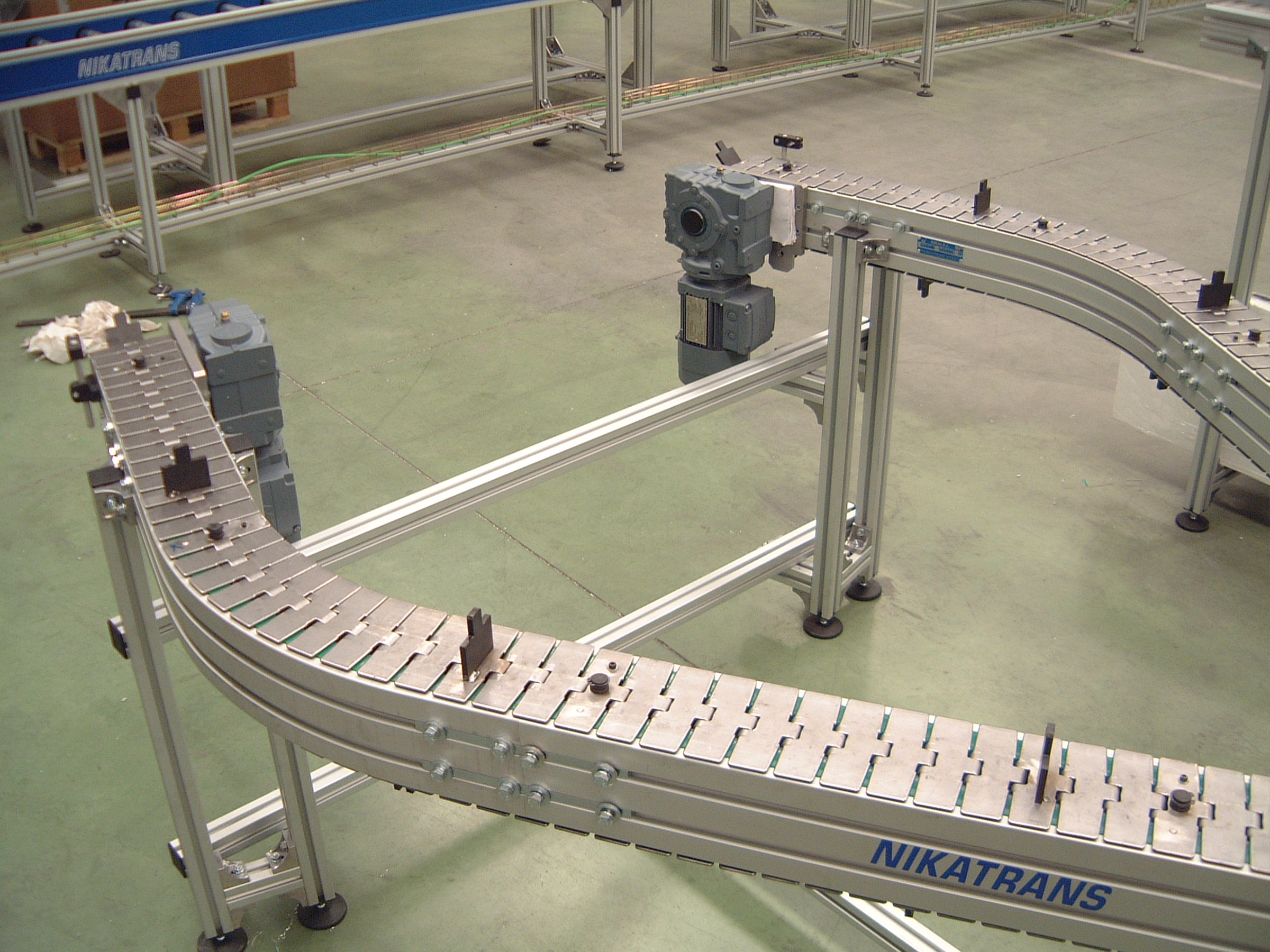

Production line conveyor systems

Wire Mesh Conveyors.

Production line conveyor system

Production lines with maximum flexibility The conveyor line consists of maintenance-free, fully accessible conveyor tracks with an integrated busbar with 48 DC drive power, which supplies the drive of the .

