Plastics used in injection molding

We offer quality used injection molding machines in brands such as Van Dorn, Husky, Toshiba, Krauss Maffei, Milacron, and many more.The cost difference between thermoset and thermoplastic injection molding is not black and white.

The Complete Guide to Injection Molding Materials

However, in 1868, a man named Hayat improved it so that it could be processed into finished shapes.History of Injection Molding.Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting ), glasses, elastomers, confections, and most . Here, we break down each step of the foam injection molding process. ABS is commonly found in plastic toys such as Lego bricks, but it’s also often used in many types of electronics, tools, and home repair equipment.

Injection Molding: Definition, Types & Processing Techniques

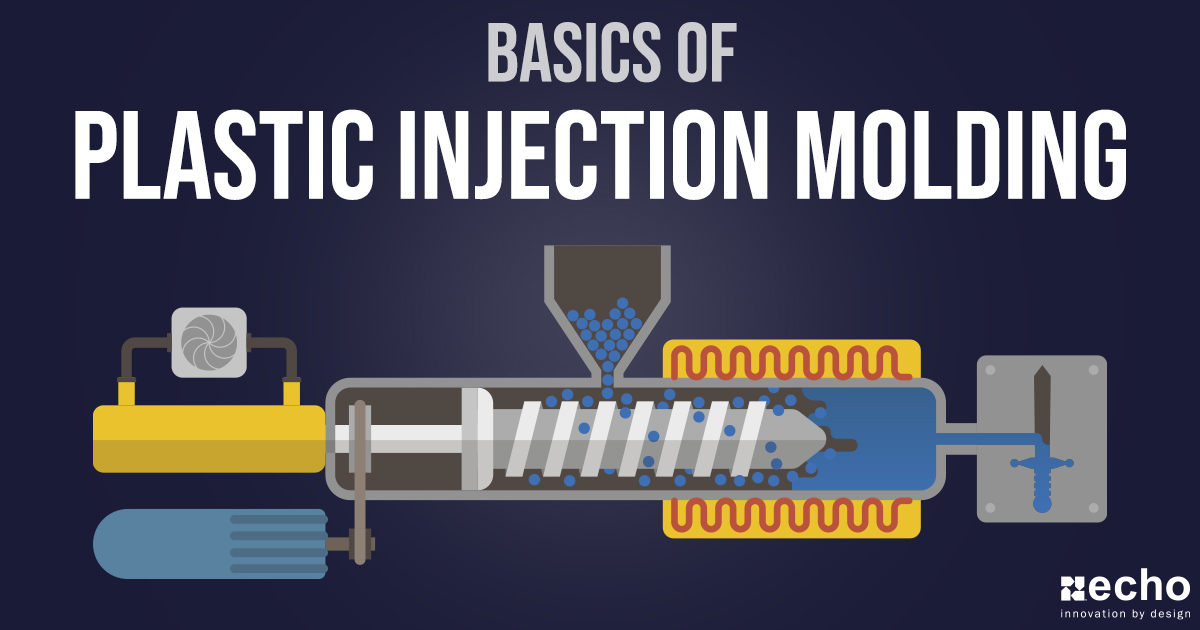

It involves precise control over material, temperature, and pressure. The mold then cools, and the plastic solidifies.Plastic injection molding is better than 3D printing for larger production runs, stronger parts, faster production, and a larger variety of materials that can be used, including fillers. When manufacturers need to create products or parts with specific material .

