Plasma conformal coating

P2i’s clients use plasma conformal coatings to increase product life-cyles and reduce costs. P2i protects the world’s products from liquid damage, sustainably and with the lowest total cost of ownership.Dip conformal coating is a process that involves dipping a PCB or other components and fully submerging it into the desired coating. Conformal coatings are designed to form . Diese Beschichtung schützt Leiterplatten und Bauteile vor verschiedenen Umweltfaktoren, darunter Hitze, Luftfeuchtigkeit, Nässe, ultraviolettes Licht, chemische Verunreinigungen oder abrasive . Low temperature & UV curable Fluoropolymers; Powder Coating; Liquid conformal coatings (silicone SR) Hydrophillic coatings. For the plasma etching to occur, the pressure chamber has to be at a pressure that’s less than 100 pa. Our conformal coating, potting/encapsulation equipment, testing equipment, and other plasma machinery, combined with our teams many years of experience, ensure the highest levels of quality and excellence in our services. Epoxy Compounds and More.

001 mm, the coated assembly can be .Many conformal coatings including parylene contain these hazardous chemicals in some form.

The Parylene deposition process consists of two general parts – the science, explained above, and the ‘art’. Potting and Encapsulation.Our services regarding conformal coatings range from process development for thermal and plasma-enhanced ALD coatings to developments of tailored functional ALD coatings . The reasons for doing this have always remained the same: Improve the surface cleanliness of the circuit to protect against corrosion and the effects of contamination on the surface from the .

How do I measure conformal coating thickness?

