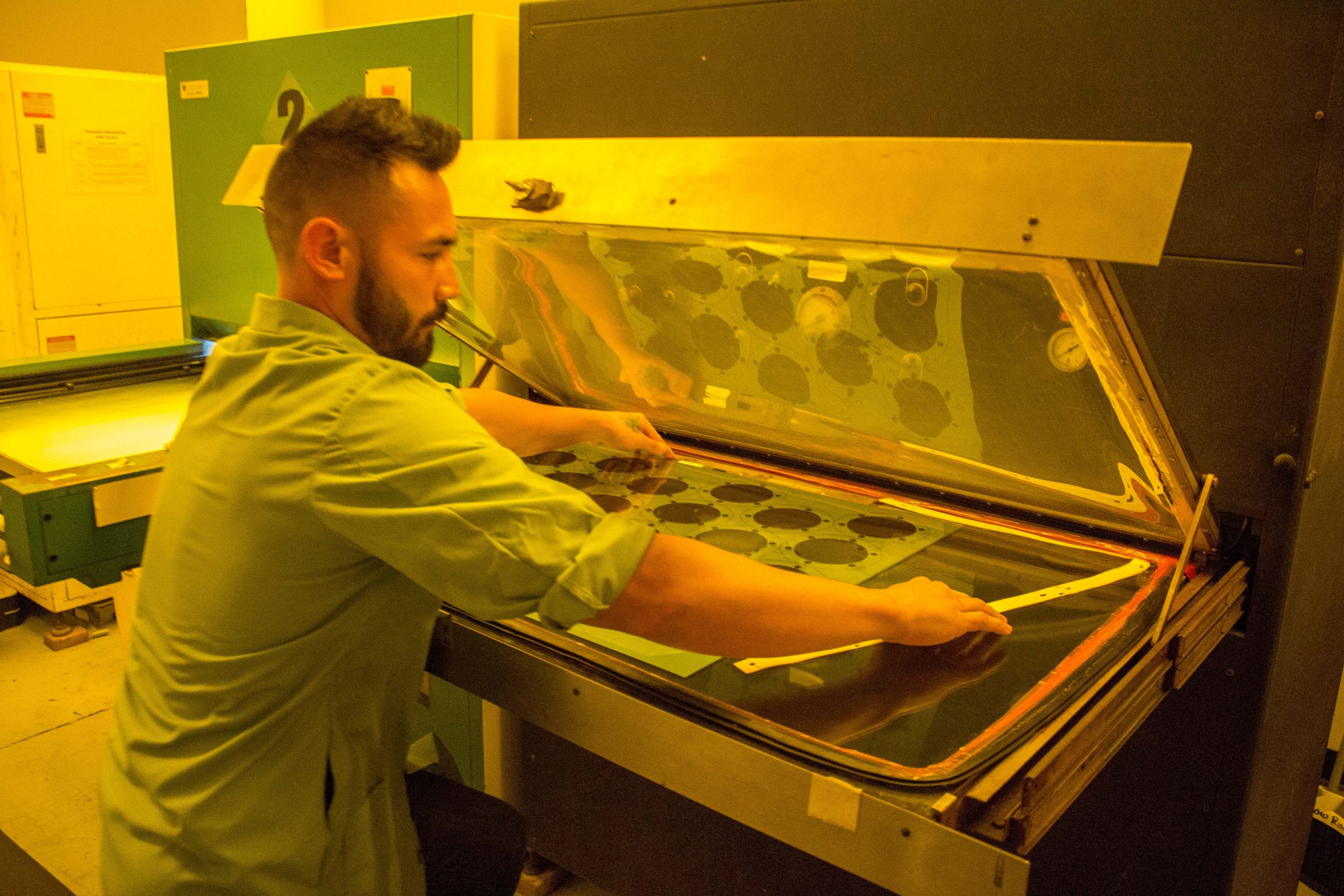

Photo chemical etching process

Photo Chemical Etching is a process used to etch away the copper on the bottom of the board, leaving only the copper on the top.

sales1@tmnetch.

