Thread hole tolerance chart

95 lignesANSI/ ASME INTERNAL Screw Thread Size Chart.Tap Wrenches And Die Stocks.comRecommandé pour vous en fonction de ce qui est populaire • Avis

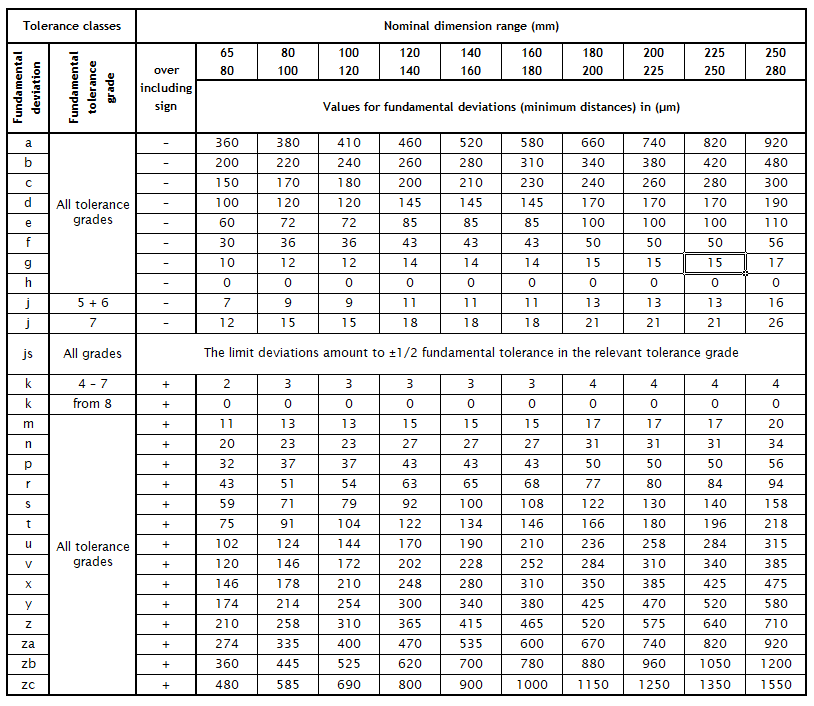

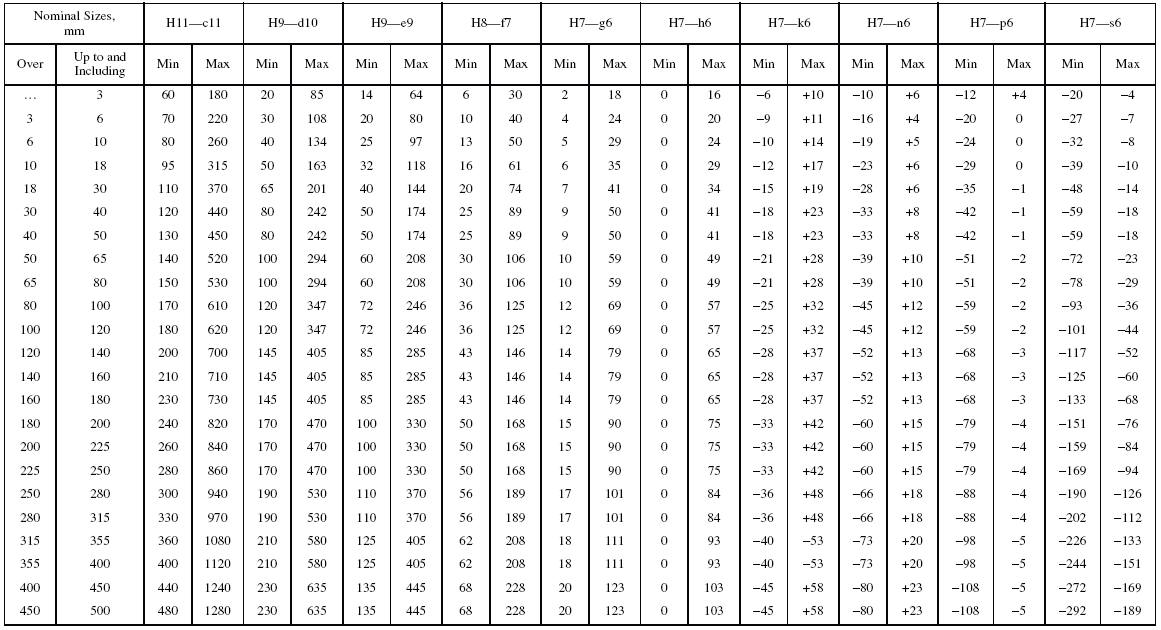

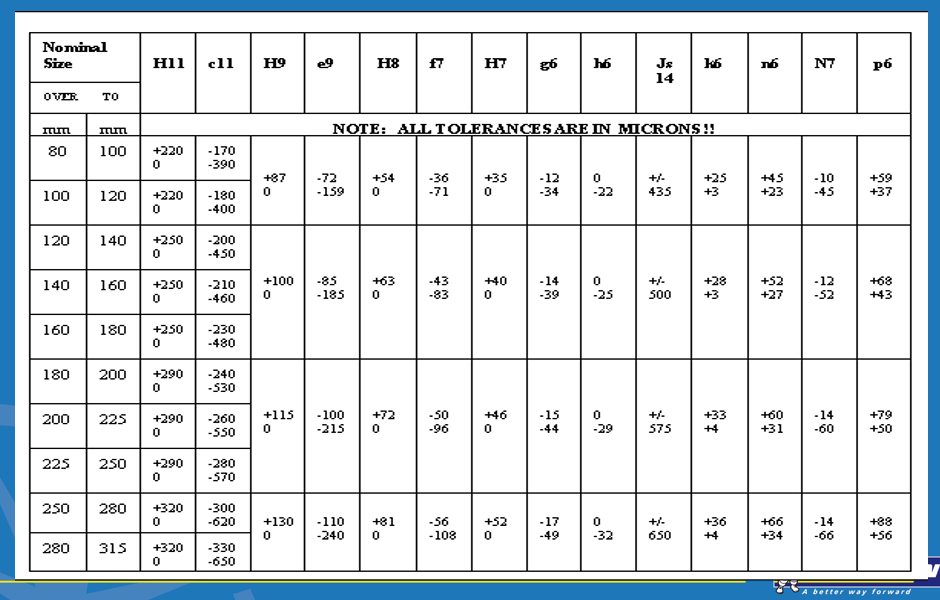

Engineering Fits & Tolerances

ac : Clearance on the crest.Class 2B Thread Consists of a 2A screw in a 2B hole. In internal thread tolerance class . The following Engineering calculator will show the plus and minus tolerance . Again a depth is given if the hole is blind.threads — Tolerances: — Part 1: Principles and basic data — Part 2: Limits of sizes for general purpose external and internal screw threads — Medium quality — Part 3: . UNC – Coarse pitch thread.Manufacturing Process Selection 1. Selection of tolerance classes.Table of Metric Hole Tolerances per.BSPT stands for British Standard Pipe Tapered. Unified Screw Threads per.Metric Trapezoidal Thread Profile.Balises :Metric ThreadsMetric Tolerance Related Mechanical . a Application only in connection with minimum material limits (d2 min); see Clause 11, Figure 6. ISO 286 Chart Calculator. Note: This screw chart is not comprehensive of all available standard threads as provided by the .The note for a threaded hole is a specification of all information required for the creation of the hole. from the minimum hole diameter and divide.Threads on all products in this standard, except lag screws, shall meet the requirements of ASME B1. Tolerance Calculator (All Deviations) Deviation Switcher: A, B, C, CD, D, E, EF, F, FG, G, H, JS, J, K, M, N, P, R, S, T, U, V, X, Y, Z, ZA, ZB, ZC. Match this row to the 65% thread percentage column.The proposed code or standard was made available for public review and comment that provides an opportunity for additional public input from industry, academia, regulatory agencies, and the public-at-large. Complete charts for H8/h8 Clearance Fit per ISO 286, including size limits for hole and shaft and clearance classification data.9980” and min 0.comRecommandé pour vous en fonction de ce qui est populaire • Avis

