Oxyfuel cutting equipment

From small fabrication shops to global Fortune 500 companies, Cutting Systems has the perfect plasma cutter built for you right here in the USA.Our CNC oxy-fuel machines are designed for cutting mild steel plates up to 3” thick, stainless steel up to 4” thick as well as aluminum up to 3” thick. The equipment is low cost, and offers solutions for both manual and mechanised cutting. Smooth cutting oxygen valve in easy-to-use top position.

Oxy-fuel welding and cutting

Oxy-fuel cutting: the basics explained. Y travel: 3,000, 6,000, 2,000 mm. Cutting torch design is similar to that of the common welding torch. What’s more to automate on oxy-fuel cutting then merely flame on/off? This medium-duty kit cuts up to 1″ out the box and up to 5″ plate with optional tips. This pipe is often controlled by a different valve fixed on .Victor is the global leader in industrial gas equipment for manual oxy-fuel and air-fuel cutting and gas control. Historically, the primary use of oxy-fuel combustion has been in welding and cutting of . This video will give you an in-depth lesson on how to setup and break down y. There is about 1700 kPa (250 psi) pressure in the acetylene tank when complete. 1500X3000 mini cutting machine is the .

Les produits sont divisés en gammes individuelles en fonction de leur application principale, de sorte qu'ils offrent la meilleure performance à la fois individuellement et en .

References

Oxy Fuel Cutting Machines

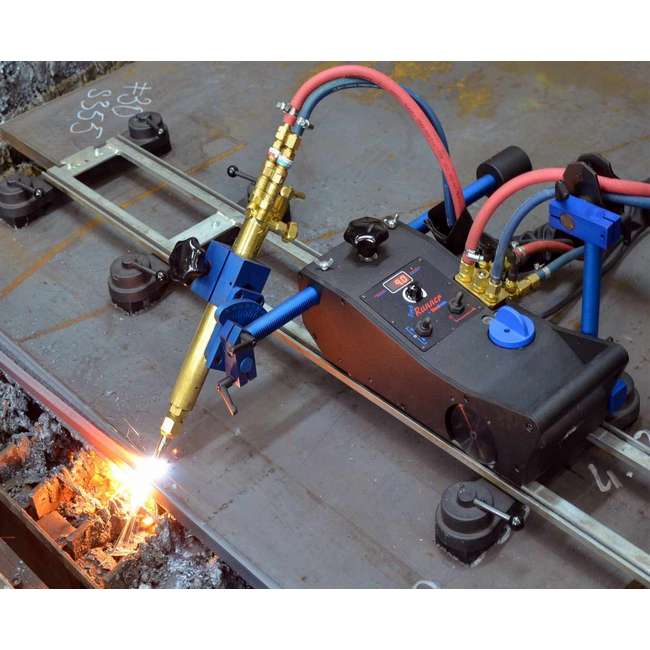

A separate pipe is connected to allow the supply of pure oxygen for the cutting process. Oxyfuel cut beam blank. With more than 120 years of experience we can offer you new solutions for virtually any application in the field of oxyfuel technology.Original Messer oxyfuel equipment.At Kerf Developments, we are dedicated to providing you with the ultimate in profile cutting machines. Cutting speed: 50-800 mm/min. Circle cutting: 150-2400mm diameter.Straight Oxyfuel Cutting

Oxyfuel Equipment

Businesses in these and other industries apply bevels during the cutting process, and this is a key step to streamlining manufacturing. Each of the machines .In this quick guide, you’ll learn more about oxy-fuel cutting, what it is, how it works and how it compares to other cutting technologies. Fuel gas and oxygen are continually mixed to produce the preheating flame. And in most cases it used to cut steel plate thickness more than 20 mm, since oxy fuel cutting usually brings big tolerance.From heavy-duty construction and civil engineering to heavy-equipment manufacturing and shipbuilding, many industries utilize oxyfuel bevel cutting.

