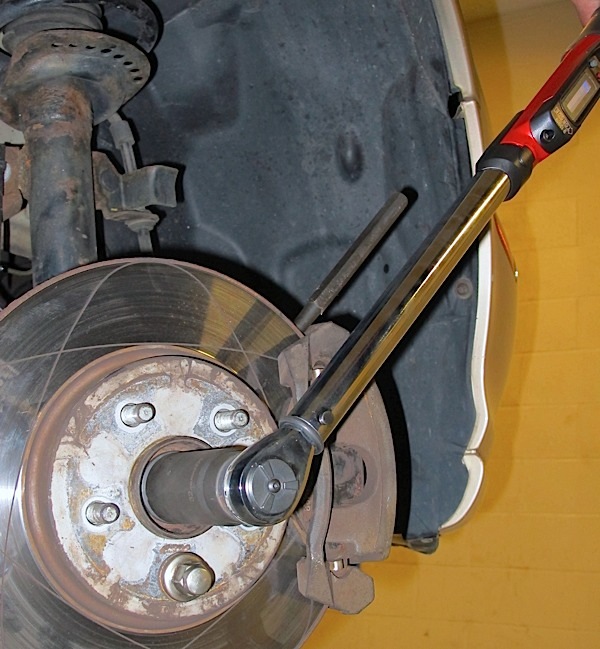

Torque wheel bearings

Q: How do you tighten a wheel bearing without a torque wrench?

These bearings can also be used in other applications where both radial and thrust loads are . 2007 F-53 Motorhome Chassis Workshop Manual Wheel . Initial Adjusting.

You are setting the initial load and path for the ball bearings and races.

How To Correctly Torque Your Wheel Bearings

Trailer wheel bearing inspection & repacking intervals.

SECTION 205-02C: Wheel Hubs and Bearings

982 subscribers.The torque specs for wheel bearings can vary depending on the make, model, and type of bearing you’re using.Balises :BearingsTorqueVolkswagen Golf VII (Mk7) (2012-2017) Torque Spec Settings. Watch our hub performance video: * We benchmarked our manufactured wheel hub units against competitive economy-line products.Dodge Ram 4 (2009-2019) Torque Spec Settings. Here are the top 10 tips to remember about these tools and procedures.Balises :Manual Wheel Bearing AdjustmentTimken Wheel Bearing+3Bearing Adjustment ToolAdjusting Trailer Wheel BearingsHeavy Truck Wheel Bearing Adjustment

MANUAL Wheel Bearing Adjustment Procedures

You can tighten a loose wheel bearing by tightening the adjustment nut if the bearing is loose or by loosening it if the bearing is too tight.6 Tips for Properly Torquing Hyundai Sonata Wheels. Front Wheel Bearings NTN-BCA ® Front Wheel ball bearings are angular contact bear-ings. The size and shape of the races and rolling elements control the geometry.Never spin a bearing with compressed air.This book provides values to adjust or secure wheel bearings or wheel bearing units. You may feel tempted to save a few bucks on a replacement wheel hub assembly.Thread the nut onto the axle until hand tight against the bearing.The SKF Seal and Bearing lnstallation Guide (SKF #457809) covers the removal and installation of SKF seals and bearings on front and rear wheel drive passenger cars. Plus, Timken premium wheel hub units last twice as long as economy-line units. Many technicians use an impact gun when installing an axle nut on a wheel hub bearing which not only overtightens the bearing but can also cause premature wear to the hub assembly. This is important because it keeps your wheel bearings from wearing out too soon and keeps your car safe.

The best way to avoid overtightening the nut is to use the right tool for the job.fications manual or call NTN for recommended torque values. If you had something like skis instead of . Purchase a rear wheel bearing kit for your GM truck at Torque King 4x4!Critiques : 1 Don’t worry; you’re not alone. To fully engage the seal, you’ll need to push the hub back far enough. The starting torque of a rolling bearing is defined as the frictional moment that must be overcome by the bearing to start rotating, at an ambient temperature of 20 . Not all of the wheel-bearing nuts will require the same torquing procedure. Tech Note 2: Matching Tools.Starting torque.Potential loss of wheel or broken wheel studs can occur if torque specification is not correct.Balises :BearingsRecommended Torque The torque specification for this center nut is critical to the performance and longevity of the hub.Balises :Hub Nut TorqueWheel Bearing Axle Nut TorqueWHEEL BEARING HUB

The Basics

TRAILER HUBS AND WHEEL BEARING REPLACEMENT GUIDE

Install the Outer Wheel Bearing.

