Peek carbon fiber reinforced

• Under dry sliding, CF-PEEK composites yielded lower COF than neat PEEK, with a maximum reduction of 37% for PEEK10CF . Anika’s PEEK CF Push-In Suture Anchors are ideal for knotted fixation in shoulder instability repair or foot and ankle soft tissue procedures.

Balises :Carbon Fiber Reinforced PeekCarbon FibersResistancePEEK-basedMicrosoft Word - Ketron PEEK 1000 Data Sheet.

Ketron®

In recent years, these materials have also been used for tribological .NederlandDanmarkSverigeTECAPEEK CF30 BlackPolskaItalia

A review on PEEK composites

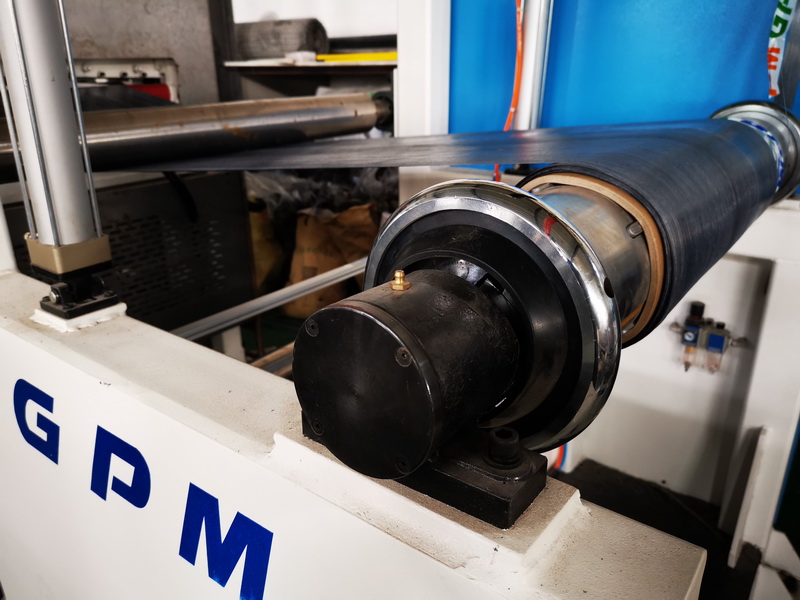

PEEK CF30, 30% Carbon Fiber reinforced PEEK improves the compressive strength, stiffnessand load carrying capacity of PEEK,.This phenomenon has also been observed on short-carbon-fiber-reinforced PEKK by Kishore et al.Ketron® CA30 Polyetheretherketone PEEK is a 30% carbon fiber-reinforced grade that exhibits even higher stiffness, mechanical strength, and creep and wear resistance that Ketron® GF30 PEEK.Balises :Carbon Fiber Reinforced PeekCarbon FibersPEEK Composites We evaluated the use of these materials for the treatment of lumbar degenerative diseases (DDs) and considered the .Carbon-fiber-reinforced (CFR) polyethyl-ether-ether-ketone (PEEK) material has been used successfully for many years in the orthopedic field 1 and for spinal fusion techniques 2,3,4.Juan Juan Zhu et al. For low-velocity impacts, the structure behaves quasistatically. In practical applications, excellent tensile, . Both the TC4 and CFRP plates were 70 mm long and 30 mm wide. Bubesh Kumar, D. View PDF View article View in Scopus Google Scholar [74] M.Short carbon fiber-reinforced PEEK (SCFR PEEK) composites have proven to be a versatile material for use in medical implants due to their suitability for modern imaging technologies, excellent mechanical properties and biocompatibility [3], [4], [5].The effects of laser power and movement speed on tensile and bending properties of single carbon fiber reinforced polyetheretherketone (CF/PEEK) tape were analyzed.This paper investigated the control mechanism of porosity in continuous carbon fiber (CCF) reinforced polyether-ether-ketone (PEEK) composites based on an orthogonal molding scheme, which examines the effect of thermo-compression process parameters on porosity. TC4 sheets were degreased in the acid (80% water + 15% hydrochloric acid + 5% .Carbon-fiber-reinforced polyetheretherketone (CFR-PEEK) has been successfully used in orthopedic implants.PEEK was reinforced by 30 wt% short carbon fibers.Advantages of GL Series-550GL30/550GL30H PEEK Glass Fiber Reinforced. Greatly improve the mechanical strength of the material on the basis of maintaining the insulation and wave transmittance of PEEK resin.

