Pressure swing adsorption nitrogen production

Svetlana Ivanova Robert Lewis.

The higher temperature operation provides more efficient .

Pressure swing adsorption (PSA) nitrogen

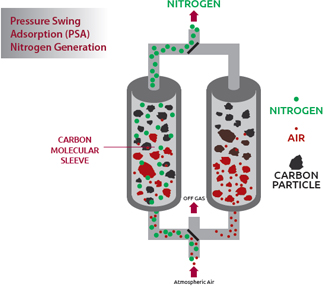

The gas composition and pressure in the month-long storage and recovery phase can vary substantially; meanwhile, the recovered H2 has to be pure, especially for fuel cell .net(PDF) APPLICATION OF PRESSURE SWING .It can be used to remove contaminants, prevent combustible dust explosions, and create a nonreactive production environment in settings where oxygen may cause explosions or harmful oxidation.Pressure swing adsorption (PSA) is a well-established gas separation technique in air separation, gas drying, and hydrogen purification separation. Learn more about how it works here. In the process of PSA nitrogen generation, a highly efficient CMS method is used to generate a high purity . The classification involves distinct colour codes. As this does not occur naturally it has to be created artificially, there are many ways to achieve the . Our PSA nitrogen generators . Nitrogen production from air using carbon molecular sieve adsorbent and pressure swing adsorption has been studied by running experiments on a two-bed semi-industrial unit and also .An example of particular industrial relevance is nitrogen generated by pressure swing adsorption from compressed air.

Abstract The specific oxygen production capacity and the oxygen recovery of a pressure swing adsorption (PSA) process for the production of oxygen from ambient air by selective adsorption of nitrogen can be increased by operating the process at a superambient temperature. After the switch, tank A starts regenerating while tank B .In this work, a detailed simulation and optimization is carried out to explore the feasibility of pressure-vacuum swing adsorption (PVSA) technology for on-site .

The separation of air for nitrogen production can be carried out by pressure-swing adsorption over a carbon molecular sieve. To ensure higher CH4 yields and avoid its release in the atmosphere, the LFG is collected below the atmospheric pressure by . However, though nitrogen is the most abundant gas in the atmosphere, it is not readily available because it must undergo purification to make it .

Nitrogen generator

The reason it is so useful is it’s abundance, however like all the noble gasses the benefit can only be realised in levels of high purity.February 05, 2021.Pressure swing adsorption is commercially used for the separation of air as an alternative to the conventional cryogenic separation process. Bathen

Nitrogen separation from air by pressure swing adsorption

Below, we cover .Hydrogen storage in a depleted gas field is a promising solution to the seasonal storage of renewable energy, a key question in Europe’s green transition.Inlet Temperature and PressureNitrogenAdsorptionSystemHow to Remove Contaminants From Compressed AirDryer

Pressure swing adsorption

The economics are compared with those of three other nitrogen sources: (1) combustion of natural gas; (2) membrane-based air separation; and (3) purchased liquid nitrogen. On the other hand, the . The most important industrial PSA process, the nitrogen PSA process, has been developed during the last ten years into a highly efficient technique for producing nitrogen on site. A kinetically based separation of .PSA is a cost-efficient process for producing high purity nitrogen.Oxygen Adsorption Kinetics Study used Pressure Swing Adsorber (PSA) for Nitrogen Production. Grey H 2 designates hydrogen derived from hydrocarbons (fossil fuels), sourced from approximately 6 % of global natural gas or 2 % of global extracted coal, .At present, nitrogen production from air by pressure swing adsorption (PSA) is simulated almost exclusively at low product purity levels (< 99% N2).92 % with a flowrate reducing to 2000 m 3 /h.Pressure swing adsorption, which utilizes Nitrogen-selective adsorbents, is one of the well-known methods used in the design of medical oxygen concentrators. This method of production of nitrogen gas relies on the ability of adsorbent material to separate a gaseous mixture into its components.

High-Purity Nitrogen by Pressure-Swing Adsorption

Published 8th May 2016.34K and a = 124. The embodiment consists of one or more pairs of adsorbent layers contained in a .Table 1 shows H 2 production technologies. We can deliver nitrogen . The separation is kinetically based, .One way of generating nitrogen is through Pressure Swing Adsorption.netProducing Nitrogen via Pressure Swing Adsorption | AIChEaiche. The most important industrial PSA .This review considers the economics and technology for on-site production of nitrogen from air by pressure swing adsorption (PSA) .

