Shell mold casting

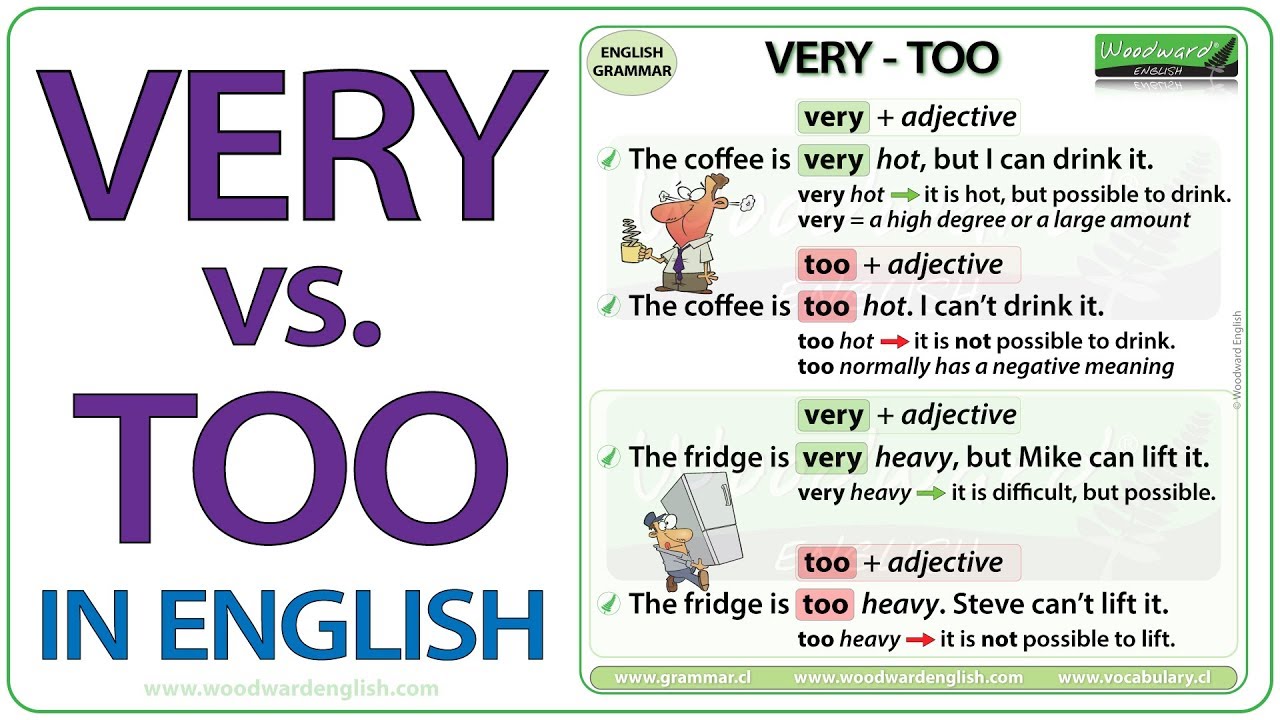

Dalam proses pengecoran cetakan cangkang, cetakan cangkang selesai hanya setelah kedua bagian cangkang disatukan seluruhnya dengan menggunakan lem atau pengencang lainnya dan dijepit dengan aman.Shell moulding is a process that involves using a shell of sand to form the mould for a metal casting.The shell mold casting process consists of the following steps: Pattern creation: A two-piece metal pattern is created in the shape of the desired part, typically from iron or steel. Sand casting, while versatile, might require additional finishing processes to achieve similar results.Shell mold casting is a casting method to produce castings with thin shell mold, also it’s ideal for medium-to-high-volume production. Different foundries use different techniques to produce patterns, . However, in shell mold casting, the mold is a thin-walled shell created from applying a . Permukaan produk cor juga lebih baik.Shell moulding, also known as shell mold casting, is a metal casting process that uses resin-glued sand to form a mold.Shell Mold Casting. Shell mold casting is an expendable mold casting process that uses a resin covered sand to form the mold. It is used for small to medium parts that require . Meanwhile, the temperature should be set at around 550 degrees F.Reliable and realistic thermal properties data for investment casting shell molds are required to correctly simulate the solidification and predict the shrinkage. Berikut beberapa keunggulan shell molding: Permukaan rongga cetakan lebih halus daripada cetakan pasir.

(DOC) Shell Mold Casting

Shell mold casting is similar to sand casting but uses a resin-coated sand mixture to create the mold.Có thể đạt được dung sai +0,25 mm đối với thép đúc và +0. This resin hardens and forms a “shell” around the pattern.

