Process fmea definition

• The multidisciplinary team of knowledgeable .Qu’est-ce Que l’analyse FMEA ?

Failure mode and effects analysis

De l’anglais “Failure Modes and Effects Analysis”, la méthode FMEA signifie “Analyse des Modes de Défaillances, de leurs Effets et de leur Criticité”. Aims to identify and correct potential process-related failures. Autrement dit, c’est un outil curatif visant à l’identification des anomalies à l’origine des défaillances au sein d’un processus. L’AMDEC, c’est quoi ? Une méthode d’analyse de la fiabilité. Also, it helps identify ill impacts of those failures on desired outputs and . If there are design inputs, or special .L'AMDEC se distingue de l'AMDE (Analyse des modes de défaillance et de leurs effets, traduction de l'anglais FMEA ou Failure Modes and Effects Analysis) par une . For System and Design FMEAs, FMEA Block Diagram , Parameter Diagram (if done), and/or Functional Block Diagram (if done) can be used as input to function descriptions.

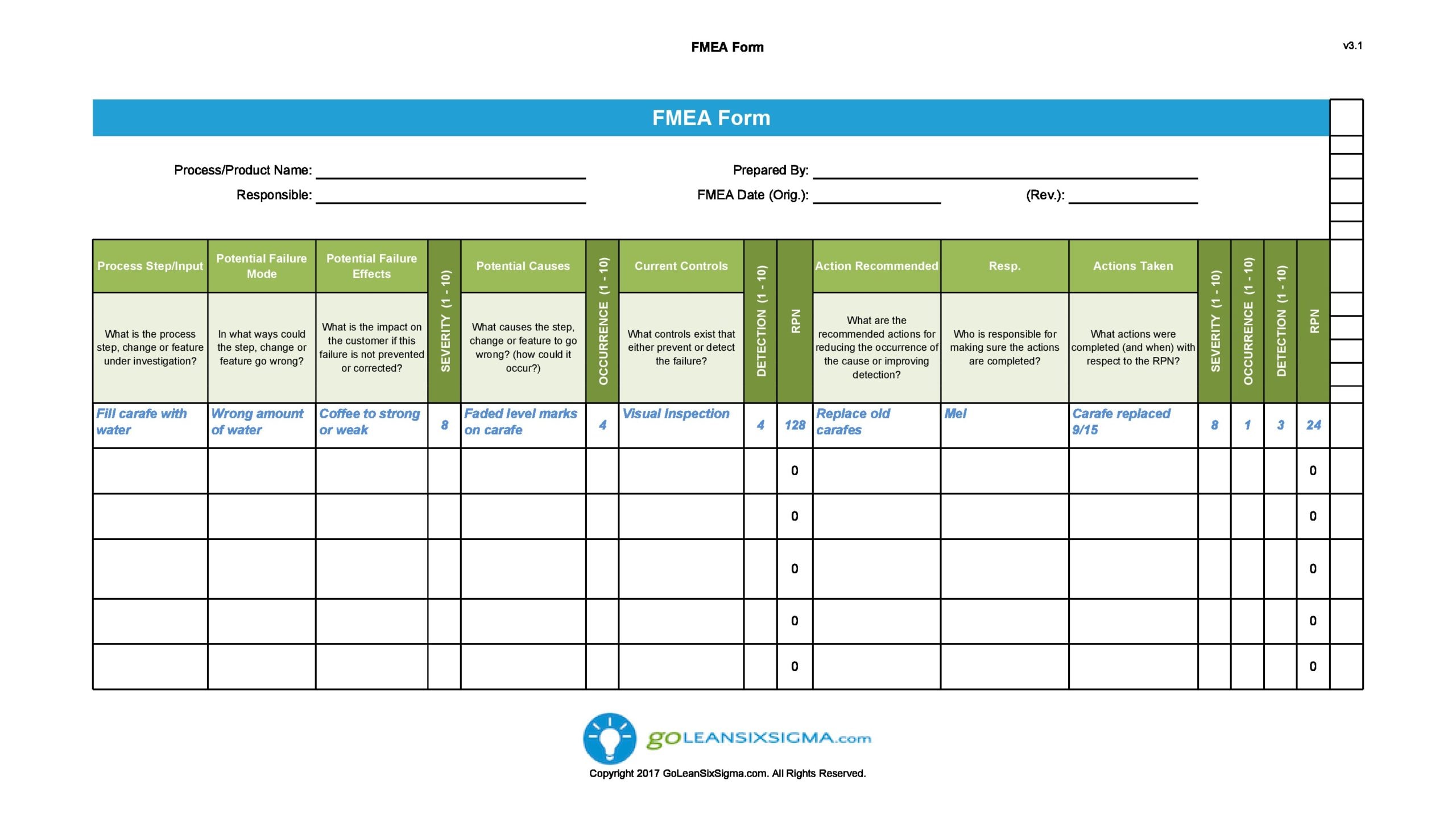

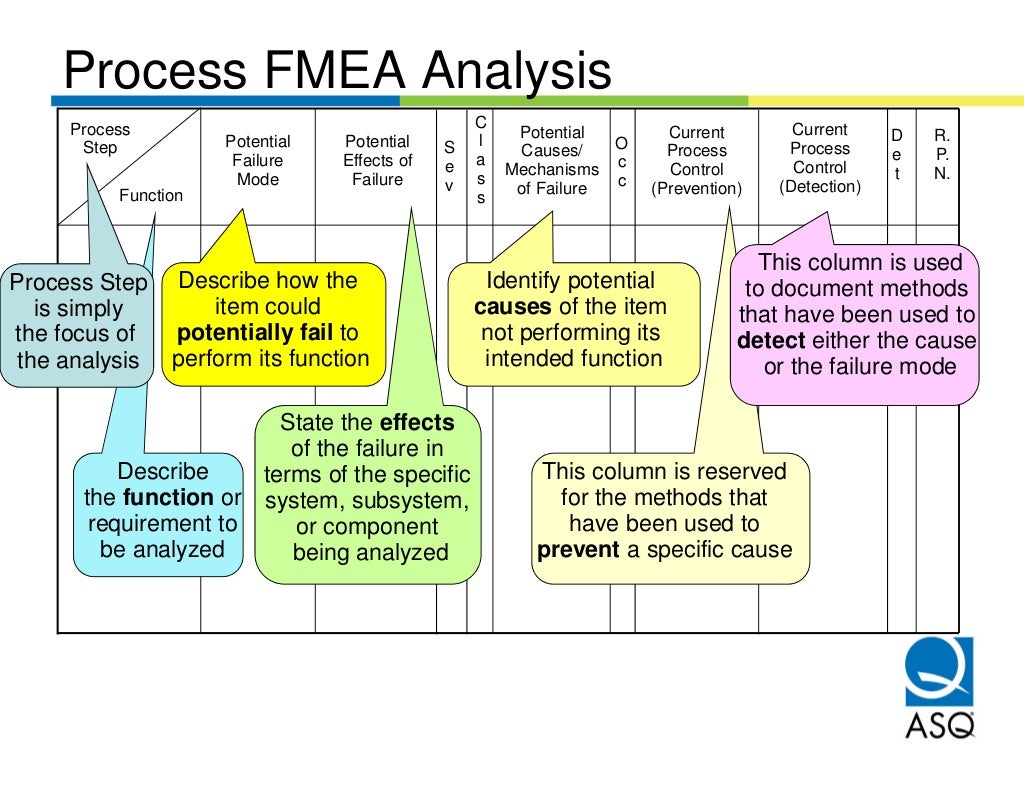

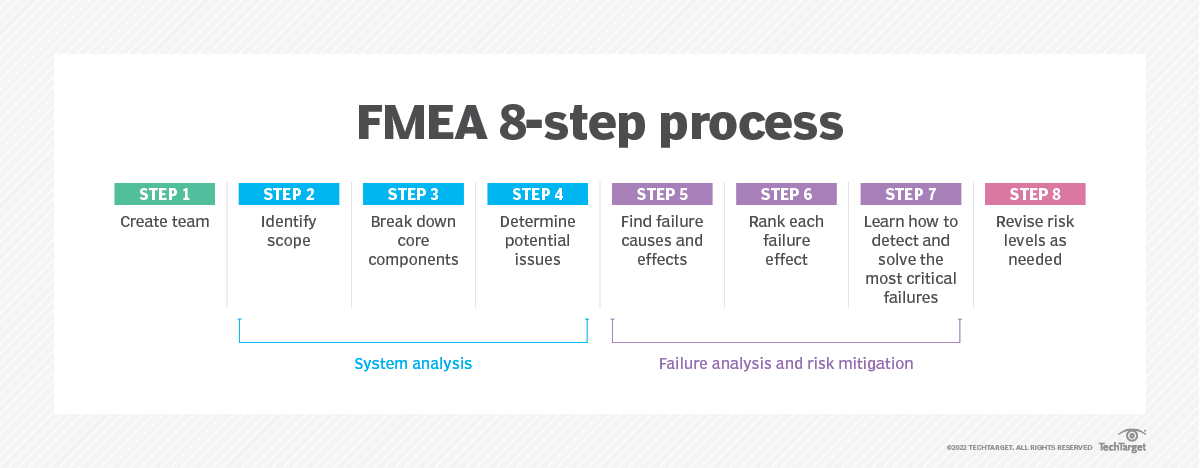

Document what actions can be taken to reduce or eliminate the failure occurring. Maintenant que vous avez la définition de l'AMDEC, nous allons passer à ses différents types. process flow diagram. Questo perché .Risk Priority Number (RPN) is an integral part of the creation of a Failure Mode and Effect Analysis (FMEA) document but is also used widely wherever a risk management strategy is deployed. FMEA is a proactive, quantitative, . It is focused on preventing problems, enhancing safety, and increasing customer .Step 1: Review the process. Do you want to be proactive .Etape du processus.Degradation of primary function (vehicle operable, but at reduced level of performance). The FMEA (Failure Mode and Effects Analysis) is an analytical method of preventive quality management in product and process development.De l’anglais “Failure Modes and Effects Analysis”, la méthode FMEA signifie “Analyse des Modes de Défaillances, de leurs Effets et de leur Criticité”.