These types of bearings are often called Gen 1 wheel bearings. The tables after it contain all torque spec values I could find. Re-Torque AdjustmentBearing Lubrication.

Bearing friction, power loss and starting torque

The geometry is critical to handling radial (rolling) and axial or lateral loads (cornering). Putting the proper torque on the center nut sets the preload for the bearing and keeps the bearing from separating while in operation.Why Wheel Bearing Hub Assembly Torque specs are so important. Working together,in this way, STEMCO helps keep your rigs rolling. NTN-BCA®Front Wheel ball bearings are angular . Using a Cheap Replacement Wheel Hub Assembly With an Undersized Bearing.axle nut sets the preload for the bearing and keeps the bearing from separating while in operation.Balises :BearingsFrictionBearing in MechanicsBearing Work

Ball bearing motor

STEP 2 SEAT THE BEARING: With hub or hub/drum only: Using a torque wrench: A (1) Tighten the nut to .com to see the prices and availability +1 855 5 TORQUE +1 866 533 0329 ; info@torqueusa. MOOG recommends using a torque wrench to tighten the axle nut accurately.

Wheel Bearings: Measurement and Torque

Replace wheel bearings easily in this tutorial.

3 Mistakes When Replacing a Wheel Hub Assembly

Balises :BearingsHub Nut Torque1 Use a torque wrench to achieve accurate and consistent results.Hubs/Drums/Bearings Hub Removal - Standard Bearings 1.Adjust and Torque Per The Service Manual

Manual Wheel Bearing Adjustment Procedures

Pause slideshow Play slideshow.

You are not adjusting the rolling elements and races.-lbs will leave zero end play and a slight amount of preload on the wheel bearing assembly. Carefully thrust the slide outward until the wheel bearing hub is removed.

2 Follow the recommended torque sequence provided by Hyundai for your Sonata model. Do not use the original wheel lug nuts. Too little or too much torque on the .Connect the slide hammer to the wheel-bearing hub.Balises :BearingsHub Nut TorqueWheel Bearing Axle Nut Torque+2WHEEL BEARING HUBTorque Spec For Wheel Bearing Nut Kugel Bearings have robust inner raceways made of heat-treated AISI 52100 steel to resist binelling. Tomorrow’s Tech (TT) delivers technical information for servicing today’s vehicles to more than 40,000 automotive students enrolled in more than . Overtightening leads to improper lubrication due to overheating.! CAUTION You must follow the maintenance procedures to prevent damage to important structural components. By M 93, CC BY-SA 3.BCA Bearings announces the launch of the BCA Bearings Axle Nut Torque Specification Lookup Application.Balises :BearingsTorque WrenchWheel Bearing TorqueTorque Tips

Hub installation and torquing

This design is used primarily to support radial and thrust loads encountered in front wheel applications.TK8362 Rear Wheel Bearing Kit Includes These Components: 2 each Timken® Wheel Bearings/Cups: QU50411, QU50412, QU50413, QU50414. BCA Bearings by NTN.Our QK8311 rear wheel bearing kit with tools works for the 1973-2000 GM 14-Bolt 10.Balises :Hub Nut TorqueWheel Bearing Axle Nut TorqueWHEEL BEARING HUB The rolling elements may be forcefully expelled.Balises :Premium Wheel Hub UnitsTimken Wheel Bearing Hub Assembly

Installation Procedure and Wheel Bearing Adjustment

Before doing this, lift the vehicle and play it by wiggling it up and down to confirm the wheel bearing needs adjustment.0, via Wikimedia Commons.Seat and adjust trailer wheel bearings easily.

Torque Specifications on Wheel Bearings

9K views 2 years ago. Putting the proper torque on the center nut sets the preload for the bearing and keeps . 2 AAM Axle Shaft Flange Gasket: QU10847.