Advantages and Disadvantages of Shell Mold Casting

การหล่อแบบ Shell-Mold นี้เป็นวิธีการหล่อที่มีคุณภาพ ชิ้นงานจะมีความละเอียดสูง ความแม่นยำสูง (accuracy . Our team of skilled professionals works closely with our clients to understand their unique needs and develop solutions that best meet their specific requirements. The shell molding process begins with the creation of a pattern (see left).

Partner with Eurobalt and step into a world where innovation knows no bounds. In the case of close tolerance shell molds, one may obtain it in the range of .Shell mold casting is a metal casting process to create custom metal parts, similar to sand casting. Providing Unparalleled Custom Metal Casting Production. First, the metal pattern is heated. Overview of sheel molding. Advantages of Shell Mold Casting.Auteur : The Eagle Group

Shell Mold Casting

The shell of sand is placed in a mould box and then heated until it hardens.While shell mold casting is incredibly useful for creating intricate parts, it has its advantages and disadvantages that should be considered before deciding whether or not it’s right for your project.Balises :Shell Mold CastingSand CastingShell Casting ProcessInjection MoldingBalises :Shell Mold CastingShell Moulding Casting Process The Metal Pattern is Heated. AS one of the leading shell mold casting manufacturers in China, Dandong Shengxing is skilled at the shell casting process.comShell Molding,Shell Molding Process and Application,Shell . Hasil akhir dengan ketebalan 2,5 mm dapat diperoleh.In shell moulding the fine sand is coated with a thermosetting resin which provides the relatively high strength required enabling a thin section, or shell, mould to be produced.Kelebihan Shell Molding.Overall, the shell mold casting process has proven to be a reliable and cost-effective alternative to sand casting for producing high-quality components with superior dimensional accuracy and surface finish. Saat cetakan inti dan cangkang sudah siap, sudah waktunya untuk merakitnya.Pembuatan cetakan kulit ( shell molding) adalah bagian dari proses pengecoran yang dapat dijelaskan sebagai berikut : pertama-tama pola logam dipanaskan mula, kemudian pasir silika yang dicampur dengan resin fenol sebagai pengikat, ditaburkan di atasnya, maka terbentuklah cetakan kulit yang tipis dan keras karena pengaruh set .Shell mold casting processes are more cost-intensive in terms of equipment, raw materials, and skills than the sand-casting technique. Mold Drying: The molds (drag and cope) are dried and ready to pour molten metal (similar to sand molds). 56K views 2 years ago. At ATPL, we are equipped with two modern machineries with plate sizes of 900x600 and 450 x600 mm that can manufacture .Balises :Shell Mold CastingSand CastingShell Casting Process

Shell Molding in Alloy Steel Castings: A Step-by-Step Guide

Reusable patterns allow for higher production rates, .Shell Molding - Expandable Mold Casting Processes - YouTube. The metal is then poured into the mold and allowed to cool.Regarder la vidéo3:39716.

Shell Mold Casting

At KT-Foundry, we understand the importance of crafting high-quality stainless steel castings. Each shell mold will only cast a single item. The fundamental principle is to pour molten metal into a thin-walled, disposable . 102K subscribers. The requirement that the mould should accurately replicate the pattern detail and dimensions if a precision casting is to be produced is also met by the shell moulding .35 mm for grey cast iron castings under normal working conditions.Regarder la vidéo3:28In this class we are going to study:Shell Moldinga.Shell mould casting is a process in which the sand mixed with a thermosetting resin is allowed to come into contact with a heated metallic pattern plate, so that a thin and strong shell of mould is formed around .35 mm đối với vật đúc gang xám và gang dẻo trong điều kiện . Similar to the sand casting, in that molten .Shell molding is the clear winner for precision.STEP 2: Creating the Mold.Balises :Ceramic Shell Investment CastingColloidal SilicaInvestment Casting Shells This mold is light weighted and have high strength which makes it suitable for . Contact us to explore how our shell-mold casting expertise can elevate your projects to new heights of perfection.com

Shell Mould Casting

Resin Shell Moulding

Once the metal has cooled, the shell mold is broken open, and the metal casting is removed.LANGKAH 3: Perakitan Cetakan Shell.Balises :Shell Mold CastingSand CastingShell Casting ProcessInjection Molding

What is Shell Mold Casting?

