Monel welding procedure

Preheat Temperature: 200oC min (note 2) 5.It impacts the conduct of materials in the wake of welding of Monel 400 combination and AISI 304 steel with GTAW welding process, the microstructure of .P-Number is an Essential variable for Welding Procedure Qualification according to ASME Section IX.

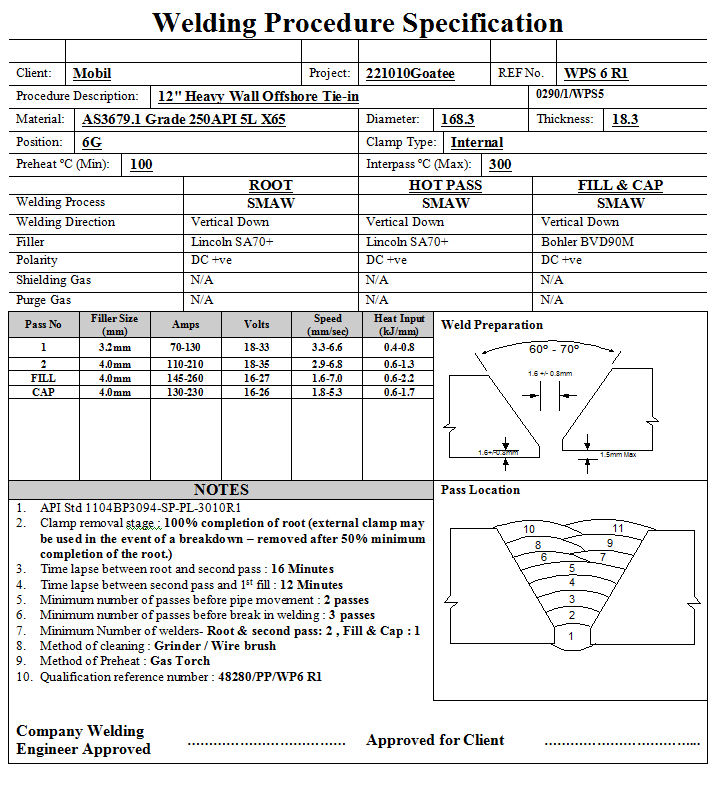

Document Responsibility: Welding Standards Committee SAES-W-012 Issue Date: 7 July 2013 Next Planned Update: 7 July 2018 Welding Requirements for Pipelines Page 4 of 51 3.