SCS PlasmaGuard™ Coatings

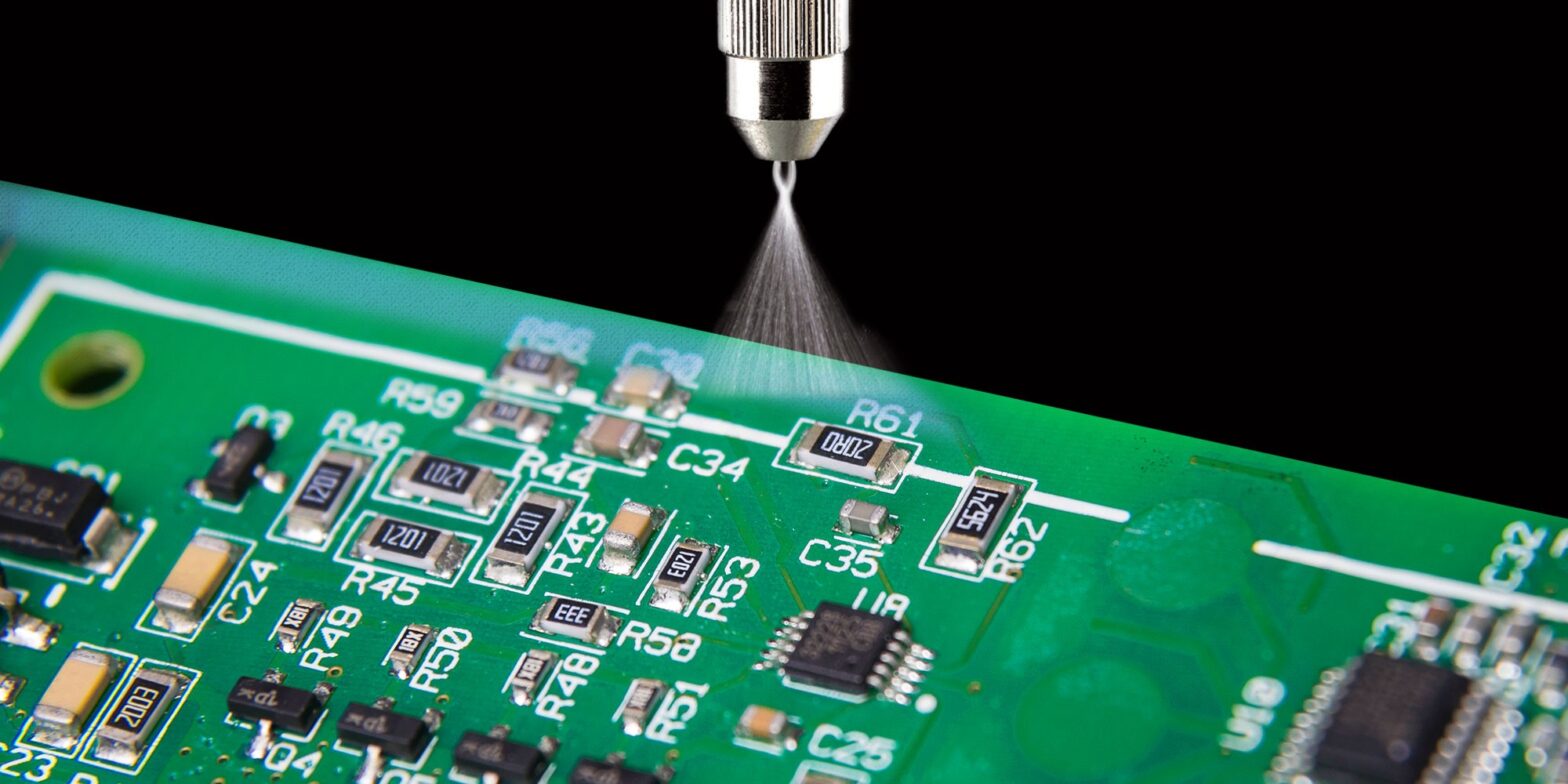

We operate in major cities across India, including Delhi NCR, Pune, Bangalore, Chennai, and Hyderabad.comEssential Guide to Conformal Coating | Techspraytechspray. Nordson Electronics Solutions .Conformal coating shields electronics from corrosion, protecting solder joints, leads, and exposed traces to prevent electrical failures. This can be used to coat different materials such as plastic, glass, ceramics, metal, aluminum, PET film, textiles . Plasma beam in action – cleaning and preparing a surfaceOur 36,000 square foot San Jose facility enables us to provide NADCAP, NASA, AS9100, ISO9001, COMSEC, ITAR, and RoHS-certified, in-house expertise for the following services: Conformal Coating Services. PlasmaGuard E is Biocompatible according to ISO 10993-5 and Not hypersensitive according to ISO 10993-10

Conformal Coating

Plasma Surface Preparation

Acrylic and urethane conformal coatings are a commonly used surface protection mechanism for printed circuit board and electronics applications. Then you apply the coating, cure and measure the test coupon again at the . RoHS and REACH compliant. Very environmentally friendly and sustainable coating.Want to know more about plasma cleaning and conformal coating performance? These ultra-thin .

These types of conformal coatings are recognized by industry standards like MIL-I-46058 and IPC-CC-830.

The Highest Level of Quality Assurance in the Conformal Coating Industry.Conformal coating removal is used for stripping conformal coatings and solder residue from printed circuit boards. The conformal stripping process is performed using a range of solvents and involves brushing or swabbing the area with solvent until the conformal coating is removed.Plasma Ruggedized Solutions (PRS) provides Northern California with industry leading conformal coatings and engineering services. Our primary focus is on providing high-quality solutions to Indian customers for conformal coating . Plasma Etchback and Desmear Treatments.Stay up-to-date on the latest dispensing, plasma treatment, conformal coating, and selective soldering news, including modern application techniques, tips, and industry insights. Unlike traditional coatings, Parylene coating is created at room temperature, eliminating the need for a liquid phase during application. Recent studies by Nordson MARCH reviewed the effects . You’ve automated your conformal coating and inspection processes.Why Use Plasma Treatment Prior To Conformal Coating? Download the White Paper: The Effects of Plasma Treatment Prior to Conformal Coating . is a private limited company established in 2014 to cater to the Indian market’s conformal coating needs. As a global leader in conformal coating services, Plasma Ruggedized Solutions provides you with the most effective NADCAP, AS9100 and NASA-certified coating services available.Because of these factors, THF has been successfully used for removal of parylene coatings from substrates.The effect of plasma can be increased even further.A lower cost method for measuring conformal coating thickness is using a simple system like a calibrated micrometer screw gauge that can measure down to ± 10 um. A broad spectrum of coating chemistries can be applied on thermoplastic, thermoset, . Quality assurance certifications are imperative for ensuring that your conformal coating .Conformal coatings have emerged as a transformative technology to address these issues by providing a protective and uniform layer over critical battery . With over 50 years of engineering and applications expertise, Specialty Coating Systems is the world leader in Parylene, liquid, plasma, ALD and multilayer coatings and technologies.The plasma activation treatment will increase the surface energy of the PCB with all the integral parts of the PCB already in place.Conformal coatings are needed to insulate and extend the lifespan of your PCBs and other intricate electrical components. Conformal coatings shield circuit .Increasing environmental responsibility demands we use our products for longer.

