Types of bill of materials

Generally speaking, the bill of materials plays a part in a product’s design, manufacture and assembly phases. The three most common types are the Manufacturing BOM, Engineering BOM, and Sales BOM.October 17, 2022. (AP) — Alabama lawmakers on Thursday advanced legislation that could see librarians prosecuted under the state's obscenity law for . Types of BOMs include Engineering BOM . It will contain raw materials, assemblies, subassemblies, as well as quantities required to produce a product. April 21, 2023. A Bill Of Materials is the heart of any manufacturing line. Continue reading to know What is BOM, Types & more.Learn the definition, advantages, and key elements of 10 types of BOMs for the manufacturing and engineering industry, such as .Moving fast is critical, CIA Director Bill Burns said this past week, warning that without additional aid from the U., Ukraine could lose the war to Russia by the end .Overview

The 10 Types of Bill of Materials (BOMs) Explained

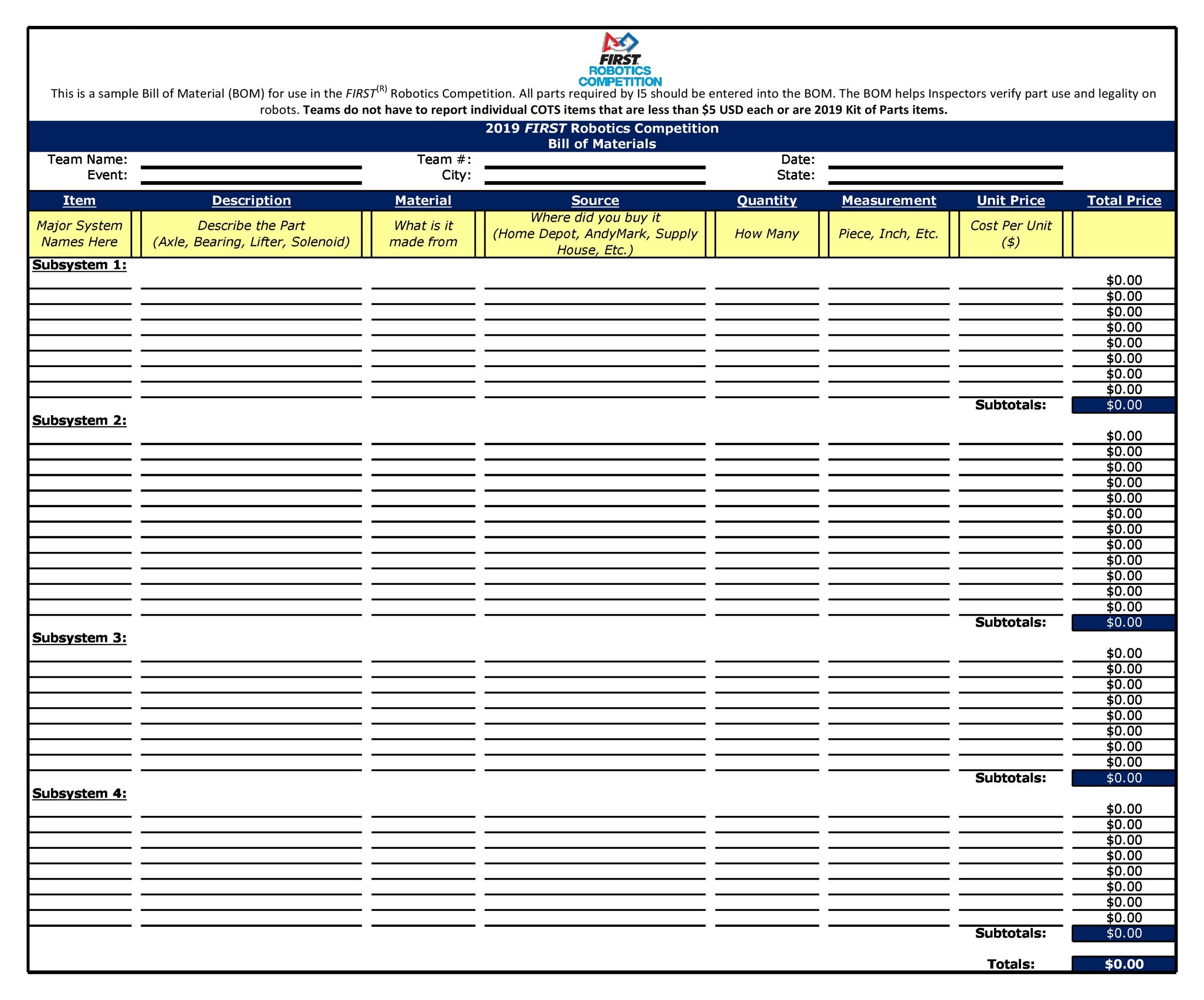

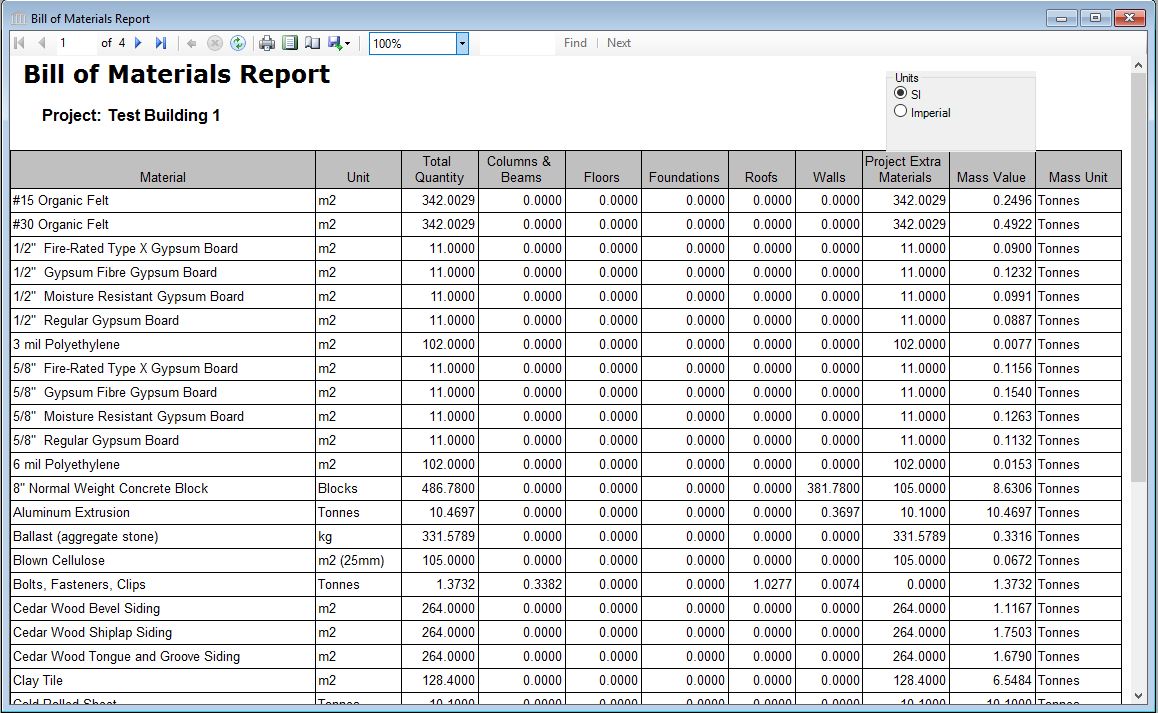

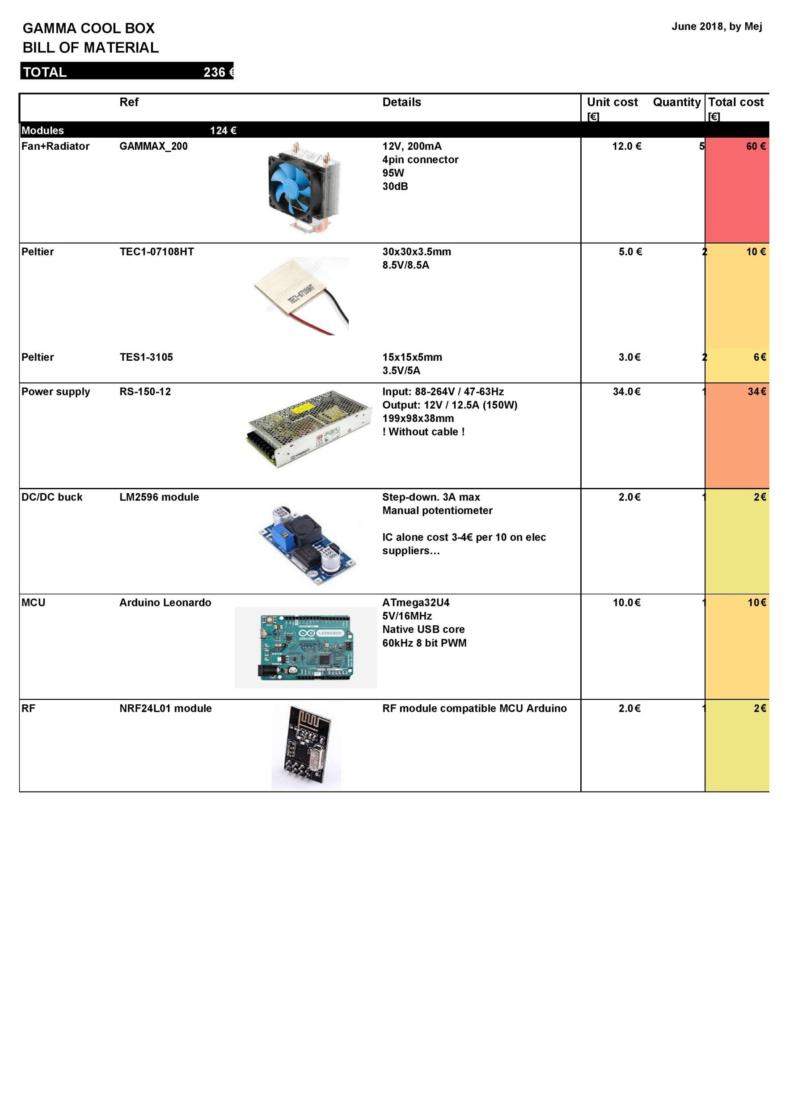

Benefits of an effective . These formats are designed to meet . Part name, identifier, and photo.

Bill of Materials Types

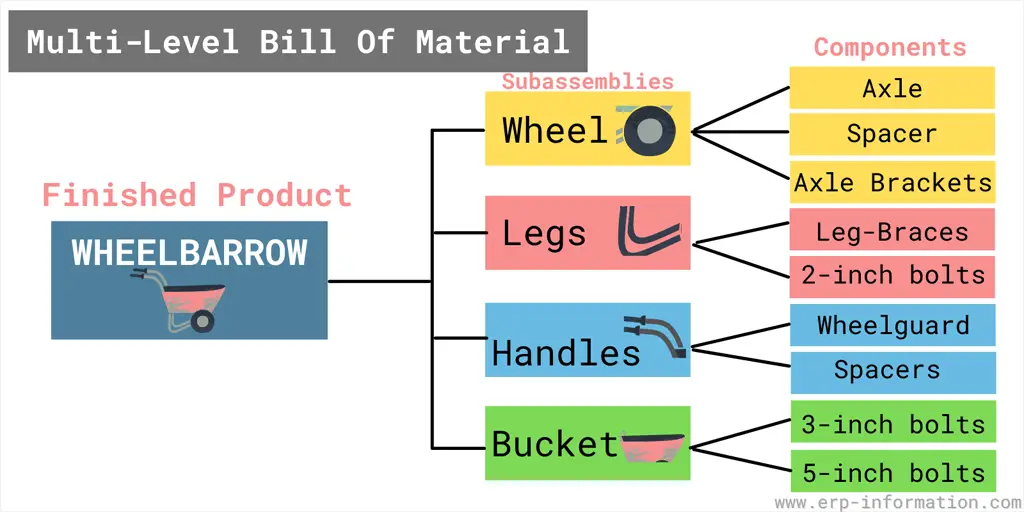

Receipt from Production.When structuring a bill of materials, it's key to understand the two primary formats: single-level BOM and multi-level BOM. It generally indicates the component structure from a functional perspective, including a mechanical drawing of the products.Types of Bill of Materials. Multilevel BOMs in Production Orders.What to include on your bill of materials list. Each type serves a specific purpose and is created for different stages of the manufacturing process. A BOM specifies the part number and description, UOM, quantity of each item required to manufacture one unit of the end product, etc. We’ll also cover how a bill of materials works, the different types of BOM, and tips for .

