Mass customization production

A careful review and analysis of several products produced under the MC protocol demonstrates that, while some products are designed, produced and delivered as customized products, other products are assembled from modules to achieve customization.Mass customization is a process that combines the individuality of customization and the advantages of mass production to meet changing customer requirements.Overview

What is Mass Customization?

Mass customization combines the personalization and flexibility of custom-made business manufacturing and takes it to another level of mass production, which offers a lower unit cost.Mass customization and manufacturing is the process of designing, engineering, and creating products that meet a customer’s unique needs and . Custom production typically focuses on quality over quantity and customization over speed.Mass Production to Mass Customization. However, it is a business model that allows for the customization of products according to customer needs, while maintaining the efficiency of traditional mass production methods. Anda memahami betul kebutuhan dan preferensi .Mass customization.Mass Customization (auf Deutsch auch als kundenindividuelle Massenproduktion oder seltener als individualisierte Massenfertigung bezeichnet) bezeichnet die Verknüpfung von Massenproduktion mit individuellen Produkten, die nach Anforderungen des Kunden hergestellt werden. Untuk memahami mass customization lebih mendalam, perhatikan studi kasus berikut ini.

How technology can drive the next wave of mass customization

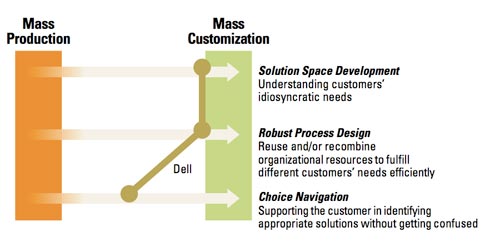

Les fabricants OEM et les fournisseurs doivent gérer des processus de fabrication « lean », synchroniser les opérations et réduire les stocks tout en augmentant la production. Mass Production.68 3 Das Mass Customization-Konzept ihrem Bezugsrahmen (vor allem der Produktionswirtschaft und dem Marke-ting). Kaplan and Haenlein use Porter’s value chain to show the different steps at which mass customization can be integrated (see Fig.Mass customization in business refers to the ability to customize products and services. In essence, it is a paradigm that .

Issues and challenges of mass customization

The change could be as small as changing color or as complex as changing an entire product.

Mass customization

Mass customization is a manufacturing approach that allows customers to personalize products while the business retains some of the speed and low costs of mass production.

Vorteile der Massenproduktion wie Skaleneffekte, .

Contoh Mass Customization.Mass customization as a state-of-the-art production paradigm aims to produce individualized, highly variant products and services with nearly mass .

Aggressive competition, reduced product lifecycles, and significant demand .

