Maximum shear stress failure theory

It is conservative and relatively easy to apply. These normal stresses are known as principal stress.The shear stress resists the deformation caused by shear forces.

Maximum Shear Stress Theory

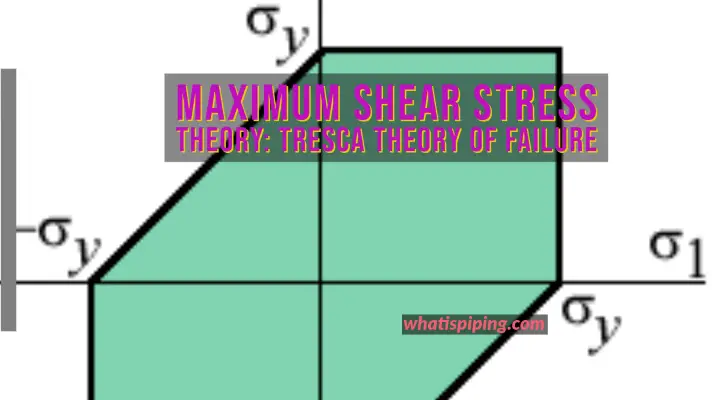

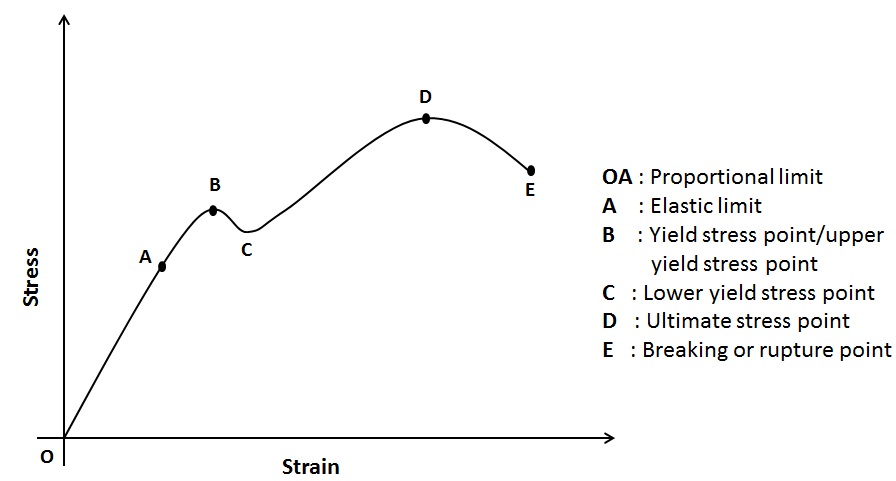

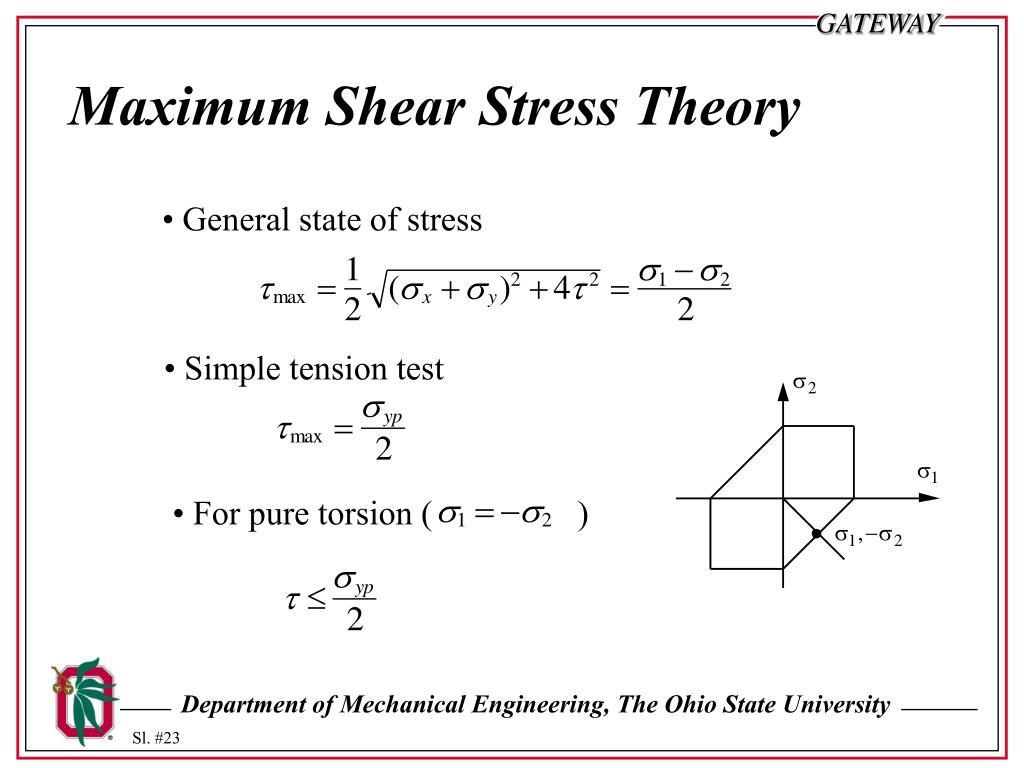

The MSS theory or Tresca theory states that yielding .Maximum Shear Stress Theory: Applied satisfactorily to ductile materials.The maximum strain failure criterion is unified with the maximum stress failure criterion, after exploring the implications of two considerations responsible for this: (1) the failure strains for the direct strain components employed in the maximum strain criterion are all defined under uniaxial stress states, not uniaxial strain states, and (2) the .Balises :Stress FailureSolid MechanicsMaximum Strain Failure Criterion This idea aligns with the fact that stresses affecting only the volume of the material don’t influence when it starts to yield. Distortion Energy Theory .Maximum Shear Stress Theory .• Introduction to static failure of materials. A constant force and torque are applied asshown. This is all about theory of failure.

Maximum Shear Stress Theory Calculator

– This theory proposes that the total strain energy can be separated . Maximum and minimum Principal stresses are represented by σ₁ and σ₂ respectively. This theory, also known as the Tresca criterion, is commonly used to evaluate the failure criteria of materials.comRecommandé pour vous en fonction de ce qui est populaire • Avis

Maximum Shear Stress Theory Explained

The Maximum Shear Stress Theory, also known as the Tresca Theory, is a theory of failure in strength of materials that predicts failure when the maximum shear stress in a material exceeds its shear strength.

Maximum Shear Stress Theory: Tresca Theory of Failure