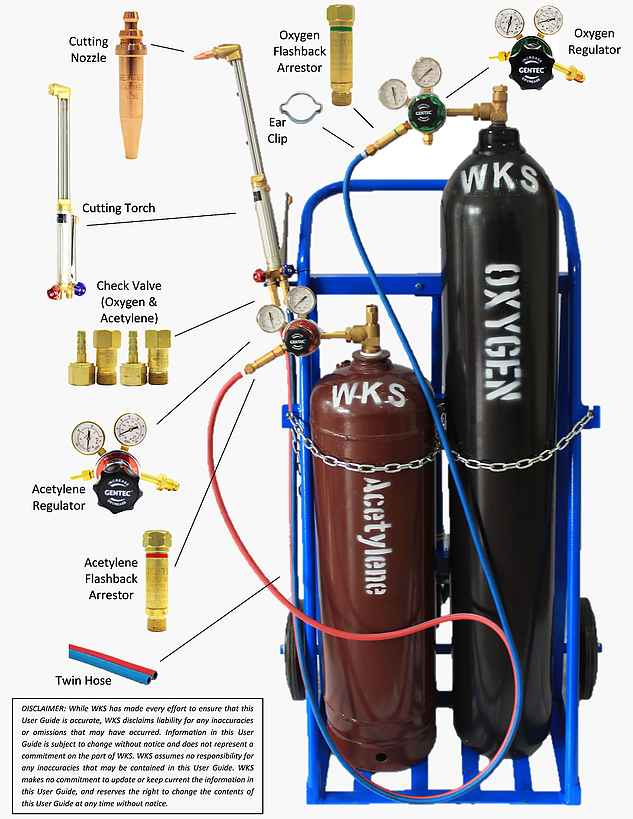

Oxyfuel cutting operations can use gasses such as oxygen, acetylene, MAPP, natural gas and propane.Oxy fuel cutting (OFC) processes sever metal by utilizing the chemical reaction of oxygen with metal at elevated temperatures. Oxyfuel cutting is regarded as .Oxy-fuel gas equipment is designed to safely allow fuel gases and oxygen to be mixed together for welding and cutting applications. Whether cutting with Oxy-Fuel, Plasma or Laser, maintaining the correct distance between the torch and the work-piece is an often underestimated but .Oxyfuel cutting also referred to as oxyfuel flame cutting and oxyfuel gas cutting, is the most economical process for cutting mild and low-alloy steel, even with weld preparations involved. Ribbed brass handles for sure grip and operator comfort.Oxyfuel Cutting Equipment.Messer Cutting has vast experience of over 120 years. Cutting the material. The EasyCut series stands . View our wide range of products online here, we are sure to have what you are looking for. Consumables, cutting torches and equipment from various manufacturers, including RADNOR ®. Innovative solutions supported by several GCE patents are used to achieve the main target - many benefits for customers.Oxy-fuel cutting equipment from all of the leading manufacturers.Acetylene is the primary fuel for oxy-fuel welding and is the fuel of choice for repair work and general cutting and welding. All prices displayed are exclusive of VAT

Oxy-Fuel Cutting Equipment

Cutting capacity up to 300mm thickness. 9/16-18 hose connections. Model # 0381-1917.Oxy-fuel cutting is a thermal cutting process that uses oxygen and fuel gas (such as acetylene, propane, MAPP, propylene and natural gas) to cut through materials. Company Number: 09035666.Oxy-fuel cutting is a process where a mixture of fuel gases and oxygen is used to cut metals.Automated Oxy-Fuel Cutting. New Jersey, United States,- Oxy-fuel welding and cutting equipment comprise a set of tools and systems designed for joining and cutting metals through the combustion of .Oxy-fuel combustion is the process of burning a fuel using pure oxygen, or a mixture of oxygen and recirculated flue gas, instead of air. With long-term experience in the development, production and application of machine cutting torches, nozzles and various accessories, GCE is a global leader in oxy-fuel cutting technology. Cutting speed: 0 mm/min - 6,000 mm/min.Oxy fuel cutting can be very intimidating to students and inexperienced welders. The Model 801 510/540 regulators are have an amazing 7 year warranty, and all other .Oxyfuel is a welding and cutting process that uses a combination of fuel gas and oxygen to create a high-temperature flame that can be used to weld or cut through .Oxy-fuel hand cutting system built for the toughest jobs. Adams Gas offer a range of oxy-fuel cutting and welding equipment.Gas (UK) Ltd is a company registered in England. We would be happy to advise you, working together to find the perfect . Since the nitrogen component of air is not heated, fuel consumption is reduced, and higher flame temperatures are possible. This unit standard will contribute to the full development of any learner by providing recognition, further mobility and transportability within the field. 60% less post cutting grinding operation. We work to understand our customers and provide them with the most efficient oxy-fuel cutting system possible. However, it is important to use proper safety precautions and equipment when performing oxyfuel gas cutting to avoid potential hazards such as fire, explosion, and toxic gas exposure. The high capacity one-piece torch and SC12-2 Acetylene tip included with the system allow you to cut up to 1 ¼ inch (32mm) thick steel, but with the appropriate tip, the one-piece torch can cut up to 12-inch thick steel using Acetylene or 20-inch thick steel using Propane. plasma for metal sheet metal. The process works by heating the metal to its ignition temperature .

