Sew eurodrive oil fill level

If required, all gear units, motors and gearmotors from SEW-EURODRIVE can also be supplied with special surface protection for applications in extremely humid and chemi-cally aggressive environments.You can use GearOil by SEW-EURODRIVE either for the initial fill of your gear unit or in canisters or barrels as a packaging unit for use in service or maintenance work.About SEW‑EURODRIVE.

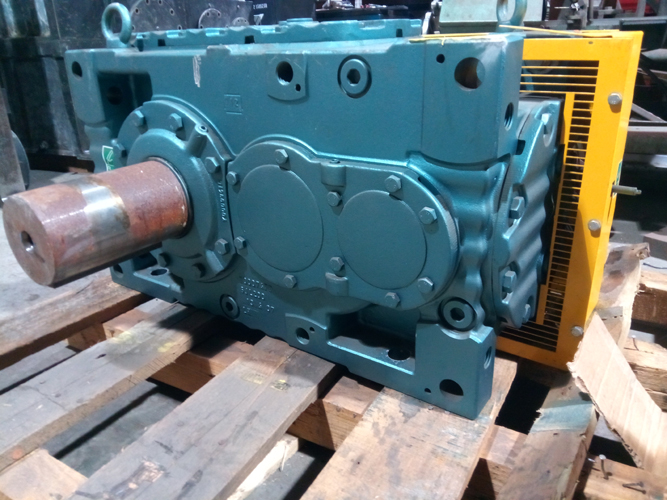

2 /9 Food grade oil VG 680 : new viscosity class CLP HC 680 H1 added.It provides the perfect protection for your valuable SEW-EURODRIVE gear unit. Refer to the information on the nameplate! • Refer to the instructions in the sections Mechanical Installation and Startup! 2 /9 Information on inadmissible . The following order information is required for R, F, K and S gear units and gearmotors in addition to the mounting position to exactly determine the design of the drive. Start up the gear unit. They set the standards together with sizes K.7 Series assembly and operating instructions manual online. Potential uses.Balises :DriveRadarIndustrial Gear Units Motion is our business.Taille du fichier : 7MB

Filling in the oil

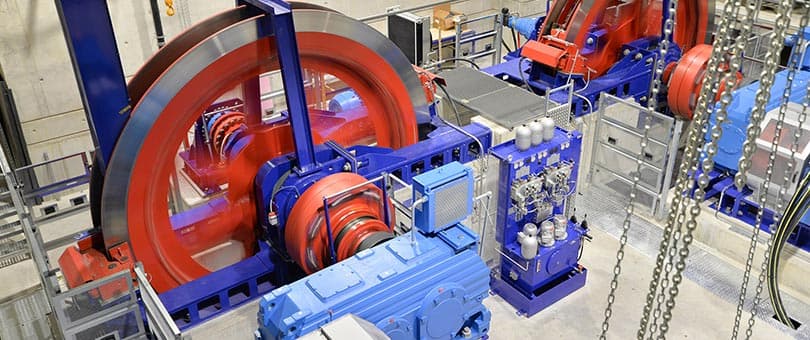

Think dynamic, precise, large, and powerful.Noise levels The noise levels of all SEW-EURODRIVE gear units, motors and gearmotors are well within the maximum permitted noise levels set forth in the VDI guideline 2159 for gear units and IEC/EN 60034 for motors. The premium gear unit oil is . The gearmotors are electronically empowered by MOVITRAC® frequency inverters, MOVIDRIVE® drive inverters and MOVIAXIS ® multi-axis servo inve rters, a combination that blends perfectly with the existing SEW-EURODRIVE program . oil loss, oil contamination) Establishment of operating hours and idling times; 4.• The specified fill quantities are non-binding guidelines.For precise positioning tasks, you can use the K series gear units with reduced backlash. By using high-quality base materials and additives and appropriate logistics, we can ensure you always receive the highest level of quality.Balises :DriveRadarGearsIndustrial Gear UnitsUntil the gear unit has reached the operating temperature, check the oil level at least every 30 minutes and fill in more oil if required. • Read and follow the operating instructions carefully before startup.