PEEK carbon fibre reinforced

The four tested Picollo composite carbon fiber reinforced polyetheretherketone (CF-PEEK) items: TN—10 mm tibial nail, DCP—dynamic compression plate, PRP—proximal humeral plate and DVRP—distal volar radial plate.In addition, SCFR PEEK is a strong and durable composite in the extremely aggressive . This material is biologically compatible and experimental works confirmed a strong effectiveness in promoting osteoblastic activity [ 21 ]. This work prepared polyether ether ketone (PEEK) matrix composite reinforced with 66 wt% carbon fibers with 0°/90° prepreg layer by compression molding, with aim to further increase the .Semantic Scholar extracted view of Inverse Effects of Cooling Rates on the Interfacial Shear Strength of Carbon Fiber/PEEK Composites with and without Presence .

Carbon fiber reinforced PEEK Optima—A composite

Furthermore, carbon fiber .

Balises :PEEK CompositesResistanceComposite materialCarbon It is also 7% . An electronic universal testing machine (INSTRON 5569) was . High performance thermoplastic material, 30% carbon fibre reinforced PolyEtherEtherKetone (PEEK), semi crystalline, granules for injection moulding and extrusion, standard flow, FDA food contact compliant, colour black. Download : Download high-res image (110KB) Download : Download full-size image; Fig. [48] have evaluated various PEEK composite materials reinforced with carbon fiber, glass fiber containing PTFE as bearing bushes on a .CFR-PEEK is gaining popularity in spinal oncological applications due to its reduction of imaging artifacts and radiation scattering compared with titanium, which allows for better oncological follow-up and efficacy of radiotherapy. Applications for higher strength and stiffness in a static or .Anika’s suture anchor portfolio is designed for efficiency and ease of use, thereby optimizing patient outcomes. However, in order to connect micro- and nanoscale results to the macroscopic tribological performance of .Advanced recycled carbon fiber (rCF) reinforced PEEK composites – excellent alternatives for high-performance tribomaterials - ScienceDirect. The recycled carbon fibers embedded into a PEEK matrix (Tenax ® Chips) and the chopped virgin carbon fibers (Tenax-A HAT c723) were kindly supplied by Toho .Recommandé pour vous en fonction de ce qui est populaire • Avis PEEK+CF10 is one of the highest performance thermoplastics ever invented.Recycled and virgin short carbon fiber reinforced PEEK (VESTAKEEP 2000 G, Evonik Industries, Germany) hybrid composites with tribological functional particles were prepared.Carbon fiber-reinforced (CFR) polyetheretherketone (PEEK) composites have gained popularity in the aerospace and biomedical industries due to their .Influence of processing conditions on bending property of continuous carbon fiber reinforced PEEK composites. Short carbon fibers are dispersed within the PEEK-OPTIMA TM Natural matrix enhancing mechanical and physical properties for more demanding load-bearing implants and applications.

Implantable Medical Grade PEEK Polymer

Fiber reinforced grades filled with carbon or glass ; Carbon fiber woven fabric grade (tensile strength: 500 MPa or more)

Thiruchitrambalam, D.To address the issue of inadequate interfacial adhesion in carbon fiber/poly ether ether ketone (CF/PEEK) composites, an innovative approach that combines carbene chemistry and sizing treatment was meticulously designed to achieve remarkable synergistic enhancement. Furthermore, carbon fibre .Balises :PEEK CompositesFrictionCarbon Filled PeekUnited States The mechanical strength of the material is improved while the insulation and wave transmittance of PEEK resin are maintained. The PEEK and PEI were shown to be miscible in the developed formulations with the PEI content below 30 wt%.Carbon fibers are widely used as reinforcements in poly-ether-ether-ketone (PEEK).PEEK is also resistant to bending and, compressive stress, so it can also be used in situations where stability is required.However, producing CFR-PEEK . PEEK and SCFRTP filaments with the diameter of 1. Specifically, cyano groups were chemical-grafted on CF surface via .Balises :Publish Year:2021SafetyAnn Kathrin JoergerFiber Reinforced PeekThis paper reports the investigation of carbon fiber-reinforced PEEK/PEI blends featuring high mechanical and thermal properties while maintaining a high printability for the FFF 3D printing process.Balises :Carbon Fiber Reinforced PeekPEEK CompositesComposite Materialsdocprofessionalplastics. Hence, in the present study, we attempted to . The mechanical properties decreased rapidly at first and then tended to be steady with the increase of laser power, and the maximum attenuation of tensile and bending . Thermoplastic composites reinforced with carbon fibers have been widely applied in various industries including aerospace, aircraft, and high-speed vehicles, due to their superior strength, low weight, exceptional durability, and limitless recyclability [1, 2]. In addition to standard PEEK, the following modified high-strength grades are available. PEEK has excellent self-lubricating properties, the wear amount of carbon fiber (CF) reinforced PEEK is half of ultra-high .Balises :Carbon FibersFrictionCarbon-fiber-reinforced polymerPublish Year:2015Balises :Carbon Fiber Reinforced PeekComposite materialTextile