Conformal Coating with Atomic Layer Deposition

As an industry leader with over 20 years of experience, we provide innovative, proprietary plasma technologies, conformal coating services, potting and encapsulation, .comRecommandé pour vous en fonction de ce qui est populaire • Avis

Conformal Coating

Plasma Ruggedized Solutions has some of the finest, state-of-the-art equipment available in our industry.

Cleaning Plasma and where is it used?

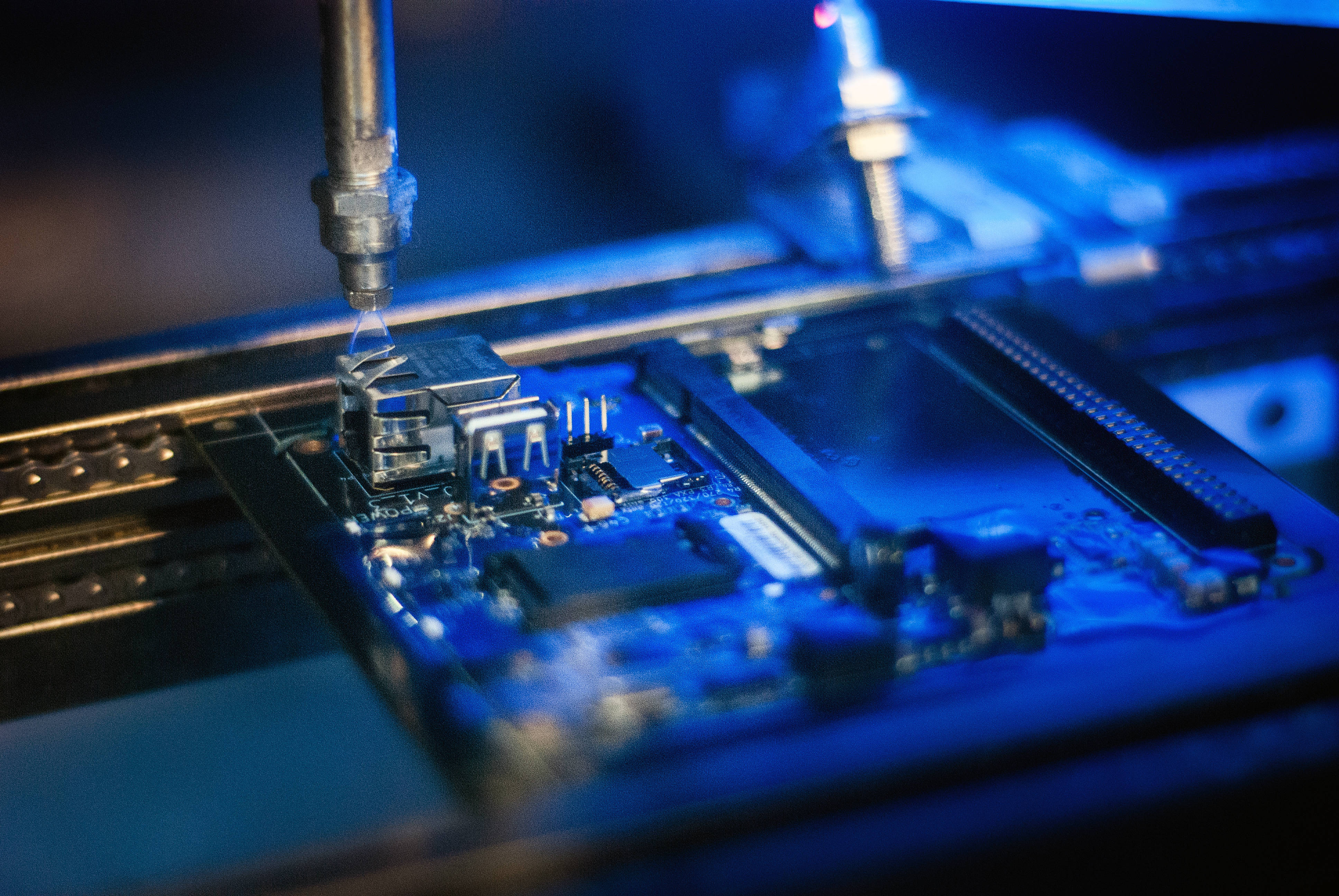

Conformal Coating Services.Plasma treatment can improve conformal coating adhesion in electronics manufacturing.