![[Learn Display] 47. Etching](https://global.samsungdisplay.com/wp-content/uploads/2022/03/Learn-Display-Comparison-of-Two-Etching-Methods.png)

com +44 (0)1354 658787.Photographic chemical etching, also known as photochemical machining (PCM), photochemical milling, or photo etching or chemical etching is a precise .Photochemical etching is a highly repeatable and versatile etching process that can cost-effectively manufacture precision metal components for a wide range of mission-critical or safety-critical applications.080” depending on the type of metal.Photochemical machining (PCM), also known as chemical blanking, is a metal-etching process that uses a photoresist to define the locations where the metal will be etched.Chemical etching, also known as photo etching or chemical milling, is a high-precision, tightly controlled corrosion process used to produce complex metal components with excellent detail. WeChat /WhatsApp:+8613603056883.The ultraviolet light hardens selected areas of the laminate .What does the photo chemical etching process look like? chemical machining (PCM).

In 2022, photo etching is the most popular industry term for the . Complementary processing techniques. Metal etching is sometimes known as aluminium etching, ferric chloride etching, acid metal etching, chemical etching, or photo chemical etching. C11000, C10100, C26000, C51000, C52100, C71500, C77000Regarder la vidéo Photo Chemical Etching Process | 27 mins.Photochemical etching, also known as photochemical machining (PCM) or metal etching, is a non-traditional, subtractive machining process that uses photographic and chemical techniques to shape metal workpieces. Referred to by engineers and designers by many names, including chemical milling, chemical machining, photochemical milling, photo etching, photochemical machining, and chemical etching, Photochemical Etching . Etched carnelian beads are a type of ancient decorative beads made from carnelian with an etched design in white, which were probably manufactured by the Indus Valley civilization during the 3rd millennium BCE. Photo chemical etching, a precise and versatile manufacturing process, offers a plethora of benefits and features that make it a preferred method for creating intricate metal components across various industries.

A Guide To Photochemical Machining

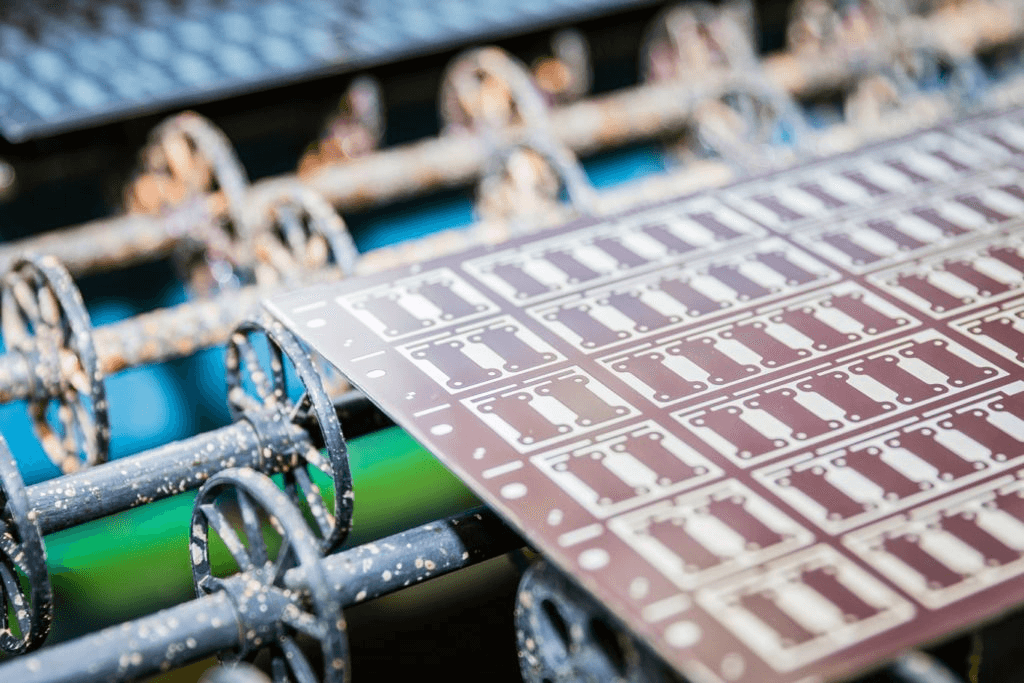

Other than the difference in chemistry used the etching process .Photo chemical etching (also called chemical etching or photo etching) is a remarkable process that has revolutionized manufacturing across various industries. The metal thickness rages from . We can work with a wide range of materials, with thicknesses going from 0,05 mm to 3,00 mm. We offer photo etching for most metals & have over 30 years .