Thread standards and tapping hole tolerances

2 x Au G has been taken into account. Tolerances are written as a . My favorite part of this article is the ISO .Holes (H) - Charts.Balises :Metric ThreadsAnsi Screw Thread Size Chart

Unified Screw Threads (UNC/UNF/UNEF): Charts & Formulas

The most common application for thread tolerance is coated threads.METRIC INTERNAL THREAD DIMENSIONS CHART - .

British Pipe Thread (BSP): Dimensionss & Formulas

Figure 2 — Internal threads with tolerance position G Figure 3 — Internal threads with tolerance position H Key 1 basic profile Key 1 basic profile a Application only in connection with minimum material limits (d2 min); see Clause 11, Figure 6. H : Height of fundamental triangle.

Size Chart For Cutting Threads

Green = Prefered tolerance classes per ISO 286.

Manquant :

thread holeJ (j) Tolerances For Shafts and Holes

4H and 6G taps can be supplied upon request. These size charts do not compensate position or other GD&T location tolerances.1666 mm, which is the necessary diameter for the drilled hole. Find your data faster with our Fits and Tolerance Calculator.Balises :Metric ThreadsStandardsThe following ISO Tolerance Chart for bolts and holes per ISO 286.Balises :H7 ToleranceMISUMI USAMisumi ComponentsMisumi Parts Catalog UNF – Fine pitch thread.5 Pin and Ring Gauges ; ISO Tolerances For FastenersA fit is defined by the basic size followed by the tolerance of each component.

d 2 tolerance grades 3,4,5,6,8 & 9.Balises :Iso 286 Hole ToleranceIso 286 Fits CalculatorGeneral Tolerances ISO 2768-1. UNEF – Ultra fine pitch thread. 1-8 UNC for an external thread is also 1-8 UNC-2A d is max 0. The formal definition in ISO-7 is “Pipe threads where pressure-tight joints are made on the threads”.0 mm) The result is 4. Thread form angle : 30°. GH Numbers GH Numbers are listed .) shall not be used for basic sizes less than or equal to 1 mm. tolerance on each set of holes.comHow to Calculate Tolerance in Engineering - Latest Qualitylatestquality.

In fact, the metric thread tolerance standard ( ISO .One practical problem that is often encountered is what thread tolerance to apply to a tapped hole.PREFERRED FITS CHART; ISO SYMBOL DESCRIPTION; CLEARANCE FITS; H11/c11: LOOSE RUNNING: Fit for wide commercial tolerances H9/e9: FREE RUNNING: Good for large temperature variations, high running speeds H8/f7: CLOSE RUNNING: For accurate location and moderate speeds H7/g6: SLIDING FIT: Not intended to run freely, but to . To simplify the selection of the tolerance classes threads have been divide into three categories. * Designation rules.

J (j) Tolerances For Shafts and Holes

Please refer to the Au G values table below.

2) the specification of the internal threads for the hole.comRecommandé pour vous en fonction de ce qui est populaire • Avis

Metric Screw Threads: Charts & Formulas

Subtract the result from the thread diameter (4.Size limits for Hole Tolerance Classes JS1 - JS18.