The combination of pressure swing adsorption (PSA) with a downstream redox chemical looping cycle to remove trace oxygen is proposed for the production of . For an uninterrupted production of gas this process is continuously repeated. PRISM PSAs can economically produce nitrogen gas at flowrates from less than 2,000 scfh to greater than 60,000 scfh .Industrial & Engineering Chemistry Research2019, 58 (8) , 3314-3328.The pressure swing adsorption is a milestone in the science of gas separation.62 kg/h) have been obtained at T = 301. It is known that the adsorbent . First, tank A is in the adsorption phase while tank B regenerates. Back then, three . In the second stage both vessels equalize pressure to prepare for the switch.Nitrogen rejection from natural gas is a capital intensive process.Landfill gas (LFG) produced from municipal solid waste substrates represents an important source of RNG and the market for its upgrade is facing significant challenges in terms of energy consumption and operating costs.Pressure Swing Adsorption is a technology within nitrogen generators that can provide nitrogen with very high purity levels. The categorization of H 2 production methods is primarily based on the nature of the H 2 feedstock. One of the core technologies in many nitrogen gas generators today is Pressure Swing Adsorption (PSA), using Carbon Molecular Sieve (CMS) adsorbent.The optimal conditions were found to be an adsorption pressure of 6 bar, an adsorption time of 250 s and a purity of up to 97. Among nitrogen adsorption plants of various types, pressure swing adsorption (PSA) plants have found the broadest .608 kg/h) and water vapor (107.The maximum results for the flowrates of nitrogen (87. Svetlana Ivanova, Robert Lewis.Our nitrogen pressure swing adsorption (PSA) plants are designed for on-stream applications that require clean, dry, high-purity nitrogen for inerting, blanketing and purging processes. Reactions and Separations.orgNitrogen separation from air by pressure swing adsorptionsciencedirect. Pressure swing adsorption (PSA) can be a cost-effective method of onsite nitrogen generation for a wide range of purity and flow requirements. Comparison of nitrogen production by cryogenic method and pressure swing adsorption (PSA) With the rapid development of industry, nitrogen has been widely used in the fields of chemical industry, electronics, metallurgy, food, biology, medicine, etc.

Pressure swing adsorption: Principles, processes and applications

Currently, for the large-scale separation of nitrogen and oxygen cryogenic and pressure swing adsorption (PSA) are the most utilized technologies.A novel rapid pressure swing adsorption (RPSA) process is described for production of 25–50% oxygen enriched air. The demand for nitrogen has increased significantly year by year.Onsite nitrogen genera-tors, such as pressure swing adsorption (PSA) or membrane systems, can be more cost-effective than traditional cryo-genic distillation or stored liquid nitrogen, particularly if an extremely high purity (e. International Journal of Hydrogen Energy.Pressure swing adsorption (PSA) processes based on carbon molecular sieves have been known for more than twenty years.

And it is the best process for separation of air, if the process does not need 100 per cent pure oxygen or nitrogen.127734 Corpus ID: 228828363; High-purity nitrogen production from air by pressure swing adsorption combined with SrFeO3 redox chemical looping @article{Bulfin2020HighpurityNP, title={High-purity nitrogen production from air by pressure swing adsorption combined with SrFeO3 redox chemical . In this work, a detailed simulation and optimization is carried out to explore the feasibility of pressure-vacuum swing adsorption (PVSA) technology . Pressure Swing Adsorption (PSA) Nitrogen Production. The effects of feed flow rate, purge-to-feed ratio (P/F), and adsorption . How does Pressure Swing Adsorption work? Nitrogen is currently produced . A short review on pressure swing adsorption (PSA) technology for nitrogen generation from air.9999%) is not required. Industrial & Engineering Chemistry Research2018, 57 (14) , 5093-5105. Zykamilia Kamin; Mohd H.

Oxygen Production by Pressure Swing Adsorption

Steinfeld

Dynamic simulation of high-purity twin-bed N2-PSA plants

Pressure swing adsorption (PSA) is a cost-effective method of onsite nitrogen generation for a wide range of purity and flow requirements. Pressure Swing Adsorption, on-site nitrogen gas generation.

Oxygen Adsorption Kinetics Study used Pressure Swing

It is a technology that can be used to generate nitrogen or oxygen for professional purposes.comRecommandé pour vous en fonction de ce qui est populaire • Avis

Nitrogen Generation by PSA

2136 kg/h), oxygen (140.Pressure swing adsorption (PSA) nitrogen generators ensure a constant and consistent supply of high-purity nitrogen to facilitate uses on-site.PRISM ® Pressure Swing Adsorption Process Overview.Nitrogen makes up 78% of the atmosphere, it is also one for the most widely used of the Noble gasses in the world. For the first time, Natural Zeolite minerals from Jordan are studied as a Nitrogen-selective .Air separation by adsorption is often carried out by Pressure Swing Adsorption (PSA) or Vacuum Swinging Adsorption (VSA) operation modes, due to their shorter cycle time and simplified control, in addition to the possibility of being operated under temperature and pressure conditions close to ambient conditions for small-scale .Producing Nitrogen via Pressure Swing Adsorption.

Producing Nitrogen via Pressure Swing Adsorption

A two-bed pressure swing adsorption (PSA) system for nitrogen separation from air using carbon molecular sieve is studied. This method is applied in this work to design a smart oxygen concentrator prototype.Nitrogen separation from air by pressure swing .