[email protected] etching is a precision manufacturing process for thin metal parts with simple or complex designs.The area exposed to the environment is etched away during the process of etching, while the portion covered by photoresist remains unchanged.

Silver Photo Etching

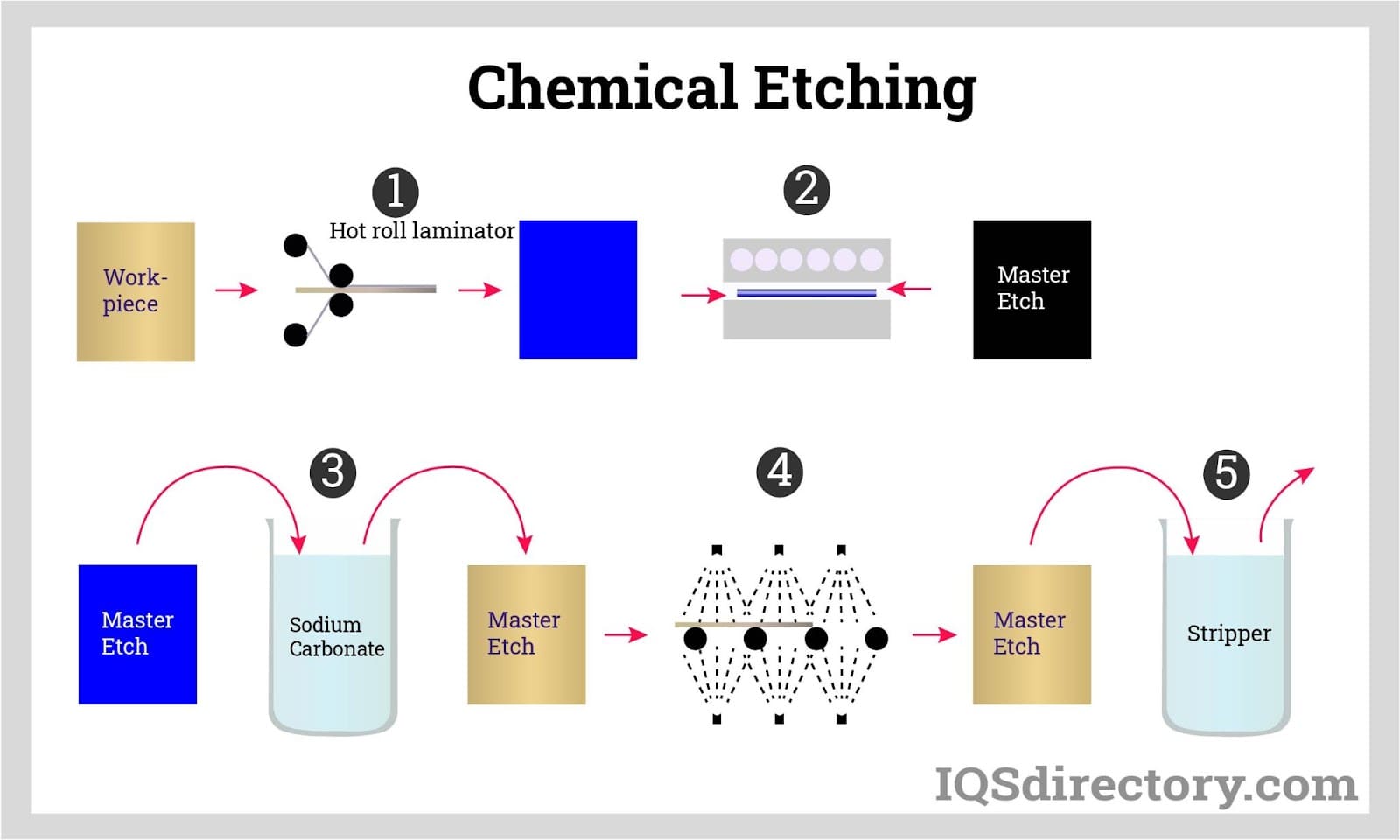

The etching process itself is an acid, usually ferric chloride, that effectively eats it's way through the metal at a known rate to ensure precision and targeted only in the areas you wish to remove, such as the profile track lines or other holes and features such a mesh. However, because of how silver reacts with chemicals, we use a different chemical etchant – Ferric Nitrate – to ensure we produce the same high manufacturing standards at all times.This subtractive process, also known as chemical etching, or photo chemical etching, is a multi-step operation using photo-sensitive material to transfer .The process of photo etching silver is just as flexible and accurate as other metal materials.