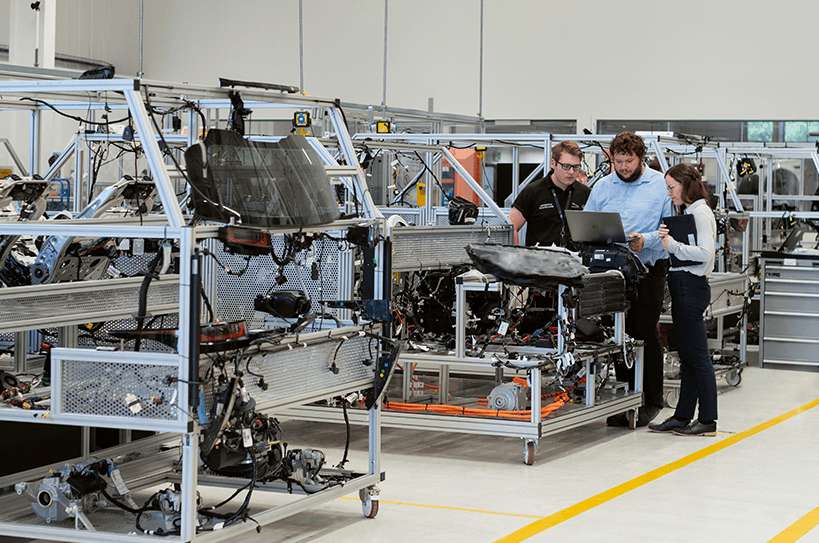

Traditional mass . This approach allows manufacturers to tailor products according to individual customer preferences, while also maintaining efficiency in production. Piller, “Reducing the Risks of New Product Development,” MIT Sloan Management Review 47, no. It involves offering customizable options or configurations, allowing customers to personalize a product to their preferences and needs.Mass Customization is a business model that manufactures and distributes custom goods to mass production standards (O'Sullivan & Sheahan, 2019). Misalkan Anda memiliki bisnis manufaktur sepatu yang telah berkembang dari produsen sepatu tradisional menjadi pelopor mass customization.Classification of Mass Customization Production (MCP) Systems.While mass production allowed manufacturers to reduce human errors and production costs it unfortunately totally disregards the consumers’ needs for personalization because the products are made at a standard quality for the mass. MC draws from other production strategies such as .Mass customization uses “ modularization to simultaneously increase product variety and maintain mass production efficiency ” and technology “ to tap more effectively all . It offers customized production of goods and services as per consumer requirements. Joseph Pine II outlines what was then a novel concept in manufacturing, where product developers combine the economies of scale from low-cost mass production with the tailor-made spirit of the pre-industrial craft system.After mass production and then mass customization, the time is almost ripe for mass personalization. Improve visibility, efficiency, and control of manufacturing production and operations, within and across global/local plants.

An introduction to personalization and mass customization

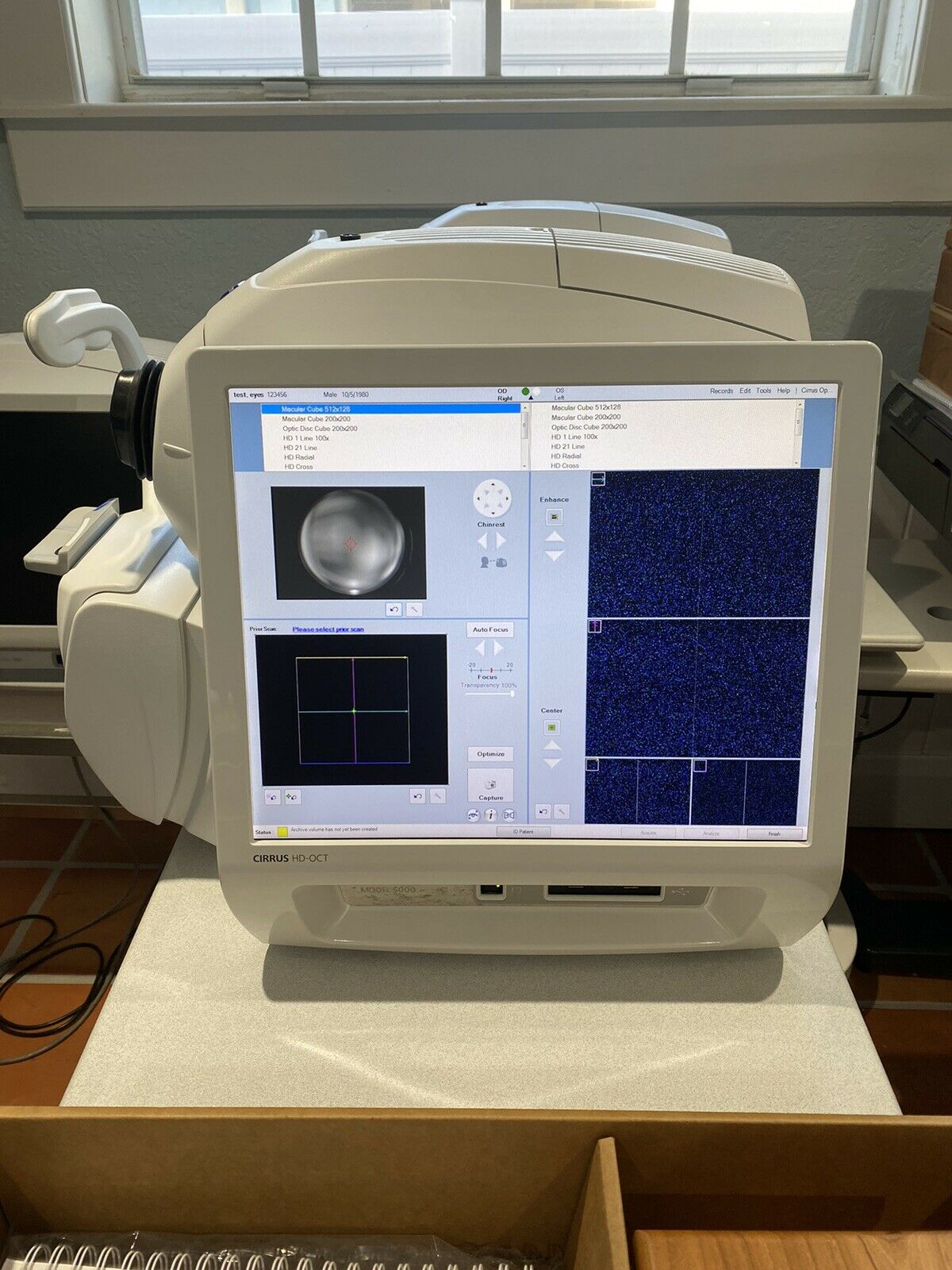

The production system of mass customization using 3D body scanning technology. Mass customization (MC) is defined as a production process or production strategy that aims to provide personalized products and services with the perspective of . To deal with an unpredictable and extremely complicated business environment, as well as shifting consumer demands, businesses are .