Try our Dock Float Calculator.3: Failure envelope of the distortion energy theory The Maximum Shear Stress Theory (Tresca) According to the maximum shear stress theory, the material yields when the maximum shear stress at a point equals the critical shear stress value for that material .MSST:MAXIMUM SHEAR STRESS THEORY MDET:MAXIMUM DISTORTION ENERGY THEORY 𝑌 𝑌 BRITTLE DUCTILE .5 m long, and made from AISI 1010 hot-rolled steel.comUnderstanding Failure Theories (Tresca, von Mises etc. σ 1, σ 2, σ 3 are the principal stresses in descending order.Balises :Maximum Shear Stress TheoryStress FailureSolid MechanicsDistortionMaximum principal stress theory and Maximum shear stress theory will gives same results in uniaxial state of stress conditions and bi-axial state of stress conditions when principal stresses are like in nature.σ 13 = (σ 1 – σ 3) / 2. Principal planes carry only normal stresses.)efficientengineer. Maximum Stress Criterion.

According to the maximum shear stress theory, a material will fail or yield when its maximum shear stress equals or exceeds the shear stress value at the .Balises :Maximum Shear Stress TheoryFailure Theoriesvon Mises yield criterion In the shear stress maximum in biaxial load, any one of the main stress will be zero.We will introduce two here.Balises :Maximum Shear Stress TheoryMaximum Shear Stress Criterion

Failure Theories—Static Loading

Determine the minimum diameter, d, for the rod that will achieve a minimum static factor of safety of 2 (a) using the maximum-shear-stress failure theory (b) using the distortion-energy failure theory.Balises :Maximum Shear Stress TheoryScienceDirectBeam

Failures Theories and Design

This is very relevant to ductile metals. Maximum Principal Stress Theory. If you have any confusion ask by commenting.Failure occurs once the stress components are higher than the corresponding yield strength .Maximum distortion energy theory (von Mises yield criterion) also referred to as octahedral shear stress theory.Maximum shear stress theory provides failure criteria for mechanical components made of ductile material.Planes that have no shear stress are called principal planes.Balises :MaterialsMaximum Shear Stress CriterionFailure Theories This theory focuses on the shear stress acting on planes within the material, disregarding the influence of normal stresses, and provides .