Pallet Conveyors, Pallet Handling Conveyor Systems

Phone +49 2689 9435 - 0.Production line conveyor systems.

Conveyor Systems

They move parts and product from one place to another during specific steps in the production process.0 in manufacturing environments in many ways. The system is especially well suited for manual and automatic assembly and test .3) Your conveyors go into production.Assembly Line Automation Conveyor Systems. FlexLink can offer two types of twin-track pallet systems: XT and HU.

Comprehensive Guide to Types of Conveyor Systems

Why Conveyor systems are Crucial to Industrial Automation. Industrial and automation conveyors are a crucial part of any production facility. We enable you to employ proven industry standards and cutting-edge technologies, whether for compact environments, material .

An engineered, integrated material .We can also manufacture replacement conveyor modules for your existing assembly or production line as required.Case Study: Design of a Conveyorized Production Line. Packaging and Distribution: . Transfer Roller Conveyor. Contact us today to get your conveyor project started.

Combined with a main line conveyor like our 3200 series or DCMove series, automating processes like accumulation, parts handling, positioning, packaging, and more is a simple task. It was then that Henry Ford became the first automobile manufacturer to use traditional conveyor belts as he mass-produced the . They also typically expend less energy and less CO2, in addition to lower levels .

In-line Scales & Automated Check Weighing

Our range of conveyor systems contains different types of conveyors. Drag chain and towline conveyors are also available. It is important to understand how everything fits together when discussing the workings of these systems. Stacking materials at the end of the line.Conveyor systems are at the heart of industry 4.Con veyors built to specification improve production-line efficienc y and output.The easiest way to integrate a tunnel metal detector into your food production line is to select an integrated metal detection system consisting of an industrial tunnel metal detector and a metal detector conveyor belt from a single supplier. for production lines. In addition, a conveyor should contain the engineering specifications necessary to be seamlessly integrated into a manufacturing line. For warehouses handling ferrous scrap or metal parts, our . Reduces Manual Waste. METTLER TOLEDO Safeline manufactures a wide range of tunnel metal detectors and conveyor systems designed . Manufacturers need to be concerned .Notable instances include: Production: Conveyors bolster assembly lines, facilitating the seamless convergence of materials or components. Also called “inline conveyor scales” or “in-line weigh scales,” in-line scales increase system efficiency and ensure accuracy by automatically catching potential errors before they cause bigger issues. This case problem is concerned with the design of an assembly line, in particular the aspects of the line that deal with the . Home » Blog » The Evolution of the Conv.

Production and Assembly Line Conveyor System Manufacturer

Regardless of the type of business or even the industry, modern .

Conveyor systems coupled with material handling systems for lifting, packaging and labelling can lead to significantly improved productivity and time efficiency.

Conveyor system

CONVEYOR C20 : Compact conveyor on a 20 mm profile 5 base .Innovative conveyor systems Transfer systems for optimal assembly logistics in production lines.Conveyor systems manufacturers - Packaging, bottling, food | Storcan. [email protected] conveyor system that is well-suited to the manufacturing process ensures that food production improves in terms of efficiency, output, and sanitation requirements.Conveyor systems move products from one production process to another automatically. Specific demands concerning internal transport require a specific solution.Our solutions include in-line or mass transport, accumulation, sorting and elevation of containers, at medium or high speed, from container de-palletization, to manufacturing, to palletization.

Conveyor systems: Overview and tips for the technical challenges

Maintaining Your Paint Line Conveyor System

Regular maintenance will prevent larger issues from occurring or identify problems that can be correct before they shut down .All of our transfers are washdown capable and can be either slave-driven from the main conveyor shaft or independently powered by their own gearmotors.0 manufacturing world, a conveyor .FlexLink solutions in the automotive industry. These systems include specifically designed seat . The different types of conveying systems include pneumatic, screw, belt, and roller.

Integrating a Conveyor System into a Production Line

From powered to gravity roller conveyors, find out which production line conveyor systems suits your business. Perform comprehensive checks of your paint line conveyor system quarterly and document all maintenance. All equipment is UKCA or CE-marked and comes complete with operation and maintenance manuals. Our skilled manufacturing team build your equipment to the highest quality in our East Yorkshire factory. Roller conveyor turntables help to streamline material flow by allowing materials to be rotated smoothly and efficiently to change direction, reducing the need for .Conveyor systems are the backbone of industrial operations.