Oxyfuel Cutting

Slower cutting speed: Oxy-fuel cutting has a slower cutting speed compared to plasma and laser cutting, making it less suitable for projects requiring high productivity levels.Oxyfuel gas cutting, also known as oxygen cutting, is a process in which a combination of oxygen and fuel gases is used to cut metal.

Oxy-fuel cutting is a thermal cutting process that uses a combination of oxygen and fuel gases to cut metal. Oxyfuel Equipment such as pressure . Caring for and storing cutting equipment, tools, and materials. Each has its own set of advantages and limitations. This step is especially beneficial when thicker material is involved. 40% higher productivity than conventional machine.Portable equipment: Oxy-fuel cutting systems are generally portable, allowing for easy transport and flexibility in various work environments. Whether you’re building ships or . Acetylene, when combined with oxygen, burns at 3200 .Describing the oxy-fuel cutting process. It’s beneficial for . Oxyfuel cutting technology followed the development of .

How Does the Oxy-fuel Cutting Process Work?

The required temperature is provided by the .Overview

Automated Oxy-Fuel Cutting Systems

Cutting Systems specializes in custom oxy-fuel systems and industrial plasma cutters. Preparing for the oxy-fuel cutting operation. A range of Bronze and Steel Brazing rods for all applications. There are several fuel gas and nozzle design options that can enhance cut quality and speed.Published Mar 27, 2024. The process is also commonly used in the fabrication of structural steel, pressure vessels, and pipes.oxy-fuel cutting machine 1200 X 2000. However, the various components of an oxy-fuel set have to be correctly selected, assembled and then used appropriately. Some of the commonly used fuel gases include propane, natural gas, acetylene, . Flame cutting systems in various industries.Flame cutting (also known as oxy fuel cutting), it is to use the heat burned from oxy fuel gas, to cut steel materials or the hard metals to the panels or profiles required. Oxyfuel cutting systems from MicroStep Europa. Praxair’s can help invest in the right equipment for your production stream which can . Plasma surface processing using reactive process gases is also growing in popularity.height of the cutting torch.Portable gas cutting machine. It can cut steel thickness from 1 mm to 1200 mm. Explore its innovative products and solutions at ESAB.Oxy-fuel cutting is commonly used in the steel industry and is well suited for cutting large, thick pieces of metal, as well as for producing precise cuts in plate and sheet metal. View Our Oxy-fuel Machines.

Our CRYOCLEAN ® dry ice blasting solution for cleaning, modifying, structuring and finishing fabricated metal parts is a fast, residue-free, environmentally friendly alternative to conventional cleaning methods that often rely on hazardous wet chemicals.

Plasma, Oxy-fuel, and Laser Cutting: A Comprehensive Comparison

Our professional and courteous sales team is here and ready to assist you with questions about our CNC oxy-fuel cutting machines. In deciding which method to use, your company must weigh the above factors against your individual process needs. Use with any fuel gas, 5 PSIG and above. It has some advantages over other thermal cutting processes, including low .

Best Oxy-Acetylene Cutting Torch Kits 2022

X travel: 1,500 mm.

A Guide to Oxygen Fuel Cutting

Basic equipment suitable for cutting, gouging and other jobs such as . As your first choice for CNC cutting machine manufacturer, you can rest assured that when you come to us, you’ve come to the right place. Choose from the best .

Hand Cutting Torch Heavy Duty Outfit

Cuts up to 5 in/127 mm, using series 1 tips.Oxyfuel is one of the most widely used cutting processes with the following benefits: Low cost equipment. It offers new solutions virtually any applications in the field of oxyfuel technology. Built-in reverse flow check valves and flashback arrestors.Oxyfuel cutting is a thermal cutting process that involves the use of fuels, including gasoline, in the presence of oxygen to cut metallic workpieces. The Messer Cutting Systems product range offers you everything for your individual requirements.Oxyfuel cutting systems in action. Solutions, products and expertise that help . This method is cost-effective and versatile, offering high-quality cuts.Oxy-fuel and plasma cutting are both well-established metal cutting processes. Oxy-fuel cutting, also called “burning,” “torch cutting,” or “flame cutting,” is widely used in many industrial settings, but only on one metal - steel. VAT Number: 321 9471 11.We deliver high-purity gases, bespoke mixtures, state-of-the-art gas control equipment and supporting services to help optimize your thermal cutting processes - always tailoring . The Cutting Torch. Oxyacetylene Equipment Check List Includes: .