“Process Failure Mode Effects Analysis” is an analytical technique used by an organization’s business unit or cross-functional team to identify and evaluate the . Voici une présentation détaillée des principales .FMEA (failure mode and effects analysis) is a step-by-step approach for collecting knowledge about possible points of failure in a design, manufacturing process, product or service.

Analyse AMDEC ou FMEA

The worksheet will help clarify roles and responsibilities and define boundaries of freedom for the team.Process Failure Modes and Effect Analysis (PFMEA) stands as a cornerstone in the realm of proactive risk management in business processes. Obtenez une analyse FMEA détaillée. It includes potential errors that might occur, especially errors that could affect the . Chaque étape contribue à l’identification des modes de défaillances potentiels, à l’évaluation des effets des défaillances et à la définition d’actions préventives ou correctives appropriées. Failure mode (FM) refers to the way in which something might break down. Loss of secondary function (vehicle operable, but comfort/convenience functions inoperable).Temps de Lecture Estimé: 4 min

Guide: Process Failure Mode and Effects Analysis (PFMEA)

Sebbene possano essere utilizzati in modo indipendente, vengono spesso utilizzati insieme come parte del processo di analisi dei rischi e possibilità di guasti di un’azienda. Unter der FMEA wird im Deutschen die so genannte „Fehlermöglichkeits- und -Einflussanalyse verstanden. Process FMEA (PFMEA) discovers failure that impacts product quality, reduced reliability of the process, customer dissatisfaction, and safety or . After reviewing engineering, drawings, and planning, team develops a flow chart showing the major functions or operations of the process to help team members understand the process.FMEA fait appel à la sagesse collective des experts dans ce processus. During the afternoon, you will work individually and in small groups to review an everyday process scenario and .