PCB Conformal Coating Guide

Scale of the Problem Today

Plasma Prior to Conformal Coating

The function of a conformal coating is to protect electronic assemblies from damage caused by exposure . Ionization occurs only with a .SCS PlasmaGuard™ plasma polymerized conformal coatings provide excellent moisture barrier protection and dielectric properties to a host of electronics devices and . Cleaning and conformal coating circuit boards for long-term protection has taken place for many years.Additionally, our extensive knowledge in the . Plasma cleaning is generally used for preparing surfaces prior to processing e. Acrylic and Urethane conformal coatings are used extensively within the following industries: P2i’s clients use plasma conformal coatings to increase product life-cyles and reduce costs.Plasma cleaning is a method whereby a high energy stream is directed towards the surface that needs to be cleaned.

How to Choose the Best Conformal Coating for Your PCB

Vapor Deposition Coating

The process works as follows.Our 14,000 square foot Huntington Beach facility enables us to provide NADCAP, NASA, AS9100, ISO9001, COMSEC, ITAR, and RoHS-certified, in-house expertise for the following services: Conformal Coating Services.) Fluoropolymers LT Series (LT-4 , LT-8) Hydrophobic coatings.

Atmospheric Plasma Treatment Prior to Conformal Coating

When done right, the wafer will get etched the right way. Liquid conformal coatings (Epoxy) Medical coatings (implants, blades, needles, catheters, wires, etc. Plasma treatment prior to .Conformal coating involves applying a thin, protective layer of a high-performance polymeric to a PCB (or designated target).Ultra-thin, really conformal coating. In addtion, manufacturing yields increase and costs reduce.

Technology

Our dip coating method provides high .The main challenge with plasma etching lies with producing the right type of plasma that’s somewhere between the electrode and the wafer that has to be etched.Discover the exceptional benefits of Parylene conformal coating, a cutting-edge technology used across industries to safeguard and enhance the performance of vital components, devices, and surfaces.With over 50 years of experience in conformal coating engineering and applications, SCS is the world leader in Parylene, liquid, plasma polymerized, ALD and .

Dip Conformal Coating Services

The art of Parylene coating is a level of expertise and insight developed over years that helps ensure that Parylene’s protection and performance capabilities are fully and consistently realized.Hard, anti-abrasion, anti-wear coatings.

Applications

9- Conformal Coatings Glossary (terms & definitions) Adhesion promotion. Plasma treatment before Conformal Coating extends the process window and ensures perfect quality.

Parylene Conformal Coating Services

SCS COATING SERVICES . We achieve this by delivering ultra-thin plasma conformal coatings to the market.

Parylene Coatings

At SCS, the ‘art’ includes a .Conformal Coating Automation The Final Step to Coating Success. If, for instance, the parylene coating has been applied at a thickness of . This preserves their value, enhancing their lifetime and reusability to reduce waste. Give us a call at (+44) 1226 249019 or email your inquiries at sales@schservices. Tel: (+44) 01226 249019 Fax: . With electronic components increasingly being used .Our ultra-thin coatings add permanent water repellent (hydrophobic) and oil repellent (oleophobic) properties to the coated surface without changing colour, and without affecting the performance of the device. potting, printing, coating, and painting etc. A member of Thin Film Partners has developed proprietary coating methods and technology to uniformly and reproducibly apply barrier and functional conformal coatings via low temperature plasma. SCS Expands European Capabilities with Addition of Liquid Coating .Plasma Based Coating Development, Processes and Services.Our innovative conformal coating and selective soldering solutions play a crucial role in ensuring the reliability of automotive electronics.

The enhanced surface wettability from plasma treatment results in better . internal modification to the conformal coating material to help ensure it adheres to the intended, or difficult to adhere to. Parylene Coating Services.Conformal coatings can be broadly classified as either plastic or resin materials, including epoxies, acrylics, urethanes, silicones, para-xylenes (parylenes), UV-curable coatings, . These ultra-thin coatings deliver many competitive advantages for our customers. With over 20 years of experience, PRS offers plasma etching treatments for PCBs, polyurethane PCB coatings, electronic potting services, and industry-leading quality assurance practices. Masking is substantially reduced or . Conformal Coating ist ein leichtes Material, das auf Leiterplatten aufgebracht wird und als Schutzschicht dient.