The Definitive Guide to Plastic Injection Moulding

Some notable developments include: Bio-based and Recycled Materials: Increasing emphasis on sustainability has led to the development and adoption of bio-based plastics and recycled materials in injection molding. These pellets are typically made from various types of thermoplastic polymers, such as polypropylene, polyethylene, polystyrene, and others.Thermoplastic injection molding is a type of injection molding in which molten thermoplastic is injected into a custom-built mold before it is cooled and hardened into a plastic part. Most plastics processing sites use gas simply for space heating but some processes use gas as part of the process, e. Polycarbonate (PC) PC-ABS plastic. Hayat and his brother Isaiah also registered the patent for the first plunger injection machine in 1872. Acrylonitrile Butadiene Styrene (ABS) Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic of engineering-grade with a low melting point that makes it easy to mold.9 Common Types of Plastics Used in Injection Moulding. While this machine was relatively simpler . Available with various surface finishes and textures, its opaqueness supports the use of . This is the technique most commonly used today. The global medical injection molding market size was estimated at USD 22. Many of the same materials used in blow molding are also good choices for injection molding, including ABS, HDPE, PS, PU, Santoprene, PP, and LDPE. TPU combines the properties of rubber and plastic, making it suitable for applications requiring both elasticity and toughness. The process is simple in principle; a plastic material (usually called a resin) is melted and forced into a mould via injection. Pv stands for the filling pressure, usually between 150-350 kg/cm^2. Shot sizes are . They are melted and injected into a mold under . The choice of plastic will depend on the properties required for the final product.

The Most Common Plastic Injection Molding Materials

Plastic Injection moulding is a widely used manufacturing process to produce plastic components due to its affordability, effectiveness, and high .Common Thermoplastics Used: High Density Polyethylene (HDPE): Known for its strength and resistance to impact. Thermoplastic Polyurethane (TPU): Thermoplastic Polyurethane (TPU) is a versatile elastomer used in injection molding, known for its flexibility, abrasion resistance, and excellent mechanical properties. It is also called polyamide 66 or PA 66. Some are clear and others are opaque. Metals used in MIM include steel, copper, and aluminum alloys, each offering unique properties.

Injection Moulding of Plastics: An Overview

Thermoplastics: Thermoplastics are the most commonly used materials for injection molding production. Where gas is used for hot water only then this is generally relatively constant over the year.

10 Types of Injection Molding Materials

Design guidelines play a critical role in .Injection Molding Formulas Series 1. Increasing consumption of plastics in healthcare applications, technological advancements, and rising demand for medical .Energy Management Systems – The Gas Bill. Because injection molding’s manufacturing process simply involves the injection and cooling of plastic, a part can be formed within a few minutes at the most, .Plastic molding processes are essential in the manufacturing industry, enabling the production of a wide range of plastic products. With resins, impurities cannot be avoided.Polypropylene (PP) PP is a lightweight, low-cost plastic with great mechanical properties, including strong tensile strength and good chemical, impact, and .

Other plastics that can be used in injection molding are: Polystyrene, Acetal, Nylon, Polyacetal, Polybutylene terephthalate, Polyphenylene oxide, Polyphenylene oxide, etc. Stability and impurities.Plastics are by far the most common materials that are produced using injection moulding. It’s a method of plastic injection where molten plastic is inserted into a mold to produce .Injection molding is a manufacturing process used to produce plastic parts in large volumes. Plastics are more stable than resin and lack impurities. Unlike their crystalline counterparts, these materials lack a precise, ordered molecular structure.8% from 2024 to 2030.The injection molding industry continually evolves, with ongoing advancements in materials and innovations. The process is very cost-efficient, accurately producing parts at quick cycle times, making it ideal for large-scale production. From injection molding to .Medical Injection Molding Market Trends .

Foam Injection Molding: Types, Process, and Applications

Moreover, injection molding is most commonly used to process polymers and produces identical products from a mold.

The Most Common Plastic Injection Molding Materials

Am denotes the projected area of the mold cavity in cm^2. Heat melts the plastic, which is mixed together. Engineered Thermoplastic . Acrylonitrile Butadiene Styrene (ABS): . Modern rotational molding .Injection molding is a technique that involves injecting molten plastic into a mold.Injection moulding materials include metals, glasses, elastomers and confections, although it is most commonly used with thermoplastic and thermosetting polymers.Heaters, whether used in industrial applications like injection molding or for residential and commercial heating, offer several benefits. Injection molding is compatible with so many plastic materials that its products are common in every household and industry. It has improved mechanical properties due to its more ordered molecular structure. The ability of injection moulding to produce .