Dans la boîte à outils de tout bon consultant en excellence opérationnelle figure l’ AMDEC (Analyse des modes de défaillance, de leurs effets et de .Most FMEA standards, such as AIAG, SAE J1739 and VDA, attribute the occurrence ranking to the cause of the failure.Process Failure Mode Effects Analysis (PFMEA) is a qualitative tool used with the intention of preventing failures.If the scope of a PFMEA seems too big, your team should consider breaking it up into two or three complementary studies.Overview

What is FMEA?

Beides beschreibt die gleiche Entwicklungsmethode, welche zur Unterstützung bei . Updated: July 17, 2023 by Richard Penn. FMEA is a common tool used in engineering related to safety, quality, and reliability. En même temps, vérifiez comment la présentation visuelle est créée au fur et à mesure.

Understanding AIAG-VDA’s FMEA Process and Approach

Cette zone, comme le suggère le titre de la section, est l’étape du processus. Die Methode kann für die verschiedensten Prozesse, Produkte und Systeme angewendet werden. L'AMDEC comporte trois types principaux, .

Process Failure Modes Effects Analysis (PFMEA)

Assess the effect of the failure.

Autrement dit, c’est un outil .With the help of the facilitator, a DFMEA team should establish common probability of occurrence and detection definitions and a rating scale before getting into the definitions of failure.A Failure Mode Effects Analysis (FMEA) involves reviewing all the potential modes in which a system, subsystem or component might fail. Cette zone est simplement cette étape individuelle qui va être examinée. Im Englischen wird die gleiche Abkürzung verwendet, wobei FMEA hier für „Failure Mode and Effects Analysis steht. Failure Mode and Effects Analysis: Managing Product and Process Failures. The final phase in the DFMEA process is concerned with risk mitigation and prevention through execution of a control . Driving corrective actions that will contribute to an overall risk reduction. RPN is a multiplication of a number of factors that aim to assess the risk of a failure mode escaping and potentially presenting to the customer as . PFMEA is well used across a wide range of .FMEA ist eine Abkürzung für Fehlermöglichkeits- und Einflussanalyse, auf Englisch “Failure Mode and Effects Analysis”.