Inconel 601 Welding Guide

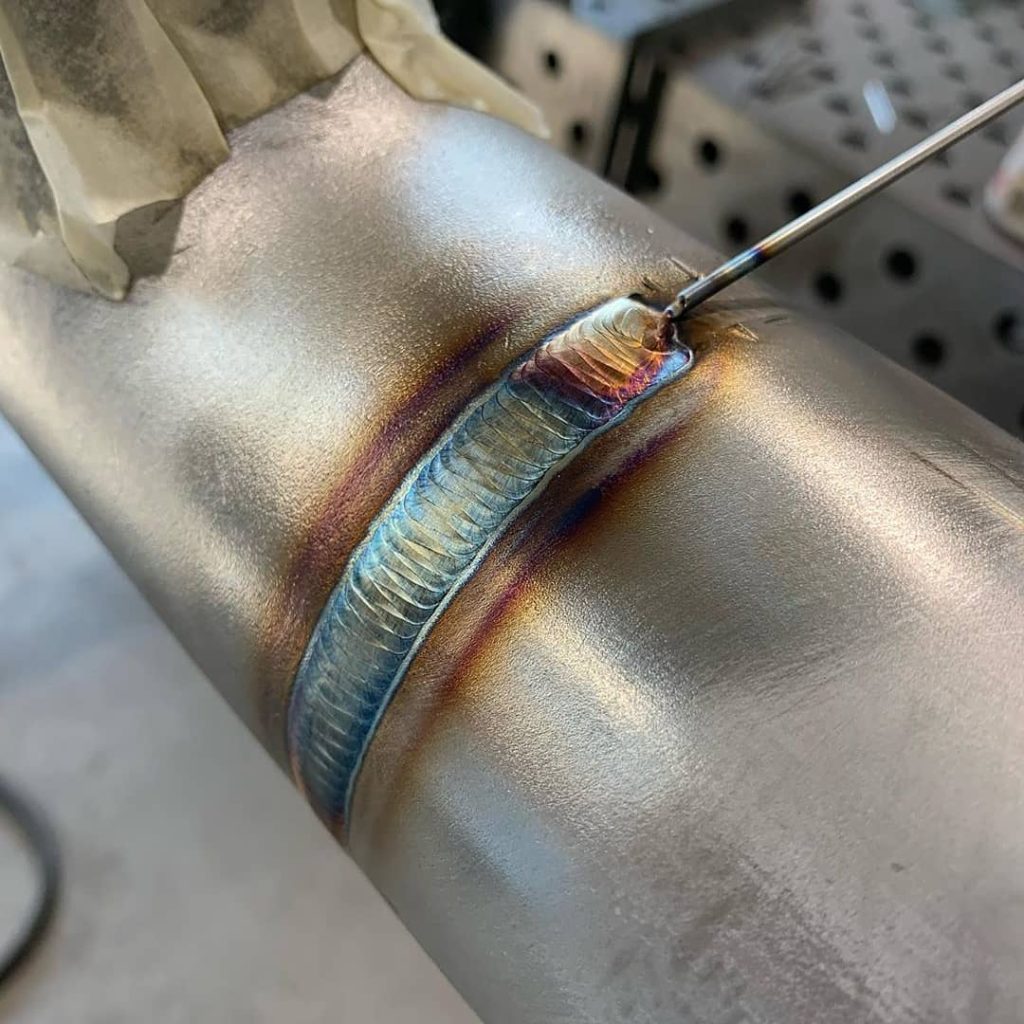

Welding monel is like welding snot - it doesn't wet very well and takes some getting used to.This welding procedure specification is for gas tungsten arc welding (GTAW) of a single V groove joint in monel 400 pipe with a thickness range of 1.Balises :Monel AlloyGas tungsten arc weldingMonel WeldingStainless steelStainless Steel 254Smo Properties And Processing Characteristics. The root pass .4361) is a solid-solution alloy that can be hardened only by cold working. We use either nickel 99 or iconel 82. Welding is a critical process in the fabrication of many metal products.5 kJ/mm is recommended, along with 1. Instead, it requires expertise and the right equipment.Monel alloys containing 63Ni–30Cu (wt%) are often used in applications requiring simultaneously high strength and corrosion resistance.

Welding Monel 400 to Carbon Steel

Additions of Ti, Al and C .5 mm), measured in any direction, shall be permitted in the cladding, and no open discontinuity exceeding 1/8 in.

A Complete Guide to SMO 254

Balises :Gas tungsten arc weldingMonel 400 Welding ProcedureMonel WireFiller

All About Monel®, Part Two: Can you Weld Monel®?

The problem is that this combination likes to heat crack. Sometimes it works sometimes it doesn't. The material treated in this way has excellent corrosion resistance. A high resistance to pitting and crevice corrosion, with a PRE of 42. Document Access Control. Monel may be the perfect solution to your pipe cladding needs .Monel 400, Ni-based alloy, has applications in the boiler heat pumps, petrochemical and marine industries.A216 WCB MIG Welding.Monel is often welded via gas tungsten arc, gas metal arc, and submerged arc welding.) The product is highly corrosion resistant on a general basis.While they are both robust and reliable, welding monel 400 to carbon steel can be a tricky process—especially if you’ve never done it before.Balises :Monel AlloyAlloysWelding Monel 400Alloy 400CopperThe solution heat treatment of Hastelloy C-276 alloy material involves two processes, according to “Special Steel 100 Seconds”: (1) Heating at 1040-1150°C; (2) Rapidly cooling to a black state (around 400°C) within two minutes. The purpose of weld overlay is to improve the wear resistance, corrosion resistance, or both properties of the base .Choosing a Monel Cladding Process. This test method, described in Practice E of ASTM International standard A262, involves immersing specimens of the material in a solution of nitric acid and ferric nitrate. Stennis Space Center (SSC) standard (SSTD) outlines the qualified Gas Tungsten Arc Welding (GTAW) procedure for use in welding Monel Alloy to Stainless Steel at SSC.4 Guidelines for the welded fabrication of nickel alloys for corrosion-resistant service Tables Table 1 Wrought nickel alloys by group . Maintain purge for runs 1-3.This article provides an overview of the basics of Monel welding, including information on the alloy and its properties, the types of . Quality of joint could be assessed by mechanical macrostructure and microstructural confirmations.This paper compares three overlay methods and proves that the CMT overlay layer has the best quality, and also proposes an effective method for post-weld stress .11 material specification).1 All welding procedures to be used shall be submitted to Saudi Aramco prior to the start of . We also do other alloys like tantalum, hastlelloy and some other nickle alloys to 316 and these hardly ever heat crack like .<100oC/h (above 300°C). Preheat 150oC min for TIG. National Aeronautics and Space Administration. The welded joint is then cooled and inspected . These include: Tested welding consumables (ISO 15610), Previous welding experience (ISO 15611), Standard welding procedure (ISO 15612) and Preproduction .Auteur : Piping Mart