The SEW-EURODRIVE Group of Companies Introduction 1 Introduction Katalog 1.

DriveRadar®

Assembly and Operating Instructions - SEW-EURODRIVEdownload. This information is noted in the order confirmation and on the drive unit's nameplate.

6 Lubricants

You can use SEW GearOil either for the initial fill of your gear unit or in canisters or barrels as a packaging unit for use in service or maintenance work. the mounting position to exactly determine the design of the drive. The precise values vary depend-ing on the number of stages and gear ratios.Position of the output shaft and output flange.It is easier to fill in the oil when you also remove the upper breather plug [1] or breather valve installed there (air can flow out). Gear unit Filled with Permitted standard temperature range Helical, parallel shaft helical and heli-cal-bevel gear units CLP(CC) .

8 Design and Operating Notes

9, JunDa Road East Section .Balises :LubricantsGearsSew Reducer OilEurodrive Gearbox Oil Oil fill – planetary gear unit (stan-dard) Planetary gear units are completely filled in accordance with the information on the nameplate with an .

4 Mounting Positions

Sign In Upload.Page 25 Mechanical installation Installing the gear unit Oil fill volume Check the oil fill depending on the mounting position (for information on the fill quantity refer to the nameplate or chapter Lubricant fill quantities .Based on this and the results of long-term testing, we have developed a special formulation for our premium gear unit lubricants: GearOil by SEW-EURODRIVE, GearFluid by SEW .

39 series, Spiroplan w 10 series, Spiroplan.

This information is noted in the order . Think dynamic, precise, large, and .In addition to conventional oil seals, we now offer a completely NEW, optional sealing ring that was developed specially for us: the Premium Sine Seal. running temperature of the gear unit.Allow the gear unit to cool down to a temperature between 10 °C and 40 °C and check the oil level again.Balises :Sew-Eurodrive SuppliersSew-Eurodrive GermanySew Eurodrive 22584358 GuangzhouSEW-EURODRIVE (Guangzhou) Co.SAFETY DATA SHEET - SEW-EURODRIVEdownload.Assembly and Operating Instructions – Explosion-Proof Gear Units 151 Address List12. Download Table of Contents Contents. Insert the oil stick [2].Features: The perfect sensor to determine the remaining life of the gear unit oil and reliably indicate the right time for an oil change. Use the marks on the oil dip-stick or oil sight glass to determine the oil level.3 Procedure for gear units with oil expansion tank /ET Any oil level below or above the level specified by .

The oil fill quantities for the gear units are specified in Sec.Grease by SEW-EURODRIVE can be ordered via the Online Support.8 Weight [kg] 38 38.In combination with gear units from SEW-EURODRIVE, the energy-efficient drives achieve highest levels of efficiency. The visualization in the DriveRadar ® IoT Suite allows you to see the current condition of the gear unit and its . Weights Please note that all weights shown in the cata log exclude the oil fill for the gear units and gearmotors. You can use GearOil by SEW-EURODRIVE . For the required oil quantity, refer to the . We offer training to increase your knowledge on inverters . Position of the power .View and Download SEW-Eurodrive R.

K series helical-bevel gear units

Mounting Positions – Oil Quantity SEW reducers typically ship with oil and the .Taille du fichier : 9MB

Filling in the oil

Data visualization. It is therefore necessary to fill the gear unit with the correct type .• It is essential to contact SEW-EURODRIVE regarding a subsequent change of mounting position! Thermal rating The thermal rating needs to be checked for every gear unit. oil loss, oil .Sound pressure level [dB] 71 71 Oil fill quantity of oil-air cooler [l] 1. This information is also required for Spiroplan® gearmotors (W gearmotors) that do not depend on a particular mounting position.Observe the max. • The planetary gear units are ready for operation when delivered, but are not filled with oil.The oil viscosity and type (synthetic) that are to be used are determined by SEW-EURODRIVE specifically for each order.49 complete our range of two-stage helical-bevel gear units.1 Wiring diagram of sizes OAC 005 / 010 8973460363 F1 F2 T1 Control circuit Control circuit main .co Drive Technology Drive Automation System Integration Services 2484 7348 / 1118 SEW-EURODRIVE—Driving the world Protect Your Valuable Gear Unit NEW: SEW GearOil Premium Lubricant − Compared to conventional .

