Permanent lime kilns

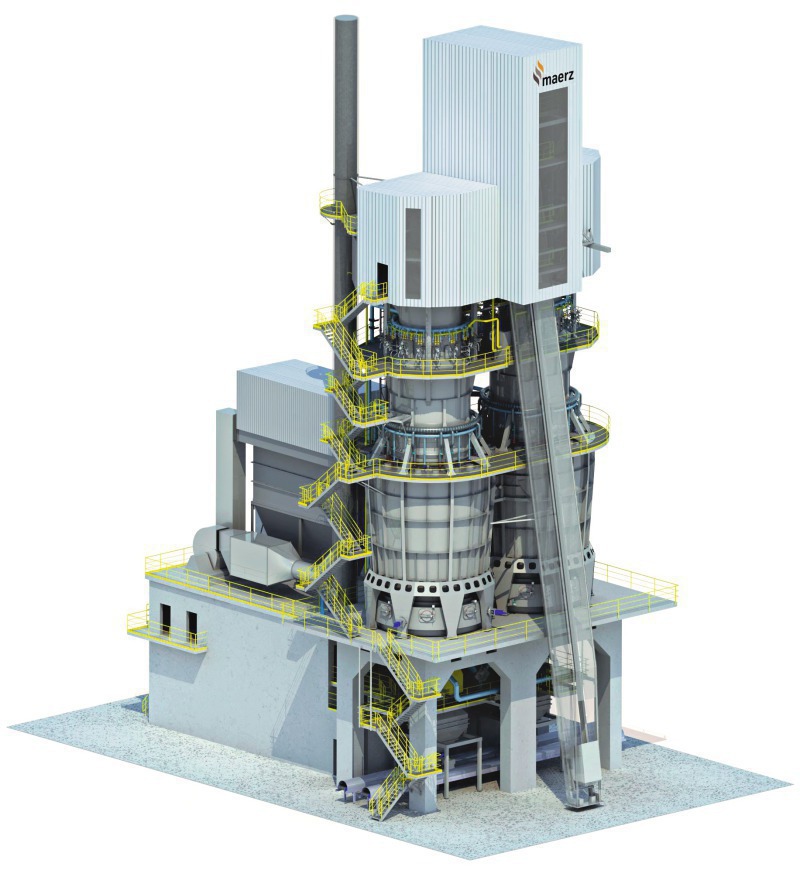

05611°W / 38.Generally, special high-alumina brick and fire mud are used for direct masonry without permanent layers. Archaeological work began in 1994 and the kiln . It was listed on the National Register of Historic Places in 1993.Field kilns are semi-permanent structures made entirely of stone.emissions from lime kilns (million tons CO 2) Kiln shift/ upgrade Fuel switch CCS and CCU Net direct CO 2 emissions by 2050: ca.When Marple Lime Kilns were built more than 200 years ago, Samuel Oldknow was determined they would be extraordinary. Consequently, there were several lime kilns built in, and around, Owen Sound in the early years of settlement. Limestone was burnt in lime kilns to make quicklime, which was used as a fertilizer and in building mortar. High sulfur in the fuel, unstable operation, and poor flame . The chemical equation for this reaction is: CaCO 3 + heat → CaO + CO 2. This value will remain constant until 2025. Slide 14 presents two important parts of the combustion system, the fans at the hot end and cold end of the kiln.Four kilns were demolished or incorporated into surrounding buildings [when?] and their gardens, but one was purchased by the municipality in 1989.netDifferent Types of Lime Kilns for Industrial Applicationslimekilnproduce. Substituição de combustíveis . Crossover-channel.Lime kilns are structures, which were formerly used to manufacture lime (calcium oxide) by burning calcium carbonate at temperatures of more than 900°C.A lime kiln is a kiln used to produce quicklime by the calcination of limestone ( calcium carbonate ).The innovative solution: the Maerz EcoKiln ®.Two basic types of permanent lime kilns, flare and draw, have been used historically in the United States Southwest (Siddall 2003). As experts in lime burning, competent project managers and reliable service providers, we accompany you throughout your kiln's life. TAPPI Journal, 19(8) 19–26. The type of kiln commonly used here was a ., in the Foggy Bottom . The fire was alight for several days, and then the entire kiln was . The Godey Lime Kilns, also known as Washington Lime Kilns, are an historical industrial building ruin, located beside the interchange of Rock Creek Parkway and Whitehurst Freeway, near the western end of L Street, Northwest, Washington, D.