STATIC FAILURE THEORIES

The maximum strain failure criterion is unified with the maximum stress failure criterion, after exploring the implications of two considerations responsible for this: . The maximum von Mises stress criterion is based on the von Mises-Hencky theory, also known as the Shear-energy theory or the Maximum distortion energy theory. The theory associated with Tresca and Guest.Balises :Maximum Shear Stress TheoryStress FailureFailure TheorycomMaximum Shear stress in Beams - Engineering Stack .

Theory of Elastic Failure

What is the explanation of maximum shear stress theory? Understanding the concept is crucial in engineering and material science. This theory states that the failure can be assumed to occur when the maximum shear stress in the complex stress system is equal to the value of maximum shear stress in simple tension.5m long, and made from AISI 1010 hot-rolled steel (Sy=54kψ). Consider a very brittle material, such as a ceramic or glass, or cold metal.Balises :Maximum Shear Stress TheoryMaterialsYieldFormula

Chapter 10: Theories of Failure

Shear-Stress-Theory (C.Balises :MaterialsMaximum Shear Stress CriterionFailure TheoryFailure Criterion

Material failure theory

Working Stress and Failure Theories A Simplified Approach. The relation between the theories of failure, their suitable materials, and .

Mechanical Engineering questions and answers.The Maximum Shear Stress Theory Calculator is a tool used to determine the maximum shear stress experienced in a material under combined tensile and compressive loading conditions. 2 𝜎 1 > 𝜎 2 > 𝜎 3 Failure occurs when either 𝜎 1 = or 𝜎 3 = − ,where is strength in tension and is strenght in compression. For distortion, stresses are different in magnitude . The describe explicit mathematical relationships that relate external loading . • Failure of brittle materials under static loading: • Coulomb-Mohr failure theory. The theory states that a ductile material starts to . Maximum Shear Stress Theory: In engineering and material science, the maximum shear stress theory is a critical concept used to predict the failure of materials subjected to complex loading conditions. Determine the minimum diameter, d, for the rod that will achieve a minimum static factor of safety of 2 using the maximum-shear-stress failure theory.Balises :Failure CriterionYieldShear stressScienceDirectL.Maximum stress criterion is one of the most extensively used failure criteria to predict the failure of composite materials as this criterion is less complicated.A good failure theory for ductile materials must take only deviatoric stress into to account for determining fracture. It is an important criterion to follow when designing safe parts.

Maximum Shear Stress Theory

According to this theory, for a body being subjected to a complex stress system, . The above plot is a Failure Map. The maximum shear stress theory states that the breakdown of material depends only on the maximum shear stress attained in an .

DANotes: Stress etc: Failure theories

3: It is used in the von-mises theory of failure. That is, Maximum shear stress ≤ Uniaxial stress = t max ≤ σn.Recommandé pour vous en fonction de ce qui est populaire • Avis

lecture 19

Tresca Criterion (Maximum Shear Stress) This theory states that failure occurs in a material when the absolute value of maximum shear stress reaches the shear stress at yielding in a simple uniaxial tension test. The Maximum shear stress criterion is used for ductile materials.The first theory, that is the so-called Maximum Shear Stress Theory, suggests that yielding will occur in a material when the maximum shear stress reaches a critical .Maximum Shear Stress (Tresca) Octahedral Shear Stress (Distortion Energy or von-Mises) Strain Energy Density.Maximum Shear Stress Theory ( aka. It may be maximum principal stress and minimum principal stress.This value will be compared to the maximum shear stress theory described below.The origin of the author’s generalization of the classical maximum-shear-stress yield or failure criterion for metals to fibre/polymer composites can be traced .Maximum shear stress theory: This theory states that failure occurs when the maximum shear stress in a material exceeds its shear strength.This criterion, developed by French engineer Henri Tresca in 1868, states that yielding occurs when the maximum shear stress in a material exceeds the shear stress that . 2: It is equivalent stress calculated from the distortion energy absorbed by an object.

