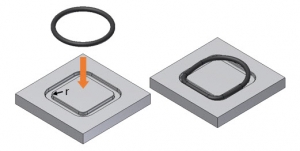

Rectangular o-ring groove

또한 O-ring 과 Groove 내부에 기체가 고립되는건, Rectangular groove 역시 .

Face Seal O-Ring Groove Design Guide

A non-circular face seal footprint might .

O-Ring Groove (Gland) Design: A Detailed Guideline

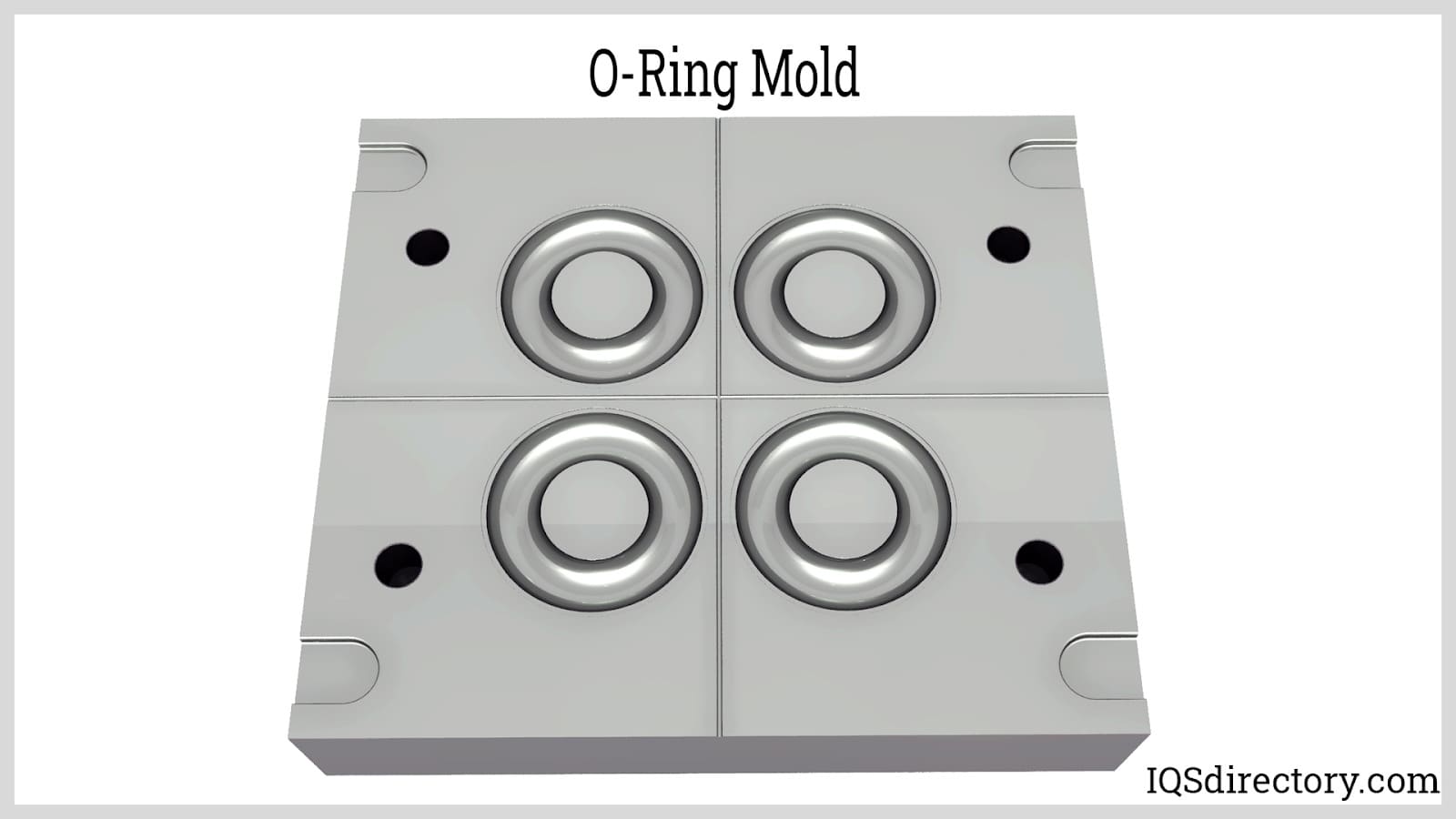

O-Ring Calculator.Design a Groove for a Specific Size O-ring.An O-ring groove/gland shape supports the seal and provides the necessary deformation for proper functionality. Also check gland fill and consider thermal effects.