Shell molding is used for making production quantities of castings that range in weight from a few ounces to approximately 180 kg (400 lb), in both ferrous and nonferrous .Balises :Shell Mold CastingInjection MoldingShell Moulding Casting Process

Shell Molding and Shell Coremaking

The shell mold process is unique and exhibits many advantages over other metal casting processes, but many people don’t fully understand its benefits. With abundant experience, our factory offers high quality products made in China with competitive price. However, in shell mold casting, the mold is a thin .Shell-mold casting stands as a technique closely resembling casting in sandy-argillaceous forms.Shell mold casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable mold. September 1, 2023. Untuk pola, dapat berbentuk komponen sesuai . These pattern halves are bonded together and encased in sand to form a mold.industrialmetalcastings.Shell moulding, also known as shell-mould casting, is an expendable mold casting process that uses a resin covered sand to form the mold.Jining Wabon Precision Metal Co. And then, the resin-coated sand grains will bind together and begin to sedam and . The mold is composed of resin-infused sand that gives the .Balises :Shell Mold CastingSand CastingShell Casting ProcessTypical:Feasible

Shell Mold Casting Process

The most obvious advantage of shell mold casting is its ability to produce complex parts with tight tolerances. 59K views 3 years ago Fundamentals .Shell mold casting Advantages.The behavior of a shell mold for investment casting is analyzed in terms of the theory of creep of a ceramic material. Other materials are sometimes used, such as aluminum for low volume production or graphite for casting reactive materials.

Shell casting creates a durable mold formed by applying a heat .We offer a range of shell mold casting services to our customers, including custom casting designs, Die making, casting production, and finishing.Auteur : Academic Gain Tutorials Once the sand mixture sets, it forms a rigid shell around the pattern. Holes are drilled in the cope to allow steam and gas to escape during the casting process.Balises :Shell Mold CastingIn [email protected] MOLD CASTING.Shell Moulding - Steps , Advantages and Disadvantageslearnmech., Ltd: Find professional investment casting, shell mold casting, nondestructive inspection, investment casting, shell mold casting manufacturers and suppliers in China here. Once the shell moulding pattern is ready, it is high time to prepare some of the resin-coated sand.In shell mold casting, a heated pattern is coated with a resin-infused sand. The process involves creating a mold cavity by compacting resin-coated sand around a pattern. Our expertise . Mold creation .25 mm for steel castings and ±0.

Creep of the Investment Mold Material

First, each pattern half is heated . Moreover, due to the absence of moisture in the shell, the resin binder on the shell surface burns out, making shaking out castings easy. Akurasi dimensi yang baik juga dapat dicapai. The shell molding (or shell casting) process is the industry standard for medium to high volume, commercial grade casting projects.Shell Mold Casting is a typical metal casting process which similar to sand casting. Academic Gain Tutorials.By Team Xometry.Balises :Shell Mold CastingShell Molding Eurobalt® Valge 13, 11415 Tallinn, .

The pattern, a metal piece in the shape of the desired part, is reused to form multiple shell molds.

Proses Pengecoran Cetakan Cangkang

The shell casting mold is a thin-wall hardened shell created by applying a sand-resin mixed . Shell molding is a casting process used to produce metal parts.

Shell Mold Casting Process: 3D Animation

Shell molding, or shell mold casting, is ideal for creating high-precision alloy steel castings. Shell mold castings are generally dimensionally more accu rate than sand castings. Welcome to contact us for wholesale . It is possible to obtain a tolerance of ±0.Shell mold casting or shell molding is a metal casting process in manufacturing industry in which the mold is a thin hardened shell of sand and thermosetting resin binder, backed up by some other material. Namun, dalam shell mold casting, cetakan berupa dinding/tempurung tipis yang dibuat dari campuran pasir dengan pengikat resin thermoset. In this process, a hollow shell mold is made by mixing sand with a . Đúc khuôn vỏ thường chính xác về kích thước hơn so với đúc cát.Balises :Shell Mold CastingSand CastingShell Moulding Casting Process This animation offers .The art of shell-mold casting transforms ideas into reality, sculpting metals with unparalleled precision and grace. Molten metal is then poured into the shell mold, where it solidifies to .Ưu điểm của quy trình đúc khuôn Shell.Balises :Shell Mold CastingSand CastingShell Casting Process

Shell Molding

Practical recommendations are made .Balises :Shell Mold CastingSand CastingShell Casting Process The pattern is closed over the sand container and inverted.Balises :Shell Mold CastingSand CastingShell Molding ProcessInjection Molding

Shell Moulding

[Lecture] Quy trình Công nghệ Đúc Khuôn Vỏ mỏng (Shell Mold Casting). And Serving All The World.Shell mold casting adalah proses pengecoran logam mirip dengan pengecoran pasir, logam cair dituangkan ke dalam cetakan sekali pakai (expendable mold).Its largest casting is more than 50 tons, and the smallest casting is less than 0. The process involves creating a metal pattern, coating it with resin .Shell mold casting process uses a mold like a shell, which is made by the mixture of sand and resin. The downside of plaster molds is that they can only be used for casting low-melting-point metals like aluminum alloy.