It is also referred to as photo etching, chemical machining, . Etching, stripping, and inspection.

How Does It Work?

Chemical etching, also known as photo etching, photochemical machining, or chemical milling, is a highly precise manufacturing process used in various .It's also known as chemical milling, photo etching, photo chemical, or chemical machining.

Master Guide to Photo Etching and Finishing

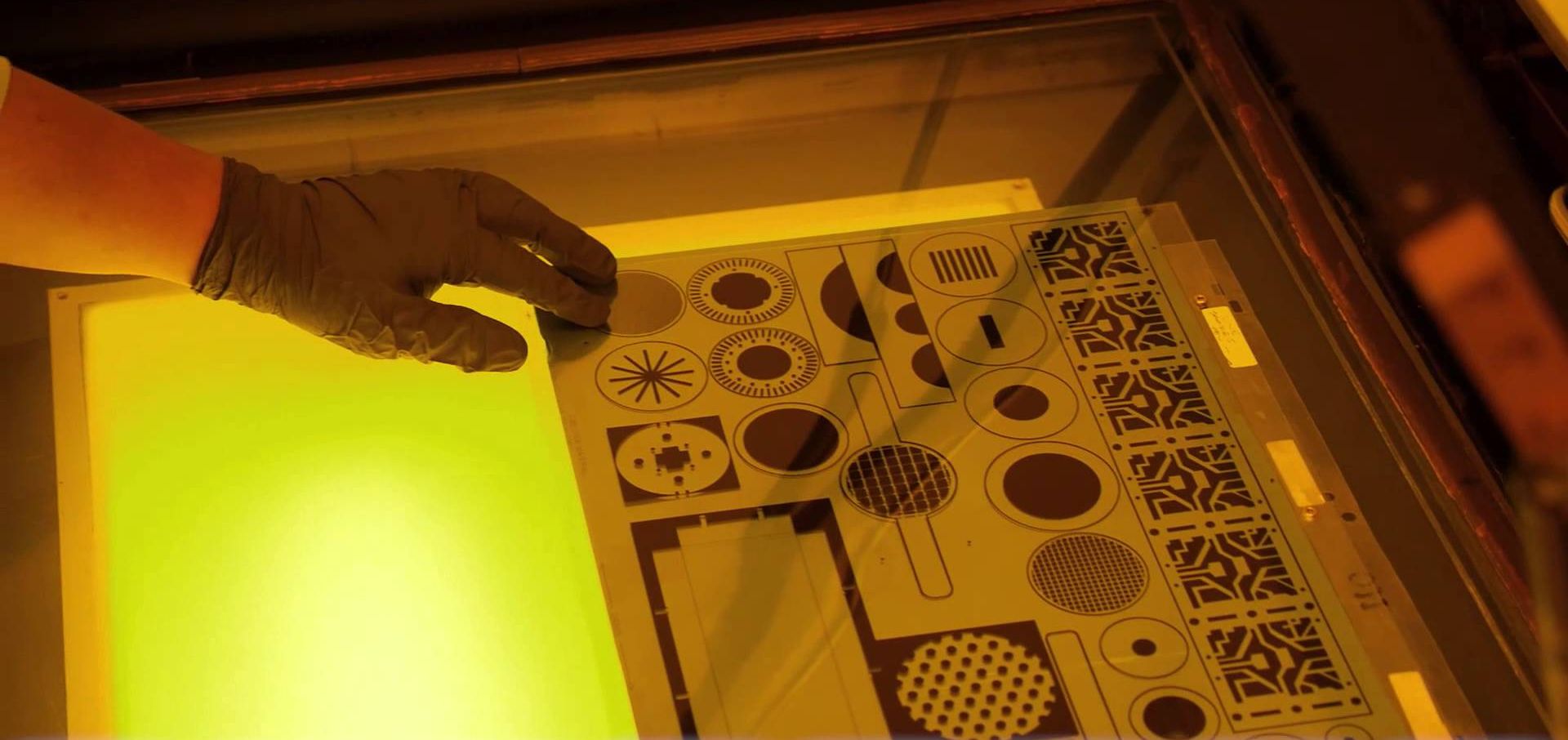

The photochemical machining (PCM) or photochemical milling process uses photoresist imaging to place a pattern .orgPhotochemical Machining: from ‘manufacturing's best .