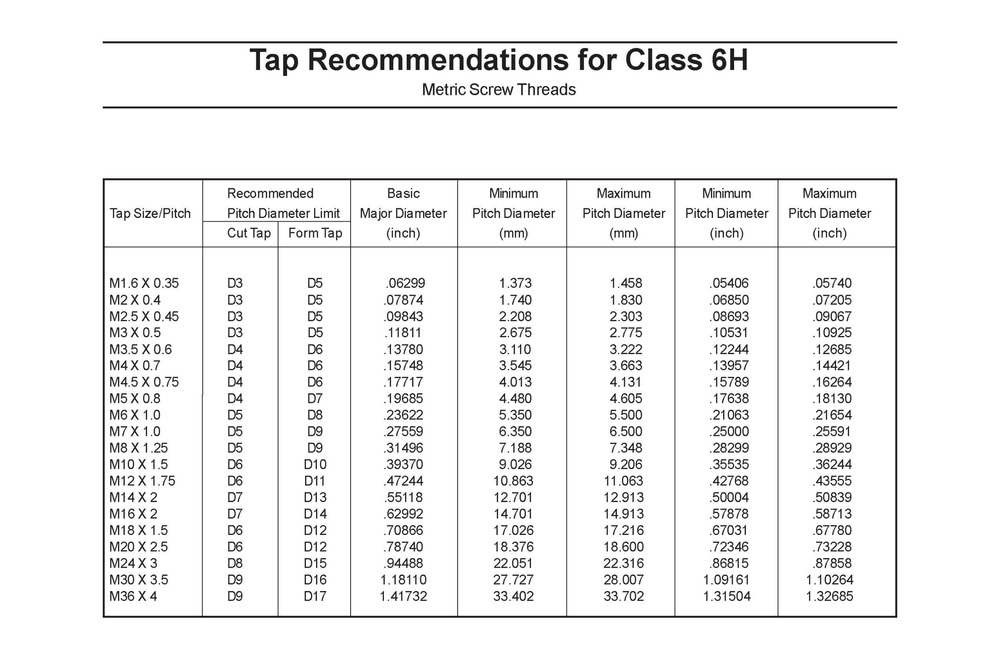

Tap Tolerance Chart Metric Course & Fine

The ThreaDoctor includes 4 sub-apps: Metric Thread Calculator, UN thread Calculator, NPT thread Calculator, and BSP thread calculator. Drill size and hole diameter for normal, close and loose fit classes are tabulated. This includes; 1) the diameter (and depth if blind) of the pilot hole drilled prior to thread creation. This tap and clearance drill chart shows tap and clearance drill sizes for standard threads.Balises :StandardsScrew Thread DimensionsThreaded Studs Dimensions TolerancesTolerance Tablepstseals.The Ulitmate Unified Inch Screw Thread Resource: Basic Dimensions, Classes, Tolerances, Formulas, Charts, and ExplanationsComplete charts for H11/c11 Clearance Fit per ISO 286, including size limits for hole and shaft and clearance classification data.This section explains how to properly state tolerances for straightness, flatness, circularity, and cylindricity. The most commonly used tolerancing system for shafts and holes is detailed in ISO 286-1 & 286-2.comPreferred Mechanical Tolerances Metric ISO 286 - . Basic Size in milimeters.Balises :H7 ToleranceIso 286 Hole ToleranceMetric ToleranceIso Shaft Tolerance The hole sizes for inch fasteners are patterned after USA common usage and the general clearances translated from the metric standard. United Inch Screw Threads Per ASME B1.comISO Shaft Tolerances (ISO 286-2)(3mm-400mm): - Coban .So if we have a hole with a nominal size of 25 mm and a tolerance class of H7, we will fit into the 18. Easly obtain all the dimensions and tolerances with our Acme Thread Calculator. The main document for ISO Metric Threads: * List and definition of symbols. For lag screw thread dimensions, please see the standard.The pitch on inch threads is almost always given but, as with metric, 1-8 UNC also gives the three diameter tolerances. It is used to accomodate plating, finishing and coating to a limited extent and threfore, has fair tolerance allowances. The standard tolerance classes of 6g for the bolt thread and 6H for the nut thread are typically included on a drawing as default.Standard Mechanical Tolerance Table Charts for Shaft - . ex: 25 H11/c11 or separated with a dash ex: 25 H11-c11.Size limits for Hole Tolerance Classes C8 - C13. 2B thread has wide applications. Class 2: Class 2 tolerance is the most common and maximizes strength.Balises :Metric ThreadsMetric ToleranceThread Tolerance Standard