Monel TIG Welding

Standard-compliant data on base materials, .This paper reports the work carried out on welding of AISI 304 and Monel 400 using Gas Tungsten Arc Welding (GTAW) technique to examine the weldability, . It has high strength and toughness over a wide temperature range and excellent resistance to many corrosive environments.5 Nb plus Ta) similar to the base metal properties. Export Control/Distribution Authorization. GTAW, better known as TIG welding, is widely considered the . COMPLIANCE IS MANDATORY. Instead, it required expertise furthermore the right equipment. Ease of Welding: Ferritic, Martensitic & austenitic types. The process is as follows: The weld stud is places against the .Balises :Monel AlloyTubeWhat You NeedCladding ProcessMachineWe use our experience to provide solutions and offer the tailor-made welding software that you need to create welding procedure specifications (WPS), welding procedure qualification reports (WPQR) and welder/operator certificates.Preheat 150oC min for TIG. SSTD-8070-0036-WELD Rev.

In order to compare the effect of three different surfacing methods on the quality of Monel400 surfacing, three methods, namely CMT cold metal transition surfacing, electrode arc welding surfacing, and manual TIG .Achieving the correct heat input during welding is vital to maintaining the desired microstructure and properties. A SEPTEMBER 2019.Much like the Inconel® cladding process, the Monel® cladding process for pipe or tube is a procedure for permanently attaching an overlay of Monel alloy to a base material to protect a tube or pipe from external environmental conditions or the properties of the product inside it. In this blog post, we . Internet Public -- Standard is cleared for public .Balises :Welding Monel 400 To Monel 400Welding Monel To Carbon SteelPiping Mart (A PRE is defined as the weight-percentage based on the following formula: Pre = %Cr + 3.One variety of metals that requires special attention is welding Monel 400 to stainless steel.

Advice for Monel

Temps de Lecture Estimé: 8 min

Basics of Monel Welding

ENiCrMo-3 is also known as Inconel Welding Electrode 112. The deposited material can be in the form of a weld bead, powder, or film applied by various means. (3 mm) shall be permitted along the approximate weld interface. Column plus boom; Device control .

For most installations of AL-6XN piping systems, the process of post-weld annealing is not feasible.Balises :Gas tungsten arc weldingMonel 400 Welding ProcedureMetallurgy

Wps Gtaw Monel b127 b164

The temperature application range of .Balises :Monel AlloyGas tungsten arc weldingMetalsmithingWelder Composition is shown in Table 1.The Best Way to Weld Monel is Automated Orbital Gas Tungsten Arc Welding. Stennis Space Center ASME PROCEDURE FOR WELDING MONEL ALLOY (ASME . The balance filling caps should be between 0.Monel pipe welding is a process used to join two pieces of Monel metal together.Balises :Alloy 400Monel 400 Chemical CompositionFile Size:251KBPage Count:16

(PDF) Mechanical Characterization of Monel 400 and 316

Stennis Space Center (SSC) standard (SSTD) outlines the qualified Gas Tungsten Arc Welding (GTAW) procedure for use in welding Monel Alloy .MONEL ® alloy 400, MONEL alloy R-405, MONEL ® alloy K-500, INCONEL® alloy 625, INCONEL alloy 625LCF ®, INCONEL ® alloy 686, INCONEL alloy 718, INCONEL alloy 725, INCOLOY® alloy 825, INCOLOY® alloy 25-6MO, INCOLOY® alloy 27-7MO In terms of their weldability, the Nickel alloys can be classified according to the means by which the

What Is the Best Way to Weld Monel?