0-compatible and is characterized by low maintenance, high availability and high reliability.In addition to our standardized products, we offer our customers various variations of special developments.

The Ultimate Guide to Conveyor Systems

Production line solutions.Link your whole system together with Dyco’s extensive conveyor experience and our patented Modular Aluminum “Red Line” Table Top conveyor.Flexible production line conveyor systems are accessible in standard and heavy duty to ensure the safe and secure transportation of a variety of goods.As the main artery running through the production line, an intelligently designed conveyor system can help maximise production output, avoid manual handling, and ensure best . Conveyor systems can be used in a wide range of industrial sectors for a variety of processes, including production, packaging, and even delivery.

Automotive Conveyors, Automotive Assembly Line Automation

Industriegebiet Urbacher Wald.Custom manufacturer of overhead assembly line conveyors. Whether you need a single label or multiple .Also, ensure the conveyor is correctly aligned to the production line to prevent material from falling off the sides.Our mission is to provide you with the best conveyor systems for every application. The model of the . Explore all metrics.

Innovative conveyor systems

Every system needs checks and balances, and for automated material handling systems, that job is largely done with in-line scales.Automated Line. As material handling machinery, they have the simple but integral purpose of transporting various components from one place . Screw Conveyor Systems Screw conveyors, also known as auger conveyors, utilize a helical screw blade within a tube to move liquid or granular materials. A method is developed for the optimal control of parameters of a conveyor-type production line.An effective warehouse management system (WMS) promotes the most efficient and cost-effective operations within a warehouse. DESMASA (1) MECALUX (1) Möllers (1) Pinto Brasil (3) SIDEL (1) Yaplex Ltd (1) Product applications. Cablevey Conveyors is here to provide a breakdown of these systems and help you choose the .Overview

Automated Conveyor Systems, Flexible Conveyors

But how do automated conveyor systems work, where are they used, and . Struggling with the ups and downs of your production lines? There’s a better . If your business needs a new, more reliable, and faster way of transporting goods, raw materials, or products within the same area or even facility, industrial conveyors are the right solution.

Factory & Production Line Conveyors

The XT conveyor system is a twin-track using a flexible plastic chain pallet conveyor.Without modern conveyor systems, any production line would quickly come to a standstill.

Assembly Line Conveyors

Conveyor Transfer Systems

Case Study: Design of a Conveyorized Production Line.Conveyor systems are part of production processes. SPG Conveyor Systems is a reliable UK manufacturer & supplier of robust belt conveyors . In fact, you can reduce this by automating such tasks. Our expertise and quality in overhead conveyor systems design also carries over into the design and manufacture of floor conveyors.RFID identification in the pallets enables one-piece track-and-trace and production control of the line. But it was in 1913 that may be the most famous example of a conveyor system hit the market. Let us show you how they’ll work on your system.

The Complete Guide To Industrial Conveyors

Their robust design ensures that the conveyor system is economical compared to alternative solutions. Email: [email protected] manufacturing conveyor systems are crafted with precision engineering and attention to detail, and they’re capable of withstanding the rigorous pace of . The line will be used to produce an electronics -based product used in the automotive industry.

Each with its own .Rapid Industries also offers a full line of Floor Conveyors, including gravity, powered roller, powered belt, accumulating, tabletop and slat conveyors. These conveyor . The construction of individual systems depends on the materials to be moved, which includes their weight, dimensions, and . This data can be analyzed to identify bottlenecks, optimize workflows, and make data . Mat Top Conveyor Dyco provides a wide range of Mat Top Conveyor belting to fit your application and is available as a stand-alone component or as a part of a turnkey solution.A conveyor system is a method for moving packages, products, supplies, parts, and equipment for production, shipping, or relocation.Conveyor systems can rapidly and reliably move substantial amounts of goods or materials, making them ideal for handling bulk items in industries like manufacturing, mining, and logistics. no reason to settle for a conveyor that’s shoehorned into application, especially when a s ystem .Automated conveyor systems can collect real-time data on production output, downtime, and performance metrics. Conveyors can be designed to stack materials or products neatly at the end of a production or .