Personnalisation de masse — Wikipédia

Understanding Mass Customization: Benefits and Challenges

It was in the early 1990s when individualized products became available again, thanks to Mass Customization.Vue d’ensemble

De la production de masse à la personnalisation de masse

” It challenges the conventional product development .

Er definiert die Zielsetzung der Mass Customization als „to offer a truly customized product – one made to the customer’s . Mass customization has become a viable approach for small manufacturers due to the onset of new marketing technologies, 3D printing and more effortless prototyping, product configurators, and advanced manufacturing ERP software.

Mass customisation is the perfect combination of mass production and customisation, which aims to provide unique products or services on a large scale and at a relatively low cost.Mass customization has the potential to help companies increase revenue and gain com petitive advantage, improve cash flow, and reduce waste through ondemand .Rungtusanatham and F.The choice of which step of the chain to select has a strong impact on the level and quality of .Tseng and Jiao ( 2004) identified three aspects of customizability—design customizability, process customizability, and perceived value of customized product. This guide will provide .大量客製化(英語: Mass customization )是一种旨在快速响应客户需求,同时兼顾大规模生产效益的运作战略。将顾客个性化定制生产的柔性与大规模生产的低成本、高效率相结合,寻找两者的有效平衡点。 大量客製化起源.Mass customization stands as a dynamic business strategy, strategically positioning itself at the intersection of efficiency and personalization.Aside from shopping apps and smartphone scanners, several other technologies — 3-D printing, networked production and high-speed data transmission — are enabling mass customization.Although mass customization, which utilizes modularization to simultaneously increase product variety and maintain mass production (MP) efficiency, has become a trend in recent times, there are some limitations to mass customization.

/GettyImages-1190952893-c21f14d3c24e46ee94364d2dcafbde7b.jpg)

There are four major approaches to mass .

大规模定制

Jie Pei, in Digital Manufacturing Technology for Sustainable Anthropometric Apparel, 2022.In other words, mass customization aims to deliver products and services that best meet individual customers’ needs with near-mass product efficiency (Tseng, et al.In his 1992 book, Mass Customization: The New Frontier in Business Competition, B.While the goals of mass production, mass customization and personalization can be summarized as economy of scale, economy of scope and value differentiation respectively, the role of the cipation.

Mass Customizations

Thus, products that meaningfully meet .The term “Mass Customization” may seem like a contradiction in terms, as it combines the concepts of mass production and customization.Mass customization definition refers to a business concept of offering customized products and services to meet the individual customer’s requirements. The goal is to offer unique products designed for the needs of each customer. Modular customization and collaborative customization are two common . Salvador, “Transitioning from Mass Production to Mass Customization—Hindrance Factors, Structural Inertia and Transition Hazard,” Production and Operations Management, in press.

The paradigm shift of mass customisation research

Traditional mass production involves the manufacturing of large quantities of standardized products in an efficient process. Mass customization has become a viable approach for small manufacturers due to the . Mass customization requires more design, engineering, and quality control than mass production, which can also reduce efficiency. However, production in larger series of products also has its advantages, and the promise of “lot size one” is still far from being the norm in several sectors of the . Some products are .Pine in 1993 introduced an industrial perspective in the new-born concept and defined mass customization as “providing tremendous variety and individual customization, at prices comparable to standard goods and services” to enable the production of products and services “with enough variety and customization that .Mass customization is a production methodology to address this shift. Each newer paradigm will encompass the goals and approaches of a prior paradigm and demand more responsive . Many changes in various aspects of the business . 早在1970年,未来学家艾爾文·托夫勒在《未来的冲击》一书中,对大量客製 .This paper reviews the development of the paradigms of manufacturing, including mass production, mass customization and the emerging paradigm of .The purpose of mass customization is to satisfy individual customer needs with near mass production efficiency (Tseng et al.It is driven by technology, and its paradigm has shifted from craft production to mass production to lean production to mass customisation (MC).Mass Customization vs. Companies tend to keep the price of production low or equal to the .