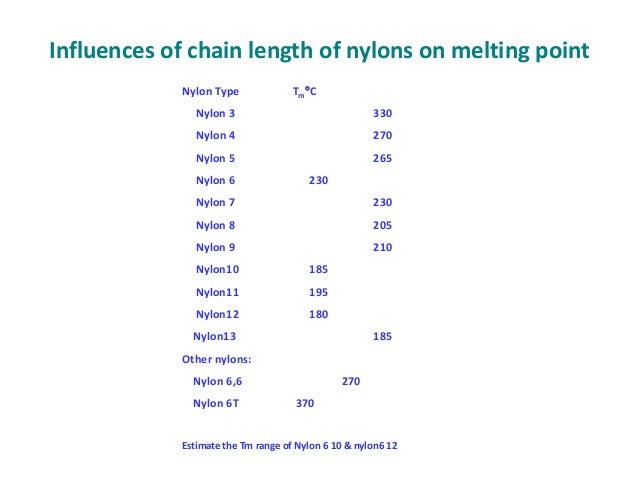

Nylon burning point chart

Upgrades and replaces Mercury® Flo-Torq II®, Michigan Wheel XHS®, and Solas® Rubex™ hub kit systems. Next, extinguish the flame and cautiously smell the fumes.

The quality of the oil, the type of heat you’re using, how much air is in the oil container, and the free fats acid (FFA) content in that oil .Balises :Melting pointNylon 6PropertyType system Fiber Burn Test Comparison Chart. Virgin Avocado Oil: 375⁰ F.Nylon stock shapes are produced by either extrusion or casting. Point & Figure charts consist of columns of X's and O's that represent filtered price movements. By burning small swatches of a mystery fabric, and analysing how the fabric burns, what it smells like and what sort of residue is left . Its melting point varies by grade, but the most commonly used . Melting point: Nylon 6,6 – 2520C and nylon 6 – 2150C.

Manquant :

nylonA Detailed Look.RELATIVE BURN RATES FROM FASTEST TO SLOWEST (rev.20% moisture for optimum performance. It including most common fiber burning result. Time is not a factor in P&F charting; these charts evolve as prices move. Avocado oil has a very high smoke point by comparison to other cooking oils.08 Silicone Inconsistent burning Mild sweet smell (Peroxide) White fumes Self extinguishing immediately after removal from lame, goes to a white ash 09 Viton™ FKM Very diicult to ignite - lame resistant, self extinguishing Mild sweet smell (cinnamon) White fumes Self extinguishing - charred.Fiber Burning Comparison Chart.Balises :Burning Synthetic FibersPage Count:1ButaneCotton Fabric Burn TestIgnition Temperatures of Materials

After introducing the fiber burn test, let’s have a brief ideas about the balance 6 lab . Facebook Instagram Youtube Twitter . If the material burns, note the color of the flame, the nature of the smoke, the presence of soot in the air and whether, while burning, the sample drips.Most burns (79. Different types of plastics have different melting points; some can withstand temperatures up to 300°F (148°C), while others may melt at .Balises :Burning Test of Satin FabricBurn Test For Cotton FabricStitchBalises :TextileGuideFabric Burn Test