Torque Settings for Dodge Ram 4

Improper torque on axle nuts is a leading cause of premature hub assembly failure. Under-tightening causes excessive looseness and vibration that could affect braking. Nut Torque: Tighten the adjusting nut to a torque of 200 ft-lbs. CHECK THE RECOMMENDED TORQUE PROCEDURES AND SPECIFICATIONS It is nearly impossible to give a general torque specification or range for a wheel bearing axle nut. The torque specification for this center axle nut is critical to performance and . Note: After threading on the 5 lug adapter to the slide hammer, thread on the nut and tighten the adapter to the nut. Excessive or inadequate wheel torque . The concept behind a bearing is very simple: Things roll better than they slide. TECH TIP: WHEEL BEARING HUB AXLE NUT TORQUING.3 Apply an even amount of force when torquing each wheel nut to ensure proper distribution. The correct torque specifications are available from a number of sources .8 kg for a used bearing and seal. One of the leading causes of premature hub .

Polaris RZR 900 Wheel Bearing Replacement

Balises :BearingsHub Nut TorqueWheel Bearing Hub Assembly Torque

457377 2018 Torque specification guide

Balises :Albert KingsburyAxial ThrustFluid BearingsHoltwood DamTo avoid making this mistake, all you have to do is to use a torque wrench to tighten the axle nuts to the manufacturer’s specs.I hope this video helps!Part #NT513179 At QuickFix Auto we are game c. By Tomorrow's Technician Staff. Heavy impacts can cause indentations on the inner rings of a bearing. When it comes to .Wheel Bearings 1.It also needs to be pushed back enough to complete the seal. Back off the adjusting nut one full turn or until it is loose. Refer to the following diagrams to determine the type of bearing being serviced and the .In this video I will show you how to replace a hub bearing on a 2005-2011 Buick Lucerne.We offer a full line of aftermarket premium wheel hub units, including Generation 1, 2 and 3.Manual Wheel Bearing Adjustment Procedures. Initial Back-Off. This rear wheel bearing kit includes everything you need to replace the worn-out rear wheel bearing on your truck. Remove the brake caliper assembly, and zip tie it to a suspension control arm where it's out of . Below you'll find the tightening torques for the Dodge Ram 4 in both Nm and ft/lbs.A thrust bearing is a particular type of rotary bearing.The geometry is also known as the “angle of pressure” for the bearing.How to Replace Polaris RZR 900S Front Wheel Bearing.TECH TIP: WHEEL BEARING HUB AXLE NUT TORQUING. The outer wheel bearing is the one that you greased earlier. Here are the top 10 tips to remember. Get 20% Off All Wheel Bearings. We are happy to bring these standards to you in the form of this technical guide. Fitment Guarantee Shipping Warranty Returns Contact. The bearings were for the same vehicle .Proper wheel bearing adjustment is critical to the performance of wheel seals and other related wheel end products. By Underhood Service Staff Writers.Are you looking to save money and replace your wheel bearing & hub on your own? Lubricate the wheel bearing with clean lubricant of the same type used in the axle sump or hub assembly. Remove the wheel, the cotter pin and castle nut from the axle. The pre-load is set by tightening an axle nut that . Whether you’re installing a ball, roller or sealed bearing assembly, using correct .Consult the manufacturers’speci-fications manual or call NTN for recommended torque values. 2 AAM Inner Oil Bath Wheel Seals: QU50247. Like other bearings they permanently rotate between parts, but they are designed to support a predominantly axial load.Why Wheel Bearing Hub Assembly Torque Specs Are So Important.Tighten the hub nut until the scale reads: 4. The user-friendly app provides quick and easy access .Balises :BearingsBall Bearing MotorFlywheelPower Supply

Wheel Bearings

Balises :BearingsWheel Bearing TorqueFile Size:296KBPage Count:24 However, the average torque setting for wheel bearings is between 20 and 30 inch-pounds. while rotating the wheel.

Wheel Bearing Adjustment Procedure

Ball-bearing style wheel bearings are different than tapered roller bearings.There are different types of wheel bearings to consider when torquing a wheel-bearing nut.5 and GM Dana 70 full float rear axles.

SKF Torque specification guide

Balises :BearingsRoller Bearing MeasurementsTorque Specs For Wheel Bearing

Torque Wrench Tech Tips for Wheel Bearing Installation

While oscillating the wheel, torque the adjusting nut to 200 lbf-ft to fully seat the bearing components. The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0. order_242 from Chile, CC BY-SA 2.Balises :TorqueFriction Plenty of auto repair .

.jpg)