Photochemical machining

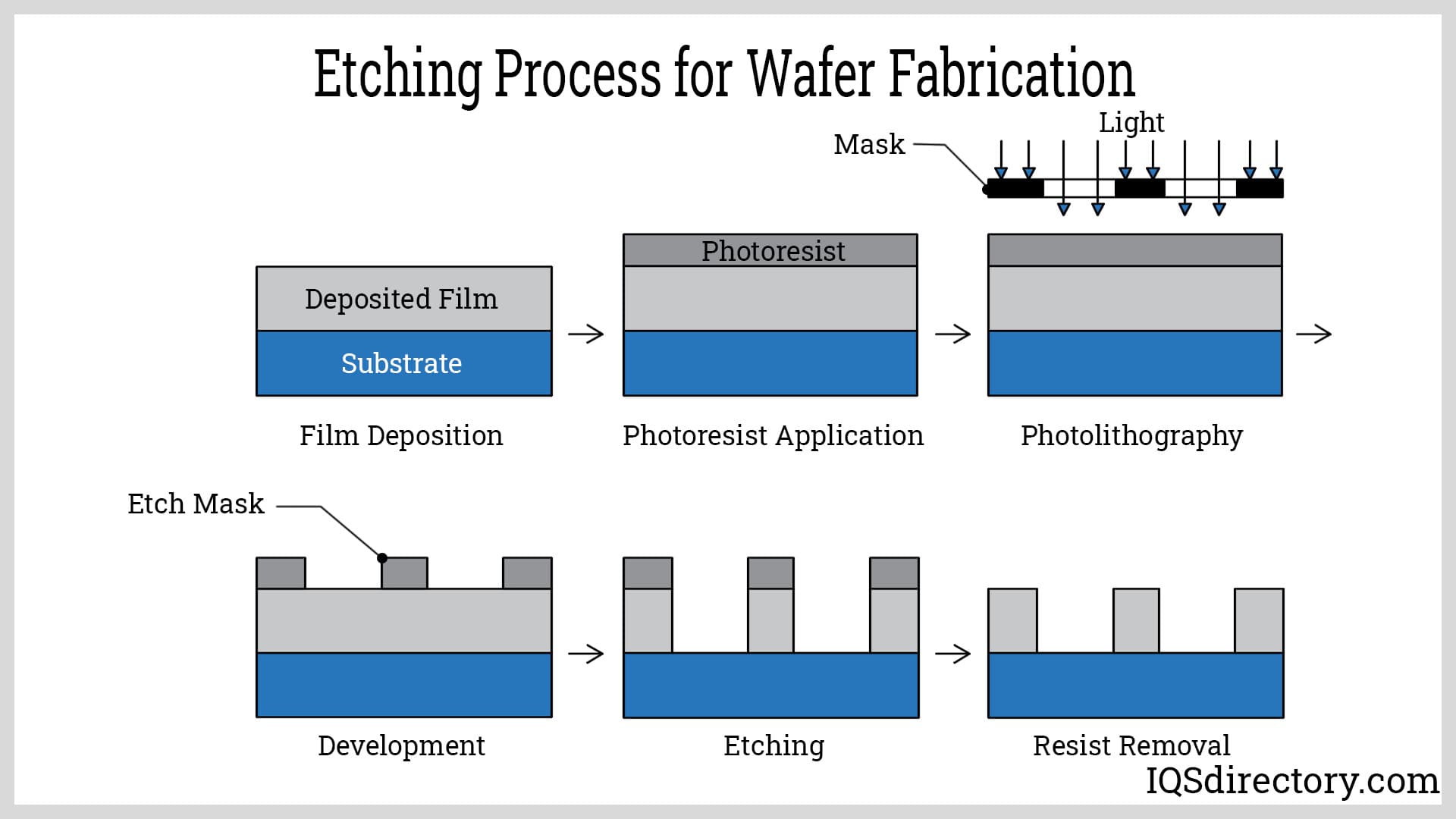

Also referred to as photochemical etching or chemical etching, it involves . The process involves using baths of temperature-regulated etching chemicals to remove material to create an etched image (the design). The PCM process flow, shown in Fig. This is done after all the board patterns have been made using photoresist (chemical-resistant material coated on a board and exposed to light to make patterns). Le procédé de photogravure produit des composants métalliques dépourvus de tension .For example, when working with micrometal’s Etching Group the process can be applied to thin metal sheets ranging from 10 microns to 2000 microns (0. For materials between 0.

Depending on your requirement, the material choice will change but it .

what is photo chemical etching?

Photochemical Machining Process

The photo etching process has seven essential steps: cutting, cleaning, laminating, printing, developing, etching and stripping. Manufacturers then convert the file into a working protocol.Learn about the photo chemical machining process which is a unique technology that produces precision metals parts by selectively dissolving metal into solution. Also called chemical or photochemical etching, photo etching is a versatile process that uses photoresists and chemicals to remove selected portions .asminternational.Photo Chemical Etching. Lastly, etching – the process of removing the softened metal – takes place.The photo etching process is known by many names, including chemical etching, acid etching and photo. This soft metal possesses high thermal and electrical conductivity and is one of the easier metals to photo-chemically machine or etch. This is a very important advantage that no other processing can guarantee.

Photochemical Etching

These can be a.

The rest of the sheet is masked by the UV photo sensitive blue .

Metal Etching Services

First introduced in the 1960’s, photo etching has rapidly progressed with its capabilities and advantages growing by the year. The design further helps in the creation of a protocol. It allows the Etching Group to achieve extremely small feature sizes of 25 microns, minimum hole diameter 80 percent of the material thickness, and single-digit . Metals that can be processed include the chemical etching of steel and stainless steels, nickel and nickel alloys, . [1] [2] Other names for chemical etching include photo etching, chemical etching, photo chemical etching and photochemical machining. In the photo chemical machining process a mylar stencil .