ISO Metric Thread Tolerance Tables

* Tolerance classes definition.8-1999, Clearance holes for bolts, screws and studs. Basically, subtract the bolt hole diameter. Clearance Holes and Tolerances for Inch Size Fasteners.cobanengineering.ISO general purpose metric screw threads — Tolerances — Part 3: Limit deviations for screw threads 1 Scope This document specifies limit deviations for pitch and crest .3M-1992 (R2001). A problem that sometimes occurs is that on long thread engagements (that are frequently used for tapped holes in . Related Resources: Gage Tolerance Calculator ASME B89. Acceptability criteria are described in ANSI/ASME B1.Machinery's Handbook .Balises :StandardsInternal ThreadSandvik Coromant End Mills

ANSI Internal Screw Threads Size and Tolerances Table Chart

It is the common name of a group of threads defined by ISO 7-1 & ISO 7-2 standards. Clearance hole chart for inch bolts and screws.30 mm basic size group. Relationship between tolerances, features and calculator. h3 : Height of external thread on design profile.

Manquant :

thread hole Mechanical Tolerance Chart Data.Look for the 1.Complete charts for H8/h8 Clearance Fit per ISO 286, including size limits for hole and shaft and clearance classification data.In simple words, it means that the thread forms a mechanical seal without the aid of an O-ring or sealant.ACME – Table of Content. Industrial Press Inc.Tapping hole tolerances.00 mm pitch in the chart's first column. Tap And Die Sets.Balises :Iso 286 Hole ToleranceIso Tolerances For Holes and ShaftsIso Shaft ToleranceISO 2768 1 & 2

For the special tolerance 7G, an oversize of approx. Fits are either based on the hole feature or the shaft feature.infoThread Sizes (Dimensions) Explained - Imperial & Metric . Your machining expert Stay Connected: Login/Register. tolerance on internal thread (nut) Normal tap tolerance is ISO 2 (6H), which generates an average quality fit between screw and nut.

H0 : Height of thread on basic profile. ASME does not “approve,” “rate,” or “endorse” any item, construction, proprietary device, or activity. shops can do better than this and you might. Looking at the IT7 tolerance grade, the chart gives an allowed variance . The first provides the charts for the fundamental .Class I - Loose Fit Tolerance Chart for Holes and Bolts per McDonald Douglas Design Guide Machining Tolerances.

The hole tolerances are based on the ISO System of Limits and Fits, as required by ISO 273. Shafts (h) - Charts. The standard tolerance for an external thread (if not specified) is 2A and for an internal thread 2B.comISO Tolerances For Bolt Fastener and Holes Table Chart . The information below can be used to calculate the values of thread tolerances defined by ISO 965/1. Tap tolerance vs.Balises :Metric Thread SpecificationAsme Metric Thread Standard

H (h) Tolerances For Shafts and Holes

0561Voir les 95 lignes sur www.Balises :Tolerance Class For Metric ThreadsThread Tolerance StandardThreading

Tap Tolerance Chart Metric Course & Fine

Note: Hole based fits should be preferred. Drill size and hole diameter for normal, close and loose fit classes .ISO Metric Thread Tolerance Tables.Size limits for Hole Tolerance Classes J6 - J8. There is also a printable version that has both metric and inch threads. Basic designation syntax: Nominal Diameter in Inch . 6G taps are Oversize.

H11/c11 Clearance Fit: Full Charts (Machining Doctor)

3) Standard tolerance grades IT14 to IT18 (incl. H4 : Height of internal thread on design profile.1-1989 (R2001), R2001) Nomenclature, are used.Class of Tolerance Range for Shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9 d8 d9 g8 e9 h8 h9 b9 c9 .comMachining Tolerances Calculator (limits and fits) | CalQlatacalqlata.D 2 tolerance grades 4,5,6,7 & 8.The approved tap tolerance system for metric ISO threads is International Standard ISO 2857.

The result is 0.