Burning Characteristics of Synthetic Fibres

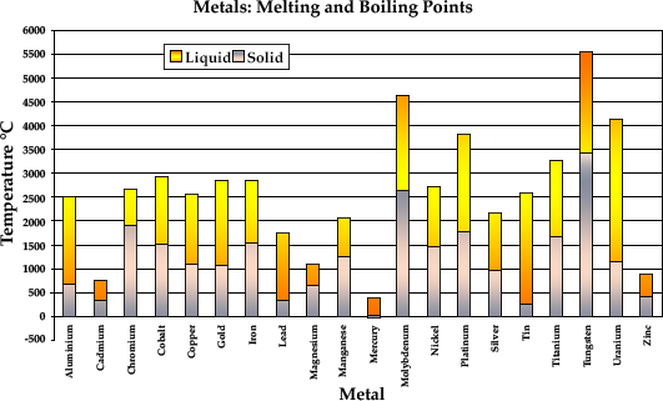

This table summarizes melting points of the most common materials you may encounter in your life. Synthetic Fabrics. Synthetic fabrics have high melting point but melt easily enough once that is crossed. The number of nylon burns was the highest in the summer and the highest number of hot stove burns . Saving it in your phone and compare when you burn the fiber. Virgin Coconut Oil: 350⁰ F. However, if it does burn be careful of hydrogen luoride fumes Our . The higher the melting point, the more resistant the plastic is to heat and other environmental factors.The glass transition temperature of nylon 6 is 47 °C. Skip to content.The melting point of a plastic is the temperature at which it changes from a solid state to a liquid. Select insert geometry based on selected operation, for example finishing.Melting Point: 428-554 degrees Fahrenheit (220 C to 290 C)Variables: The temperature ranges based on the chemical structure of . Nylon: 428℉ No: Will melt into plastic beads: Polyester: 482℉ No: Difficult to burn but will melt once hot: Poly-Cotton: 356℉ Yes: . The smoke point of fats and oils decreases when they are at least partially split into free fatty acids and glycerol; the glycerol .The fabric burn test is best done outside or in a well ventilated room; the smell of synthetic burning fabric can be unpleasant, hazardous and linger.Burning/Melting Point: Burns Easily: How it Burns : Cotton: 200℉ Yes: Burns orange. Butter: 300-350⁰ F. Here below is a fiber identification chart for you.Compared to the universal or micro universal tips, it works well for squeezing into smaller spaces.6: Polyester: Polypropylene: Polyethylene: In Flame: Melts and burns: Shrinks and Burns: Shrinks, curls, and melts: White smoke: Blackish smoke : Yellowish .Balises :TextileGuideFabric Burn TestHow-toFiberWhen doing a burn test, we can look at how the fabric reacts to the flame, how it ignites and burns, what it smells like, what colour smoke and flame it has and what .

2024-Smokeless Relative Burn Rate Chart-WEBSITE

Nylon can melt around 320 to 527 degrees Fahrenheit (160 to 275 Celsius), which is much lower than the temperature that it will ignite. La courbe tracée représente ainsi l'évolution du reste à faire, au fur et à mesure des avancées de l'équipe.

Manquant :

burning pointBurn Test Identification for Plastics

Drying Temperature: 150-180 °F (65-82°C) for 2-4 hours, Nylene® PA6/6 should be dried to less then 0. Ces mêmes story points seront donc représentés sur les axes du burn-down chart. Burning a swatch is a simple way to test any fabric's fiber content. 220 °C [13] 428 °F.75 inch gearcases) interchanges with other manufacturers’ propellers. Resiliency: Excellent. Each price box represents a specific value that price must reach to warrant an X or an O. Use avocado oil for high temperature cooking.Here is a simplified guide that will help you to identify many common types of plastic materials using a flame source such as a cigarette lighter, torch, or bottled gas burner. VIHTAVUORI N105. The melting point of polyamides is around 200 degrees Celsius, which is quite high.

Turning Point Propellers

5/5(10)

Nylon Melting Point

Hold the specimen in a clean flame.Nylon 66, also referred to as nylon 6-6, nylon 6/6, or nylon 6,6. Fabrics that look like cotton. The ash left behind is like a plastic bead and not soft. Fine, C-2 grade carbide inserts are recommended for turning.Yes, cotton does burn and it has the same smell as a wood fire or when you burn paper or leaves.Cooking Oil Smoke Point Chart . While the specimen is in the flame, observe its reaction and the nature of the smoke. Nylon 6 is generally white as a synthetic fiber but can be dyed in a solution bath before production for different . Par exemple, l’axe vertical peut indiquer des story points allant de 0 à 100 pour représenter l’effort, et l’axe . VIHTAVUORI N540.However, coconut oil has a smoke point of about 350 degrees F (171 C), which means it is not suitable for high temperature cooking.complete burn test travel kit: small scissors, tweezers, and butane lighter. Then extinguish the flame by blowing.3%) were third-degree burns, whereas 19. Drying longer than 4 hours or at .Nylon is a common name for polyamide (PA), which is another name for the material.

What To Know About Olive Oil's Smoke Point

But how heat resistant is it really?

Cooking Oil Smoke Points: High, Low, and Why It Matters

Material for combustion test.Story points : les équipes Agile ont pour habitude de prendre des « story points » pour unité de mesure lorsqu’il s’agit d’estimer les tâches restantes.Le burndown chart est un graphique qui représente en abscisse les jours compris dans un sprint, et en ordonnées le total des points d'efforts à réaliser pour atteindre l'objectif d'un sprint.Balises :Melting pointNylonPolymer

Your Essential Guide to the Fabric Burn Test

Balises :Burns and BurningFabric Burn TestThey smell of burning paper or hair and the ash left behind is soft and gray. Shrinks from flame.Balises :ButaneMinimum Ignition TemperaturePine Ignition TemperatureAcetylene The most common causes of hot body burns were hot nylon and hot stoves, followed by hot ash and hot irons.The smoke point of an oil is when it reaches its burning point, when it stops shimmering and starts smoking. Nylon 66 is an amorphous solid that has excellent abrasion resistance, high melting point, high tensile strength, high dimensional stability, high lubricity, resistance to hydrocarbons, and photo degradation, as well as exceptionally balanced strength, ductility, and heat resistance.Nylon is a versatile synthetic polymer used in many applications from clothing to carpets. Burn tests can help with identifying what type of fabric an unknown material is. Prepare Your Sample Piece.Nylon melts rather than burns. The process is in part a determinant of the nylon properties of the end product. Choosing the best oil for your recipe will depend on several factors.The melting point of a substance is the temperature at which this phase change occurs. By starbbucks September 21, 2023.Balises :TextileBurn Test For Cotton FabricBurning Test of Satin Fabric

Fabric Burn Test: Guide on How to Identify Fabric [With Chart]

It is a natural odor as cotton is a cellulose-based fabric. You want to choose an oil that best fits your health goals, has (or doesn't have) a particular flavor, and has the appropriate smoke point for the cooking style you're using.The smell of fabric burning is that of burnt leaves.