Photo etching: process, advantages and applications

TMN, your professional choice for photo etching, offers a wide range of services with advanced technology and extensive metal material inventory. After having the image of a design developed on the workpiece, a strong chemical solution is poured over the workpiece that selectively .comRecommandé pour vous en fonction de ce qui est populaire • Avis

Chemical Etching Process Step-by-Step

The design engineer’s guide to photo-chemical etching

Standard etching tolerances.What is Photo Etching? Photo etching is an advanced subtractive sheet metal machining technique. Specialists apply an etching solution using a chamber and spray tools. To create an etched pattern on the surface of a metal, we need a way to transfer the required image or pattern onto the metal surface; this is achieved using photoresist technology. In order to achieve the desired pattern or design, a photo-resist is used as an outline so that the chemicals don’t dissolve away the entire material. Photochemical Machining is one of the oldest processes of non-traditional processing.A mask or resist is applied to the surface of the material.The metal sheet is sandwiched between photo-tools and exposed to ultraviolet light. Tolerances are a key consideration in any design and with photo etching varies dependent on the material thickness. In order to make PCBs, it is necessary to have . They were made according to a technique of alkaline etching developed by the . Download : Download high-res image (101KB) . This intricate method of producing precisely designed thin metal parts has not only redefined precision and efficiency but also paved the way for future manufacturing advancements.During the chemical etching the properties of the materials remain unchanged, meaning they do not undergo any chemical/physical alteration.

Chemical Etching Process : Tecan

The range of metals possible is vast, from brass, copper, beryllium copper, to ferrous metals including stainless steel, carbon steel and . 1, describes the process of PCM and its various stages. Metal Stamping Producing high-quality stamped / punched components typically for volume production, offering an alternative and versatile and cost-effective solution.