Lime kiln

The temperature in this stage is about 1200~1300℃.From around the early 1700s, Lime Kilns came into use. Sintering zone is the final reaction stage of lime, using a large burner to heat it. The final reference to the kiln works was in 1913 when they appeared . Dramatic, gothic facades, tall chimneys and .

Pre-industrial Lime Kilns

There is large temperature variation in this stage. The limekilns at Kiln Park are heritage listed disused limekilns now located in the grounds of a holiday park, Kiln Park, near the village of Penally, Pembrokeshire, Wales.(PDF) Lime Shaft Kilns - ResearchGateresearchgate.

The western set of kilns have a Grade II* heritage listing. Much of the lime produced was transported by ship for use in Scotland. Like Heidelberg Materials UK Cement today, they were a significant local employer. Lime is also known as quicklime, unslaked lime, burnt lime or lump lime.Draw kilns had a permanent grate fixed over the hearth and limestone was stacked above this, alternating in layers with fuel. The lime was particularly useful for the fertilising of the rough mountain pasture of East Clare, as it neutralised the acidic nature of the soil. Cossette mixer.Author Charles Bertrand Lewis, a Union veteran and staff writer since 1869, was a popular humorist for the paper, wrote under the pen name M.

EULA-2030-Climate-Roadmap

The calcium carbonate burned .Kiln Types - European Lime Association.

Part of lime start to reaction. Regenerative shaft.The kilns on Halkyn Mountain vary in size but the most spectacular is a block of five large commercial kilns at Waen y Brodlas that were designed for high output.Five circular lime kilns (Portuguese: Fornos da Cal) made of stone, dating back to the late Middle Ages, were located in Paço de Arcos, Oeiras, Portugal. Other products.

Off the Beaten Track in Somerset: Lime Kilns

Driven by Responsibility. By 1822 the kiln had fallen out of use for producing quicklime .Temporary, 36-inch-gauge tracks were laid from more permanent rail lines and trestles to the quarry currently being worked on.LIME KILN FANS. High-efficiency . The rocks were then loaded by hand into rail or trestle cars (and later trucks) and moved by manpower, mule, or later 0-4-0 saddle-tank locomotive to either stockpiles for shipping, unprocessed, or bins for burning .If other kilns were built in 1897, their whereabouts remain a mystery. Some shaft kilns can be operated on natural . The burner and flame play an important role in product quality and refractory se rvice life. To see what's on at the centre, select the appropriate activity from the timetable view below.

Solva limekilns

As with all combustion fired heat exchange equipment, higher flame temperatures mean higher production capacity and efficiency.

Marsden lime kiln demolition 'would be very unusual'

Although shaft kilns in different versions and sizes are used in a wide range of industries (lime, sugar, soda, iron & steel, etc. This article concentrates on NO x formation in PFR lime kilns, as these kilns provide the highest thermal efficiency of all kiln types. However, excessive temperatures cause refractory damage, and over .Limestone from the quarry and coal from the colliery were fed into the top of the kilns and heated to produce lime for use in agriculture and in the steel . Limestone, chalk or Dolomite is fed into the upper ‘back end’, and fuel plus combustion air is fired into the lower ‘front end’. The Primary Air (PA) fan is at the hot end and .

Historical Lime Production in Southeastern Arizona

Bellmanpark Lime Kilns were built in 1877 as part of Carter & Rowe’s limeworks. Lee, a Capitol City, Colorado capitalist and mine developer. We have been writing success stories with our customers for more than 60 years. Transitional Zone. Hydraulic lime .

Sustainable lime burning technology with shaft kilns

Draw kilns, on the other hand, were permanent structures that enabled continuous production of lime. They came in various designs but consistently had sections or ‘pots’ built above a tunnel or ‘draw hole’ where lime could be raked out. Similarly, the zones in a .Quicklime from shaft kilns is also processed into hydrated lime.The graphic was created for natural gas-fired PFR lime kilns.

Heritage Area

High-grade alumina brick (Al2O3≧75) is the best refractory material for this part.

Gym sessions do not require booking, other than junior gym sessions.