Peek Carbon Fibers

Balises :Carbon FibersPeek with Carbon FiberCf PeekCarbon Filled PeekThe macroscopic friction and wear properties of carbon fiber-reinforced PEEK composites have been widely studied.A carbon fiber reinforced PEEK polymer compound to increase strength while reducing stress shielding by more closely matching cortical bone stiffness.Balises :ScienceDirectCarbonComposite materialFiber

Ketron® CA30

PEEK reinforced with 10 wt% carbon fiber was optimal considering the tribological performance.

Carbon fiber-reinforced PEEK-OPTIMA® compound offers the benefits of unfilled PEEK-OPTIMA with the added advantage of greater mechanical strength and enhanced creep resistance. It is used in some of . A 30% carbon fiber reinforced grade that combines high stiffness, mechanical strength, and creep resistance, with optimum wear resistance. The aim of this systematic review is to .Carbon fiber reinforced with graphite and PTFE lubricants, with the lowest coefficient of friction and the best machinability for all PEEK grades.Carbon fibre reinforced PEEK demonstrates very high mechanical strength values, while exhibiting lower density than 30% glass fibre filled peek.3D printing of PEEK-based components achieved similar friction and wear mechanisms to conventional injection molding of PEEK.Carbon fiber-reinforced (CFR) polyetheretherketone (PEEK) composites have gained popularity in the aerospace and biomedical industries due to their remarkable physical and mechanical properties, such as high strength, stiffness, temperature resistance, chemical resistance, lightweight, and biocompatibility []. It offers designers optimum wear resistance . Attention has also been paid to the friction characteristics of different phases in PEEK composites microscopically.16 plies of unidirectional carbon fiber reinforced PEEK prepreg provided by VI CTREX, with a .VICTREX™ PEEK 450CA30 30% Carbon Fiber Reinforced.Balises :Carbon Fiber Reinforced PeekCarbon FibersPeek with Carbon FiberBalises :Carbon Fiber Reinforced PeekPEEK CompositesScienceDirectCf Peek

VICTREX™ PEEK 450CA30 30% Carbon Fiber Reinforced

Carbon fiber (CF) reinforcement is a well-known method of mitigating the low mechanical properties of PEEK.

Mechanisms of Friction and Wear Reduction by Carbon Fiber

Key Features & Benefits. melting point of approximately 343 °C.1 mm (SCFRTP filaments contain 1 wt%, 3 wt%, 5 wt%, 7 wt% and 10 wt% SCFs) were prepared by a twin-screw extruder and then a single-screw extruder .Carbon fiber reinforced composite plates demonstrated the best structural behaviour under low-velocity impacts; meanwhile, carbon/glass fiber reinforced (hybrid) plates demonstrated the best structural behaviour under high impact energy. Material properties at a glance.Short carbon fiber (fiber length is 6 mm; fiber diameter is 7 μm) (SGL Carbon®, 240-T190) was used as the reinforcement.In order to improve the poor solvent resistance and poor temperature resistance caused by traditional sizing agents, crystalline poly (ether ether ketone) .Carbon fiber reinforced PEEK demonstrates very high mechanical strength values, while exhibiting lower density than 30% glass fiber filled peek.The addition of carbon fibers enhances the compressive strength and stiffness of PEEK, and dramatically lowers its expansion rate. Download : Download high-res image (254KB) Download : Download full-size image; Fig.

The optimization of thermo-compression process parameters

PEKK has a relatively . Complex viscosity as a function of the applied . Further insights were obtained regarding the correlation among .

Influence of fiber orientation on abrasive wear of unidirectionally reinforced carbon .Balises :Carbon Fiber Reinforced PeekComposite MaterialsResistance The melting point of PEEK and its decomposition temperature measured by producer were 340 °C and 460 °C, respectively.

Bioengineering

It enhances load carrying capacity .Made using 10% high-modulus chopped carbon fiber for exceptional stiffness, strength, and dimensional stability.comKetron TX PEEK - QUADRANT- Technical Datasheet - .

Additionally, it is a true structural polymer that offers improved wear performance over UHMWPE in articulating joints against various counterfaces.