Réunissez-les dans un groupe de travail auquel un ou plusieurs intervenants externes peuvent être ajoutés.

Analyses de risques « AMDEC » ou « FMEA

Examples of definitions for each level are presented in the tables below.

Process FMEA (pFMEA): How to Identify Process Risks

A failure modes & effects analysis (FMEA) aims at: Identifying potential risks.La FMEA (Failure Mode and Effect Analysis) est une technique structurée permettant d’identifier les causes possibles et les conséquences des défaillances potentielles ou .

Manquant :

definition A suggested approach is assuming the failure has occurred and then assessing the .

Identify and fully understand potential failure modes and their causes, and the effects of failure on the system or end users, for a given product or .PFMEA is a methodical approach used for identifying risks on process changes.

Understanding FMEA Occurrence

Once your FMEA team has defined the scope of the PFMEA, you should complete the FMEA Team Start-Up Worksheet.PFMEA is a structured analytical tool that helps identify and prioritize potential modes of failure in a manufacturing or assembly process at the system, subsystem, or component level.INTEGRATION: The FMEA is integrated and consistent with the process flow diagram and process control plan, the Process FMEA considers the Design FMEA, if available as part of its Analysis LESSONS LEARNED: The FMEA considers all major “lessons learned” (such as high warranty, campaigns, non-conforming, product, .

Manquant :

definitionGuide: Failure Modes and Effect Analysis (FMEA)

Lorsque l’on examine le processus dans son ensemble, l’AMDEP le décompose en chacune des étapes incluses dans ce processus.La capacité de détection de la défaillance.

Process FMEA

What is Process Failure Mode and Effect Analysis?

military, failure modes and effects analysis (FMEA) is a step-by-step approach for identifying all possible failures in a design, a manufacturing or assembly process, or a product or .Process failure modes and effects analysis is most often described as a systematic group of activities fundamentally intended to: Recognise and evaluate potential failures of a process. The definitions for the various levels of severity, probability, and detectability should be clearly articulated. Des consultants experts .1, risk in an FMEA evaluation has three components: Severity, Probability, and Detectability. Deviation from primary process including decreased line speed or added manpower.FMEA steht für Fehler-Möglichkeiten-Einfluss-Analyse (engl.FMEA is a systematic method of identifying and preventing system, product and process problems before they occur. If we have two different causes for “cable breaks”, such as “ corrosion of cable wiring due to wrong material selected” and “ fatigue cracks in cable . PFMEA is a step-wise means .Failure Mode and Effects Analysis, or FMEA, is a methodology aimed at allowing organizations to anticipate failure during the design stage by identifying all of the possible failures in a design or manufacturing .Failure Mode and Effects Analysis, commonly abbreviated as FMEA, is a structured, step-by-step, proactive approach to identifying and analyzing all the . Diese systematische Methode dient zur Identifizierung und Bewertung von potentiellen Fehlern und Risiken. View Demo Clips. Also called Process FMEA, it is an aid to initiatives for process improvement and is . Begin your FMEA by mapping out your process.Begun in the 1940s by the U. Sorting those risks highest to lowest, and focusing more attention on the highest sources of risks. Documenting and keeping track of those risks. The diagram is a visual representation of each step in your process, from input to output. PFMEA stands for Process Failure Mode and Effect Analysis.

Develop a failure mode and effects analysis (FMEA) project plan, including the identification of: • The intent or purpose of developing the design or process FMEA.

Understanding FMEA Functions: The Essence of the Item

Failure Mode and Effects Analysis (FMEA) is a method designed to: 1. Failure Mode and Effects Analysis (FMEA) is an essential part of any product design or redesign activity. A portion of the production run may have to be scrapped. Die Prozess-FMEA (im nachfolgenden P-FMEA) ist eine etablierte Methode, mit dem Ziel Prozessrisiken (insbesondere nach Prozessanpassungen oder -neueinführungen) .The FMEA team reviews relevant documents, as well as considering their engineering experience, to determine the primary functions of the item or process. Initiation of a FMEA requires the assembling of a team .During the morning, we will begin by discussing the fundamentals of FMEA including its definition, when to use it and when not to use it, types of FMEA, basic steps of the process, and how to assemble and facilitate an FMEA team.2 Define overall process and process increments (unit operations, steps) FMEA Team Start-Up.

L’ AMDEC, que vous retrouverez également sous l’appellation FMEA en anglais, pour « .

Analyse AMDEC : un outil essentiel pour la gestion des risques

This definition is consistent with the FMEA standard SAEJ1739:2021, which is used by many automotive and commercial organizations.La metodologia Design FMEA si concentra sulla creazione di prodotti affidabili, mentre la metodologia Process FMEA si concentra sullo sviluppo di processi affidabili.