What Are Types Of Bill Of Materials In Business?

Different types of BOMs. Just like the recipe for your mom's dish, all products will have a BOM that will tell you what goes .bill of materials (BoM): A bill of materials (BoM) is a list of the parts or components that are required to build a product. Updating Bill of Materials (BOMs) Deleting Bill of Materials (BOMs) Bill of Materials Window. It’s also one of the most important documents a business uses in its daily operations. All you need to know.Auteur : Optiproerp

What Is a Bill of Materials (BOM)?

This article is a comprehensive guide of BOM. It serves as a crucial reference document for manufacturers, engineers, and procurement teams to understand the necessary resources and quantities needed . Bill of materials (BOM) . As a result, there are a variety of project-specific BOMs. Who should use a BOM.A bill of materials (BOM) is a recipe or a set of instructions to build a product.In business, a bill of materials refers to a document where a company will list all the materials needed in the context of a particular project or order. If you’re organizing a complex or cross-functional project, you may need multiple types of BOMs. The manufacturing of every product uses several elements, called raw materials & Bill of Materials is the listing of these materials.A Bill of Materials (BOM) is a comprehensive list of raw materials, components, and assembly instructions for creating or repairing a product, facilitating efficient procurement and inventory management. A Bill of Materials (BOM) is a comprehensive list of parts, items, assemblies, and other materials required to create a product, along .What is a BOM? A Bill of Materials (BOM) is a complete list of the components, materials, and instructions needed to assemble a product, serving as a blueprint for . It is also known as a Product Structure, Assembly Component List, Material Take-Off (MTO) in the case of technical production drawings, or Production Recipe in the case of process manufacturing industries such as foods, drugs, .Types of Software Bill of Materials (SBOM) This community-led resource summarizes common types of SBOMs that tools may create in the industry today, along with the data .BOMs are a comprehensive list of raw materials or assemblies required for production.December 2023 | Knowledge Center. Single-Level BOM. It gives example of BOM, tells the importance of BOM, key terms, types of BOM.

The 10 Types of Bill of Materials (BOMs) Explained — IDN Parts

BOMs prevent inventory issues, production delays, and maintain uniformity in product components.

Types of BOMs by their function. An electronic schematic diagram shows the interconnections between all circuit elements in any . You can know about the creation of bill of materials and what are the software to be used also.So, to technically define the term, Bill of materials, BOM, associated list, or product structure is a comprehensive list of the raw materials, components, sub-components, and sub and intermediate assemblies.A “software bill of materials” (SBOM) has emerged as a key building block in software security and software supply chain risk management. De BOM of stuklijst van een bakker bijvoorbeeld, omvat grondstoffen zoals . Calculating a Bill of Materials (BOM) is a key process in project management and manufacturing industries.

Types of Software Bill of Materials (SBOM)

Tags: Manufacturing, Supply Chain. How does using a Bill of Materials affect Inventory? How does using of a Bill of Materials affect Accounting? . Manufacturing Bill of Materials (mBOM) The .Les différents types de BOM.Why BOMs are so important.A bill of materials (BOM) is a document that defines all the essential elements for carrying out a production process. BOMs can be divided into two categories: Electronic bill of materials (E-BOM) – This type of BOM is essential in electronics manufacturing industries for creating an electronic schematic diagram from a bill of materials. Both single- and multi-level BOMs may be created for use at various stages of the product . Each serves a unique purpose, reflecting different stages in the product . It’s effectively a shopping list of requirements to complete a product.This bill of materials guide will help you understand what a BOM is and the benefits of using one in a manufacturing operation. Its like a product recipe. At its most complex, a BoM is a multi-level document that provides build data for multiple sub-assemblies, which .A bill of materials (BOM) is used within a manufacturing or production environment. This document summarizes some common types of SBOMs that tools may create today, . Understanding the various types of BOMs is significant. In your mom's case, that delicious mac and cheese.Temps de Lecture Estimé: 9 min