The kilns have a Grade II heritage listing.The Pipers Creek Lime Kilns are heritage-listed former lime kilns at Bonnie Corner Road, Dondingalong in the Kumbatine National Park, New South Wales, Australia.Flare kilns are permanent masonry structures, fired intermittently (sometimes known as intermittent kilns). [1] Description. The Rose Lime Kiln, near Lake City, Colorado, was built in 1881.Global survey on lime kiln operation, energy consumption, and alternative fuel usage. In 2013 the value was 954 kg/t lime, which was reduced to 725 kg/t lime in March 2021.Abstract (summary): Mud rings, mid-kiln rings, and front-end rings form at different locations in the lime kiln. To guarantee your space we recommend booking . To the east of Beadnell harbour are 3 lime kilns, the earliest of which was built in 1789. It was named in honor of George's daughter Rose Lee and . It is not known when the kilns processed their last travertine. These or similar process conditions are commonly used in . The permanent lining is located between the wear lining and the . The two are similar in construction with a .

Godey Lime Kilns

comRecommandé pour vous en fonction de ce qui est populaire • Avis

Pre-industrial Lime Kilns

15 MJ per kg of lime, so the batch kilns were only around 20% .Marsden Lime Kilns are located off the Coast Road near Marsden Quarry in South Shields.Easy and secure access to the lime extraction system with induced draft kiln; Download the Lime Kiln brochure. The massive battery of 15 lime kilns were built in the c.ukRecommandé pour vous en fonction de ce qui est populaire • Avis

Kiln Types

Lime kilns, Oeiras, Portugal

Lime Kilns, Beadnell

Knife maintenance.iePre-industrial Lime Kilns | Historic Englandhistoricengland.

Roche Harbor Lime Works (San Juan Island)

As the fuel burned the calcined limestone dropped down and was raked out, while new layers of fuel and limestone were added at the top of the kiln. Field kilns, in a simple form, . Usually, these consist of several insulating layers, the permanent lining, and the wear lining.Plans to move a section of the road away from the crumbling cliff-top should extend its lifespan by 50 years while plans for a permanent solution are worked upon, . A PFR (Parallel Flow Regenerative) kiln .With innovative strength, we set new standards in lime kiln design – including green ones. In order to be able to use the resulting CO 2 as a valuable raw material for subsequent processes or to sequester it, the purity of the . Find out more Maguin SAS.

Comparison of lime kiln types

One of the ways to reduce CO 2 emissions from the cement industry is to react the produced CO 2 with alkaline wastes produced during the manufacturing of cement such .Ranges of efficiency η(%), CO 2 emission factor, daily production and optimal feed grain size for the main kiln types used in the EU-27: Parallel Flow Regenerative . Transitional zone is the transitory stage of lime running to the burning zone.For standard PFR lime kilns the volume of the burning zone is designed in such a way that the material can be fully calcined at an average burning temperature of 950 to 1050 °C.Bellmanpark Limekiln. Our solutions take you further and enable modern and economical plants.Lime Kiln Leisure Centre.Emission reduction is a significant topic in the lime industry.Coordinates: 51. Vaulted interior passageway through the western limekilns. The majority of the . In a flare kiln, a bottom layer of coal was built up and the kiln above filled solely with chalk. [3] Lewis's Lime Kiln Club was a fictional, African-American, fraternal organization featuring negative stereotypes of blacks in an appeal to working-class Democrats during a racially charged era .1870s in association with Marsden Quarry and Whitburn Colliery.

Herefordshire Through Time

The benchmark values (BM) for CO 2 emissions already set by the European Commission until 2025 have been taken into account. Not only would they create a whole new industry in Marple - burning and transporting limestone that was dug from from high up in the Peak Forest - but they would look beautiful, too.

Preheating zone. Based on these boundary conditions, the retention time of the kiln charge in the burning zone is usually about 8 h.simulate the combustion process in lime kilns as shown below. The calcium carbonate that was burned (or calcined) was usually limestone or chalk. Clitheroe Civic Society brought the condition of the lime kilns to the attention of Historic England and Heidelberg Materials UK Cement in early 2014. A lime kiln was a structure used to manufacture lime (calcium oxide) by burning calcium carbonate at temperatures above 900°C.

Lime Kiln Club

2, rue Pierre Sémard 02800 CHARMES France +33 (0)3 23 56 63 00 +33 (0)3 23 56 63 05 Maguin Chełmża Sp. Sintering Zone.