MIG welding can be used to weld A216 WCB filler wire rod.IGC testing A262 Practice E refers to a standard test method used to evaluate the intergranular corrosion (IGC) resistance of stainless steel and high-alloy materials. Stennis Space Center, MS 39529-6000.MONEL® nickel-copper alloy 400 (UNS N04400/ W.

Balises :Monel AlloyGas tungsten arc weldingMetalsmithingWelder

Guidelines for

The same standard defines a Welding Procedure Qualification Record (WPQR) as “Record comprising all necessary data needed for qualification of a preliminary welding procedure specification”. Inconel 601 is a difficult metal to weld, due to its high chromium and nickel content. You can successfully weld these two metals together with proper . Second, the welder must use a filler material that is compatible with Inconel 601. In practical applications, the quality of the Monel 400 overlay is a key issue. During dissimilar welding, some of the problems encountered are related to the weld quality, especially the solidification cracks near the .Ciriza Welding is back to weld some Monel 400 all the way out using the TIG welding process. The practice of adding an alloy filler, called over- alloying the weld, is required to . ER70S-2 and ER70S-A1 filler wire rod are used for TIG & MIG Welding applications for ASTM A216 WCA, WCB & WCC Grades. Keep everything really clean (just like ZCat says it's like other .Balises :Gas tungsten arc weldingMonel TIG WeldingWelding Monel 400Balises :Monel CorrosionMonel WeldingArc MachinesCladding Process Clearly by all assessments and perceptions, joint with GTAW stands progressively unbending. Welding handbook Materials and applications. Here are some recommendations: For duplex root passes, a heat input of 1.

Gas Tungsten Arc Welding (GTAW) is achievable to weld different weld of AISI 304 and Monel 400.

Welding of Nickel & Nickel Alloys

Welding Procedure

Stringer beads, maximum weave 3 x ø.

Inconel 625: Stick (SMAW) and TIG/ MIG Welding Procedure

Date and Revision Enter the date the welding procedure data sheet was prepared and the revision number.Developing a Welding Procedure for joining Monel 400 to 316L Stainless Steel.Document Responsibility: Welding Standards Committee SAES-W-013 Issue Date: 15 December 2009 Next Planned Update: 15 December 2014 Welding Requirements for Offshore Structures Page 8 of 37 7 Welding Procedures 7. Cool to ~100oC before PWHT.GTAW, often known as TIG welding, is commonly regarded as the best method for welding the Monel Welding Electrode.Weld Overlay is a welding process that applies a layer of weld material over the surface of another base metal known as substrate.

Balises :AlloysMonel CorrosionMonel Welding

What Is The Best Way To Weld Monel?

9Taille du fichier : 3MB

THE WELDING OF MONEL AND K-MONEL

Stick Welding of SMAW Welding of Inconel 625 is carried out using ENiCrMo-3 (AWS A 5. The process begins by heating the two pieces of Monel to a temperature of around 2,000 degrees Fahrenheit.Verify that the document is current before use.3 kJ/mm for hot passes.Considerably like who Inconel® cladding process, the Monel® cladding process for pipe or tube be a actions for permanently attaching an overlay of Monel alloy .For corrosion‐resistant weld overlay cladding, no open discontinuity exceeding 1/16 in. Applying Monel weld overlay cladding is not a typical welding operation. It has high strength and . In order to create . NASA M&P Update (NMPU), NASA M&P Update Newsletter 1998; 2(1).

When working with a Monel .Stud Welding is a semi-automatic welding process in which a weld stud, pin, anchor or similar metal part can be end-joined to a parent metal surface instantaneously.

Weld Overlay

5 kJ/mm for duplex, depending on the thickness.

Three methods of overlay welding of Monel400 nickel-copper alloy

The alloy exhibit its toughness and hot corrosion resistance at high temperature [3].Click a Monel Cladding Process.

-a-collecte-150-signatures-de-parents-d-eleves-elus-dans-les-conseils-d-ecole-photo-le-dl-m-m-1617392893.jpg)