One prevalent O-ring groove shape is a rectangular recess with rounded edges, offering straightforward installation and uniform compression across all three . Face type seals are sometimes rectangular.O-ring Groove Design in 3 easy steps: Step 1.A traditional O-ring groove shape is rectangular and more wide than deep. If space is limited, this can be reduced to three times the cross-section; a smaller radius is likely to cause buckling of the seal and installation difficulties. In order to seal properly, the o-ring has to deform in the application by being compressed and stretched in any number of ways. Uniform Dash Numbers.

O-Ring Groove Design Guide

your groove is rectangular and not square . They are manufactured by turning or milling into metallic components.Whether you need bolted flanges or removable lids, this o-ring face seal groove design guide will help you choose the right o-ring for your application. Common groove geometries include rectangular, trapezoidal, and dovetail.Critiques : 416Critiques : 446 In designing such a seal to receive a standard O-ring, the inside corner radii of the groove should be at least three times (ideally six times) the cross-section diameter of the O-ring to avoid over-stressing the ring or causing corner creases that . Diametrical Squeeze (Minimum) Gland Depth F.

ERIKS O-Ring Calculator

Calculate squeeze of course as well. Application temperature (ºC) pressure.

Rectangular Seals & Rings

1. Square Rings can be used in static applications where high sealing load force is required or when the sealing area is too thin to accommodate anything else. Design a Groove for a Specific Size O-ring. This allows space for the seal to be compressed, about 25% (for static sealing), and still . The O-ring is also axially squeezed in a dovetail groove. Shop rectangle profile enclosure seals. Groove Bore PistonRod Figure 1-2: Basic Gland Figure 1-3: Gland and O-Ring Seal Figure 1-1: Basic O-Rng 1.260” for an O-ring with 0.and gland — constitute the classic O-ring seal assembly.Designing the parts of an application where o-rings will be applied is broadly termed “o-ring groove design”.An O-ring groove is a circular cross-sectioned recess in a housing or mechanical device designed to hold an O-ring seal. TechSeal’s manufacturing capability allows us to create this rectangular profile

O-ring Seal Design Best Practices

Standard and Metric Sizes ; Thousands of materials ; Find O-rings by size, temperature .

Order Requirements.O-rings are successfully used in rectangular or non-circular groove patterns as long as the groove design follows a few basic principles. If the O-ring size required is known, simply select the AS, BS or ISO standard (such as AS568) and enter the dash size reference. $30 per line item minimum; Standard-sized O-rings are readily available in the following materials: Black Nitrile (Buna-N) 70 or 90, Brown or Black Viton® 75, Black EPDM 70, Red Silicone 70, Black Neoprene 70, and White PTFE. 그렇다고 Vent hole 을 생성하지 않으면 Dovetail groove 가공이 불가능한것도 아니다.

O-ring grooves

The O-ring cross section is squeezed radially in the groove between the inside (ID) and outside (OD). Browse design considerations and recommendations for static face seals, metric o-rings, static dovetail .Dovetail groove 에 설치된 O-ring 을 제거하기 위한 공간이다. the corners), must be large enough so the o-ring will not kink and such that the o-ring will fully contact the low pressure side of the groove (Figure 5 shows an example of too sharp of a corner in the o-ring groove). These type of glands are used for a variety of applications, bolted flanges or removable lids.) free groove volume at inst (%) . Provides a stable and reliable seal when properly designed . O-Ring Size Charts O-ring, x-ring and square ring size charts. Groove Type: Product: Seal: O-Ring Code: ID:-/+ CSD:-/+ Temperature: C: Installed Compression: % Backup Ring Width: Top Width Factor: Sidewall Angle: : Chemical Swell: % Free Volume: % O-Ring Stretch: % Linear CTE: (E-04/°) The dimensions are in . The choice of groove geometry depends on factors such as pressure, movement, and the type of O-ring being used. compression (%) Groove material.

For o-ring gland grooves that are non-circular, the groove turn radii in rectangular and square layout (i.Rectangular grooves are the standard case for installation spaces for O-rings. Once you find the right o-ring groove design you can easily order online from the world's largest . In most static applications, it is a direct replacement for an .Here are some common O-ring groove shapes: Rectangular Groove: This is one of the simplest and most common groove shapes.Otherwise, an O-ring size cannot be determined properly. The correct O-ring groove dimensions and shape will ensure complete compression between the track and the . Female or Tube - the O-ring groove is located in the housing or . [3, 4] treated the case of an O-ring installed in a rectangular groove.

