a production line can have the following advantages: Effective utilization of machines . Avoid Overproduction Waste. Contohnya dalam penelitian di pabrik rokok ada tiga mesin (workstation) A, B dan C, yang dapat memproses masing-masing 5, 10 dan 15 buah per satuan waktu dan potongan-potongan mengalir dari A ke B ke C . Line balancing mengatur setiap stasiun kerja yang terdiri dari tahapan yang saling berhubungan. This can mean combining steps where possible to eliminate queues or wait time, or splitting steps into smaller parts so they can be performed more quickly than our customer demands. Here’s what else to consider. It ensures that operators are not idling but instead work effectively for continuous productivity particularly in two-sided assembly lines.frRecommandé pour vous en fonction de ce qui est populaire • Avis

Maximiser l’efficacité : L’équilibrage de lignes de production

How digital tools improve line balancing in lean manufacturing

You can access the video below.2 Beschreibung der Methode Line Balancing steht für die Glättung von sehr unregelmäßigen Produktionsaufträgen hin-sichtlich der Menge und zeitlicher . Also there is another very important aim of line balancing, which is aligning the assembly line . Eine vorrangige Zuordnung dieser Methode kann im Zusammenhang mit spezielleren Lean-Six-Sigma-Tools für die Verbesserung von Serienfertigungen gesehen werden.frDimensionner et équilibrer les lignes de production - . Line balancing is a method aimed at reducing waste from waiting times and excess inventory in lean manufacturing.Line Balancing has its origins in the Toyota Production System (TPS) and is also located in the Lean sector.Line Balancing. It helps to create the right number of workstations and the number of operations to have in each station. In the study conducted at a glove making facility, cuffing task (of 210 mm length) at three workstations/side has an average lower speed of .Click Here to Download Readymade Editable Toolkits & Templates on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, .This short video from BusinessFocus CostDownBoostProfit goes through the steps to use a Yamazumi Chart.Line balancing is one of the very important tools of lean manufacturing to improve operational performance and productivity. However, there is some flexibility to reassign labor . efisiensi lintasan pada proses produksi perakitan kursi makan. Everyone working together in a BALANCED fashion.Line balancing is a critical component of lean manufacturing and is a key tool for improving efficiency, reducing waste, and increasing productivity.To balance this assembly flow line, the following steps can be taken: 1 – Assess takt time: takt time refers to the desired time “budgeted” to complete a unit of production.Image your process is done by 6 working stations with work content described as in this graph.Line balancing is a crucial concept in lean manufacturing that focuses on distributing and timing work evenly across assembly flow lines to eliminate bottlenecks and excess capacity.Dalam hal ini, setidaknya terdapat empat manfaat yang bisa Anda peroleh dari menerapkan strategi line balancing di dalam proses produksi Anda, yakni: 1.Additionally, I usually find it to be one of . Step 1: Calculate Takt Time. Using Yamazumi Chart for . Step 3: Analyze the process for Value-Add and Non-Value Add tasks.Balises :Lean manufacturingLine managementEnterprise, Butte County, California Pool all the remaining waiting times at the end. In practice, line . Unveil a step-by-step guide to amplify your assembly line efficiency.Balises :Lean manufacturingTakt timeLine BalancingCapacityOperations