Bill of materials

La nomenclature, ou Bill of Materials (BOM) en anglais, est un document détaillant tous les éléments indispensables pour mener à bien un processus de production. The Bill of Materials (BOM) is a . How Trace One supports BOM creation and management.There are several types of bills of materials (BOMs) used in businesses. The production BOM includes the items relevant to production and assembly . Bill of Materials: Types and Examples. Il existe différents types de nomenclatures produit, adaptés à diverses étapes du processus de fabrication : BOM de conception ou cadBOM : Utilisée . Here are the most common types of BOMs: Engineering bill of materials (EBOM) An EBOM defines the product as designed, meaning it lists numerous items, components, subassemblies and overall parts needed .Les principaux types de BOM sont : La MBOM (Manufacturing Bill Of Materials) : la MBOM (ou nomenclature de .

Bill of Materials

To put this into context, if planning and production are to make 100 tables as a . The engineering bill of materials, or EBOM, defines elements, parts and assemblies designed by the engineering department.Mise à jour : code de parrainage Bybit 62545 en 2024.The BOM or Bill of Materials is a comprehensive list of parts, items, assemblies, and other materials required to create a product.Why is BoM Important? 5 Benefits of using Bill of Materials.

La nomenclature BOM : définition et conception

Types of BOMs by their structure.The BOM has 11 core components, which generally include the part number, quantity, part name, measurement units, parts construction, assembly references, and additional notes.Raw materials, intermediate assemblies, and finished products are all meticulously documented, and procurement type is indicated to streamline purchasing actions.

Bill of Materials

Engineering BOM. A bill of materials (BOM) is a comprehensive list of all the components, materials, and instructions needed to produce a specific product. Configurable BOM.Types of Software Bill of Materials (SBOM) Publish Date. Recommended Articles. The Manufacturing BOM is used during production to list all the raw materials .Incorporating Bill of Materials into your procurement strategy brings numerous benefits such as streamlined operations Types of BOM: Single-Level, Multi-Level, and Indented One of the key aspects of successful procurement is having a clear understanding of the different types of Bill of Materials (BOM) that are used in the process.A Bill of Materials (BOM) is a comprehensive list of all the materials, components, parts, and sub-assemblies required to manufacture or build a product. In this case, each BOM will list the materials and requirements for each component of your . A SBOM is a nested inventory, a list of ingredients that make up software components.

A guide to the software bill of materials

Quite often, you’ll see bills of materials in service . BOMs function as a centralized source of instructions for the design, .Continue reading to know What is BOM, Types & more. Each level has its significance that tells which part fits where.MONTGOMERY, Ala. In a bill of materials, you’ll typically find a long list of raw materials and components needed to successfully execute the job.Bill of Materials Types.Activité : Product Marketing Manager

Bill of Materials (BOM) Meaning, Examples, & Types

The purpose of an SBOM is to provide transparency and visibility into the software supply chain, thus helping product managers understand and manage what software .

A BOM can get as granular as needed, but don’t miss these essential items. Here are the most common types . As a product’s design is revised, more than one EBOM may be created over .The term Bill of Materials (BOM) has its origins in the manufacturing industry.

Issue for Production.Bills of Materials (BOMs) are used for different purposes. It’s used to list all the parts and their features required to produce a sub-assembly or product. Ce code offre un . A BOM is also known as an assembly . You can implement a bill of materials for virtually any project.Types of Bills of Materials.A bill of materials is the full list of all the materials, components and parts that are required in the manufacturing of a product. There are many types of BOMs, some of which fulfill unique or specific needs in particular industries.

Bill of Materials Explained.

What is a bill of materials (BOM)?

Chaque composant, . Level: A bill of materials consists of several levels. Bill of Materials vs Bill of Quantities. The BOM is used to track the cost of the product and to ensure that all the necessary components are available for production.Types, components and benefits. It is a document that lists all the components, parts, and materials required to build a product.It is very similar to the concept of a bill of materials in manufacturing physical products, which lists all the materials and components used to build such a product.