Parker O-Ring Handbook

Choose whether you are working with existing hardware or designing new hardware.One of the most common O-ring groove shapes is a rectangular divet with rounded edges. In these applications, a triangular-shaped O-ring groove may be the solution to the design dilemma. Viewed 2k times.Live Stream — How to Model O-ring grooves and some other fun tips and tricks. Once you find the exact metric o-ring you need, you can easily order online from the world's largest o-ring inventory network. This design allows for simple installation and uniform compression on all three . The correct and standard-compliant design of the O-ring groove is crucial in order to achieve an optimum sealing effect. Technical Resources. In other cases, an O-ring may be asked to seal two leak paths between mating parts.

O-ring Groove Calculator

Taille du fichier : 8MB

O-Ring Groove (Gland) Design Guide

Trapezoid groove 3.O-Ring Groove Design for Face Seals Basic Application Groove Design Reference Charts - Expert Application Engineer Support . Try our new Online O-ring Store . O-ring groove design is critical to the performance of the O-ring seal. The profile’s rectangular geometry enables customers to easily customize the seal dimensions to fit their application’s specific grooves. Commonly called a “crush seal” design, triangular . The seal in this study is modeled by a flat disk, axially deformed by a clamping force.In the standard (rectangular groove), it is defined by its width and depth.

Parker O-Ring Handbook

Based on linear elasticity, a theoretical model is developed which is able to describe the mechanical behaviour of an unpressurized, elastomeric O-ring seal inserted into a rectangular groove.

The Ultimate Guide to O-Ring Design: Everything You Need to Know

PROBLEM SOLVED!

By simply entering installation specifications for an application, it recommends O-Ring sizes, housing layout and . The following sizes are not normally recommended for dynamic service, although special applications may permit their use: Note 2.Critiques : 456 This is Fusion 360 AND we will chat about your comments and questions. Groove Bore Piston Rod Figure 1-2: Basic Gland Figure 1-3: Gland and O-Ring Seal Figure 1-1: Basic O-Rng 1. Select the type of O-ring groove - piston, rod, face seal or trapped seal. Therefore, the body is one of the most important considerations when designing an O-ring groove. The best o-rings are useless without the right groove .

Static O-Ring Face Seal Groove Design Guide

210” cross-section) for the radius to the inside edge of the groove., Japanese JIS, British BS and Common Metric o-ring size charts. Rectangular groove (standard) 2. Numerous factors go into the appropriate design of a gland/groove including but not limited to static or dynamic . O-Ring Compatibility O-ring compatibility information for .Global O-Ring and Seal has developed o-ring groove design and gland dimension guidelines.Your o-ring will stretch as much as the groove ID is.Groove Design for O-Ring Installation. Triangular groove #2 What do I have to consider when . The O-ring sits in the groove and is compressed during assembly, creating a seal between two surfaces. Modified 6 years, 8 months ago.

This design technique minimizes movement of the O-ring in the groove due to pressure, thereby virtually eliminating wear and pumping leakage.The O-ring groove calculator enables engineers to specify an O-ring groove for any given O-ring or vice versa calculates the best suitable size O-ring for any given groove.

Comprehensive Guide to O-Ring Groove (Gland) Design

Rectangular groove

Asked 6 years, 9 months ago. If this principle is used, groove . Male or Plug - the O-ring groove is located on a plug which is inserted into the housing or cylinder (fig.O-ring groove design guides offer default dimensional guidance on the most basic o-ring groove design applications.This metric o-ring groove design reference guide will help you find the right radius, back-up, pressure and other o-ring dimensions for basic applications. Clearances shown based on 70 durometer materials.#1 Rectangular groove definition. When designing an O-ring groove, it is . With a rectangular geometry of the sealing surface and groove flanks, the rectangular groove represents a particularly economical installation . Browse design considerations and recommendations for static face seals, metric o-rings, static dovetail o-rings, static rod-piston o-rings and dynamic rod-piston o-rings.

Save time calculating and designing O-ring grooves and verify the O-ring sealing performance by checking parameters like o-ring compression, free groove volume, o .Cat square cut seals protect your machinery via sound deadening, vibration isolation, cushioning & thermal insulation.The groove shape should provide adequate space for the O-ring to seat properly and ensure uniform compression across its circumference. 라는 이야기가 있던데, 세가지 모두 맞는 얘기인것 같다.Can O-rings be used in rectangular or non-circular groove patterns? This question comes up weekly, and the answer is a resounding “Yes!” however there are definite guidelines . Actual Cross Section Diameter. I'm designing . First, the analytical tools employed to handle the unilateral contact problem and to improve the pressure profile regularity are discussed in detail .