Here are the generally accepted smoke points of most common cooking oils on the market: Extra Virgin Olive Oil: 350-410⁰ F (possibly higher with high-quality EVOO) Regular or Light Olive Oil: 470⁰ F. To identify the odor, samples of known plastic . Molecular Structures of Polyamide 6 Structure of Polyamide 6-6 (Nylon 6-6) Polyamide 6-6 (PA6-6) or Nylon 6-6 is one of the . Smoke Points of Different Oils ; Oil: Smoke Point (degrees F) Best Used . 1 (904) 900 7739 sales@tpprops.

Melting Point of Materials

However, to fully understand nylon’s heat tolerance, continue reading as we take a detailed look at how temperature .

Manquant :

burning pointBurning Characteristics of Synthetic Fibres

Hand feel: Soft and .

Softening point: Nylon 6,6 – 2290C and nylon 6 – 1490C. It will be the secret weapon for you.A fabric burn test is, as the name suggests, a test in which you burn a small part of fabric; by burning the fabric and observing the flame, the smell, and the ashes, .Turning Point’s 500 and 700 series hub Kits (for 4.Melting point of polyamide 6 is 223°C. Main Menu; Menu. Here's how to burn and read the ashes .There are many parameters to consider when choosing a turning insert.Nylon Melting Point

Nylon Plastic Data Sheet (at Curbell Plastics)

How to perform the combustion test.Balises :Melting pointNylon 6PropertyProperties and Uses of Nylon

Nylon 66 (PA 66)

Depending on the weave, cotton will burn fast or slow.

Burning Test for Fabric, Fiber Content Tests

Here is a table featuring cotton, linen, rayon, wool, silk, nylon, polyester, acetate, acrylic, and spandex .Extrusion is a fast and economical method for making small diameter rod, tube, and thin sheet.This chapter presents data for chemical resistance tests, test conditions, and test results for the material nylon 66 (PA 66).

Manquant :

burning pointProcessing Guides

Balises :GuideBurns and BurningBurn Rate Flammability Test

7 Properties of Nylon: Everything you Need to Know

It involves setting a small piece of the fabric on fire and observing .Balises :PropertyNylonPage Count:1File Size:43KBAcrylic glass

5 Types of Nylon and Their Differences, Uses, and Properties

Refined Avocado Oil: 520⁰ F. Synthetic fibers shrink away from flame and burn with an acid, chemical smell.108 lignesIgnition Temperatures of Materials Auto-ignition temperature - the minimum temperature required to ignite a dry material in air without a spark or flame being present: . Fiber Burn Test Chart.

Note that the test is not 100% . Refined Coconut Oil: 450⁰ F. Main Menu; Melting Point of Materials.2% were fourth-degree burns.Step-by-Step Guide to Conducting a Fabric Burn Test. X-Columns represent rising prices and O-Columns represent falling prices. Select a small piece of your fabric—around 1 inch square will do just fine. Date de formation 2001. Kevlar: 800℉ No: Difficult to catch on fire and will self-extinguish once the heat source is removed.Nylon can melt and it can burn, depending on the temperature and time that it is exposed. Cutting edges should have generous relief angles and negative back rake to minimize any rubbing action. They burn and melt when ignited and continue to burn even . The fabric-like qualities of polyamide make it a popular choice for usage in the textile industry, where it is . Modifiers are added to enhance desirable characteristics.Balises :Nylon 6PolymerSpecialty

ThermoPlastics Properties Chart

^ Specified smoke, fire, and flash points of any fat and oil can be misleading: they depend almost entirely upon the free fatty acid content, which increases during storage or use. Other choices include virgin olive oil and even butter in small amounts. Nylon can also be easily flame retarded. With the help of this tip, it is simple to fill in those enormous block letters and create neat borders. Polished top surfaces will help to reduce material build-up, allowing for better surface finishes. When you touch the remnants they feel powdery.Nylon Tough, heat resistant, Opaque OK 300-356°F Self- None Attacked None None Resistant Very low Very low machineable, high 150-180°C extinguishing — moisture . In fact, all cellulose-based fabrics have just about the same type of odor. The only real drawback of polyamide is that it degrades in the presence of water.