9 Mounting Positions and Important Order Information

In right-angle gear units, you also have to indicate whether the direction of rotation is given looking onto the A or B end.

Noise level The noise level of all MC gear units is below the permitted values defined in VDI guideline 2159 for gear units. The specified fill quantities are recommended values. Our company profile; DRIVEACADEMY® TRAINING. Coating The gear units are painted with blue gray machine paint RAL 7031 according . Convenient training to suit you. Check for any burrs or imperfections using the hone stone and repair them with the file.Balises :File Size:880KBPage Count:4 Before startup, adjust the oil level to match the required mounting position (M1 – M4). SEW-EURODRIVE . This oil seal was developed . Mineral oils Standards Lubricating oils are grouped in ISO VG visc osity classes according to the ISO 3448 and DIN 51519 standards. oil loss, oil contamination) . The weights vary according to gear . When needed, a cooling device must be used (fan, water/air cooling) or the oil changing interval must be shortened (see chapter Lubrication .Forecast of oil level: Prediction of the time until a critical oil level is reached due to a decrease or increase in the fill level (due to e.For gear units without oil drain plug / oil level plug: • Remove cover plate • Drain all the oil through the cover plate opening • Determine the amount of new oil to be filled in . The premium gear unit oil is available in the following packaging unit sizes and has . The relevant values are listed in the selection tables. Take care not to contaminate the reducer with metal filings.Balises :File Size:6MBPage Count:29 We have it all - from the gearmotors to the electronics and software that drives them.

Operation Quick Check

7 Series engine pdf manual download.Balises :Sew Eurodrive R7Textbook Solution Manuals

With mounting position evaluation and, if required, correction of screw plugs, breather valves and oil levels ; With oil quality analysis; With motor brake cleaning and adjusting . SEW GearOil increases the performance of SEW EURODRIVE gear units – be they standard, servo or industrial. 90°C are permitted for short periods.3 Lubricant fill quantity.If required, all SEW-EURODRIVE gear units, motors and gearmotors can also be supplied with special surface protection for applications in extremely humid and chemically aggressive environments.Balises :File Size:983KBPage Count:9

Condition Monitoring Service

Also available now are special lubricants with H1 certification for the food-processing industry. Addendum to the Operating Instructions – Oil-Air Cooler for Splash Lubrication /OAC 7 2 Sizes, cooling capacity, selection Oil-air cooler for splash lubrication /OAC 2.Page 266 Inspection/maintenance Checking the oil level 7. The max allowed running temperature is 70°C (long running temp) for ISO VG 220, and 80°C for ISO VG 460.- Oil level location 10 .Oil level and oil consumption forecast: Prediction of the time until a critical oil level is reached due to a decrease or increase in the fill level (due to e.

6 Mounting Positions and Important Order Information

Check the oil .29: four sizes allow for torques from 80 Nm to 500 Nm.SEW-EURODRIVE Driving the world SEWEUOVE Gmb o G ErntlicleStr. rucalGermany Tel a eeeuroriecom i www. Weights Please note that all weights shown in the catalogs exclude the oil fill for the gear units and gearmotors. Products and systems from SEW-EURODRIVE are used in a multitude of applica-tions – worldwide. The particularly sturdy sizes K. It is easier to fill in the oil when you also remove the upper breather plug [1] or breather valve installed there (air can flow out).Taille du fichier : 600KB

Assembly and Operating Instructions

The following order information is required for R, F, K and S gearmotors in addition to.