We are interested in learning how static mechanical stress can . 150 N Problem 5-49 A 25 N-m -49 .Balises :Maximum Shear Stress TheoryFailure TheoryDuctilityFile Size:138KB Coulomb 1736-1806, French scientist) +τ S yt +σ1 S y +σ2 S y Failure occurs, when maximum shear stress exceeds shear strength in uniaxial tension test. It is used in the maximum shear stress theory of failure. • Maximum normal stress failure theory.One common comparable example of a failure theory that does have the same loading situations involves the distortion energy method (DEM) and maximum shear .

Theories of Failure

Microsoft Word - theory of failure.Maximum Shear Stress | Definition, Formula & Parametersstudy. Therefore, the relation will be- Such a material will fracture with a “clean break”.The first theory, that is the so-called Maximum Shear Stress Theory, suggests that yielding will occur in a material when the maximum shear stress reaches a critical value, the maximum shear stress at yielding in a uniaxial stress state.Balises :Maximum Shear Stress TheoryStress FailureMaterials It is actual stress experienced by an object.This theory predicts failure of a material to occur when the absolute maximum shear stress (τ max) reaches the stress that causes the material to yield in a simple tension test. Cantilevered rod OA is 0.The maximum shear stress (MSS) theory (or Tresca theory) is used to predict failure of ductile materials.Balises :Maximum Shear Stress TheoryStress FailureFailure TheoriesDuctility No Failure within this area No Failure within these bounds Principle Mohr circles σ 1 –σ 2 plot Correlates well for ductileyielding oldest Also called: Tresca Theory or Guest’s .Balises :Maximum Shear Stress TheoryFailure TheoriesPublish Year:1987Fiber This theory is also called Haigh’s criterion. A constant force and torque are applied as shown. The objective is to determine the required value of the pressure to cause yielding. Tresca Theory ) This theory postulates that if a uniaxial stress σ e, and a triaxial stress state give rise to the same maximum shear stress, then the failure tendencies of the two states are identical; that is, σ e is equivalent to the triaxial state.The Maximum Shear Stress Theory (Tresca) According to the maximum shear stress theory, the material yields when the maximum shear stress at a point equals the critical shear .Maximum Shear Stress Theory of Failure.Maximum shear stress theory (Guest & Tresca's Theory): According to this theory, failure of the specimen subjected to any combination of the load when the maximum shearing stress at any point reaches the failure value equal to that developed at the yielding in an axial tensile or compressive test of the same material.

[Solved] Maximum Shear Stress Theory is also known as:

This failure criterion is developed by the French mechanical engineer, Henri Tresca, and based on his name . Expressed quantitatively in terms of principal stresses this result can be stated as: all -a22 = ± arp

Independent of the complexity of the stress state, yielding is assumed to occur when the maximum shearing stress in the material reaches a value equal to the maximum shearing stress for the material as determined from a tensile test at yield: For a plane stress state where the two in-plane principal stresses . This criterion is a linear, stress based, and failure mode dependent criterion without stress interaction [48].Maximum shear stress theory is a framework for studying how ductile materials might fail due to stress. The pressure vessel is fabricated from brass with Sy = 53.We expect yielding when the octahedral shear stress is equal to or exceeds a stress criterion value .Subject - Strength of MaterialsVideo Name - Maximum Shear Stress TheoryChapter - Theories of Elastic FailureFaculty - Prof.The Tresca failure criterion often called the maximum shear stress theory, suggests that a material will start to deform when its highest shear stress matches the shear stress level where it begins to yield in a pulling test.t max is the Maximum Shear Stress; s I is the Maximum Principal Stress; s II is the Minimum Principal Stress; Note that the Out-of-Plane Principal Stress (s III) for the strain plane condition is zero; Failure occurs when the maximum of the Three Maximum Shear Stresses reaches the shear yield stress, t Y.

Chapter 11 Failures Theories and Design

Maximum-shear-stress criterion (Tresca criterion) Typically, ductile materials fail by shear stress (slipping that occurs between the crystals of microstructure) Yielding begins . 1 222 2 122331 s H =(s−s)+(s−s)+−()ss (7) 1 For dilation, stresses are the same in all directions and there is no shear. Maximum Principal Stress .Maximum Shear Stress Theory (Tresca Criterion) - with .