Injection molding is the single most commonly used plastic manufacturing process, and all of us use injection molded parts every single day.

Plastic Injection Molding: Process, Prototypes, Advantages

The Foam Injection Molding Process. This characteristic imparts unique properties to amorphous plastics, such as enhanced dimensional stability, lower shrinkage rates, and better . For space heating, the gas use load will be related to the weather . It is virtually impossible to .Acrylonitrile Butadiene Styrene (ABS) ABS plastic is one of the most commonly used plastics in injection molding due to its wide temperature range, good stability, and insulating properties.

The ten most commonly used plastic injection molding materials are: #1.

This property affects the molding temperature and cycle time to some extent.

Injection Molding: Processes, Materials, and Applications

With a wide variety of tonnage machines, we are here to help you! Browse our selection of injection molding machines.

Plastic Pellets for Injection Molding: How To Make & Work?

A Guide to Identifying the Best Plastic Types for Injection Molding

Thermoplastic injection molding is a widely used manufacturing process for producing high-quality, detailed, and cost-effective plastic parts.What Type of Nylon is Used for Injection Molding? The most commonly used types of Nylon for injection molding are Nylon 6, Nylon 6/6, Nylon 66, and Nylon 6/66. This results in unique cellular structures within the molded parts. Clamping Force (F in TON): The clamping force is determined by: F = (Am x Pv) / 1000 Where: F is the clamping force in TON. This process combines the flexibility of plastic injection molding with the strength and integrity of metals. Injection molding is a manufacturing process used for the mass production of identical plastic parts.

The Ultimate Guide to Injection Molding Materials

This comprehensive guide will delve into essential aspects of thermoplastic injection molding, including design guidelines, the process itself, and the various stages involved.Common Materials for Plastic Injection Molding.

A Simple Guide To Plastic Molding

Companies use this process to .Amorphous plastics are a significant category in the realm of injection molding materials.

Injection moulding

Gas-Assisted Injection Molding Molds: Used for hollow or partially hollow parts, these molds allow gas injection into the molten plastic, creating internal cavities in the part. Most of the plastic products used today are created using thermoplastics because of how diverse this material is. Nylon 66 is a more crystalline version of Nylon 6.

Used Plastic Injection Molding Machines For Sale

There are many plastic resins used for injection molding. Some thermoplastics are very sturdy and rigid, while others are flexible and rubber-like. Here are some examples of its common uses:Plastic components are used in many industries. The main advantage of this process is the .

5 Common Plastic Resins Used in Injection Molding

This guide explores the types of plastic molding processes, compares their characteristics, and provides insights into choosing the right process for your specific needs.December 4, 2023By Chuck Connors.Material Variety: Injection molding supports a wide range of thermoplastic materials, including commodity plastics, engineering plastics, and high-performance polymers. Celluloid, a plastic material, was invented by Alexander Parks in 1851.

What is Injection Moulding, its applications and materials

Plastic is a type of synthetic resin, whereas resins are amorphous compounds that can either be semi-solid or solid. Sometimes, PC is used instead of acrylic due to its ability to maintain physical properties over a wide temperature range. Plastic is dense and hard, while resin is typically a gluey and viscous substance. They are versatile, durable, and can be easily molded into complex .54 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5., rotational molding. In-Mold Decoration and Labeling Molds : These molds allow for embedding labels or decorations into the part during the molding process, resulting in durable and high .Polycarbonate (PC) Another one of the leading plastic injection molding materials is Polycarbonate.Plastic injection moulding is a complex manufacturing process commonly used to create plastic components.April 29, 2022.The basic plastic injection molding process consists of the following steps: Plastic resin materials enter a barrel. Temperature Control: Heaters allow precise control of temperature, ensuring that processes or environments are maintained at the desired level.Top 10 Common Plastic Resins For Injection Molding. However, its popularity isn’t solely due to the quick production that’s possible with molding but also to the variability of the available materials.